Method and control system of electric discharge machining processing feed automatic control

An automatic control system, EDM technology, applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of complex operation and maintenance, complex structure, large volume, etc., to prevent arc burns, small volume, high The effect of response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

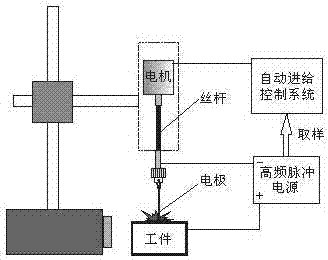

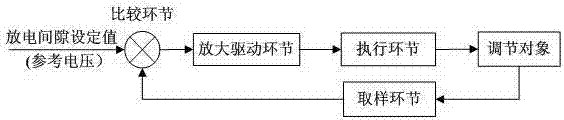

[0028] Such as figure 1 , 2 As shown in , 3, an automatic feed control system for EDM machining, the comparison circuit receiving the discharge gap is connected to the execution circuit through the amplifying drive circuit, and the feed signal of the execution circuit is fed back to the control object circuit and the sampling circuit The comparator circuit is electrically connected. The adjustment object circuit has the ability to adjust the spark discharge gap between the electrode and the workpiece during EDM, that is, according to the requirements of the set value servo reference voltage, etc., it always tracks and maintains a certain average spark discharge gap, so that the EDM can be adjusted , the distance between the electrode and the workpiece is: 0.2-0.3mm.

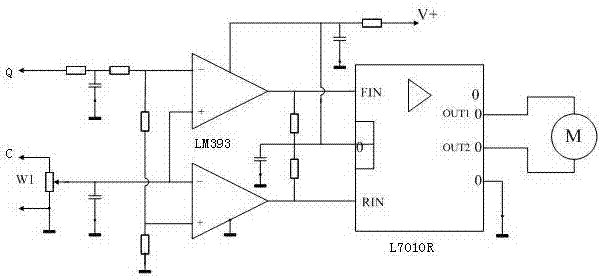

[0029] The sampling circuit uses a dual-voltage comparator LM393 that indirectly reflects the size of the discharge gap by measuring electrical parameters that are proportional to the discharge gap. The amplif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com