Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Diamond deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Simple tool for positional diamond mechanosynthesis, and its method of manufacture

InactiveUS7687146B1Specific nanostructure formationLayered productsMechanosynthesisDiamond deposition

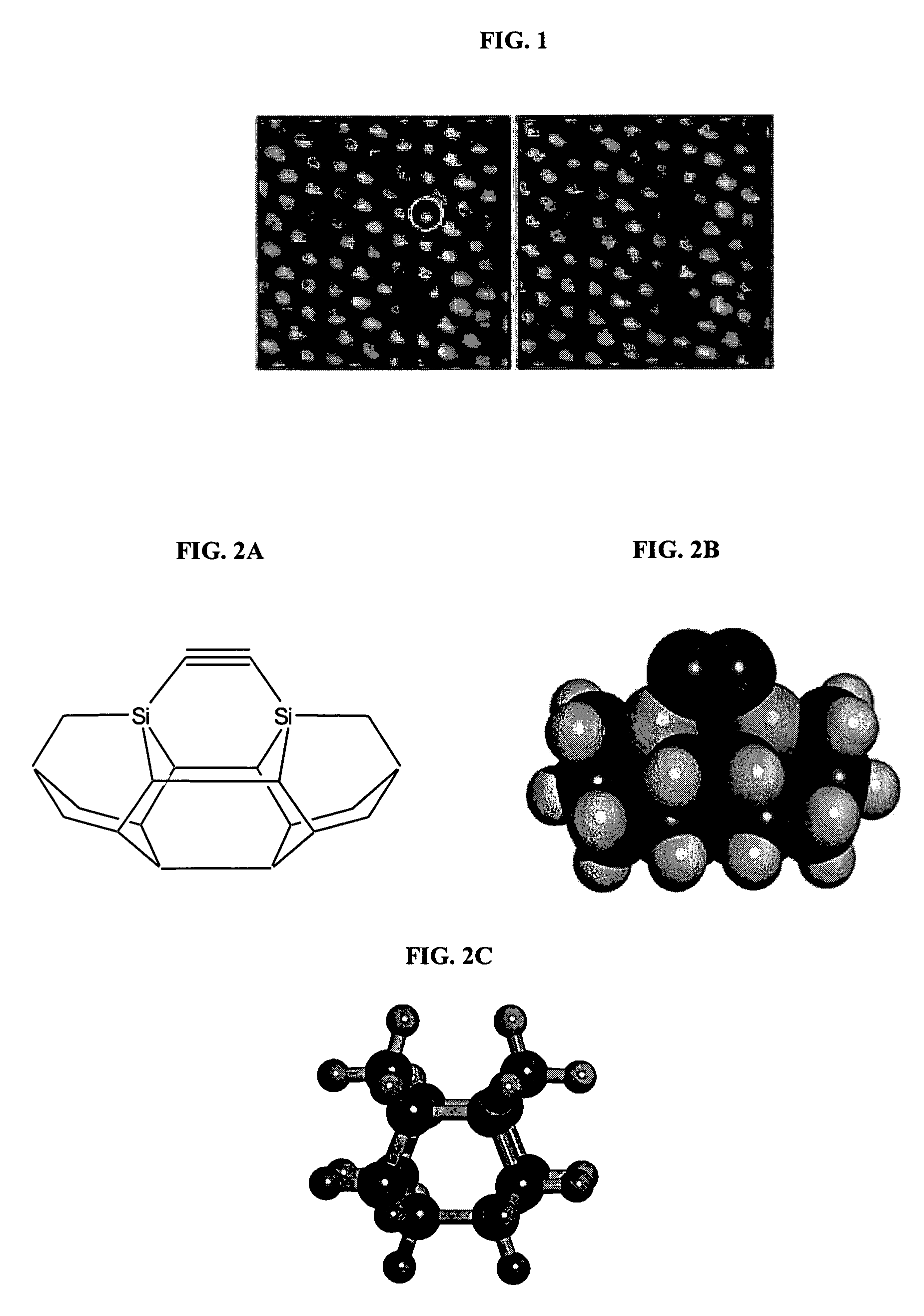

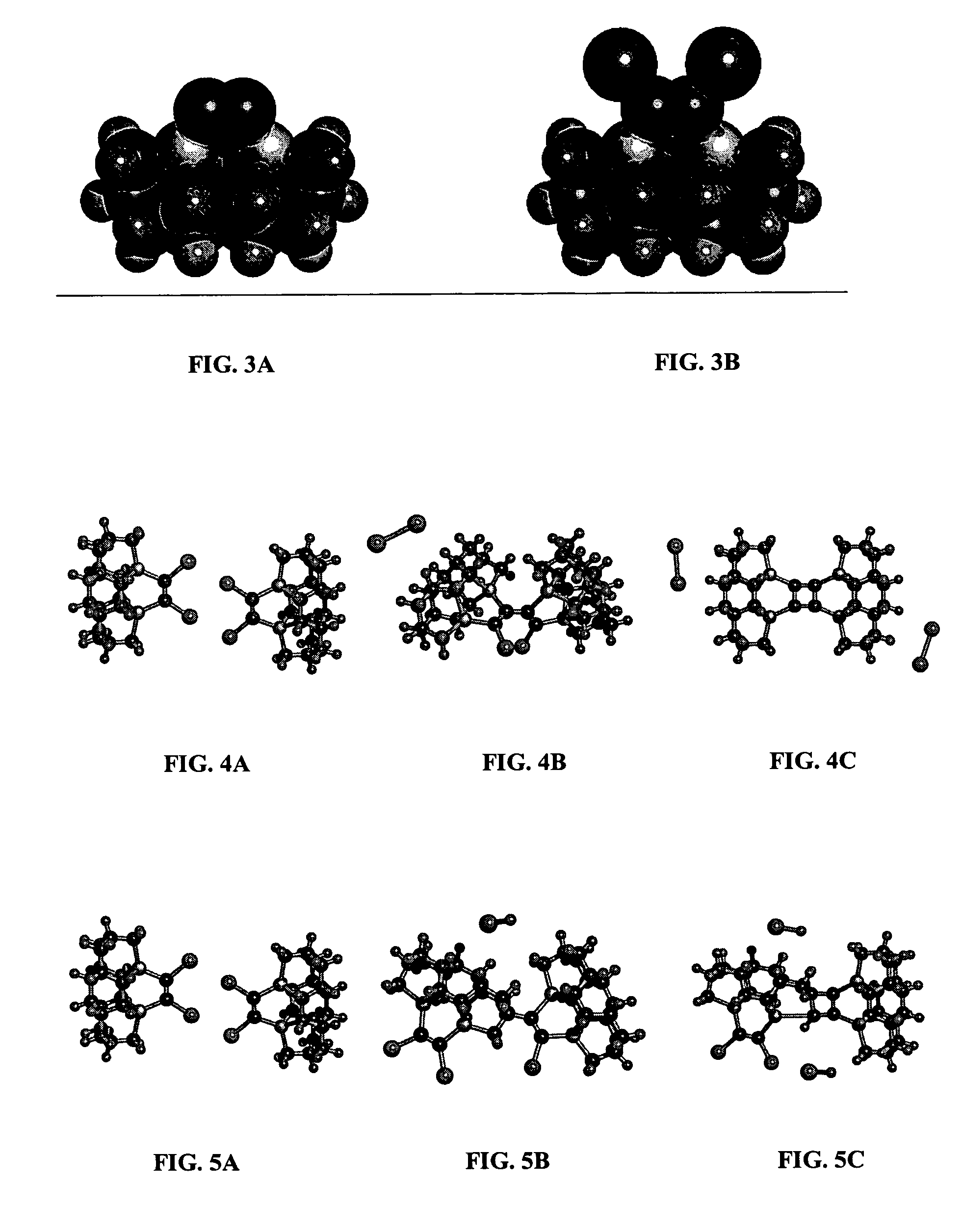

A method is described for building a mechanosynthesis tool intended to be used for the molecularly precise fabrication of physical structures—as for example, diamond structures. An exemplar tool consists of a bulk-synthesized dimer-capped triadamantane tooltip molecule which is initially attached to a deposition surface in tip-down orientation, whereupon CVD or equivalent bulk diamond deposition processes are used to grow a large crystalline handle structure around the tooltip molecule. The large handle with its attached tooltip can then be mechanically separated from the deposition surface, yielding an integral finished tool that can subsequently be used to perform diamond mechanosynthesis in vacuo. The present disclosure is the first description of a complete tool for positional diamond mechanosynthesis, along with its method of manufacture. The same toolbuilding process may be extended to other classes of tooltip molecules, other handle materials, and to mechanosynthetic processes and structures other than those involving diamond.

Owner:ZYVEX LABS LLC

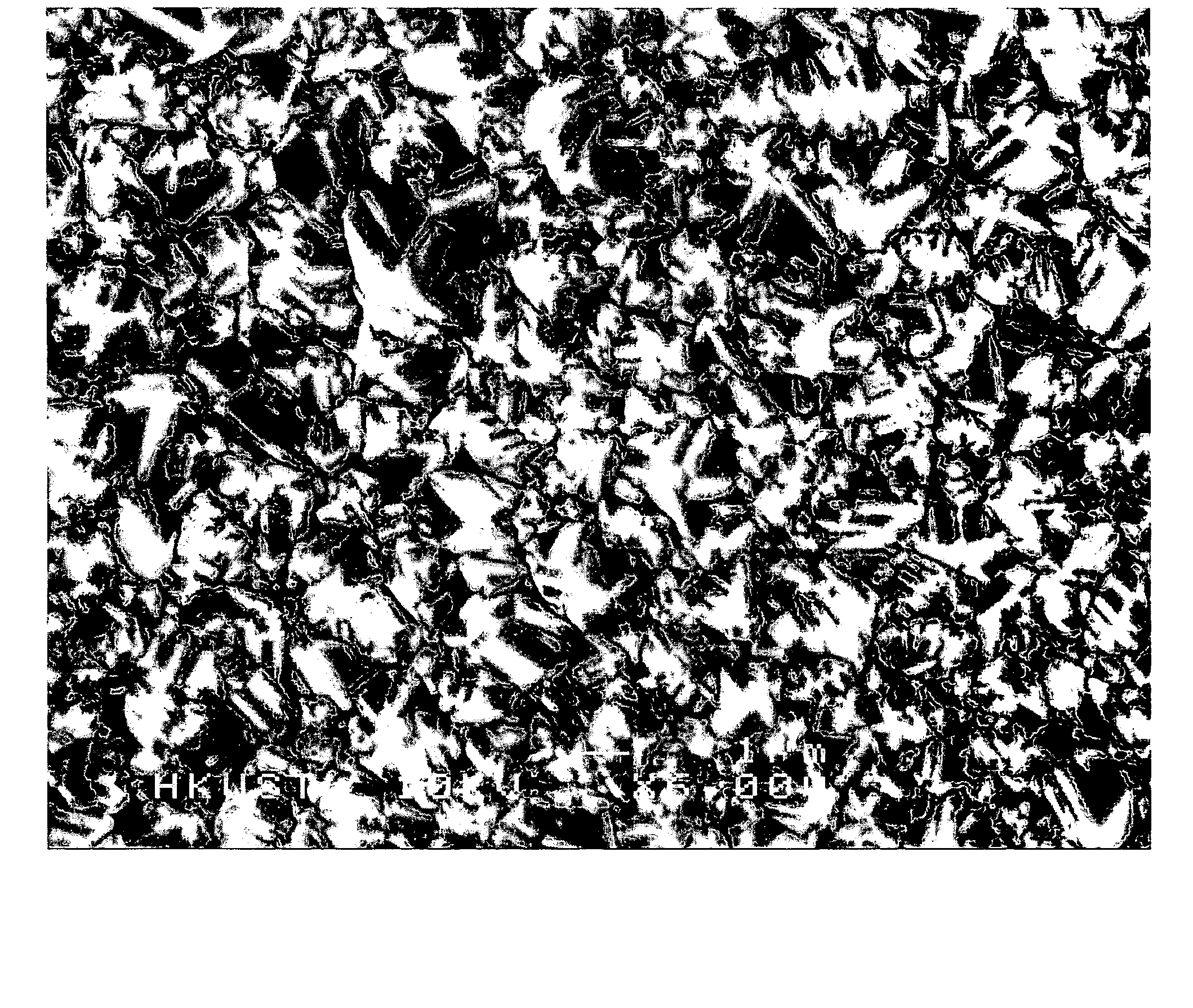

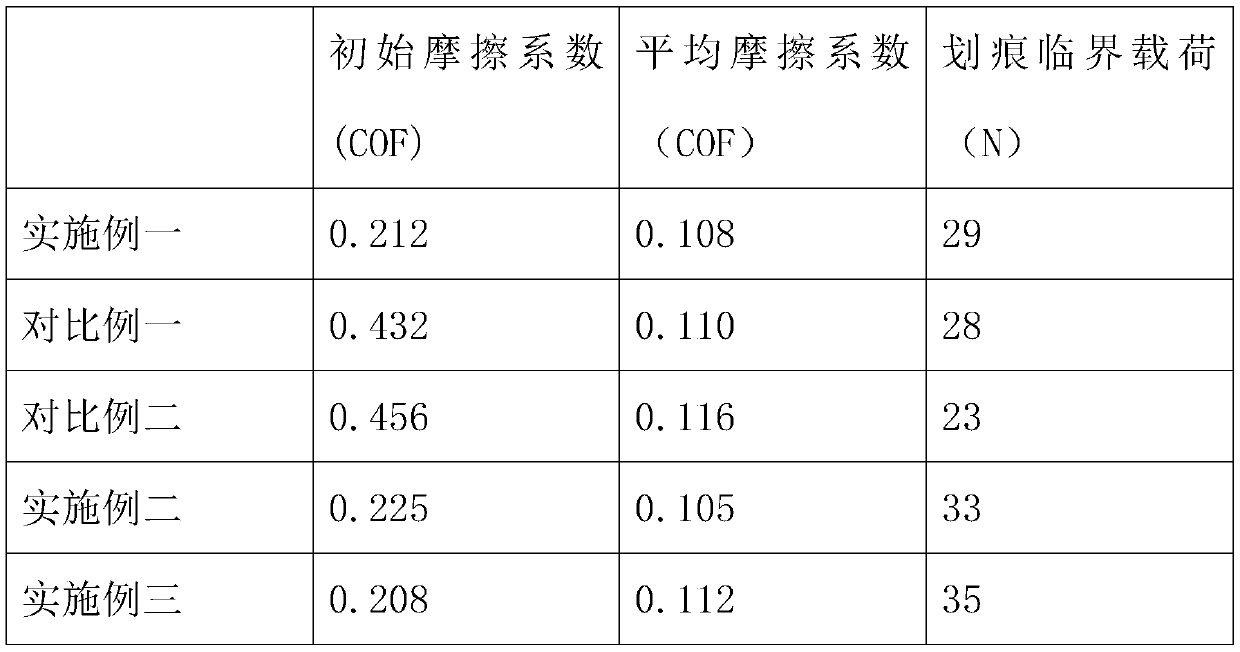

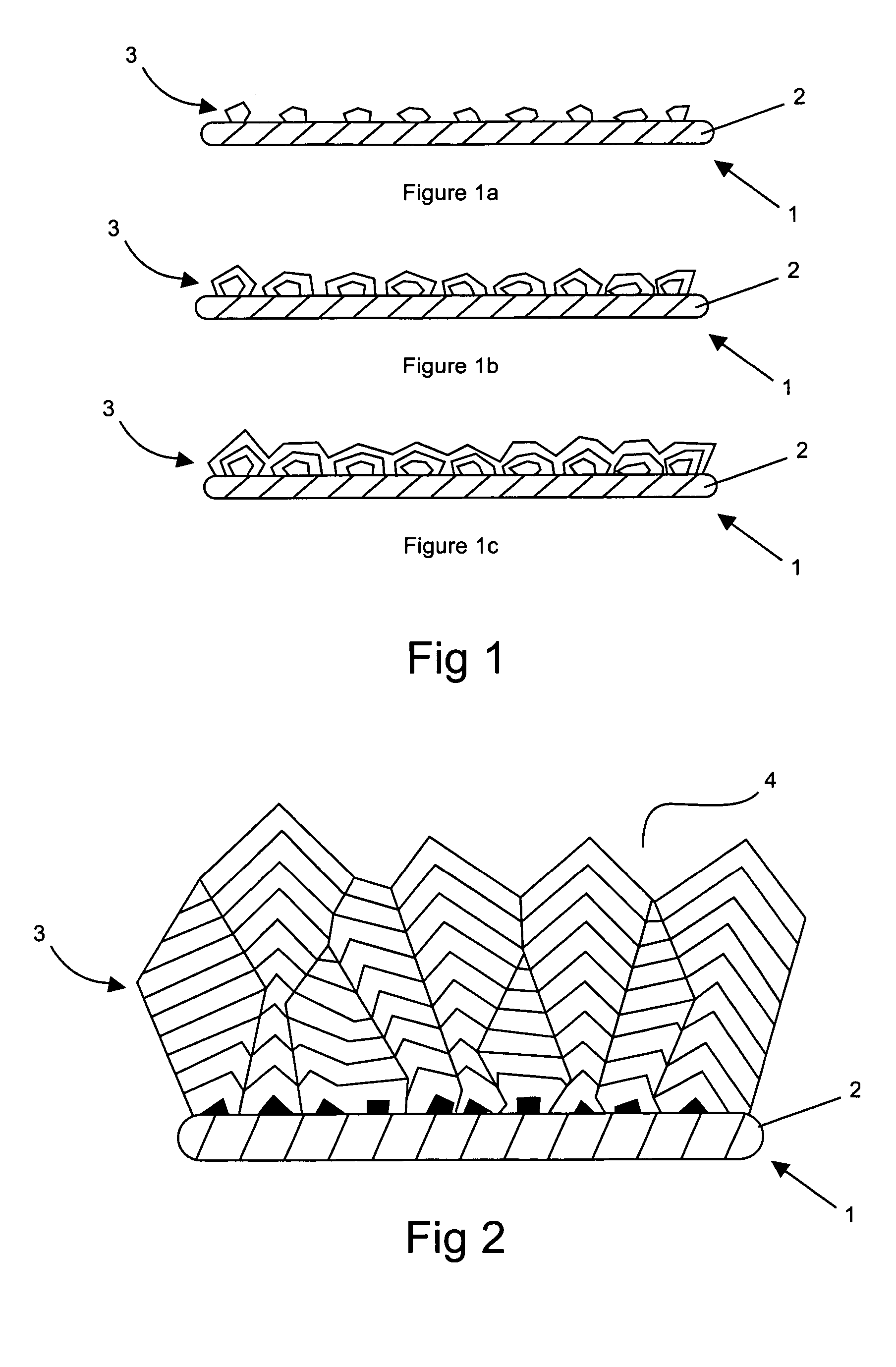

Ultrahard multilayer coating comprising nanocrystalline diamond and nanocrystalline cubic boron nitride

