Wire electric discharge machine operating with constant inter-pole distance

A technology of wire electric discharge machine and processing gap, which is applied to metal processing equipment, electric processing equipment, circuits, etc., and can solve the problem that the average continuous number of short-circuit pulses is not related to the processing gap distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

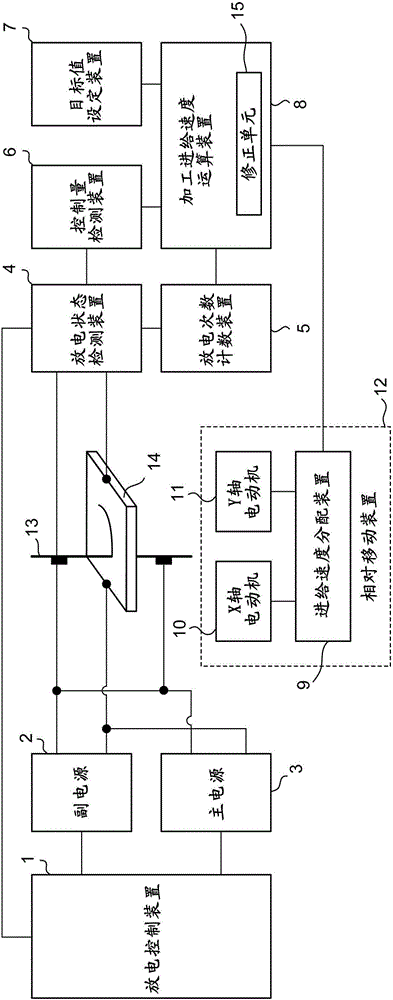

[0029] below, with Figure 1 Embodiments of the present invention will be described together.

[0030] figure 1 It is a block diagram for explaining the wire electric discharge machine of the embodiment of the present invention. The discharge control device 1 instructs the auxiliary power supply 2 and the main power supply 3 to operate according to a predetermined order, and the auxiliary power supply 2 and the main power supply 3 turn on the semiconductor switch based on the instruction to discharge the discharge to the machining gap (the gap formed between the wire electrode 13 and the workpiece 14). ) to supply electrical energy.

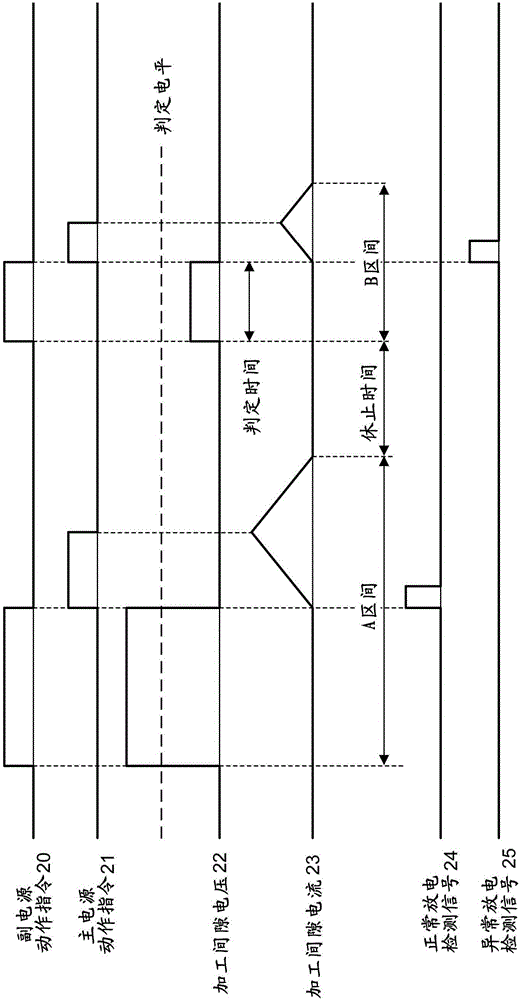

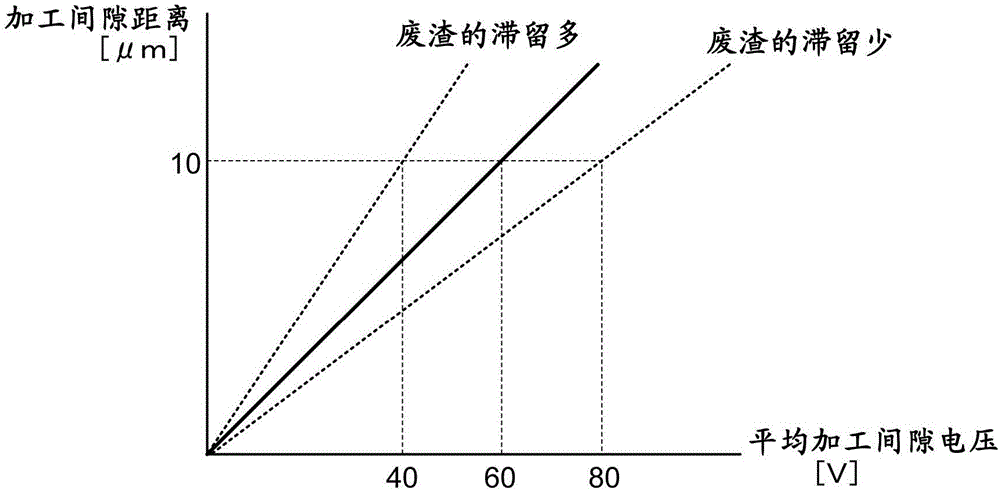

[0031] Initially, a predetermined voltage is applied to the processing gap through the auxiliary power supply 2 with high output impedance, and the power supply is switched when a discharge occurs, and a predetermined current is supplied to the processing gap through the main power supply 3 with low output impedance to melt and remove the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com