Wire electric discharge machine performing machining while adjusting machining condition

一种线放电加工机、加工条件的技术,应用在线放电加工机领域,能够解决麻烦、花费时间等问题,达到提高稳定性、消除差异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments and drawings of the present invention will be described below.

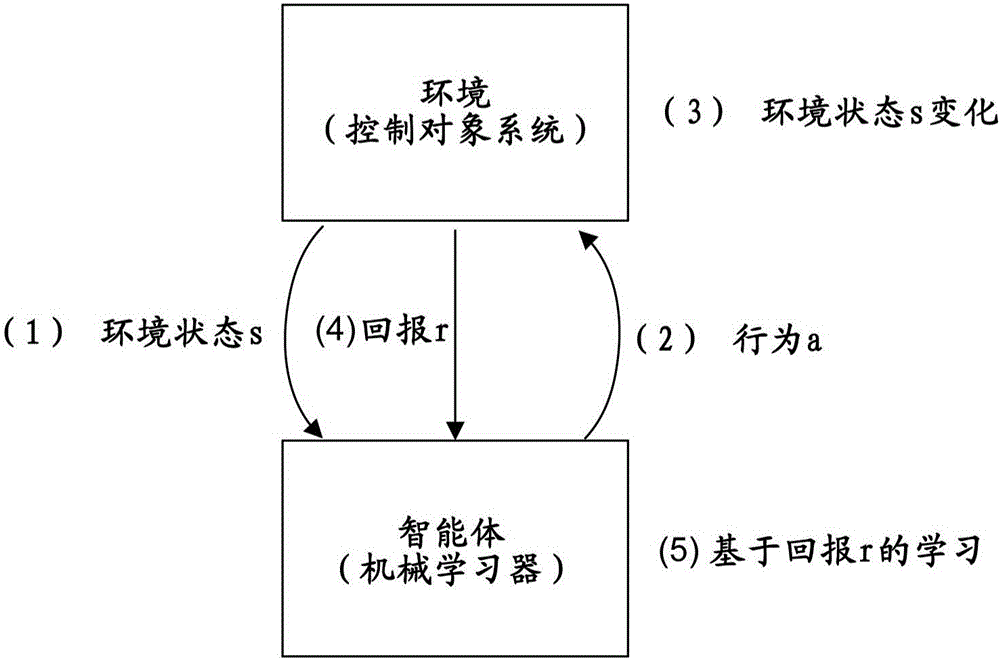

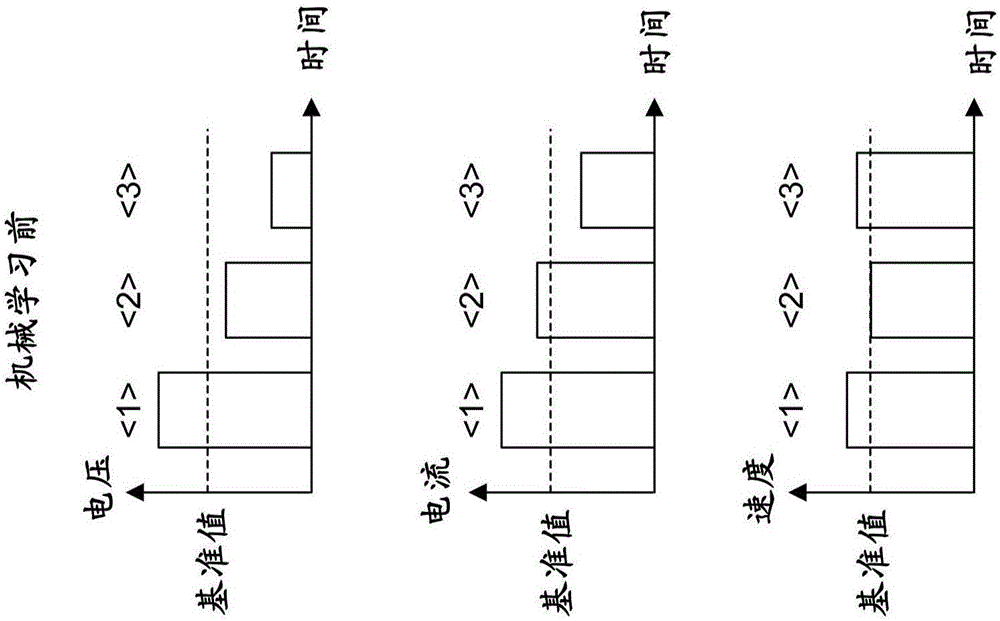

[0024] In the present invention, a machine learner as artificial intelligence is introduced into a wire electric discharge machine that processes a workpiece, and the voltage value, application time, pause time, and Machine learning for adjustment of machining conditions such as the supply amount of machining fluid, thereby