Field jet flow micro electrical discharge machining method

A field jet and electric discharge machining technology, which is applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve problems such as the inability to generate jet flow, and achieve the effect of simple and reliable device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

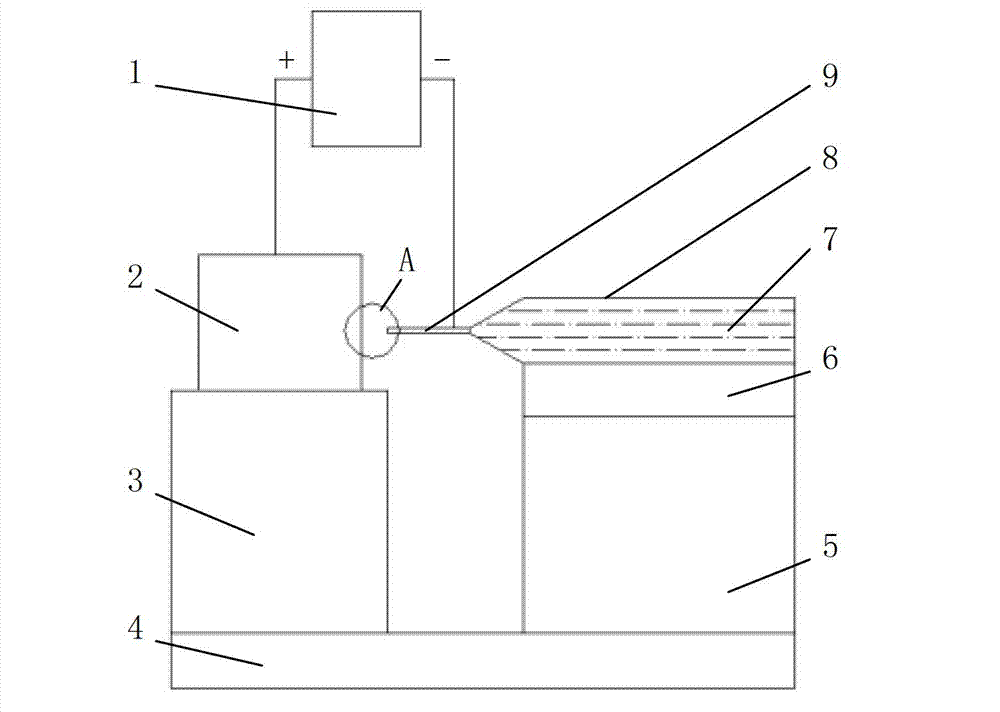

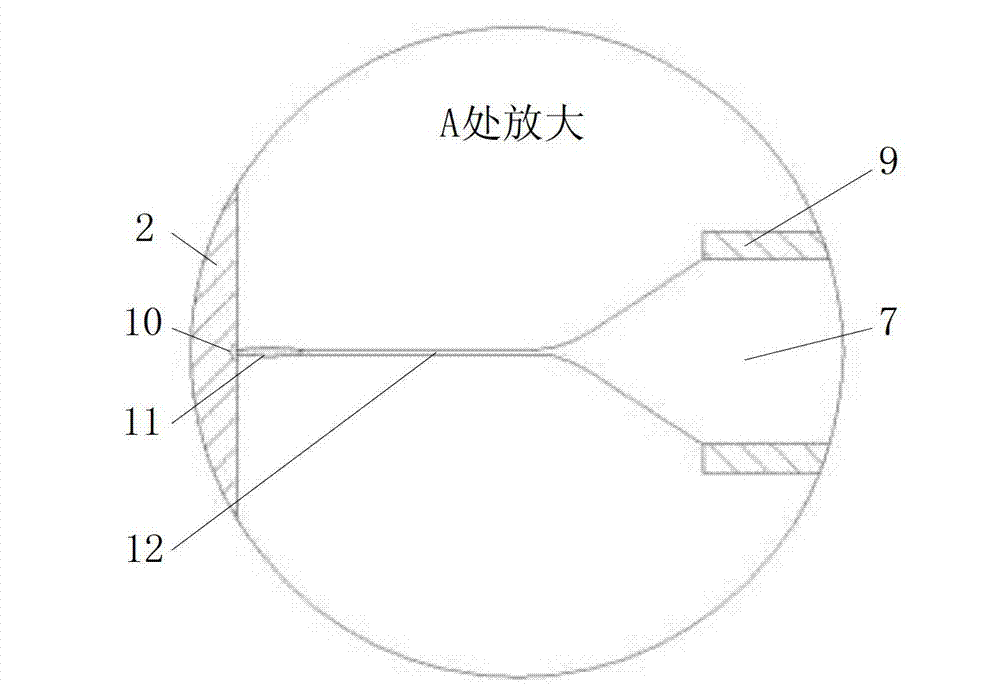

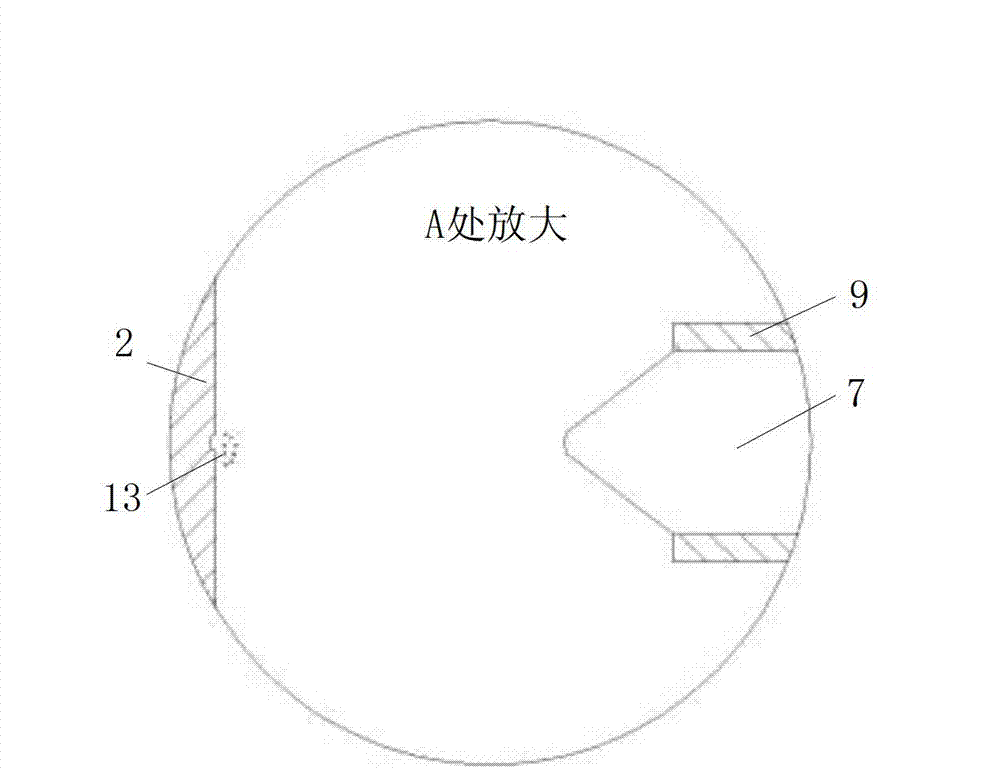

[0027] Such as figure 1 As shown, the device includes: a high-voltage power supply 1, a workpiece 2, a workbench 3 for installing the workpiece, an insulating base 4, a motion platform 5, a fixture 6 for installing the nozzle and the liquid reservoir, electrolyte 7, the liquid reservoir 8 and the nozzle 9, where: A represents the part between the workpiece and the nozzle.

[0028] In this embodiment, the electrolyte solution 7 is sodium nitrate (NaNO 3 ) solution, the workpiece 2 is made of stainless steel with flat and smooth surface, the nozzle 9 adopts an industrial dispensing needle with an inner diameter of 200 μm, and the material is stainless steel, the high-voltage power supply 1 is connected between the workpiece 2 and the nozzle 9, and the workpiece 2 is connected to the high-voltage power supply The positive pole of the output terminal 1, and the nozzle 9 is connected to the negative pole of the output terminal of the high-voltage power supply 1. The motion platfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com