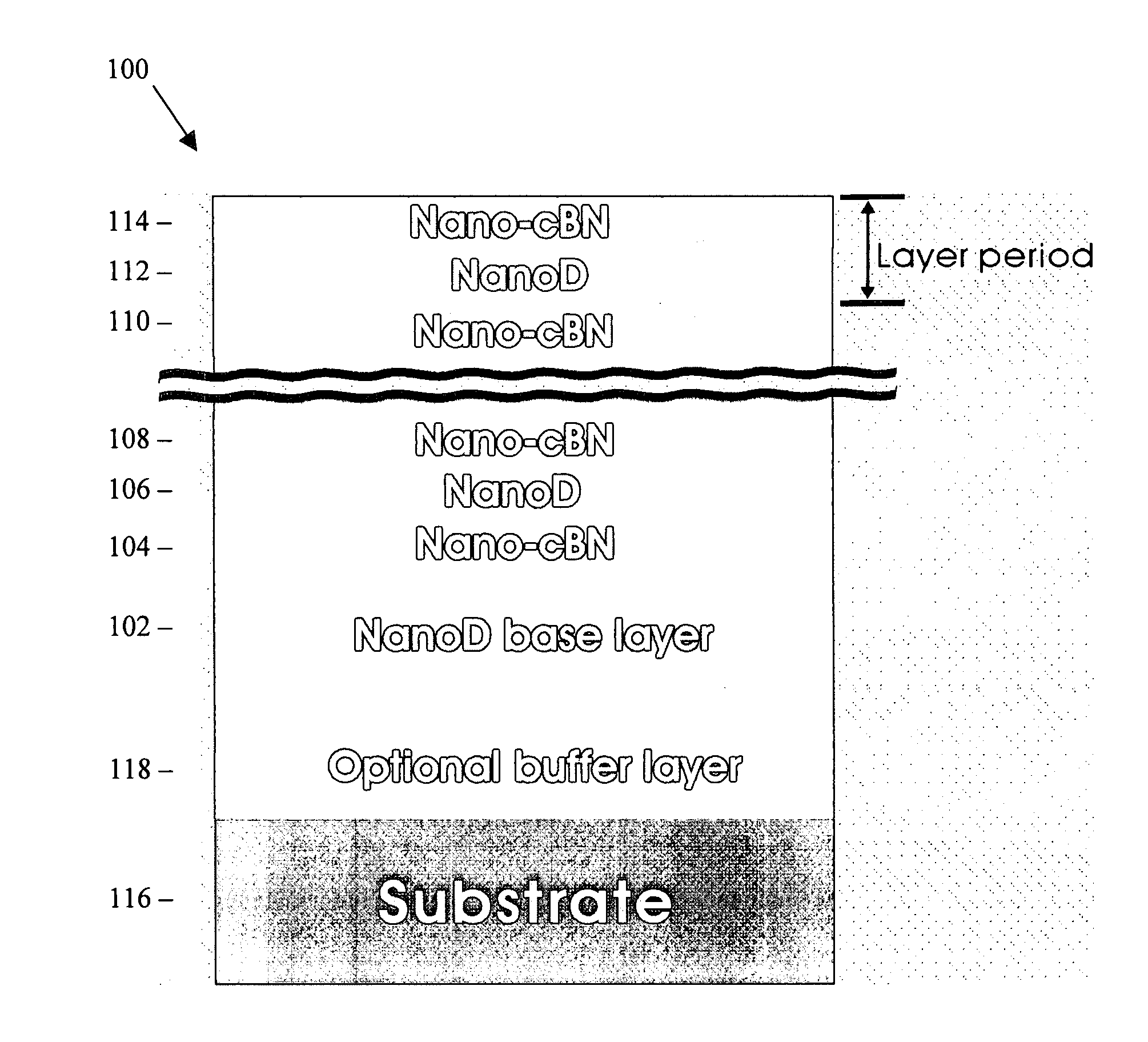

A multilayer coating (MLC) is composed of two chemically different layered nanocrystalline materials, nanodiamond (nanoD) and nano-cubic boron nitride (nono-cBN). The structure of the MLC and fabrication sequence of layered structure are disclosed. The base layer is preferably nanoD and is the first deposited layer serving as an accommodation layer on a pretreated substrate. It can be designed with a larger thickness whereas subsequent alternate nano-cBN and nanoD layers are typically prepared with a thickness of 2 to 100 nm. The thickness of these layers can be engineered for a specific use. The deposition of the nanoD layer, by either cold or thermal plasma CVD, is preceded by diamond nucleation on a pretreated and / or precoated substrate, which has the capacity to accommodate the MLC and provides excellent adhesion. Nano-cBN layers are directly grown on nanodiamond crystallites using ion-assisted physical vapor deposition (PVD) and ion-assisted plasma enhanced chemical vapor deposition (PECVD), again followed by nanodiamond deposition using CVD methods in cycles until the intended number of layers of the MLC is obtained.

Owner:CITY UNIVERSITY OF HONG KONG

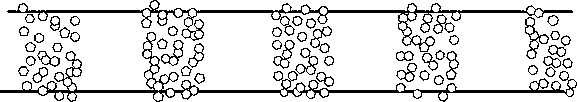

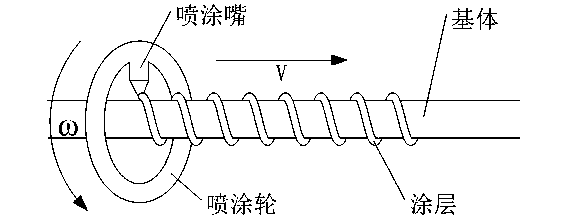

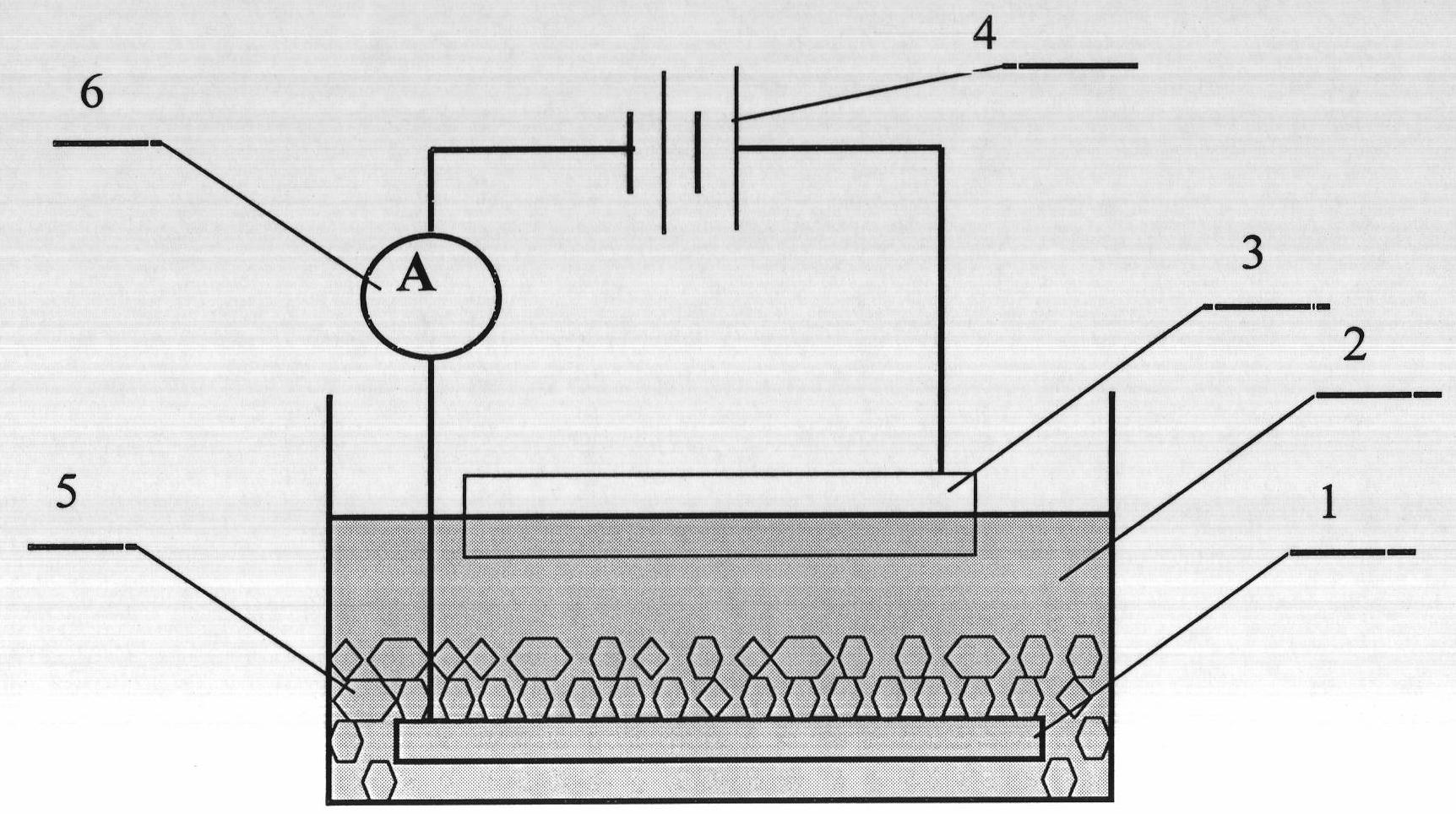

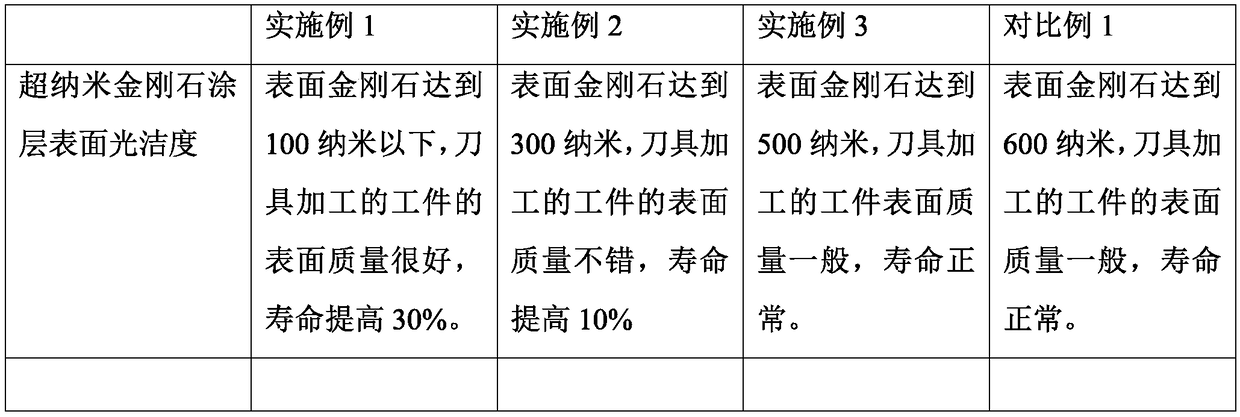

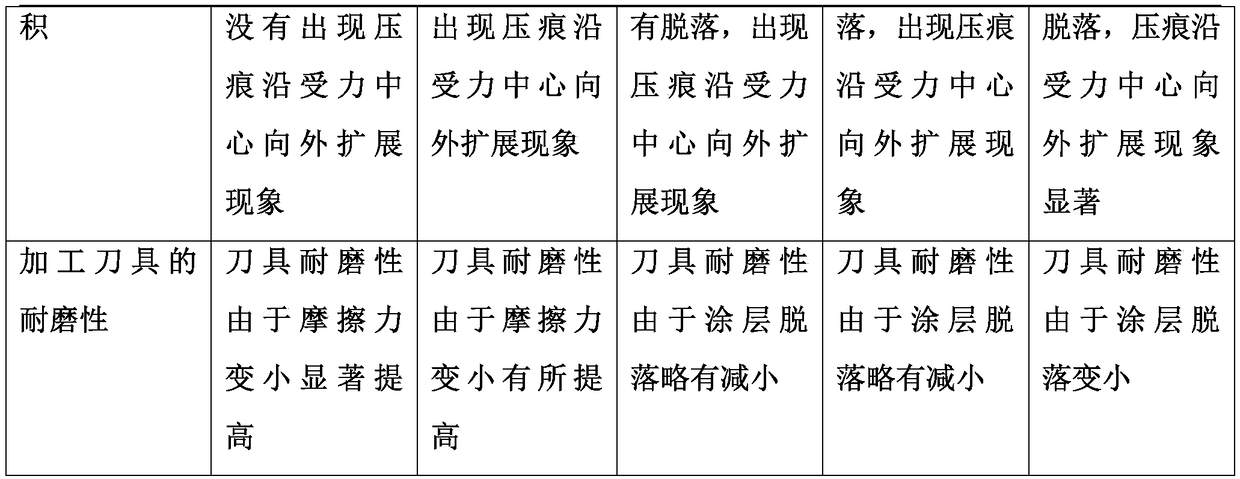

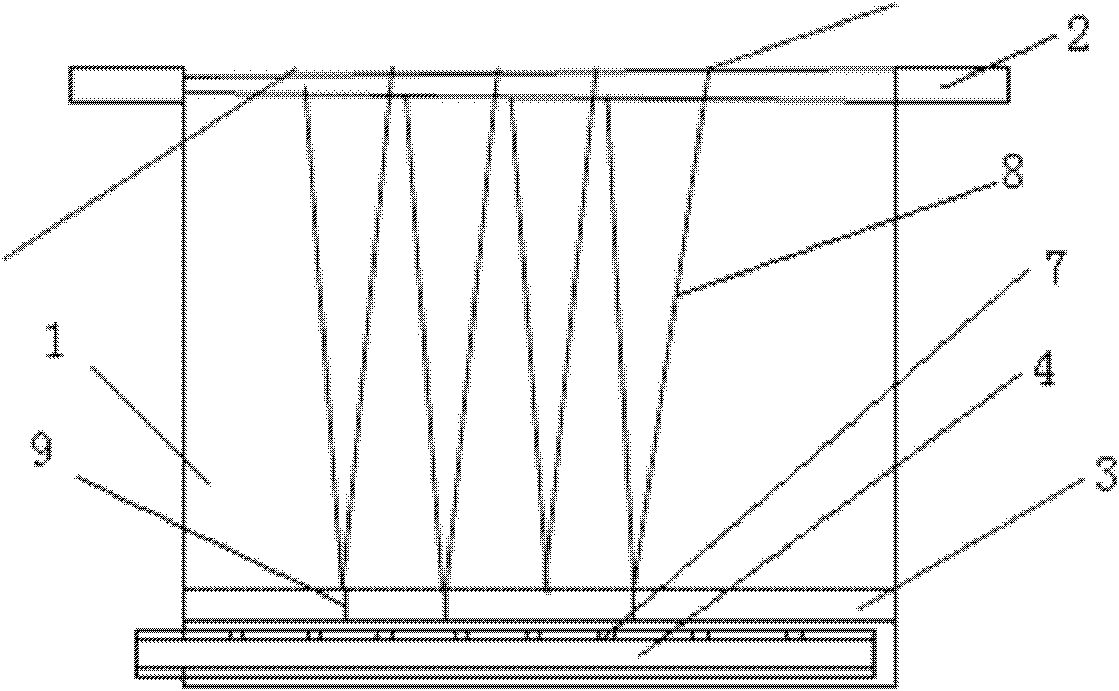

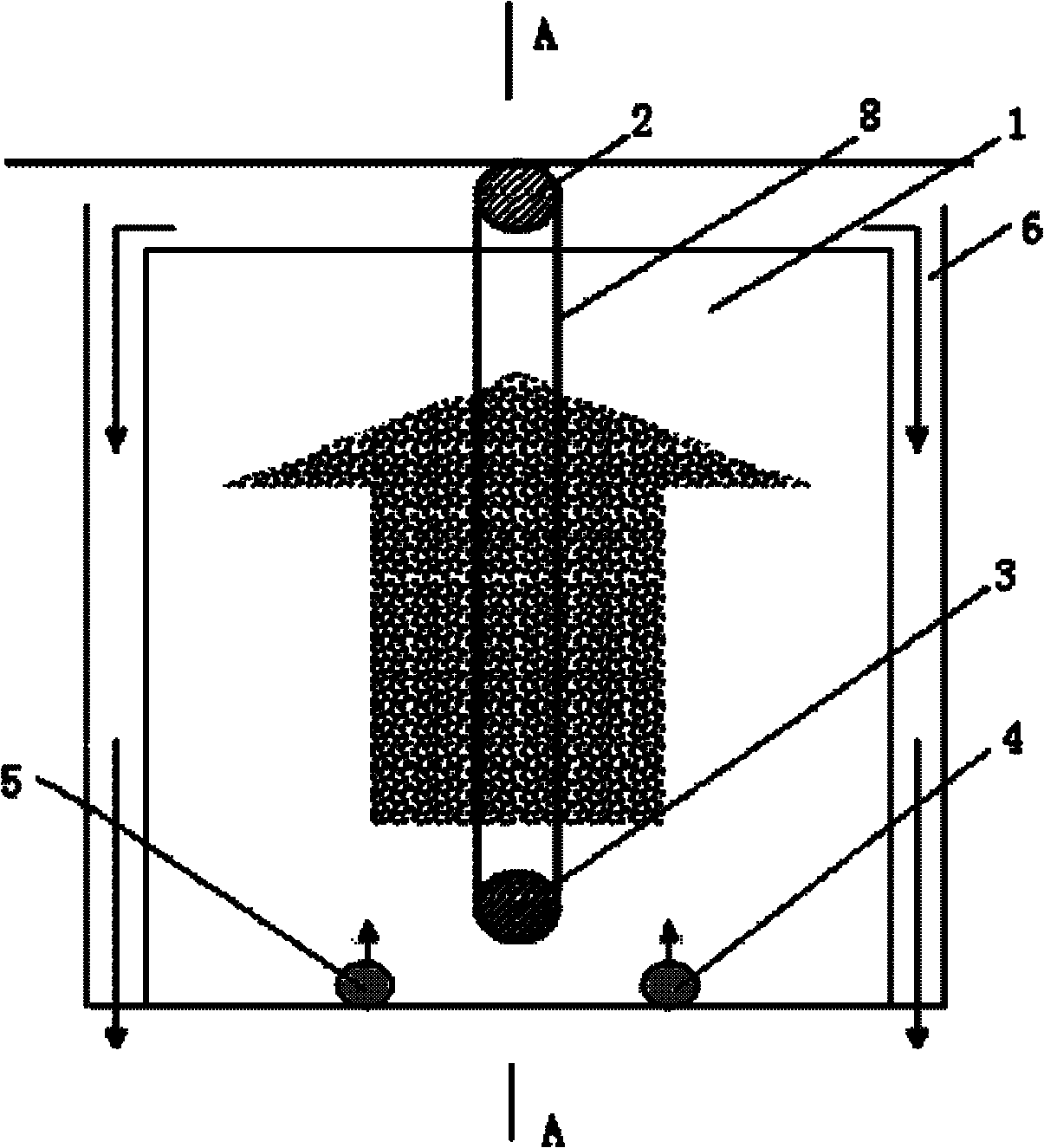

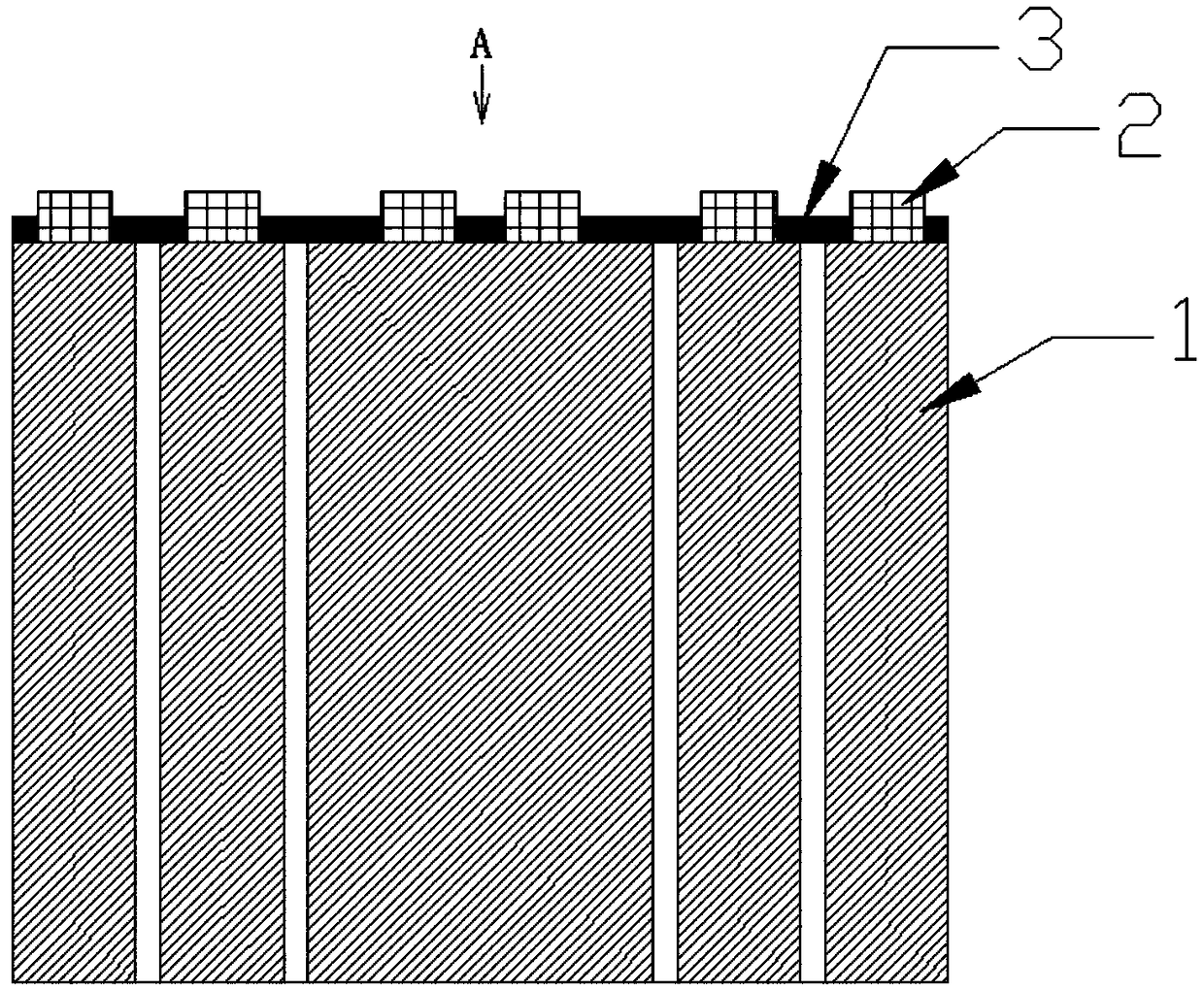

Electroplating diamond fretsaw with grinding materials controllably distributed and preparation method

