Electric discharge machining electrode and method

A technology of electrodes and electrode materials, applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve problems such as poor surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

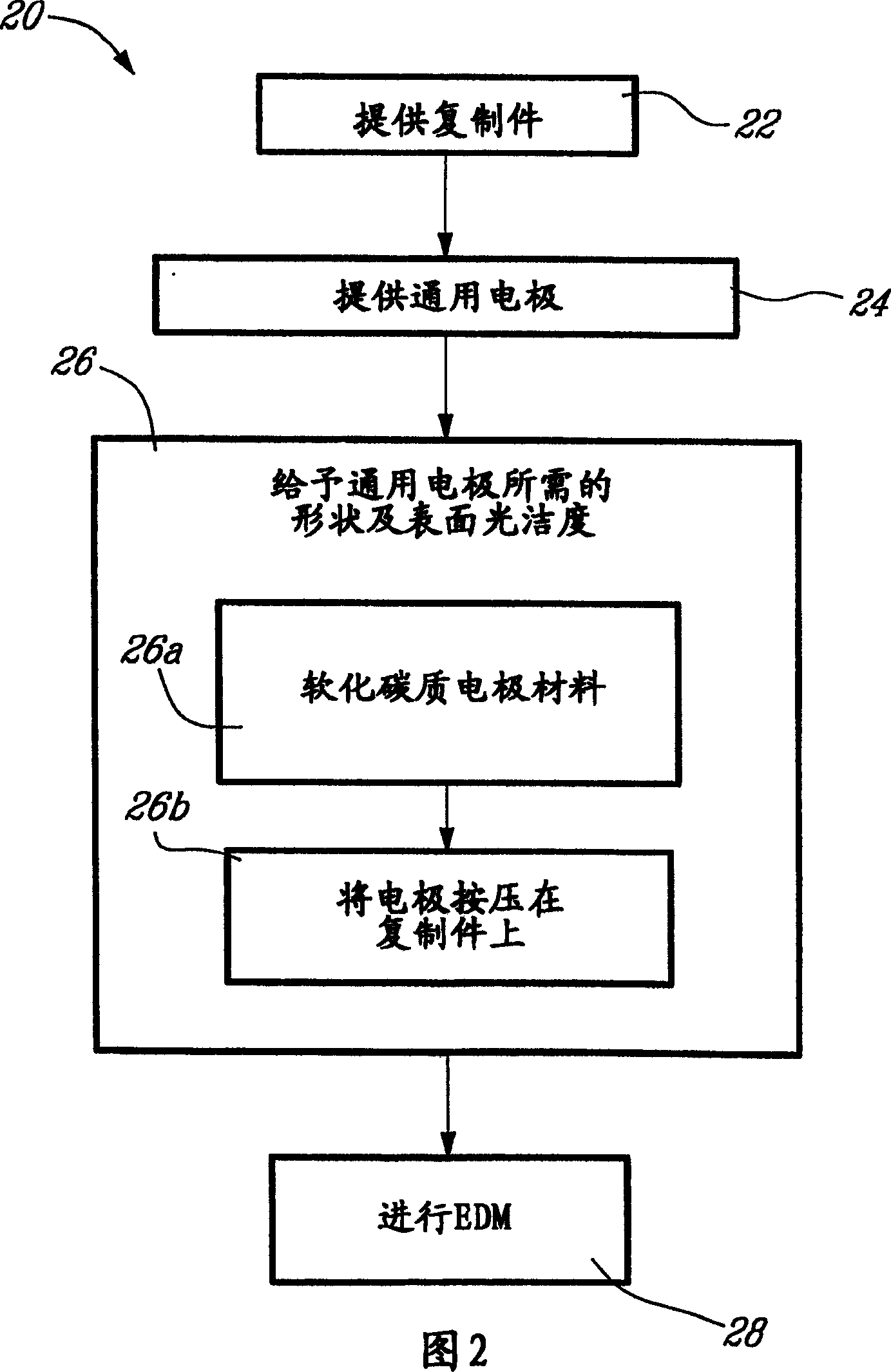

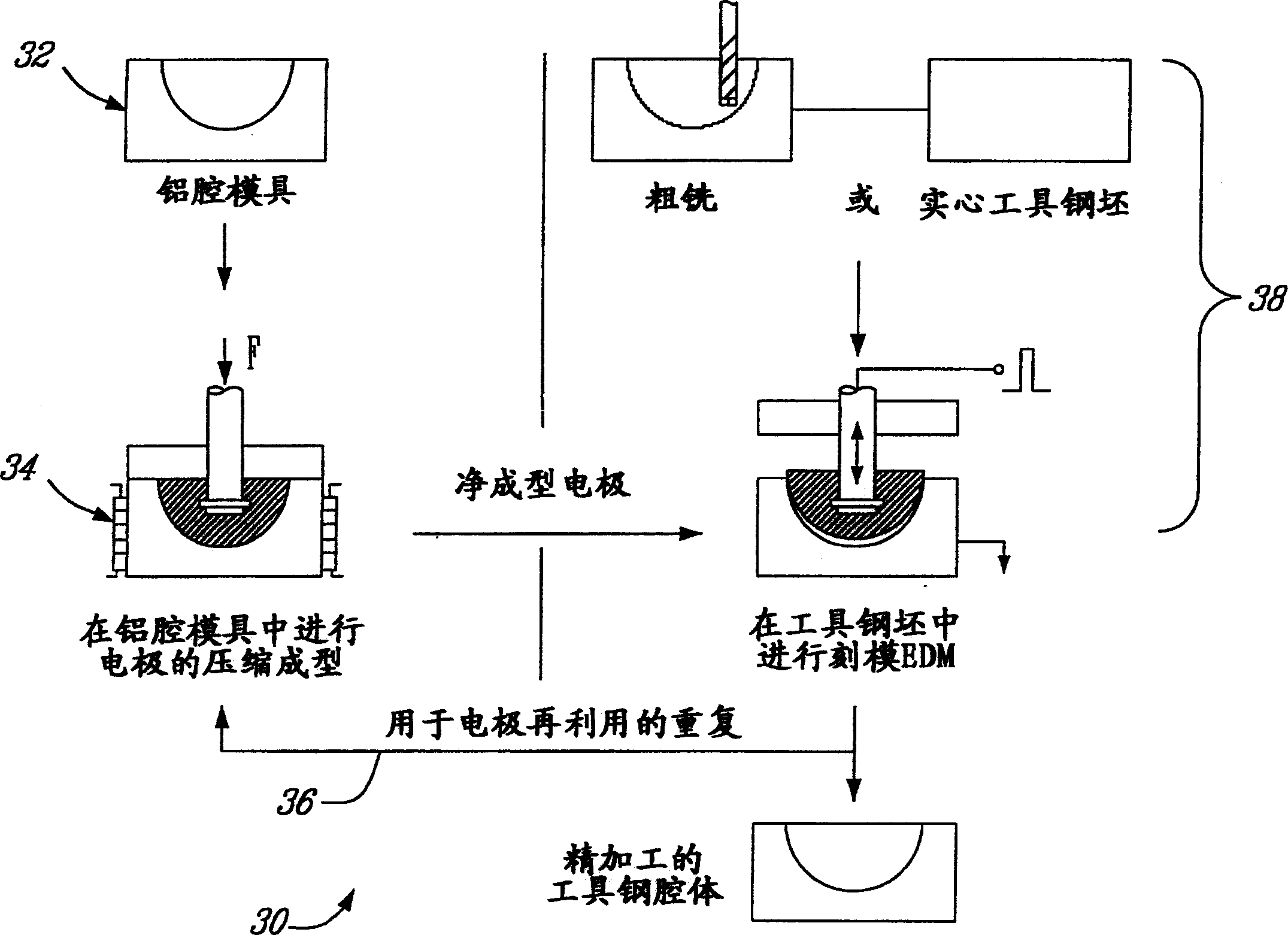

[0034] In general, it is an object of the present invention to reduce the cost of EDM operations by: 1) by providing malleable electrodes which can be fabricated with improved productivity; 2) by providing a method which uses these malleable electrodes for roughing, finishing, polishing and texturing operations.

[0035] According to a first aspect of the present invention, a plastic electrode and a method for making the electrode are provided.