adjusting the machining conditions to the optimum according to the machining state. In the present invention, the machine learner operates as a machining condition adjustment device.

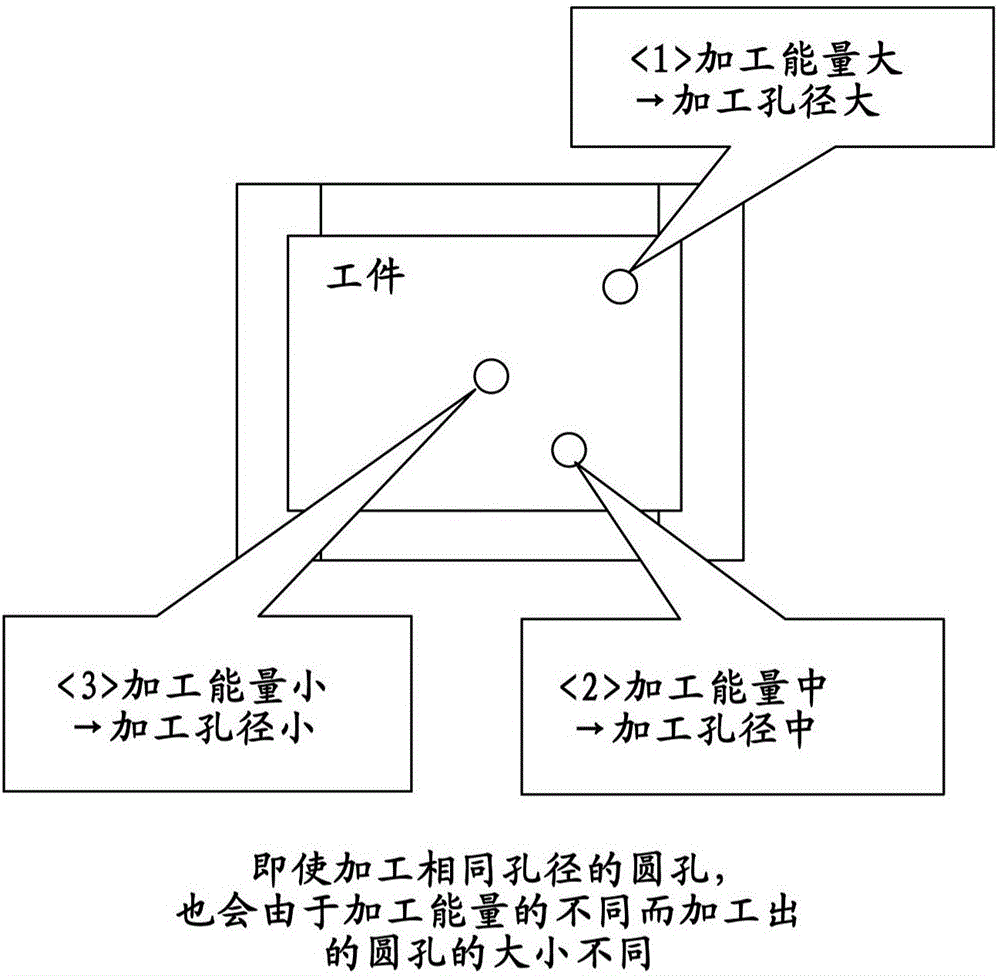

[0025] As mentioned above, in online electrical discharge machining, the actual machining speed and machining accuracy obtained under the set machining conditions vary depending on the position of the workpiece placed on the table, the secular changes of the machine, and the individual differences of the machine. For example, with such a situation: such as figure 1 As shown, even when machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com