ActiveCN103100987AReduce usageIncrease profitMetal sawing toolsGrinding devicesRegion selectionDiamond wire saw

The invention discloses an electroplating diamond fretsaw with grinding materials controllably distributed and a preparation method. The electroplating diamond fretsaw is composed of a steel wire base body and diamond grinding materials, and is characterized in that the diamond grinding materials on the fretsaw are electrically deposited on a surface of the steel wire base body according to a pre-arranged shape, and a chip removal groove is formed on a none-deposited-diamond surface of the grinding materials. The preparation method comprises the following critical steps: region selection and coating processing are conducted on the surface of the steel wire base body, and a reserved none-grinding-material surface of the steel wire base body is coated with a pre-arranged shape; sand-feeding process is conducted on surfaces of the steel wire base body, the steel wire base body enters an electroplating groove, and the diamond grinding materials are electrically deposited on an uncoated region of the base body; and coating removal processing is conducted on the surface of the steel wire base body, the steel wire base body enters a coating removal groove to remove the coating, and manufacturing of the diamond fretsaw is finished. The electroplating diamond fretsaw with the grinding materials controllably distributed and the preparation method have the advantages of being high in cutting efficiency, long in service life and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

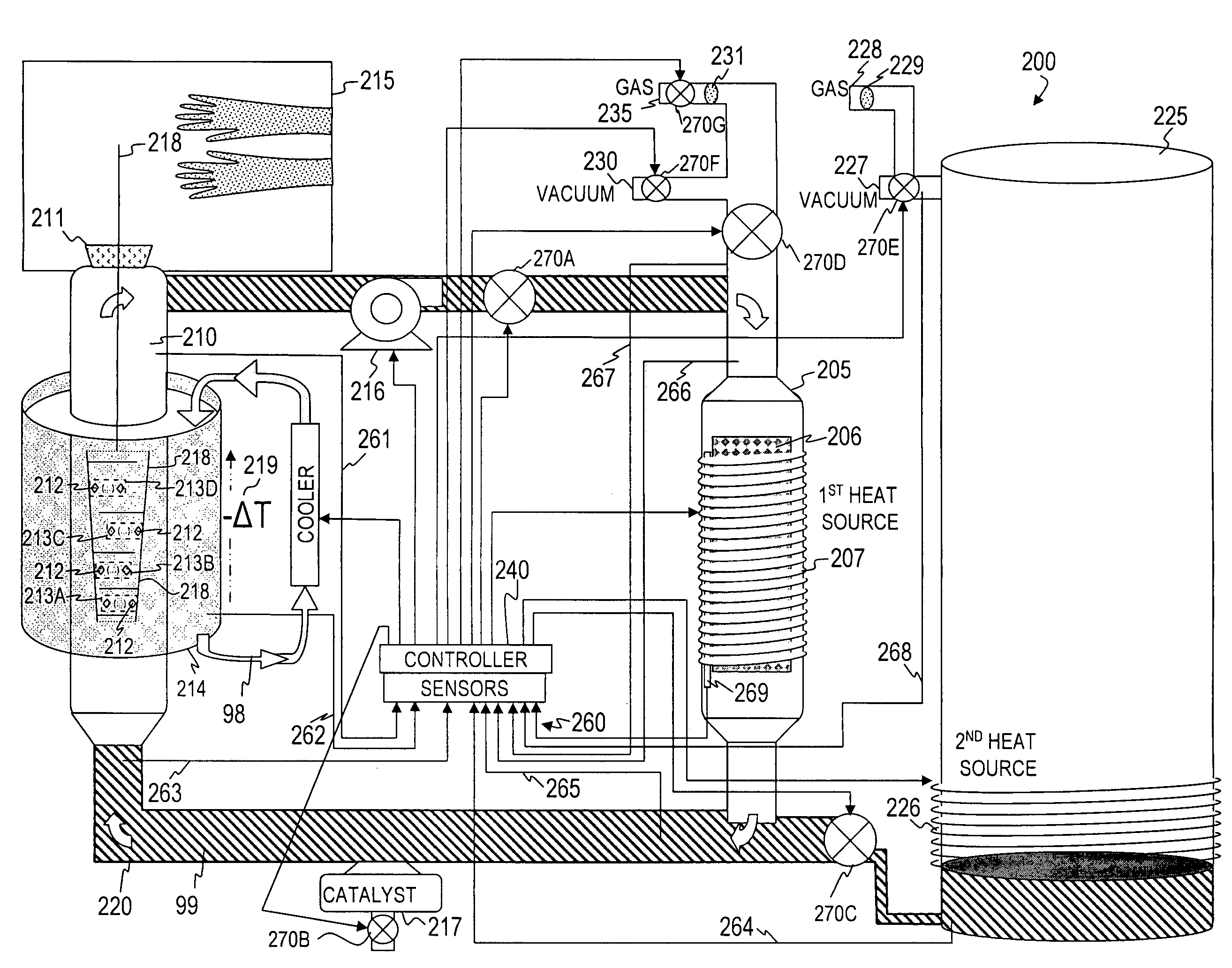

System and method for diamond deposition using a liquid-solvent carbon-transfer mechanism

ActiveUS7547358B1After-treatment apparatusPolycrystalline material growthControl signalDiamond crystal

A system and method for growing diamond crystals from diamond crystal seeds by epitaxial deposition at low temperatures and atmospheric and comparatively low pressures. A solvent is circulated (by thermal convection and / or pumping), wherein carbon is added in a hot leg, transfers to a cold leg having, in some embodiments, a range of progressively lowered temperatures and concentrations of carbon via the circulating solvent, and deposits layer-by-layer on diamond seeds located at the progressively lower temperatures since as diamond deposits the carbon concentration lowers and the temperature is lowered to keep the solvent supersaturated. The solvent includes metal(s) or compound(s) that have low melting temperatures and transfer carbon at comparatively low temperatures. A controller receives parameter signals from a variety of sensors located in the system, processes these signals, and optimizes diamond deposition by outputting the necessary control signals to a plurality of control devices (e.g., valves, heaters, coolers, pumps).

Owner:SHAPIRO ALAN JOSHUA

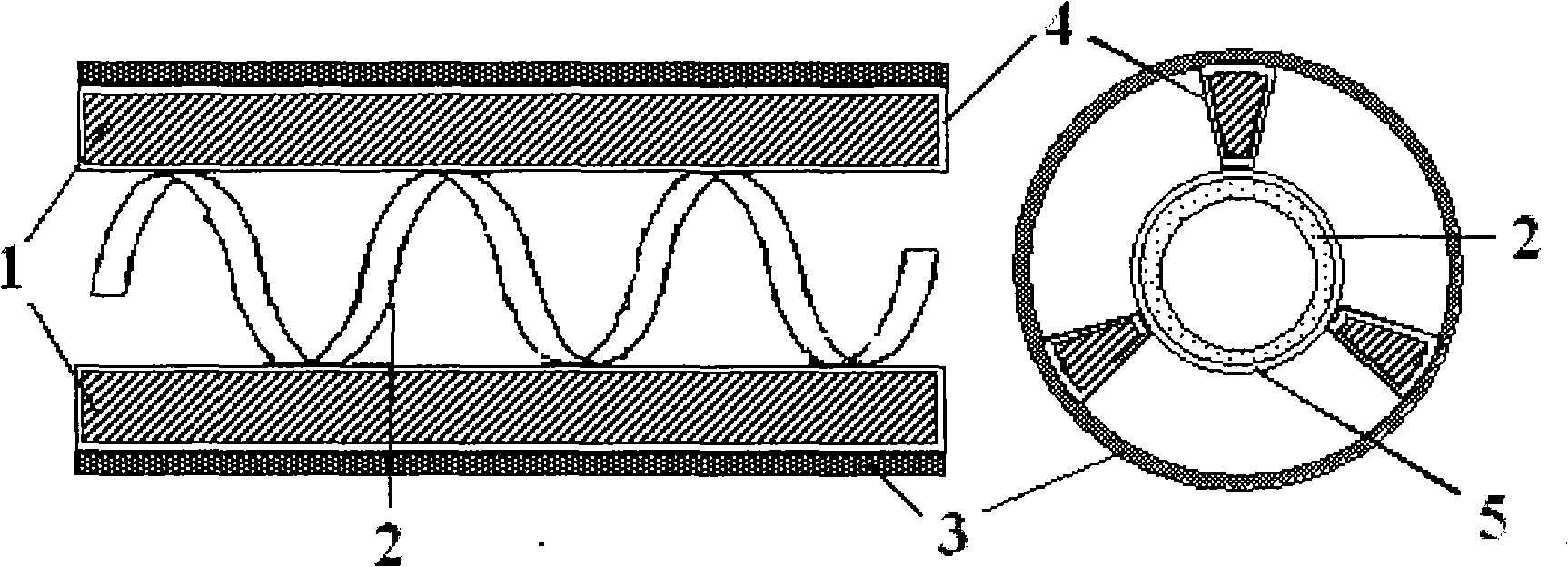

Helix TWT slow wave component and production method

InactiveCN101271803AImprove cooling effectEasy to processTransit-tube circuit elementsCold cathode manufactureHelical lineWave tube

The invention discloses a helical line traveling wave tube slow-wave component and a preparation method thereof. The method comprises the steps as follows: a cleaned medium holding rod and the helical line are arranged in a diamond deposition chamber; the diamond is deposited on the surface of the medium holding rod and the helical line to form a diamond film; the medium holding rod and the helical line with the diamond film and a metal pipe shell are fixed on a loading die and extruded into the metal pipe shell. The component comprises the medium holding rod, the helical line, a pipe shell, a first diamond film and a second diamond film. The diamond is deposited on the surfaces of medium holding rod and the helical line, therefore, the defect of low heat conductivity of other mediums is compensated, the heat dissipation capability of the slow-wave component is improved, and the problems of difficult processing and expensive price of the diamond holding rod are solved.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

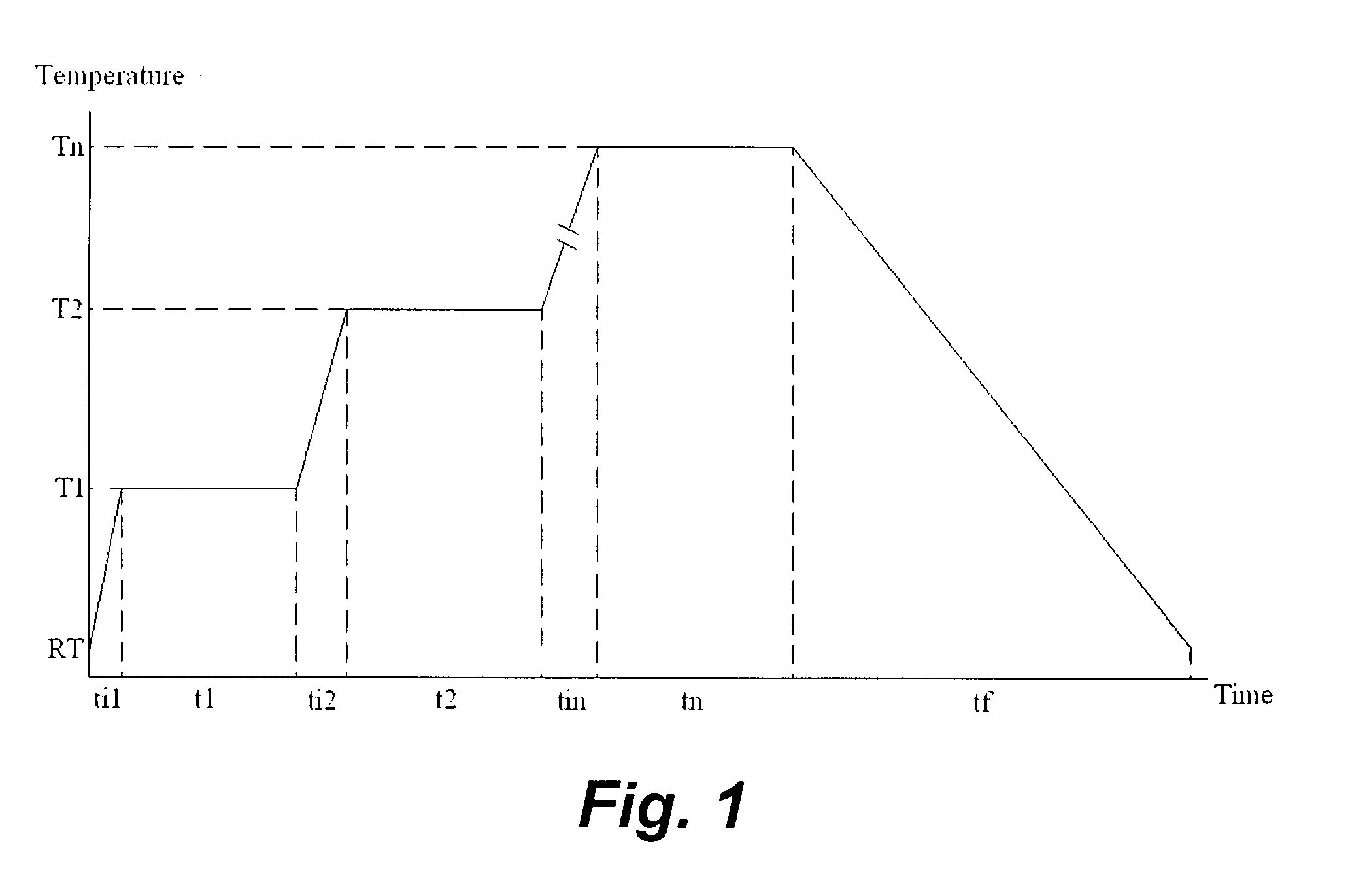

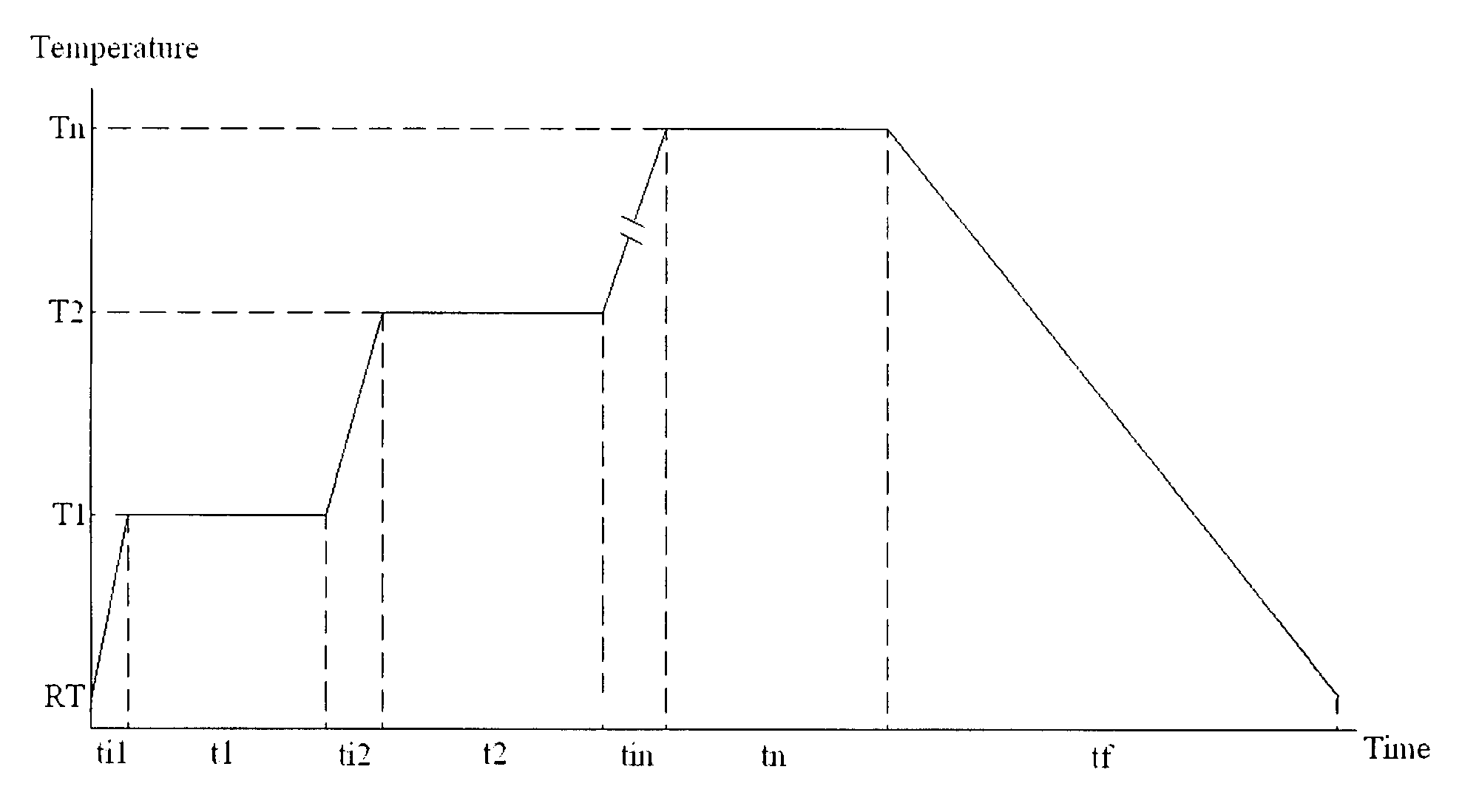

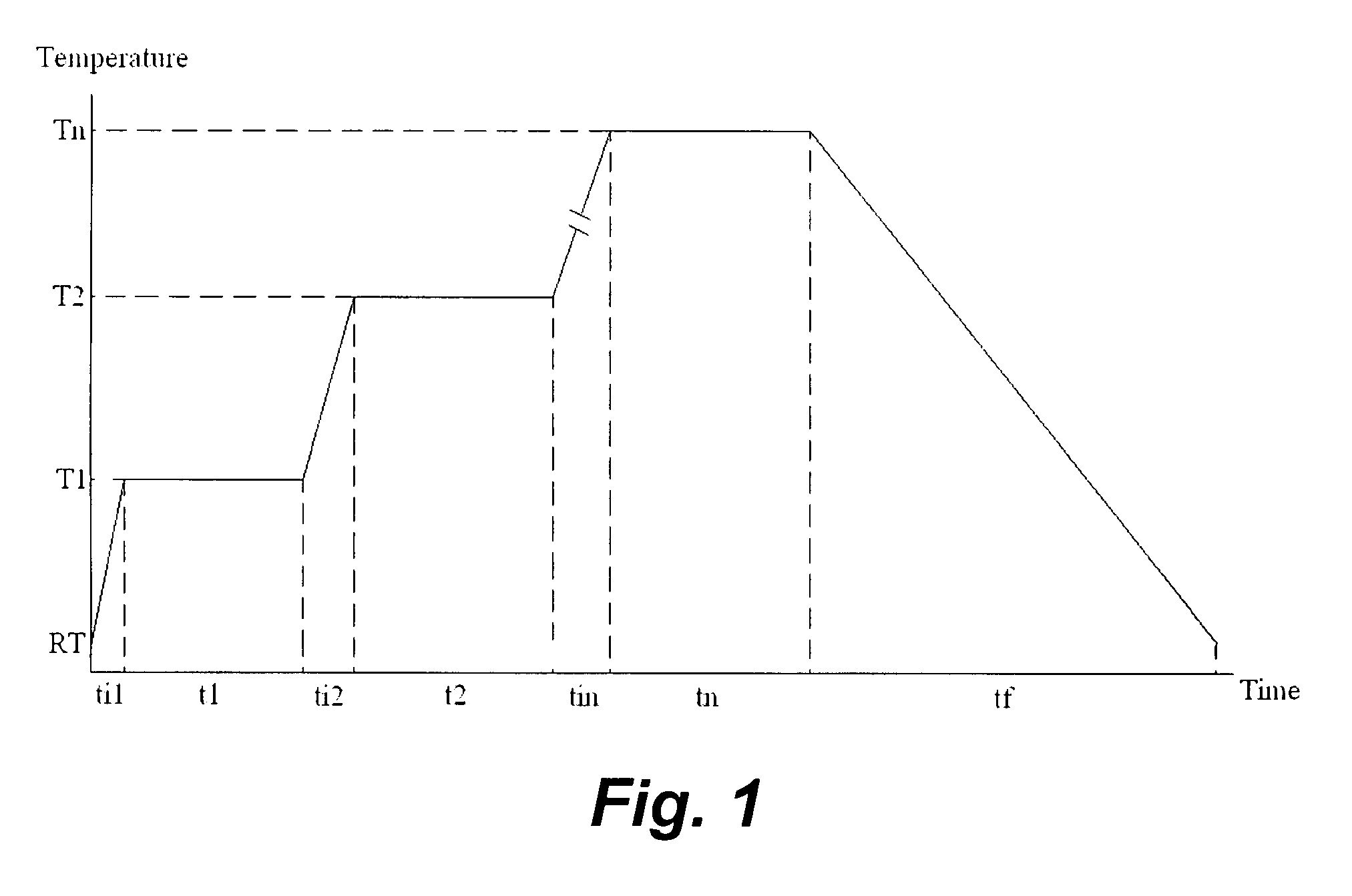

Method for making a highly stable diamond film on a subtrate

InactiveUS20080070049A1Increase substrate temperatureMultiple component coatingsWater/sewage treatmentCarbideTitanium

A method of depositing a stable diamond film on a metal substrate includes pretreating a surface of the substrate and depositing a diamond film on the substrate by way of a multi-stage chemical vapor deposition, in which each subsequent stage is performed at progressively higher temperature. The deposited diamond may be doped with boron. The substrate may be titanium, a titanium alloy, iron, an iron alloy, or any other valve metal. The diamond deposition may be a high temperature chemical vapor deposition. The first deposition stage may optionally create a carbide of diamond and substrate, and an optional mixture of diamond and amorphous carbon may be deposited to bond this carbide layer to a subsequently applied layer. The resulting product may be used as an electrode, as a tooth or blade in a cutting tool, or may have many other uses.