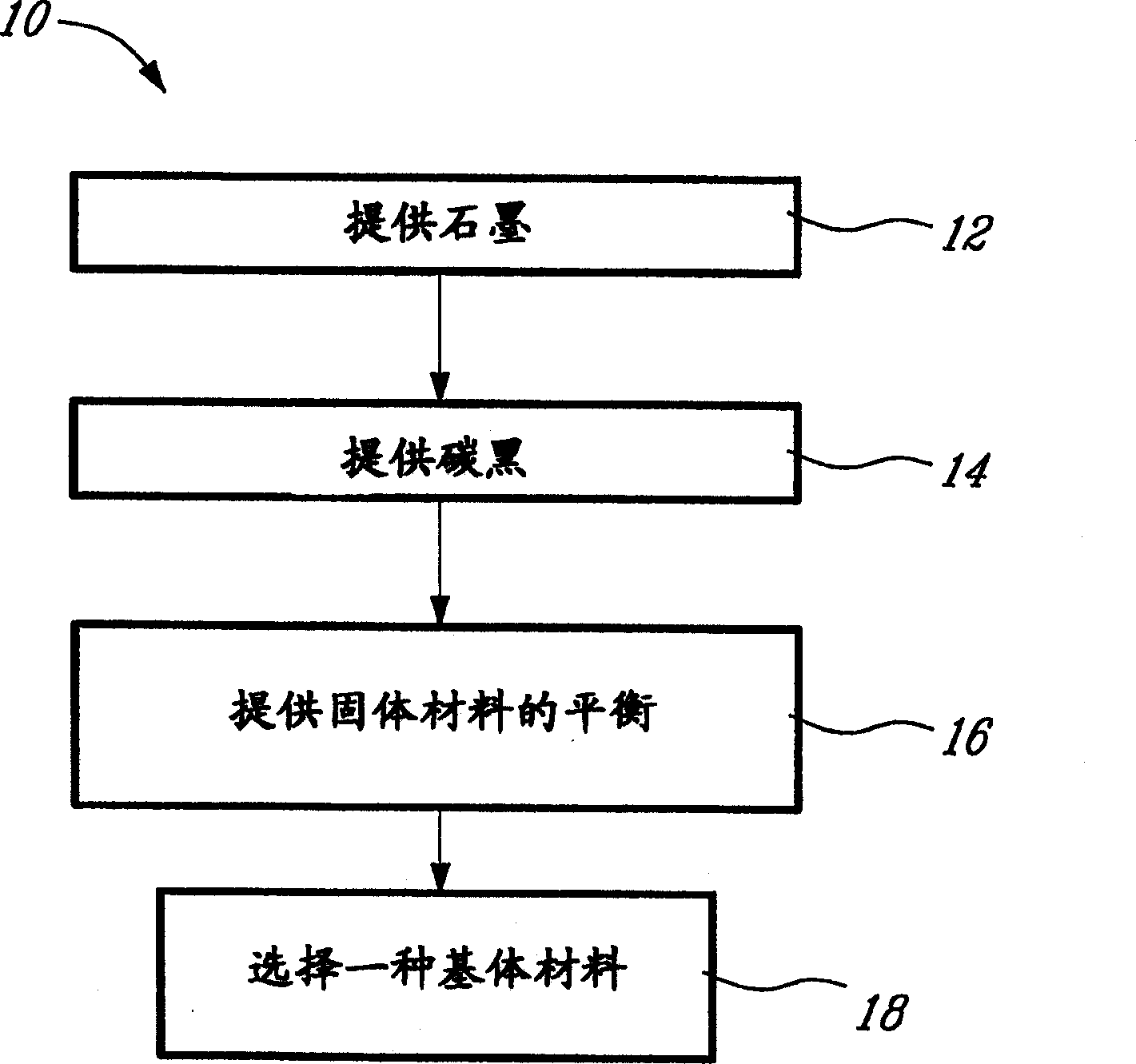

[0036] The plastic electrodes of the present invention are generally made using a plastic carbonaceous material prepared by mixing appropriate proportions of carbon powder and / or metal powder in a thermoplastic polymer or wax matrix. The amount of solid carbon is optimized to produce a material that combines the required combination of plasticity, electrical conductivity and, at the same time, formability.

[0037] The main components of the EDM plastic electrode are carbon and graphite because of their inherent high temperature resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com