Laser tool grinding method and tool grinding machine

A sharpening machine and laser technology, which is applied in manufacturing tools, laser welding equipment, metal processing equipment, etc., can solve problems such as unsatisfactory economy, high cost and difficult process of metal bond grinding wheel, and restricting the development of equipment functions. , to achieve the effect of easy real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

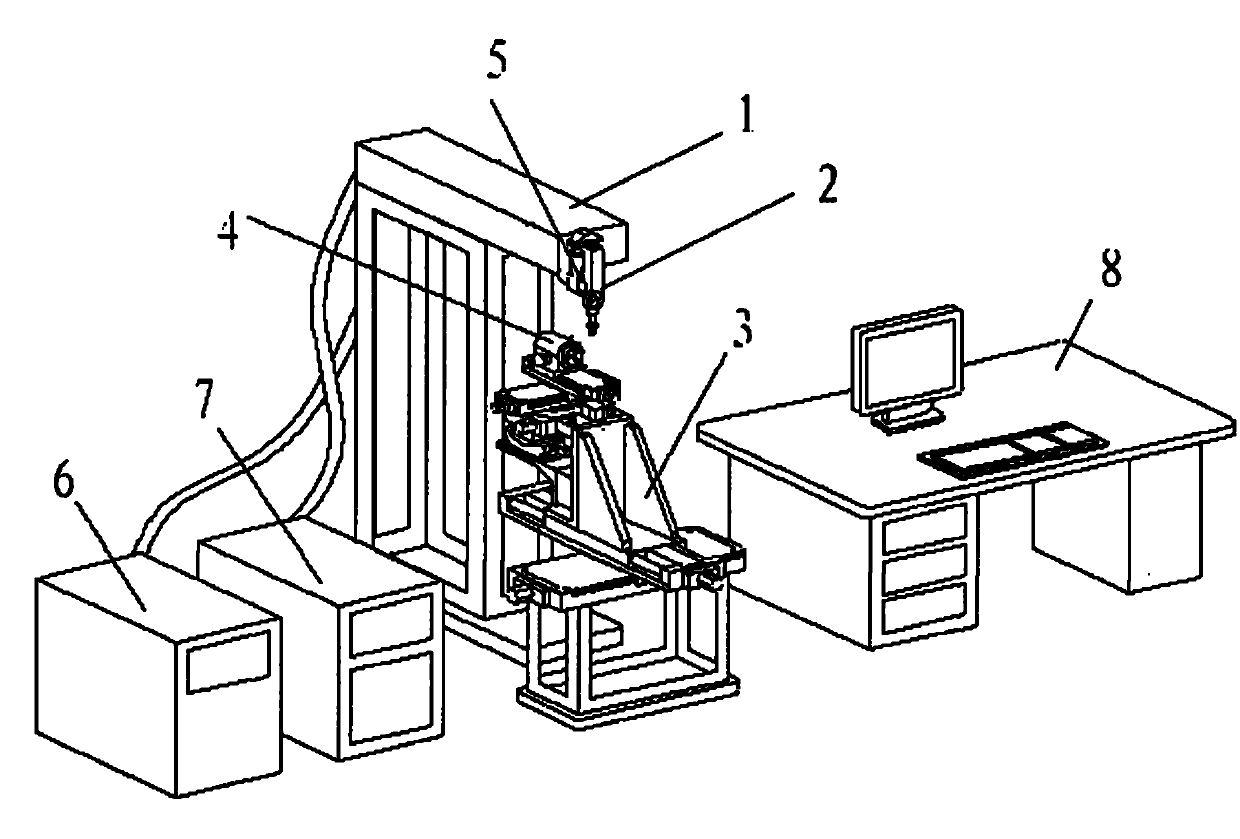

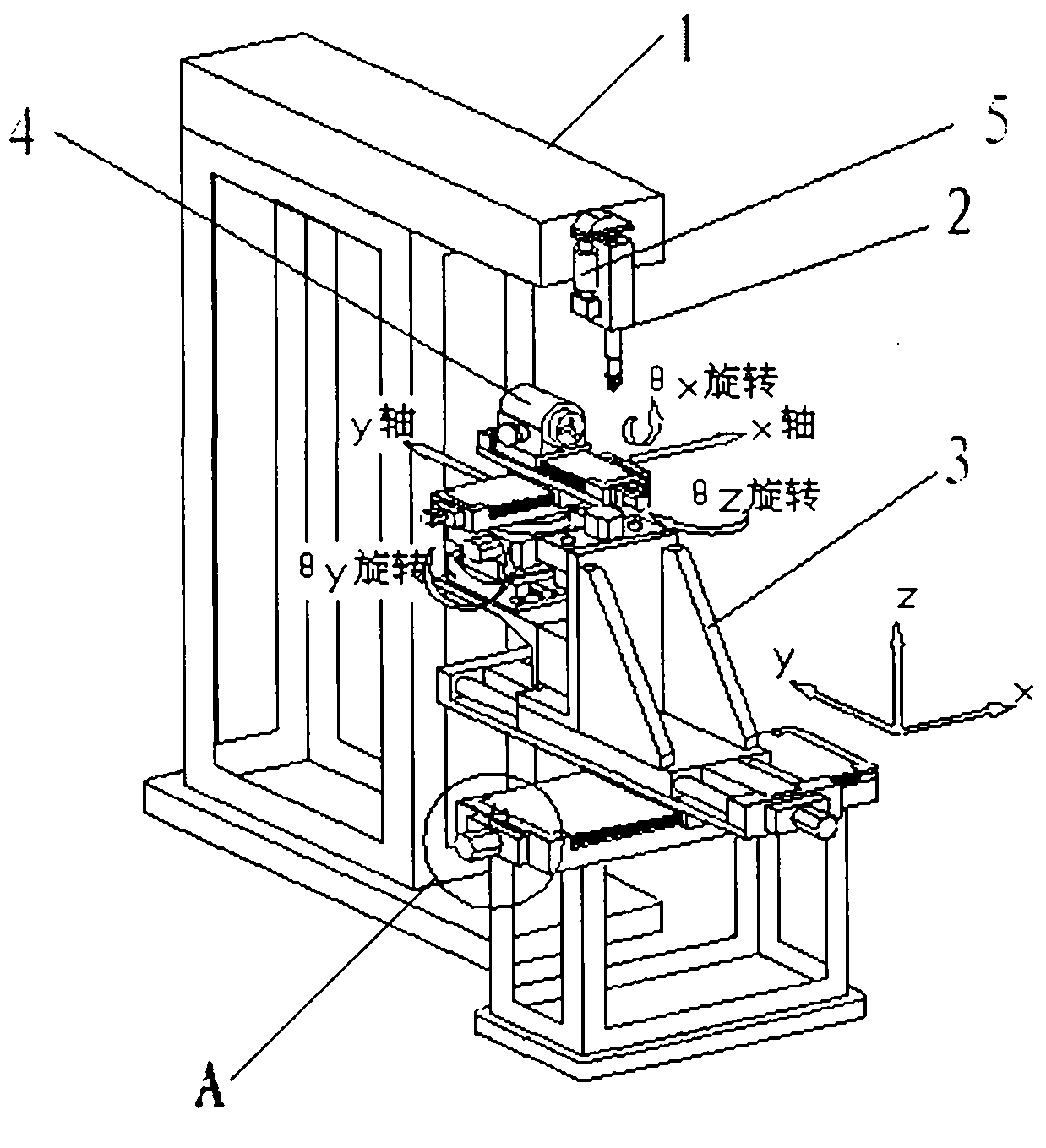

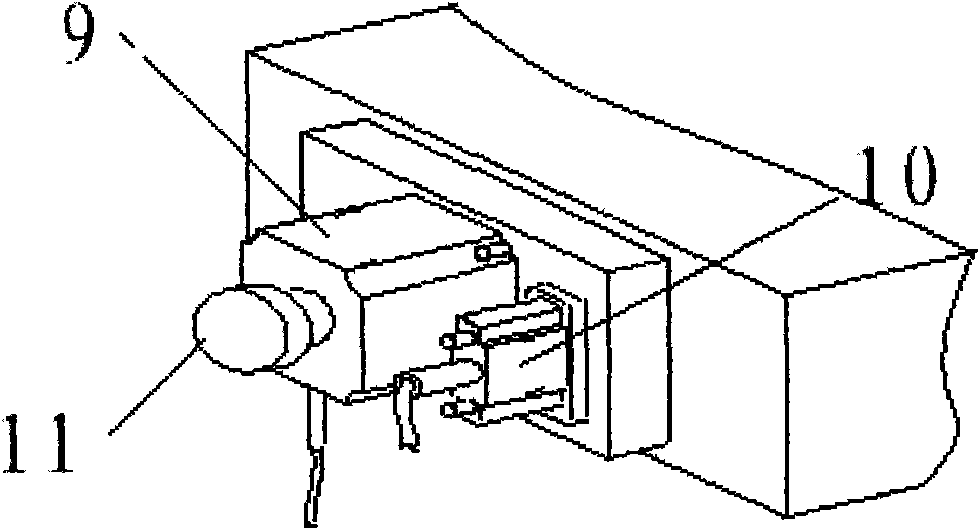

[0063] The basic composition of laser tool sharpening machine: such as figure 1 as shown,

[0064] High-quality laser 1; light guiding and focusing system 2; high-precision multi-dimensional motion system 3; installation tool fixture 4; real-time monitoring system 5; cooling system 6; power supply system 7; control and operating system 8.

[0065] The high-quality laser 1 is fixed on the body, the light guiding and focusing system 2 is installed on the front end of the high-quality laser 1, the real-time monitoring system 5 is installed on one side of the light guiding and focusing system 2, and the installation tool fixture 4 is installed on the high-precision multi-dimensional movement On the system 3, the pipeline of the cooling system 6 is connected to the high-quality laser 1; the power supply system 7 and the control and operating system 8 are connected to the high-quality laser 1, the light guide focusing system 2, the high-precision multi-dimensional motion system 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com