Owner:THE HONG KONG UNIV OF SCI & TECH

Copper-based mosaic structure interface diamond coating and preparation method and application thereof

InactiveCN101935837AImprove bindingReduce defectsElectrolytic coatingsChemical vapor deposition coatingHeat sinkImpurity

The invention discloses a copper-based mosaic structure interface diamond coating and a preparation method and application thereof. The coating consists of a copper-diamond composite coarse sanding plating layer, a copper reinforcing layer, a copper-diamond composite thin sanding layer and a CVD diamond epitaxial growth layer from the bottom to the top. The preparation method comprises the following steps of: 1, depositing the copper-diamond composite coarse sanding plating layer, the copper reinforcing layer and the copper-diamond composite thin sanding layer on a copper matrix in turn to obtain a workpiece deposited with the copper-diamond composite plating layer; and 2, performing homogeneous epitaxial growth on the diamond exposed on the surface of the workpiece deposited with the copper-diamond composite plating layer in a CVD diamond deposition system to obtain the continuous diamond coating. The copper-based mosaic structure interface diamond coating has the advantages of high purity, few impurities, low thermal stress and firm combination with the matrix, and is an ideal choice of a microelectronic heat sink material.

Owner:SOUTH CHINA UNIV OF TECH

Cast diamond tools and formation thereof by chemical vapor deposition

InactiveUS7095157B2Impedence networksPiezoelectric/electrostriction/magnetostriction machinesEtchingDiamond deposition

Owner:KINIK

Composite diamond coating hard alloy cutter mold and preparation method thereof

ActiveCN109930129AAvoid it happening againImprove stress distributionChemical vapor deposition coatingMicro nanoEtching

The invention discloses a composite diamond coating hard alloy cutter mold and a preparation method thereof. The surface layer of the hard alloy cutter mold is provided with composite coatings composed of boron-doped or non-boron-doped micron-crystal diamonds and nanocrystalline diamonds which are alternately arranged, and a layer of diamond-like coating DLC is deposited on the surface of each composite diamond coating. The preparation method comprises the steps of oil removal and degreasing, chemical micro-etching, plasma activation, plasma enhanced gaseous boronizing, plasma cleaning, diamond slurry ultrasonic grinding, nano-scale and micron-diamond seed crystal planting, and vapor-phase deposition of the diamond composite coatings. According to the method, boron atoms enter diamond crystal lattices by doping boron in the diamond deposition process, the internal stress of the diamond coatings is adjusted, and the generation of a stress sudden change region is avoided, so that the situation that the stress of each layer is not matched is avoided fundamentally, the stress distribution inside the composite coatings is effectively improved, the integrity of the micro-nano composite coatings is further improved, the substrate-film binding force is improved, and the comprehensive mechanical property of the composite coatings is improved.

Owner:HU-NAN NEW FRONTIER SCI & TECH LTD

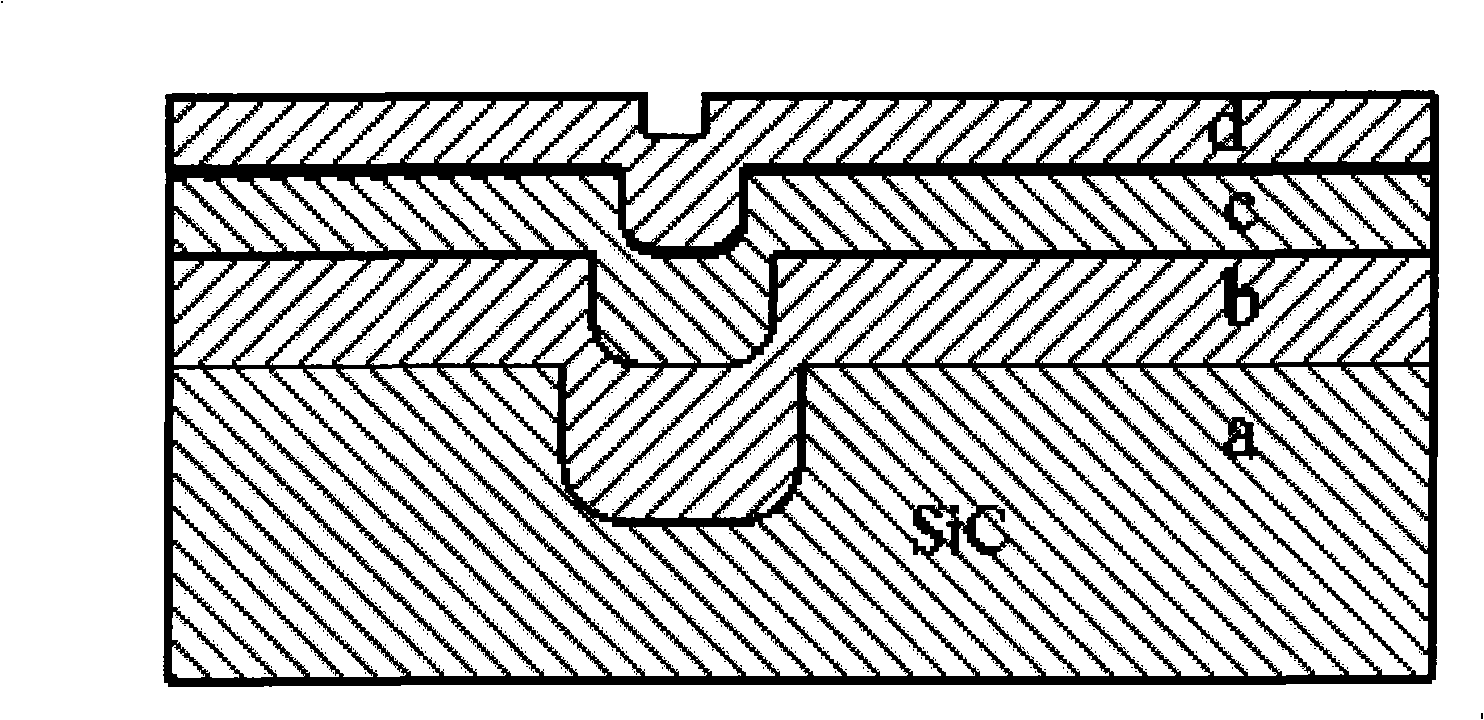

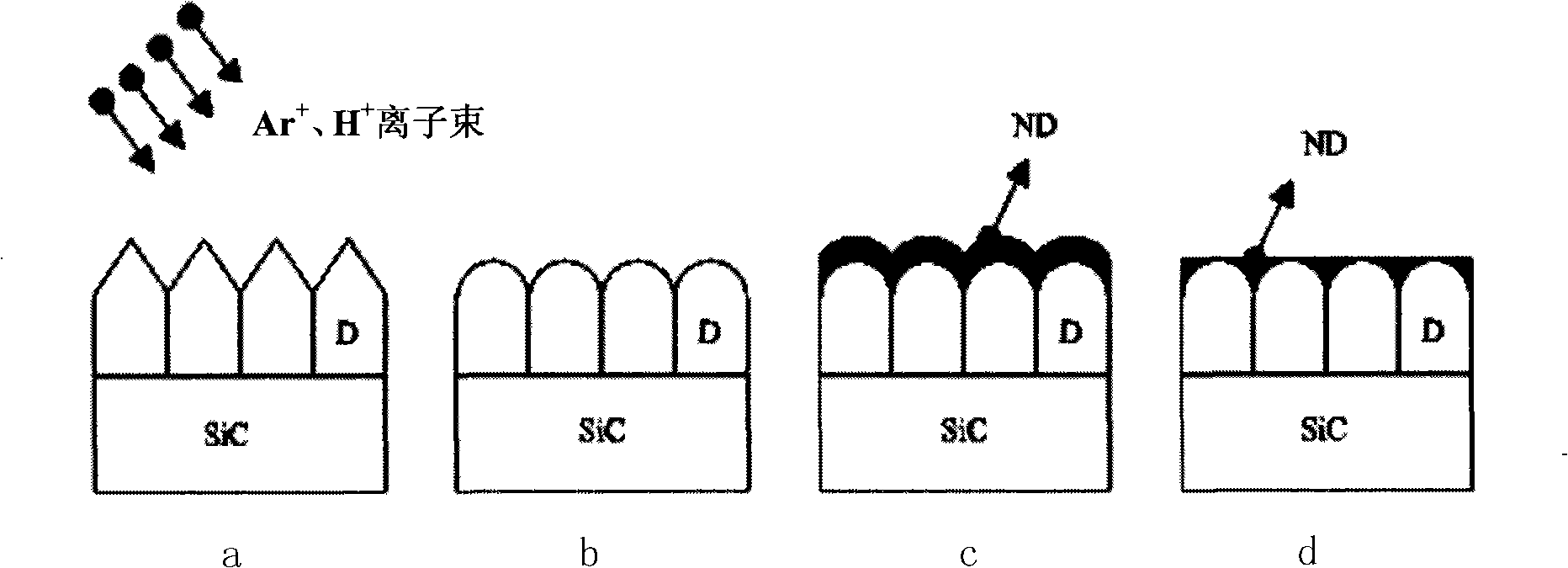

Silicon carbide ceramic and method for manufacturing composite drawing mould of diamond

The invention relates to a preparation method for silicone carbide ceramics and diamond composite drawing die. The silicone carbide ceramics is taken as a substrate, and the process of conventional diamond coating deposition, plasma polishing, nano diamond coating deposition, and mechanical polishing is repeated for a plurality of times to remove original blister defects on the surface of an inner hole of a ceramic die. During the cycle of CVD diamond deposition and polishing, a conventional diamond coating is integrated with a nano diamond coating, the plasma polishing is integrated with the mechanical polishing, the plasma polishing is inserted between the conventional coating and the nano coating, and consequently the die becomes more adaptive to the mechanical polishing after the growth of the nano coating. The die which can replace a traditional hard alloy product not only can greatly prolong the service life of a traditional die and device, improve production efficiency, remarkably improve the quality of products concerned and effectively save raw material, but also has great significance for the great reduction of tungsten and cobalt consumption and effective solution to the resource crisis faced by the hard alloy industry.

Owner:SHANGHAI JIAO TONG UNIV +1

Abrasion resistant drilling tool plated with diamond layer and manufacturing technology thereof

InactiveCN101550805AImprove wear resistanceImprove work efficiencyElectrolytic coatingsDirectional drillingManufacturing technologyAdhesive

The invention discloses an abrasion resistant drilling tool plated with a diamond layer and a manufacturing technology thereof, an extremely thin deposit layer containing the diamond is obtained by electroplating on a conductive metal substrate, and the extremely thin deposit layer plated with the diamond is then bonded to a part of the drilling tool where the abrasive resistance needs to be intensified, forming the abrasion resistant drilling tool plated with the diamond layer. The manufacturing technology thereof comprises the steps of: processing the conductive metal substrate prior to the electroplating, plating the thin diamond deposit layer on the substrate by electroplating, peeling off the diamond electroplating deposit layer from the substrate, and bonding the diamond electroplating deposit layer to the surface of the drilling tool with a strong adhesive to form the abrasion resistant drilling tool plated with the diamond layer. The invention provides a method for conveniently and rapidly applying the plating diamond layer to manufacturing a plurality of strong abrasion resistant drilling tool, and the manufacturing technology thereof is quite easy and readily.

Owner:CENT SOUTH UNIV

Diamond triode devices with a diamond microtip emitter

InactiveUS20050062389A1Improve performanceImprove emission effectAcceleration measurement using interia forcesNanoinformaticsDisplay deviceCarbon graphite

Diamond microtip field emitters are used in triode vacuum microelectronic devices, sensors and displays. Diamond triode devices having integral anode and grid structures can be fabricated. Ultra-sharp tips are formed on the emitters in a fabrication process in which diamond is deposited into mold cavities in a two-step deposition sequence. During deposition of the diamond, the carbon graphite content is carefully controlled to enhance emission performance. The tips or the emitters are treated by post-fabrication processes to further enhance performance.

Owner:VANDERBILT UNIV

Process for producing heteropitaxial diamond layers on Si-substrates

InactiveUS6274403B1Increase resistanceHigh disruptive fieldPolycrystalline material growthFluid pressure measurement using ohmic-resistance variationNucleationNegative bias

The invention relates to a method for producing heteroepitaxial diamond layers on Si-substrates by means of CVD and standard process gases, in which (a) during the nucleation phase a negative bias voltage is applied to the Si-substrate and (b) following the nucleation phase diamond deposition takes place.

Owner:DAIMLER BENZ AG

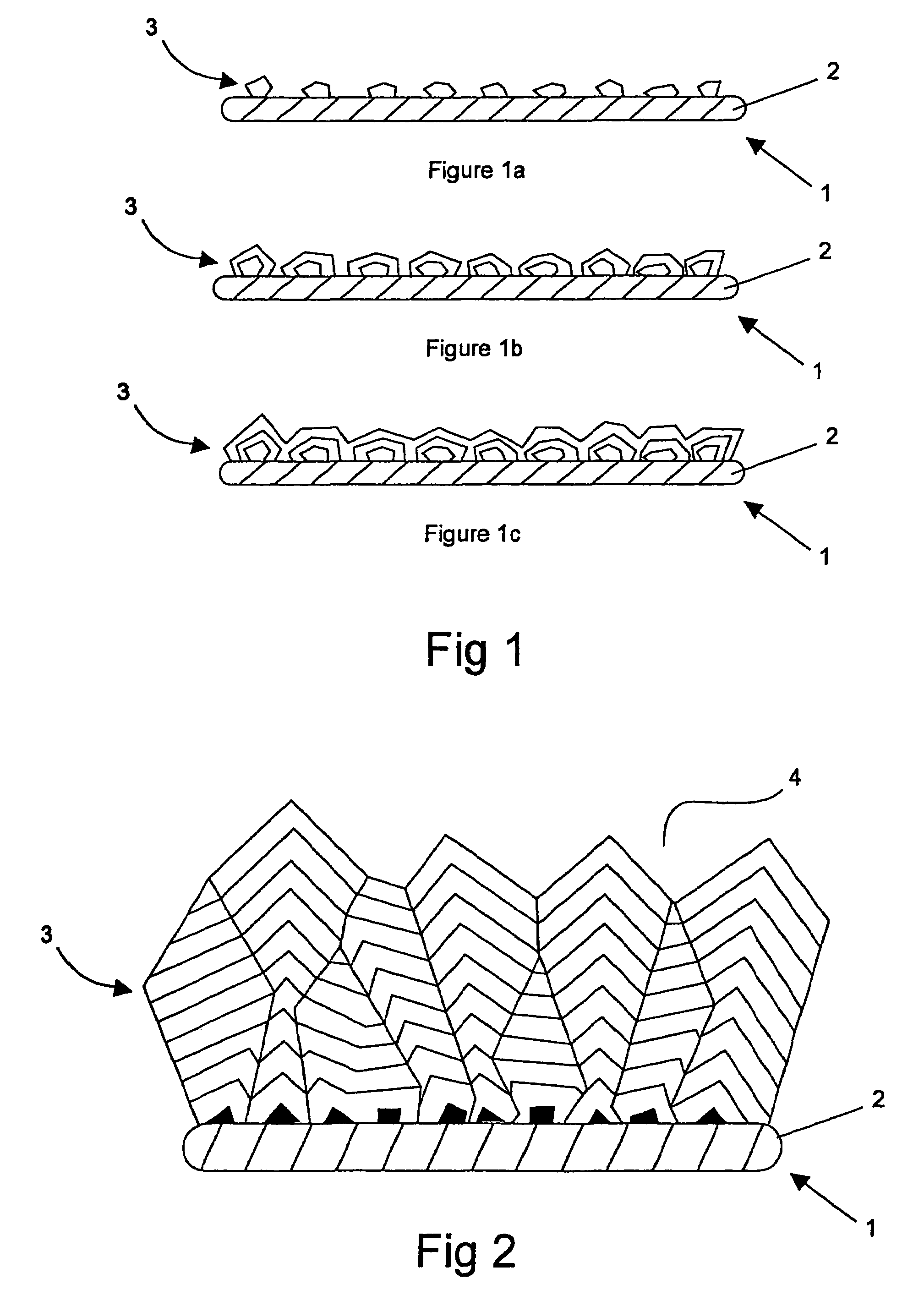

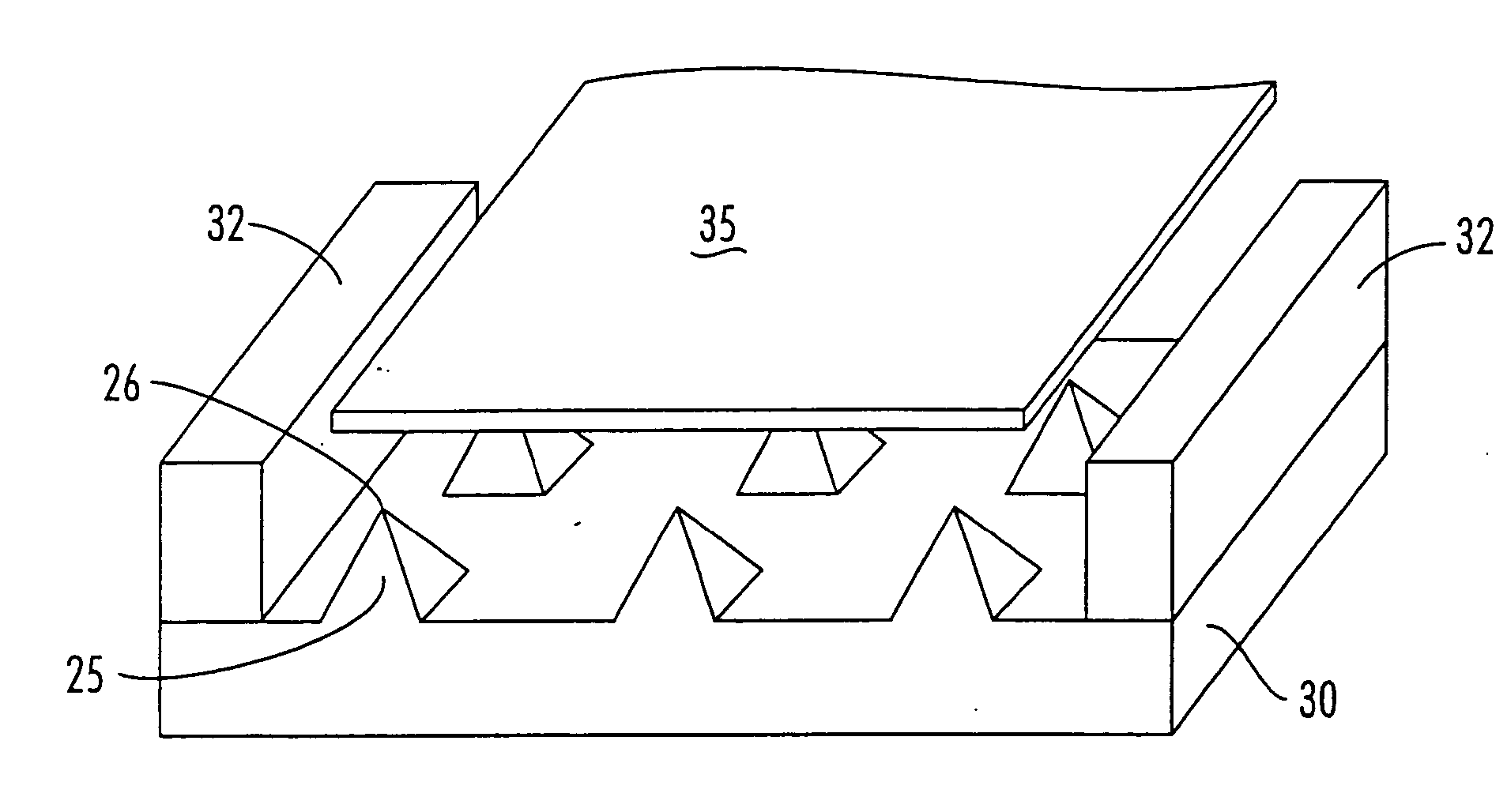

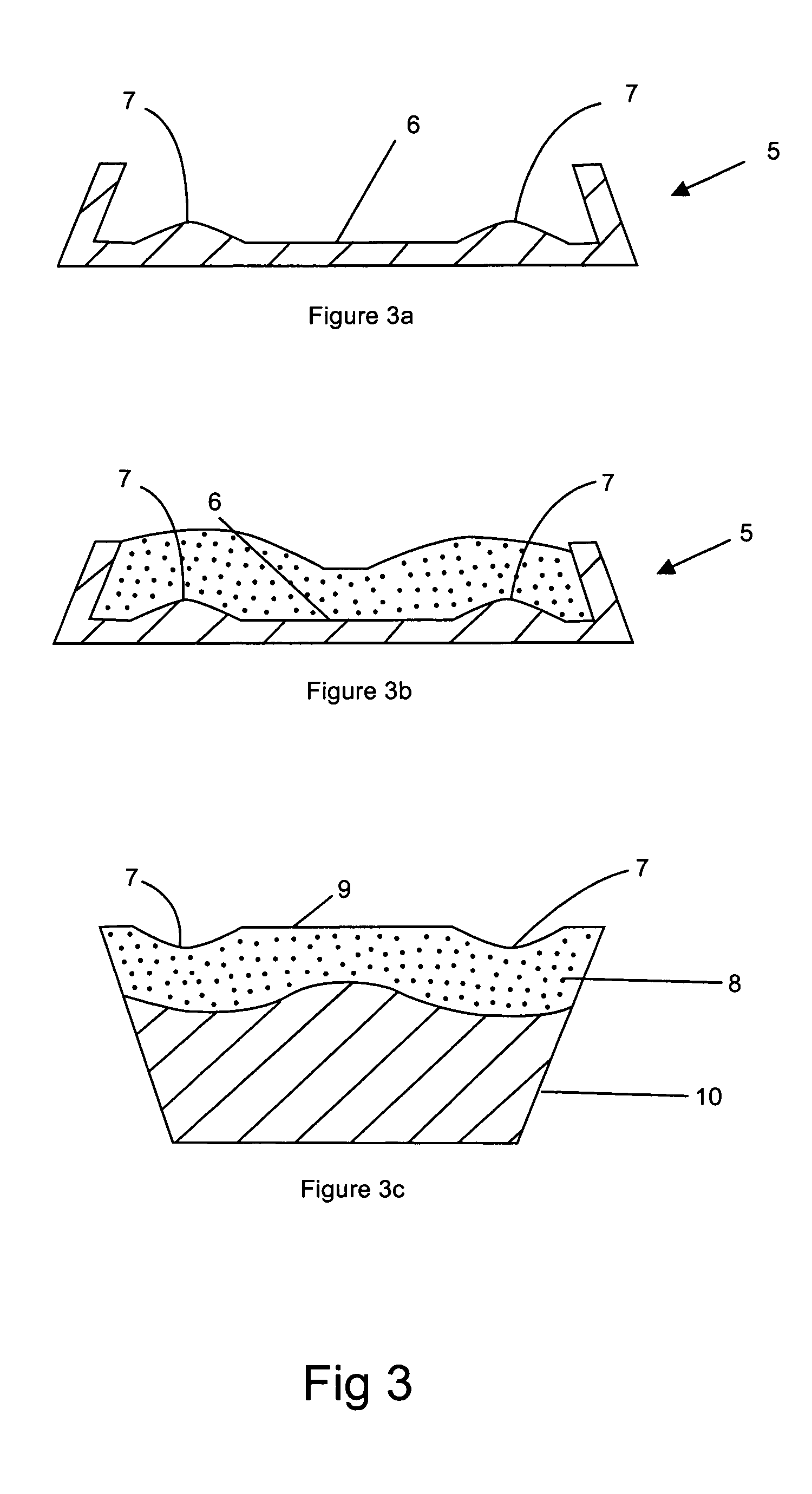

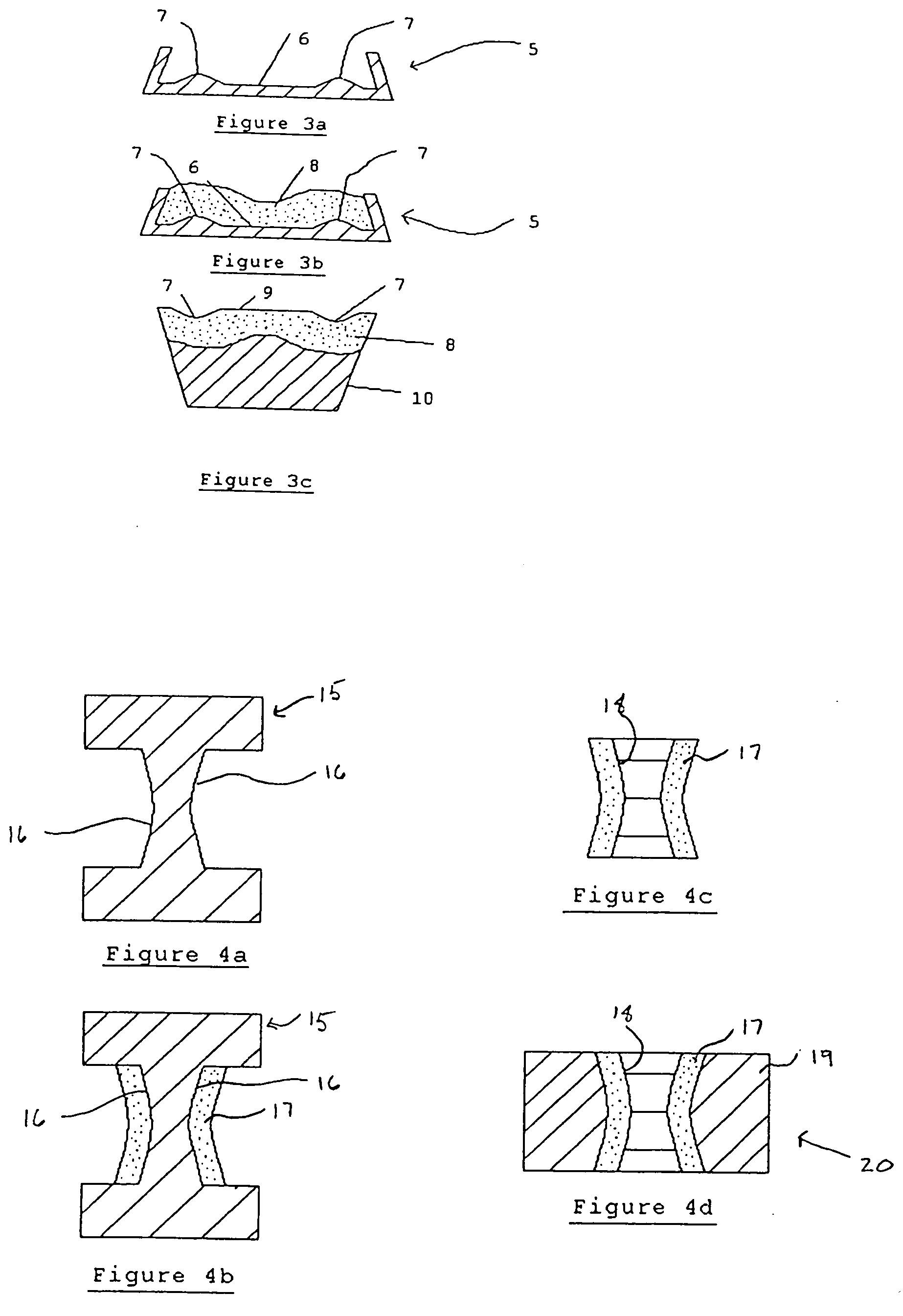

Cast diamond tools and formation thereof by chemical vapor deposition

The present invention provides diamond tools, and a method for the formation thereof, using CVD techniques. In one aspect, an ephemeral mold is provided which has a diamond interface surface configured to inversely correspond to the desired shape for the working surface of a diamond layer in a tool. After the mold is provided, various CVD techniques may be used to deposit diamond layers upon the diamond interface surface of the mold. Following diamond deposition upon the diamond interface surface, the mold may be removed by various means, such as chemical etching, etc. Thus, the working surface of the diamond receives a shape which inversely corresponds to the configuration of the mold's diamond interface surface. The diamond mass may then be incorporated into a tool, if such incorporation has not yet taken place.

Owner:KINIK

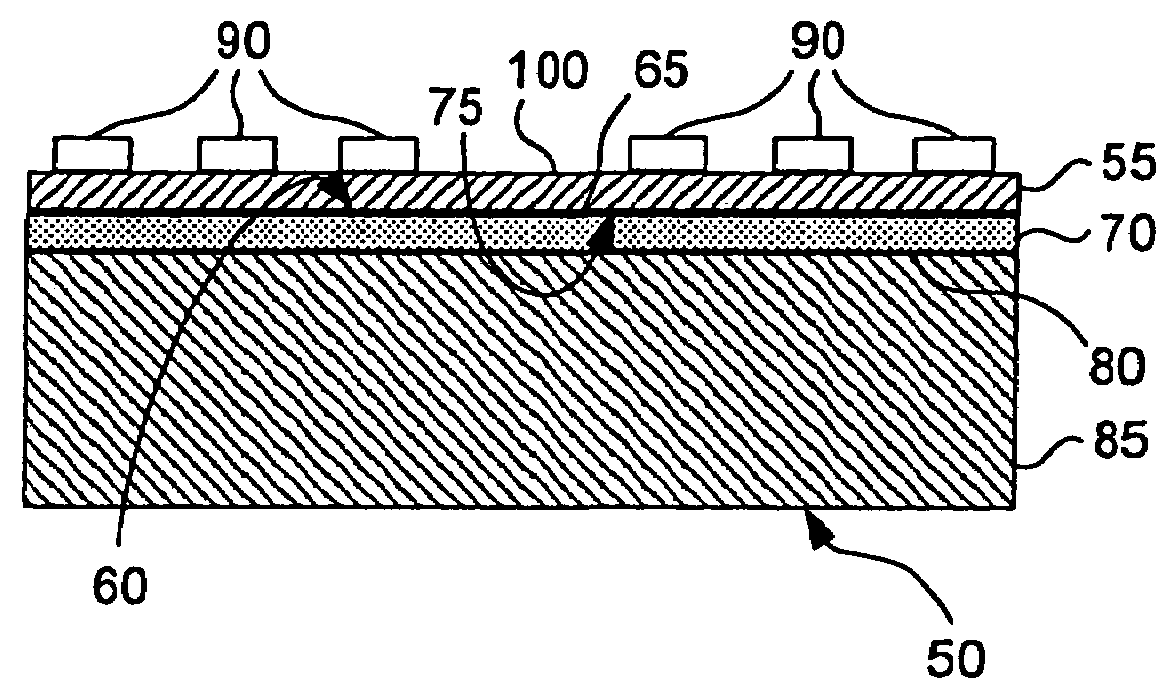

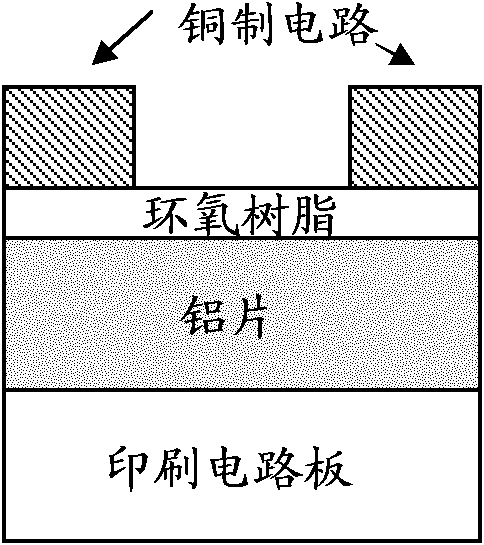

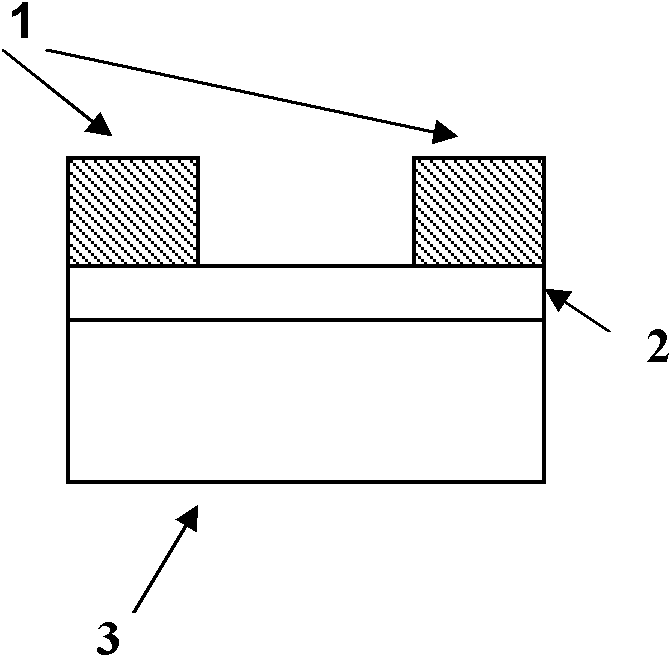

LED printed circuit board and preparation method of amorphous diamond heat dissipation and insulation film layer thereof

InactiveCN101998758ASimple processIncrease brightnessPoint-like light sourcePrinted circuit detailsElectricityEngineering

The invention relates to a light-emitting diode (LED) printed circuit board and a preparation method of an amorphous diamond heat dissipation and insulation film layer thereof, in particular to an LED printed circuit board and a preparation method of a heat dissipation and insulation dual-efficacy film layer thereof. In the invention, the problem of poor heat dissipation effect of the existing LED printed circuit board because the hard-and-fast requirement of electric insulation is limited is solved, and an LED printed circuit board and a preparation method of an amorphous diamond heat dissipation and insulation film layer thereof are provided. The circuit board is formed by adding the amorphous diamond heat dissipation and insulation film layer between a printed circuit board and a copper circuit. The preparation method comprises the following concrete steps: (1) cleaning: cleaning the LED printed circuit board by deionized water, and blow-drying the LED printed circuit board; (2) etching: etching the amorphous diamond depositing surface of the LED printed circuit board by a Kaufman ion gun; and (3) depositing: alternately depositing carbon ions by adopting different negative bias to gradually form the heat dissipation and insulation dual-efficacy film layer of an amorphous diamond film formed by alternately constructing a sub-film layer with low stress and a sub-film layer with high sp3 hybridization content. The invention is suitable for printed circuit boards.

Owner:HARBIN INST OF TECH

Diamond triode devices with a diamond microtip emitter

InactiveUS7256535B2Effective balanceEfficiency durabilityAcceleration measurement using interia forcesControl electrodesDisplay deviceCarbon graphite

Diamond microtip field emitters are used in triode vacuum microelectronic devices, sensors and displays. Diamond triode devices having integral anode and grid structures can be fabricated. Ultra-sharp tips are formed on the emitters in a fabrication process in which diamond is deposited into mold cavities in a two-step deposition sequence. During deposition of the diamond, the carbon graphite content is carefully controlled to enhance emission performance. The tips or the emitters are treated by post-fabrication processes to further enhance performance.

Owner:VANDERBILT UNIV

Preparation method of diamond film coating layer bearing supporter

ActiveCN1718853AEliminate negative effectsImprove adhesionBearing componentsChemical vapor deposition coatingHigh densityAlloy substrate

A process for preparing the bearing holder with coated diamond film layer includes such steps as removing Co from the surface of hard alloy substrate, roughing, decarbonizing, reducing, adding adhesion promoter to reacting gas, preparing the diamond film by CVD process while controlling its technological parameters by 3 stages to sequentially generate high-density layer, polycrystal layer and superfine micro crystal layer, and adhering said substrate onto the surface of steel holder.

Owner:SHANGHAI JIAO TONG UNIV +1

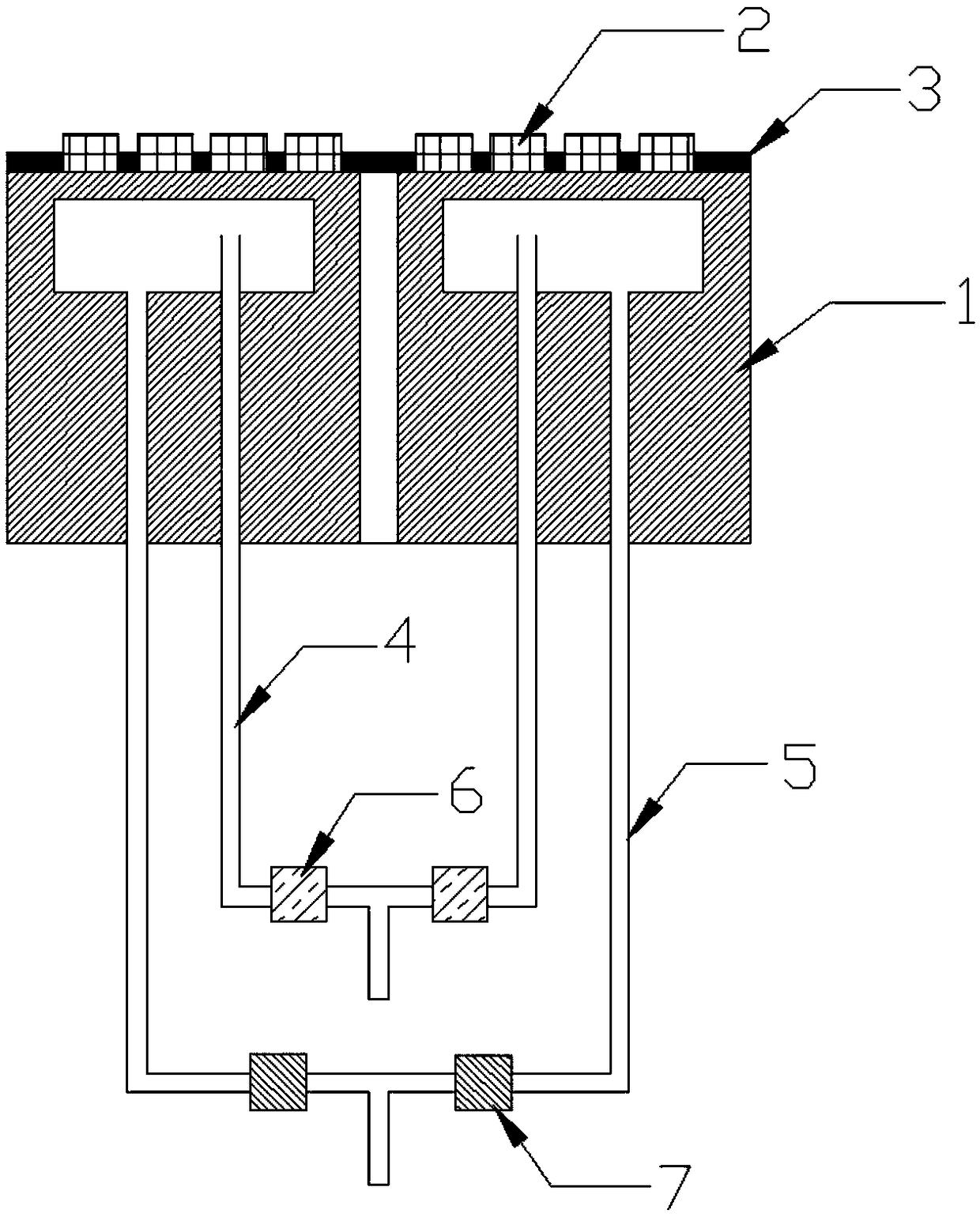

Temperature control device and method for MPCVD equipment

InactiveCN109385625AConsistent growth rateConsistent qualityChemical vapor deposition coatingTemperature controlEngineering

The invention discloses a temperature control device for MPCVD equipment, the temperature control device comprises a plurality of substrate stages, the distance between adjacent substrate stages is 1mm to 10 mm, and each substrate stage is provided with a separate cooling water path, and the cooling water path is designed as a conventional cooling waterway, and can control the cooling speed of the substrate stages by controlling the flow speed and flow rate of cooling water. By controlling the temperature of the substrate stages, the temperature of a substrate during the diamond growth process is controlled, and the temperature of a base plate is controlled during the diamond deposition process. During the diamond growth process, the surface temperatures of diamonds are controlled by controlling of heat dissipation, so that the surface temperatures of the diamonds in the deposition process are close, the growth speed and quality of the diamonds produced in the same batch are consistent, and mass production is facilitated.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

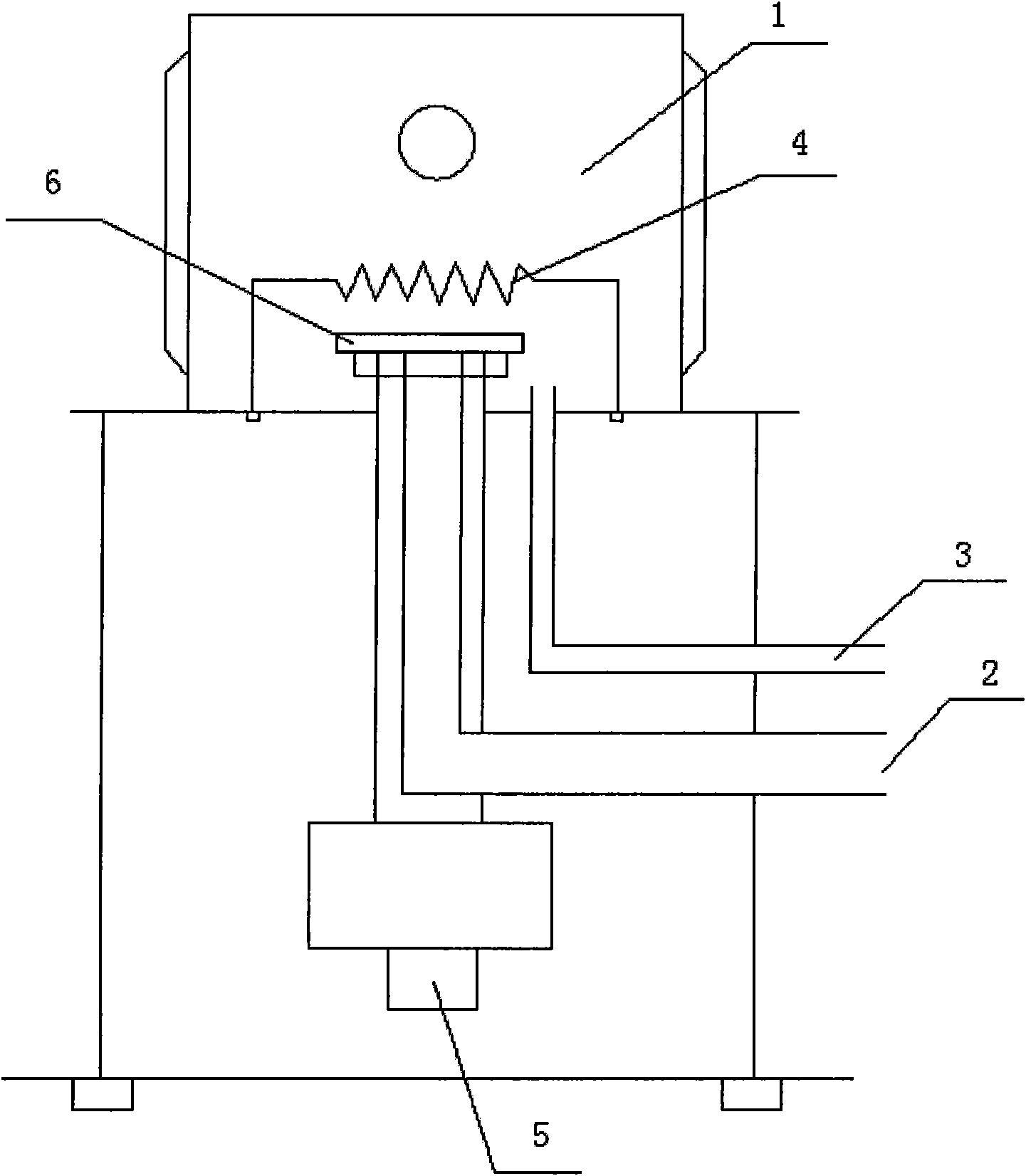

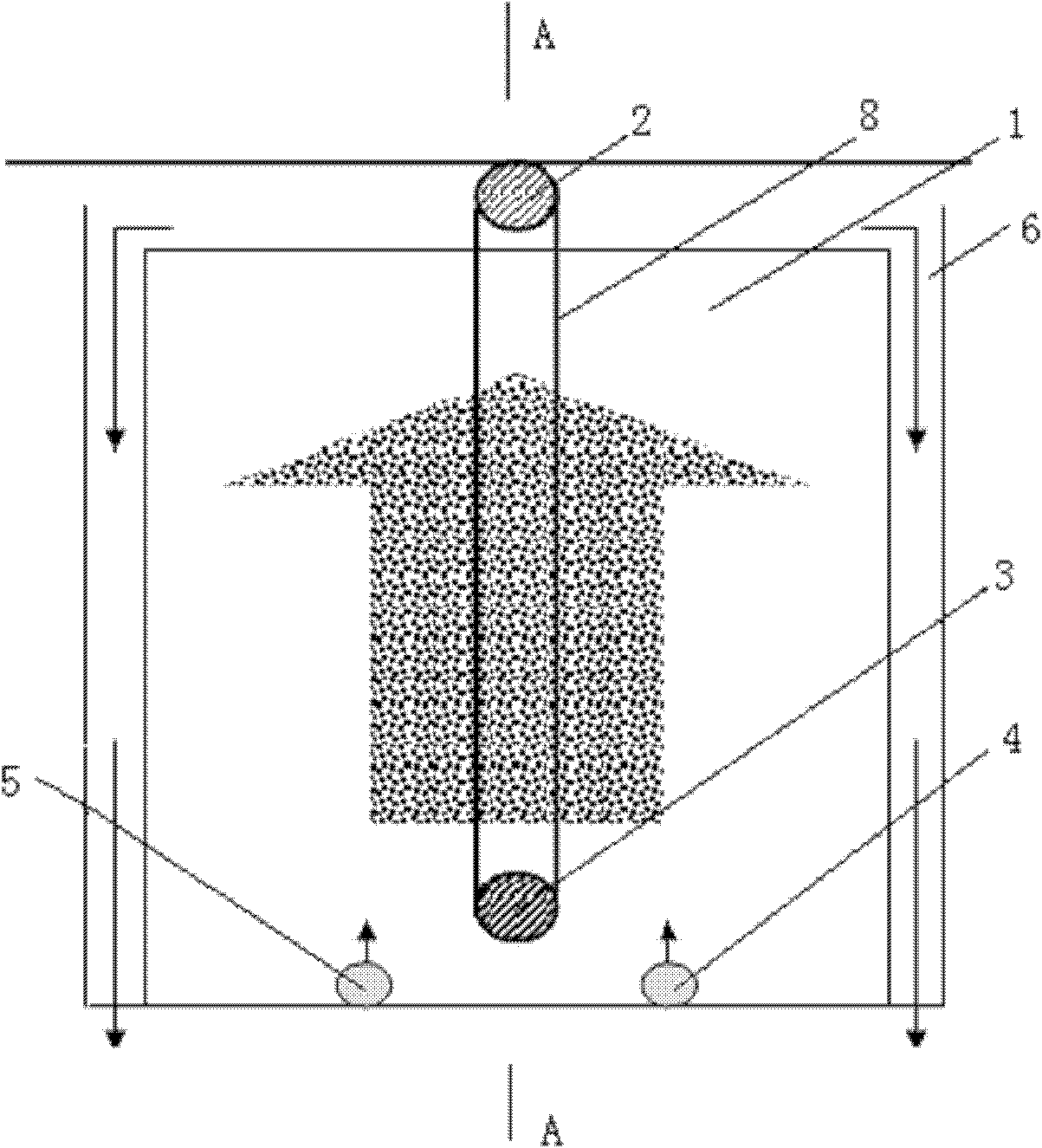

Chemical vapor diamond deposition device

InactiveCN101831626AIncrease ionization rateQuality improvementChemical vapor deposition coatingGas phaseEngineering

The invention belongs to the chemical vapor deposition field, in particular to a device of a hot wire chemical vapor diamond deposition device. The device comprises a vacuum chamber, a vacuum obtaining system, a cooling system, an air circuit, a hot wire, a mechanical rotating mechanism, a base platform, a control system, a power supply, and a Hall ion source, wherein the Hall ion source is fixedly installed at the top of the vacuum chamber, the end part of the Hall ion source is installed in the vacuum chamber, the bottom of the Hall ion source is installed at the outside of the vacuum chamber, connected to an anode power supply, the air circuit and a cooling water channel and hermetically communicated with the vacuum chamber, and a hole is arranged at the top of the vacuum chamber and used for connecting a cathode power supply and sealing. The device improves the ionization proportion of reaction gas, increases the synthesized diamond SP3 structure, reduces the resistance of a heater strip by 30-35%, has clear crystal grain facet and compact structure, and greatly improves the quality of the synthesized diamond.

Owner:晏双利

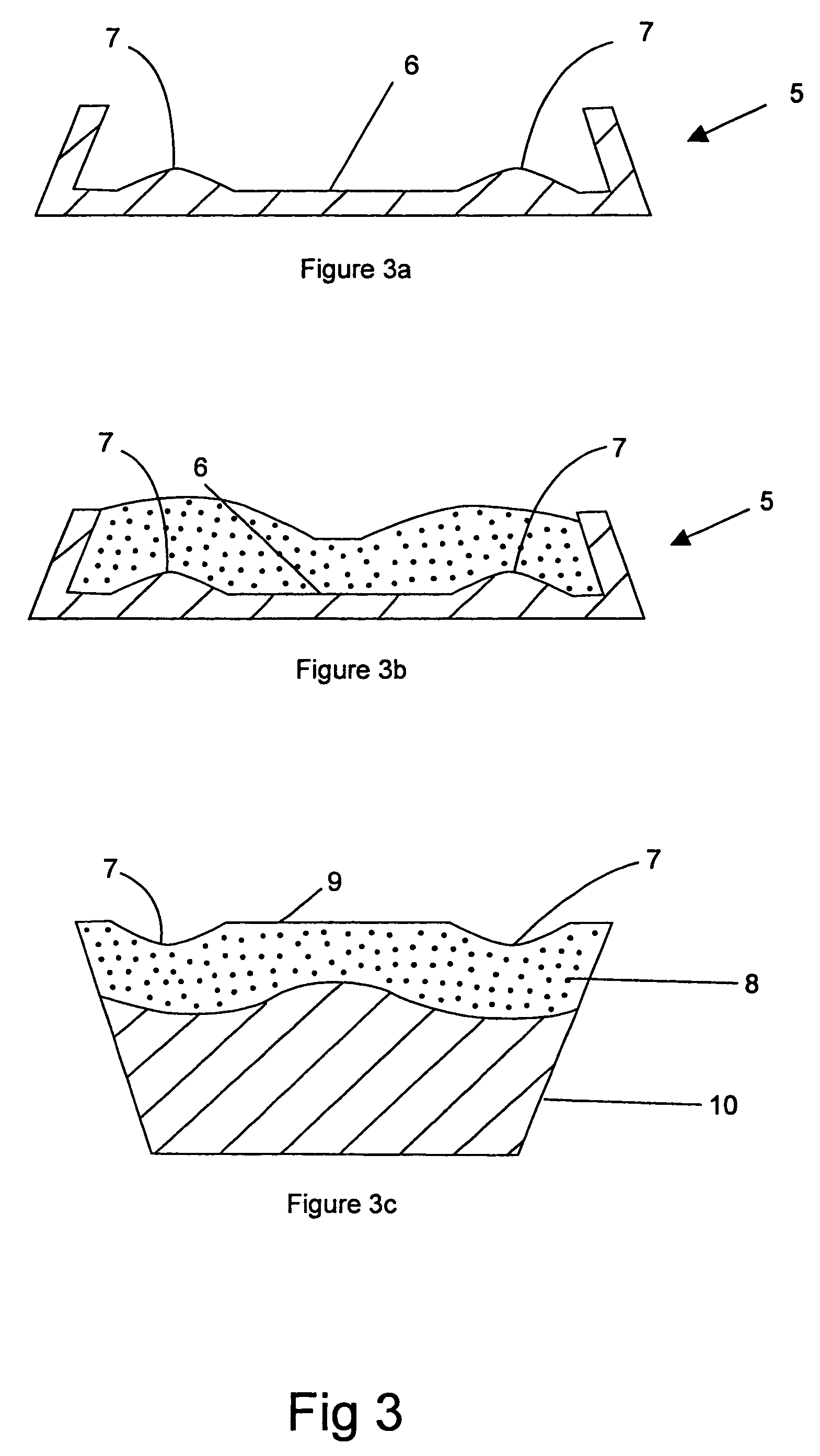

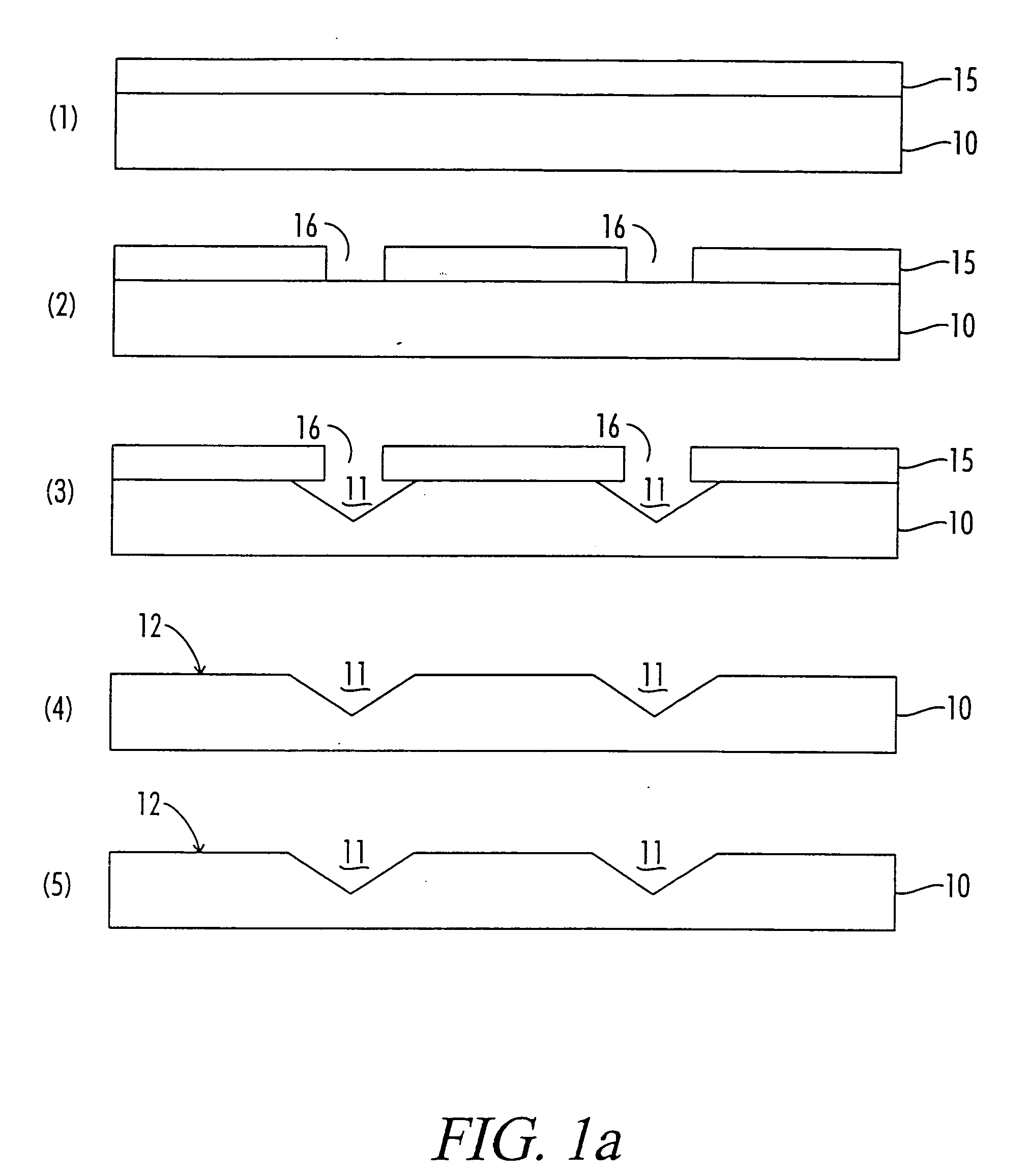

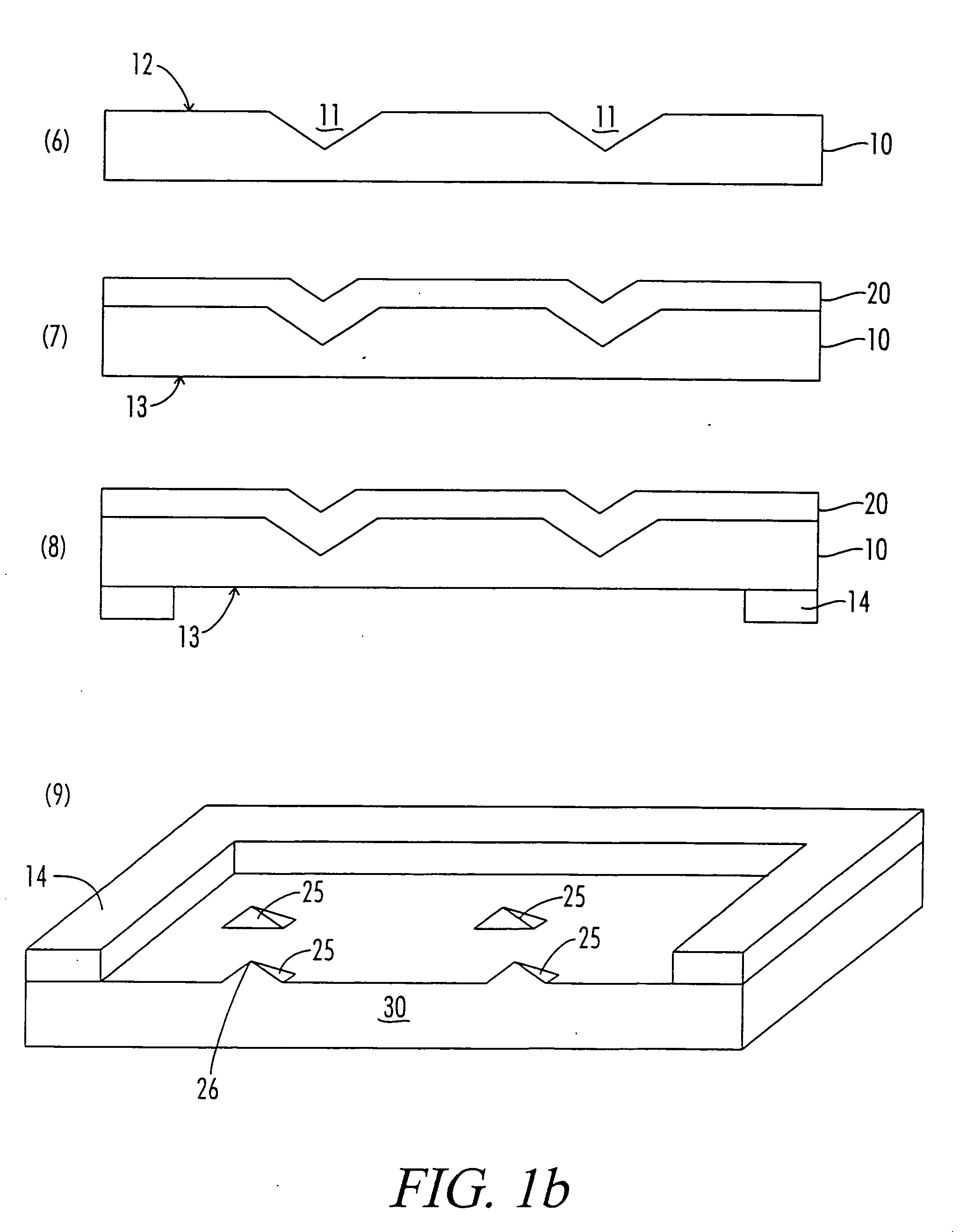

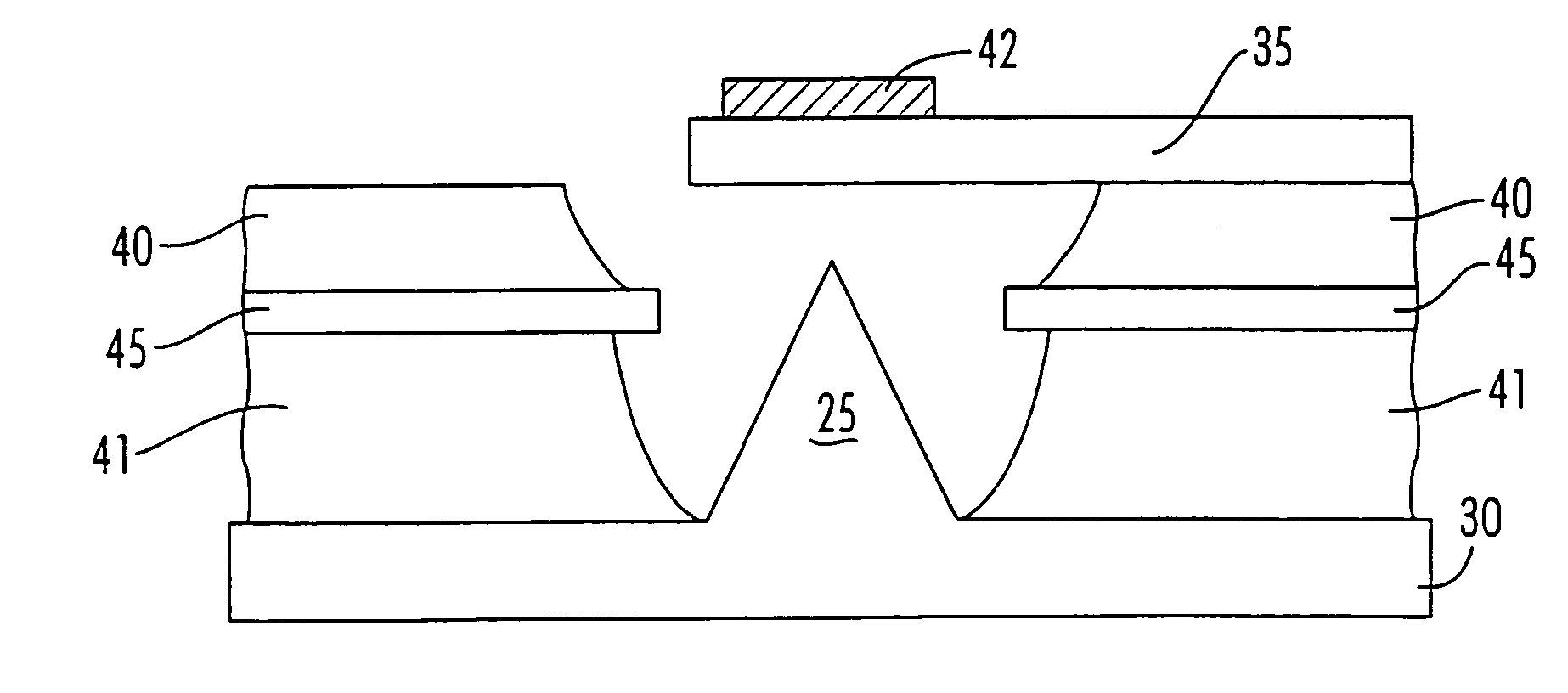

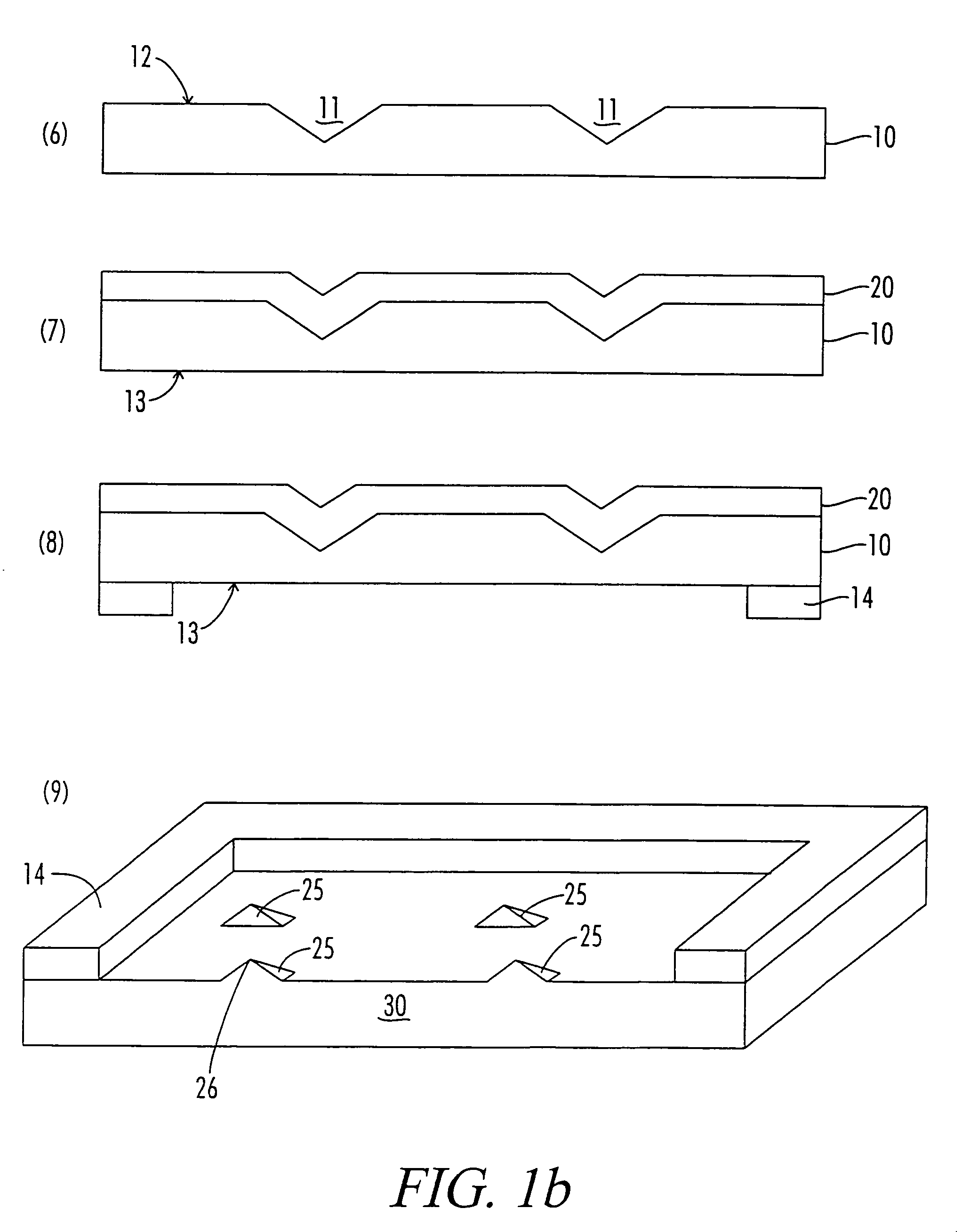

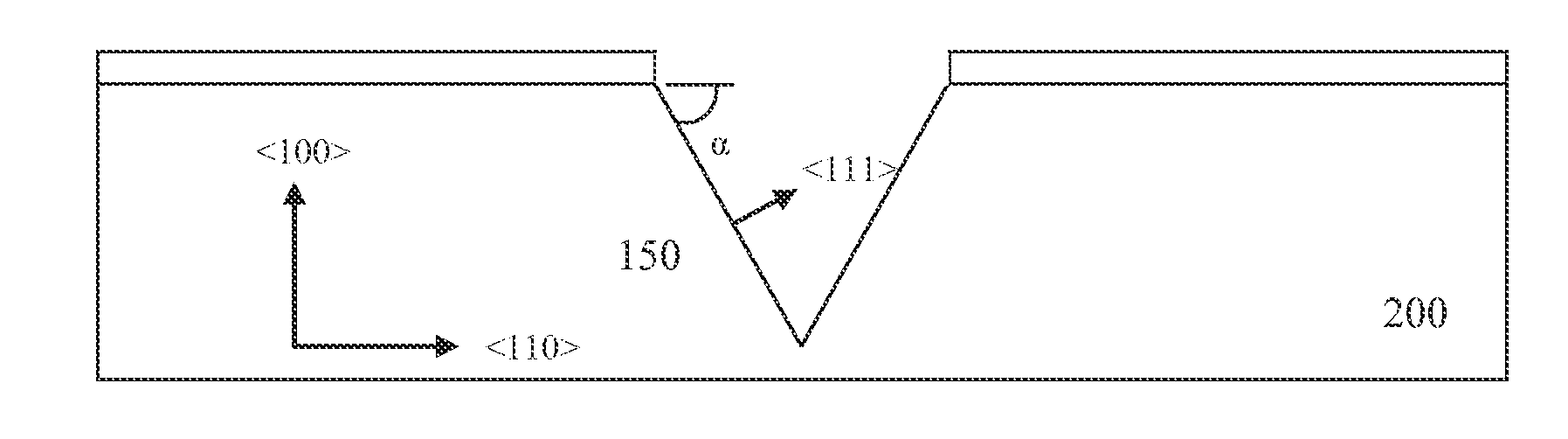

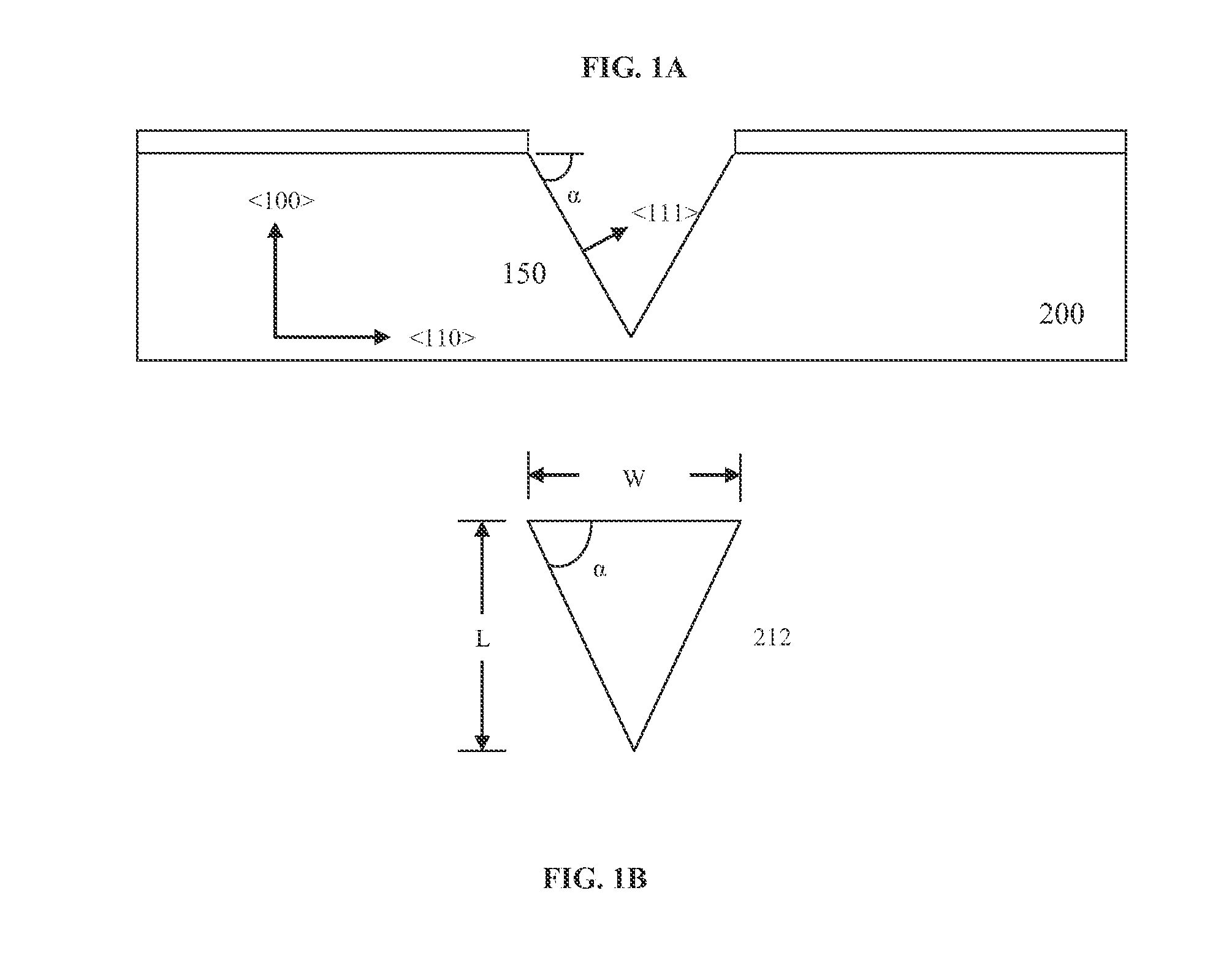

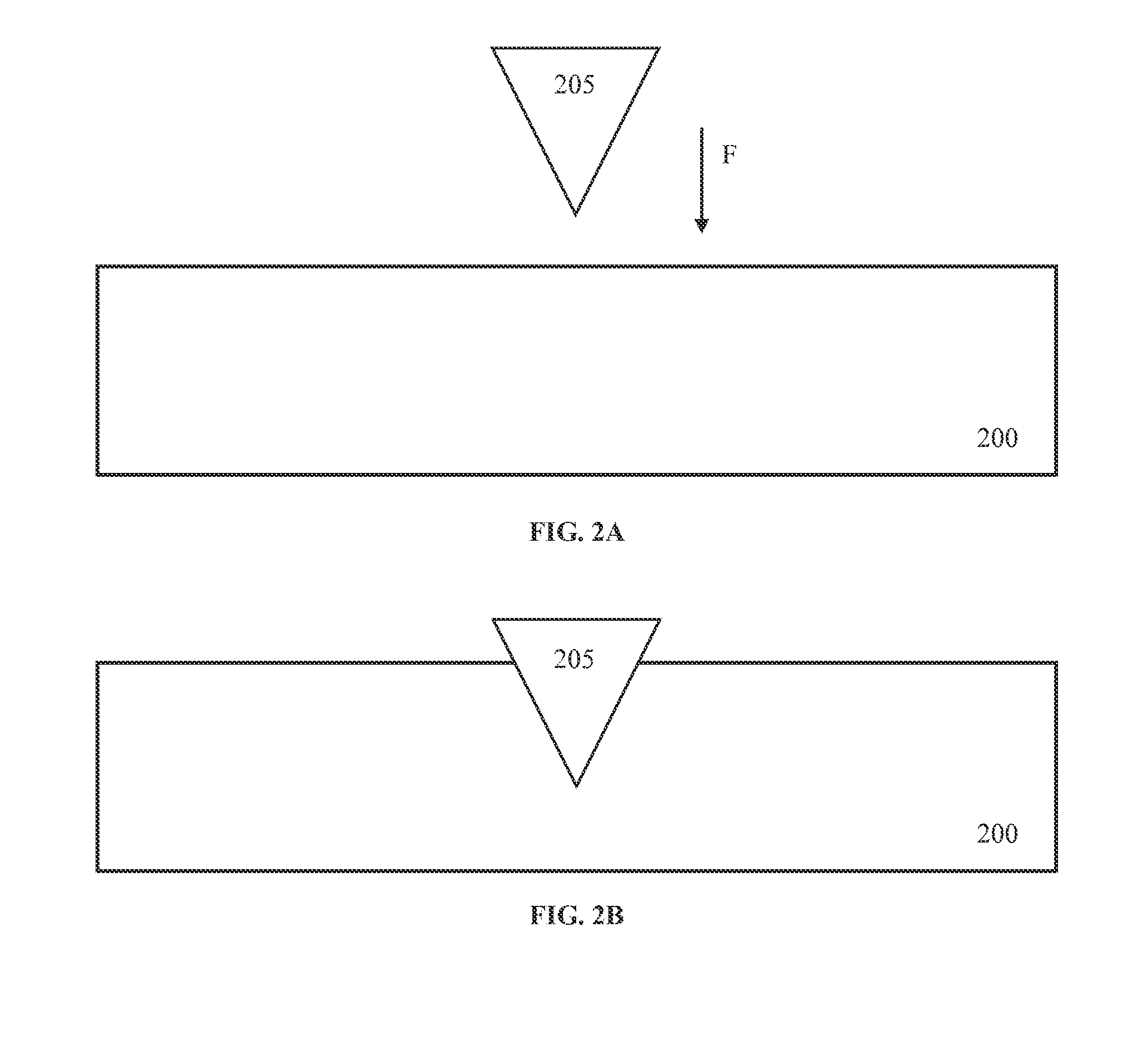

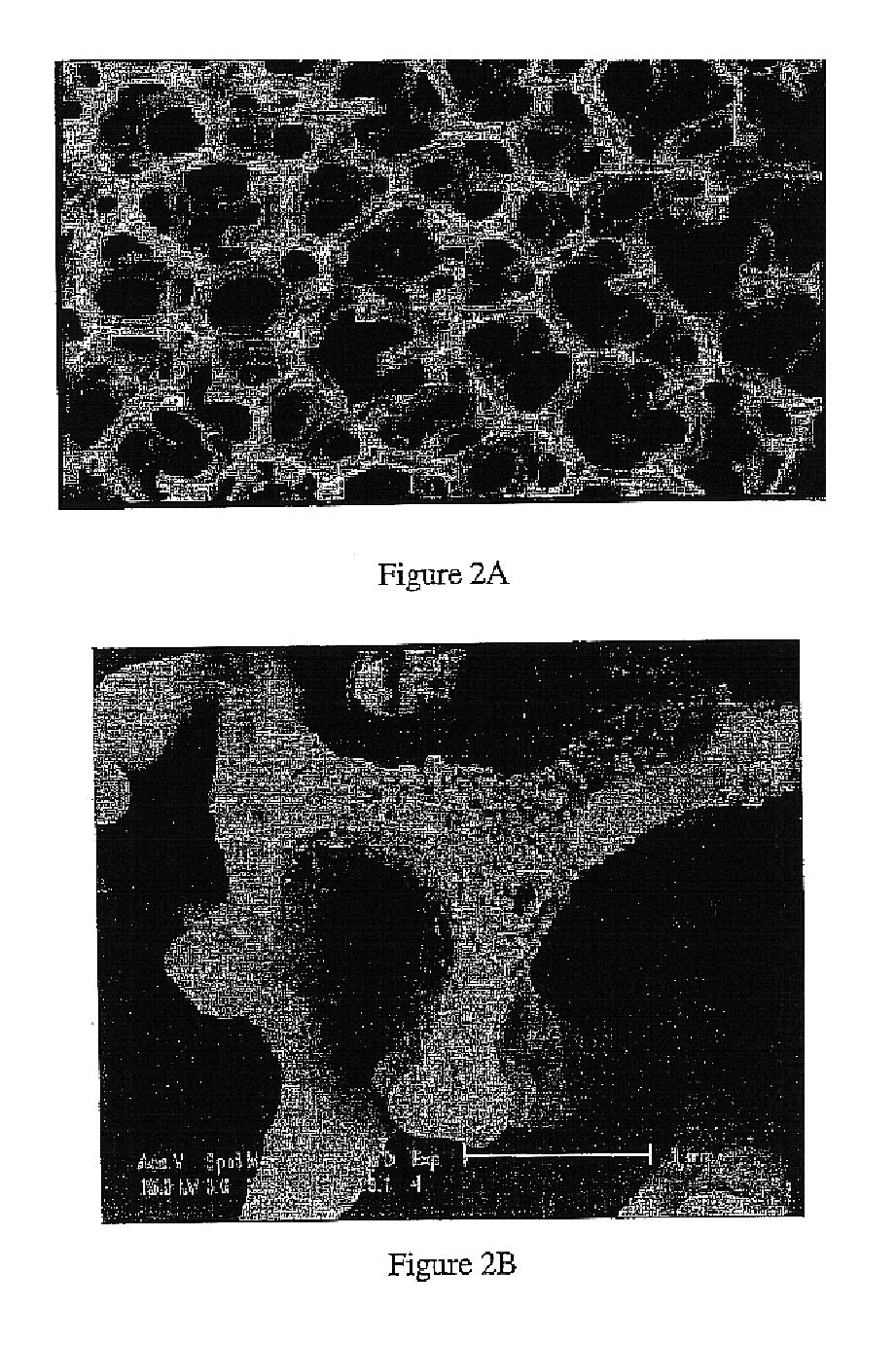

Indented Mold Structures For Diamond Deposited Probes

InactiveUS20140130215A1Decorative surface effectsCeramic shaping apparatusScanning probe microscopyDiamond deposition

The present invention discloses a method of fabricating a scanning probe microscopy probe including positioning a pattern probe over a mold substrate; indenting the pattern probe into the mold substrate material to form a mold pit; depositing a film onto the mold substrate including the mold pit; removing a portion of the deposited film to form a probe, and releasing the probe from the mold substrate material.

Owner:RAVE

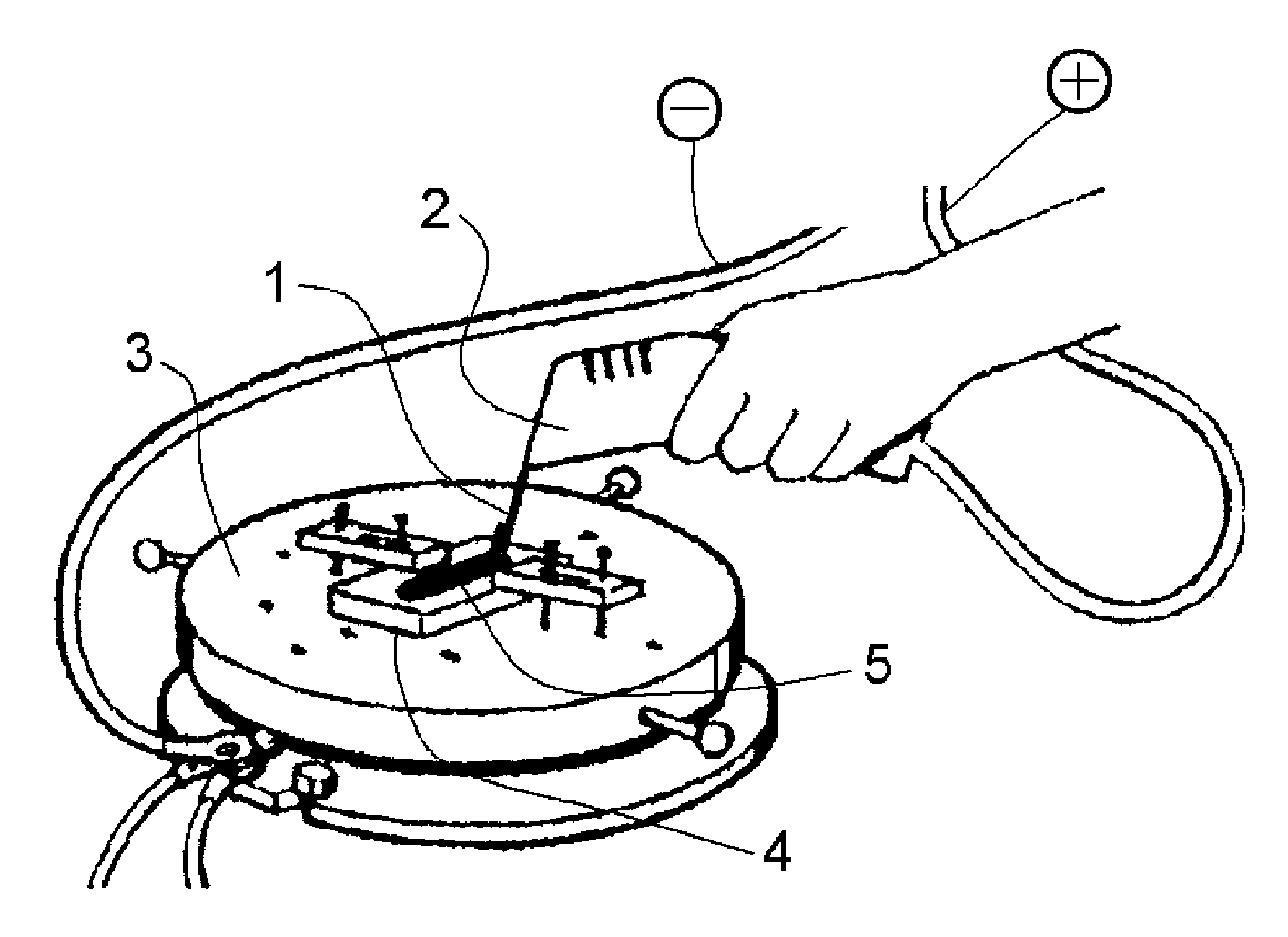

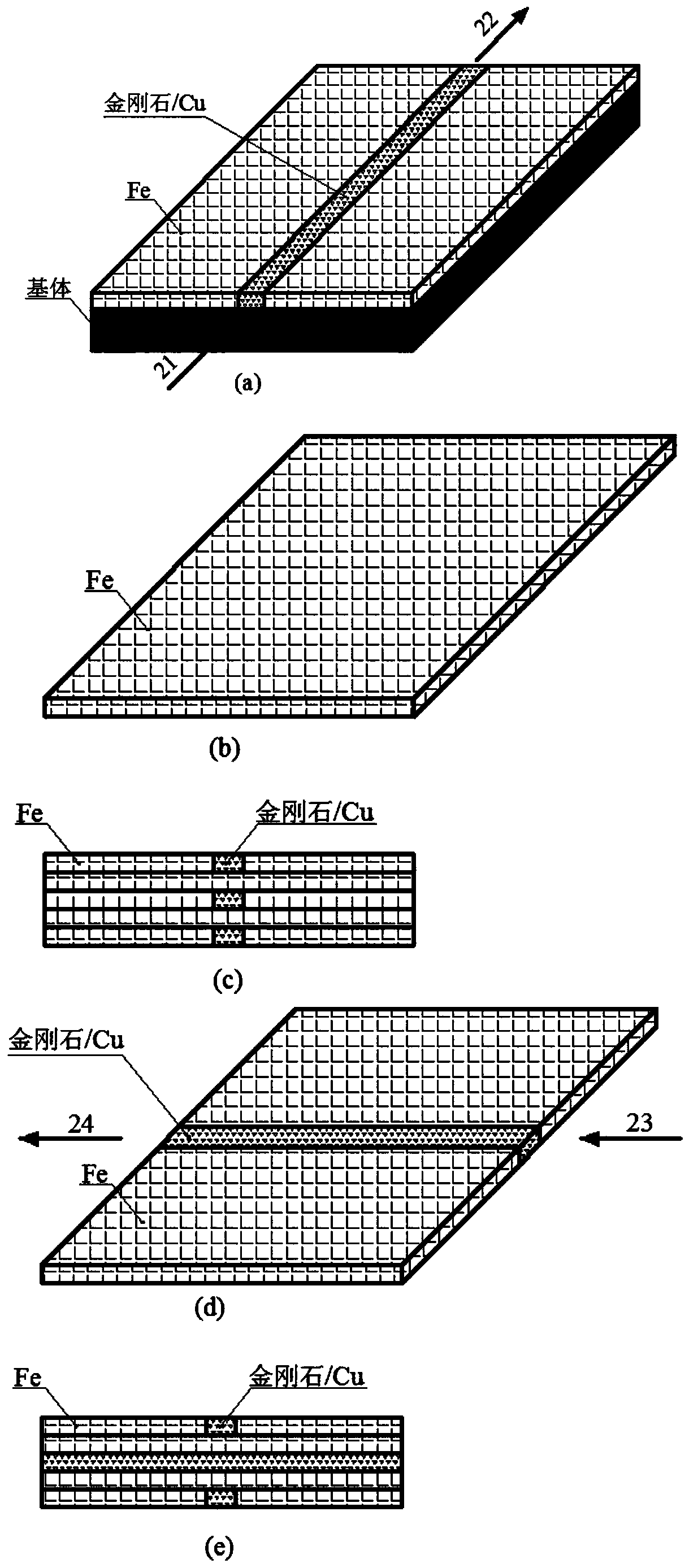

Preparation process of composite coating layer based on machining tool

InactiveCN108315716AExtended service lifeNot easy to fall offChemical vapor deposition coatingSurface finishVacuum pumping

The invention discloses a preparation process of a composite coating layer based on a machining tool. The preparation process comprises the following steps of: pretreating the machining tool, then drying, placing into a diamond deposition furnace, performing vacuum pumping in the furnace, adjusting gas-flow speed ratio of CH4 and H2 and the pressure in the furnace, heating hot filaments, adjustingthe surface temperature of the machining tool, and after depositing, forming a diamond coating layer; readjusting the pressure in the furnace, introducing Ar, gradually increasing the gas-flow speedratio of Ar, maintaining certain pressure in the diamond deposition furnace, and maintaining reaction for a period of time. The preparation process of the composite coating layer disclosed by the invention has the beneficial effects that the surface hardness and the wear resistance of the machining tool of the original diamond coating layer can be ensured, and simultaneously, due to flat and smooth surface of the ultranano diamond coating layer, the surface finishment of a mold machined by the machining tool is better.

Owner:上海三朗纳米技术有限公司

Substrate for CVD deposition of diamond and method for the preparation thereof

ActiveUS20130230715A1Problem describedSmooth connectionLiquid surface applicatorsMolten spray coatingNitrogenBoron

A substrate for depositing diamond by CVD, comprising a base body of hard material and a coating layer that holds diamond particles as seed crystal in a matrix and is deposited joined thereto on a surface of said base body, wherein:the seed diamond particles have an average particle size of 1 μm or smaller;the matrix comprises a first metal selected from a first group of Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo and W and / or a first compound between said first metal and a non-metallic substance selected from boron, carbon and nitrogen, said matrix holding the diamond particles distributed therein; anda joint zone developed as a result of a diffusion process and extending over said base body and coating layer comprises either or both atoms of said first metal and a component metal of the hard material.

Owner:TOMEI DIAMOND +2

Preparation method of directional high-thermal-conductivity diamond/metal-based composite material

ActiveCN111421141AAvoid heat damageRetain physicochemical propertiesMolten spray coatingTransportation and packagingGraphiteMetal matrix composite

The invention provides a preparation method of a directional high-thermal-conductivity diamond / metal-based composite material based on supersonic laser deposition. In the method, metal-based powder isdeposited in a full-solid state and does not need to be subjected to the process of solidification after melting in a traditional preparation technology. Besides, diamond is deposited in a low-heat input mode, so that heat damage and graphitization tendency of the diamond in a high-temperature environment are completely avoided, and physical and chemical properties of original powder particles are maintained to a large degree. The diamond is deposited through severe plastic deformation of the metal-based particles accelerated to the supersonic speed, and a bonding interface is mechanically bonded or bonded in other ways, so that surface metallization does not need to be carried out on the diamond particles, high-pressure pressurization equipment is also not needed, and the maximum heat conduction track in the composite material is a diamond-rich deposition track. In the preparation process, a diamond deposition area can be controlled in real time to control the high heat conduction direction.

Owner:ZHEJIANG UNIV OF TECH

Method for making a highly stable diamond film on a substrate

Owner:THE HONG KONG UNIV OF SCI & TECH

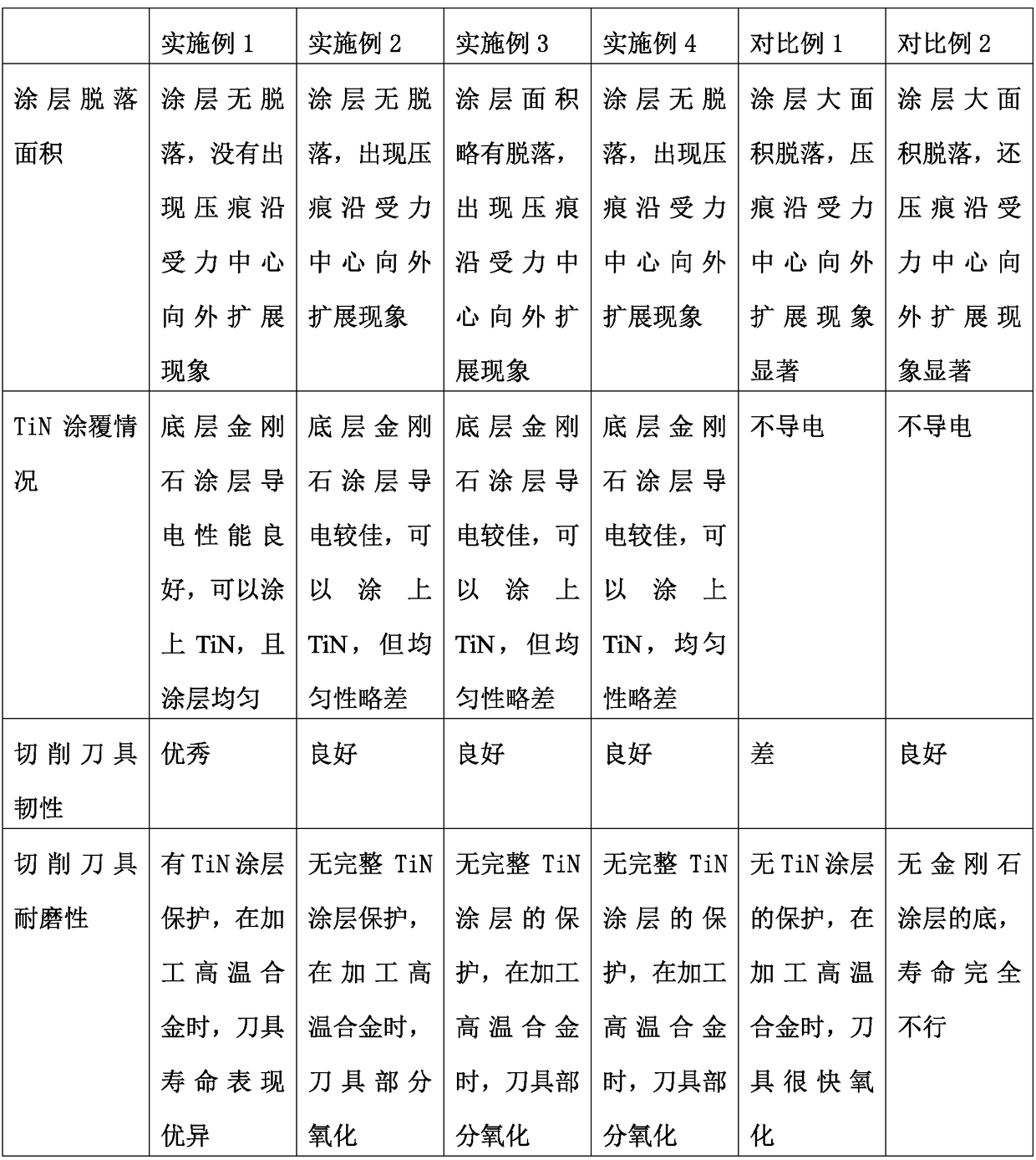

Preparation process of composite coating layer based on cutting tool

InactiveCN108315737AStrong toughnessImprove wear resistanceVacuum evaporation coatingSputtering coatingWear resistanceCobalt

The invention discloses a preparation process of a composite coating layer based on a cutting tool. The preparation process comprises the following steps of: carrying out cleaning pretreatment and cobalt-removing pretreatment in sequence on the cutting tool, cleaning, and then drying for spare use; introducing mixed gas of CH4, H2 and N2 according to the gas-flow speed ratio of 1:(100-300):(1-3),heating hot filaments to adjust the surface temperature of the cutting tool to be 600-1000 DEG C, and depositing for 6-10 hours to form a conducting diamond coating layer; and then carrying out TiN coating layer deposition on the surface of the CVD coating layer to obtain the cutting tool with the composite coating layer. The preparation process of the composite coating layer based on the cuttingtool has the beneficial effects that the tool with the composite coating layer is formed by coating the CVD conducting diamond coating layer in the cutting tool and then coating the TiN coating layeron the surface of the CVD conducting diamond coating layer; the cutting tool prepared by the preparation process is good in conductivity, strong in toughness, good in wear resistance and long in service life.

Owner:上海三朗纳米技术有限公司

Plating bath for producing diamond fretsaw

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

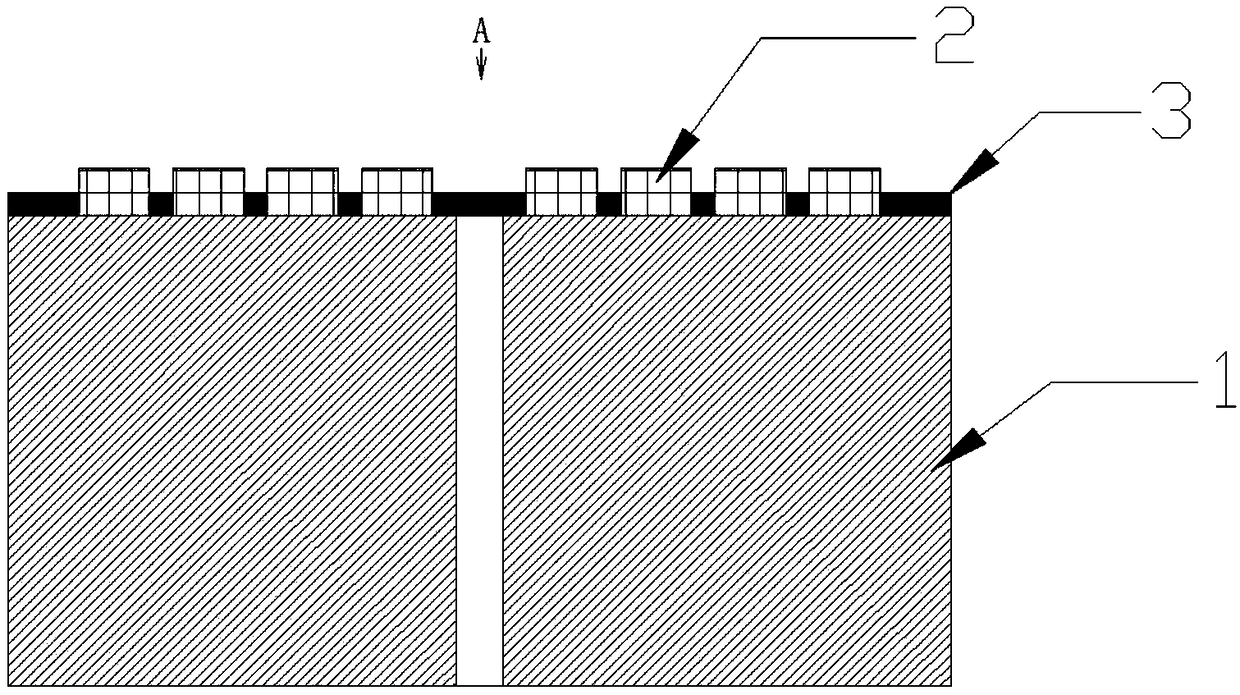

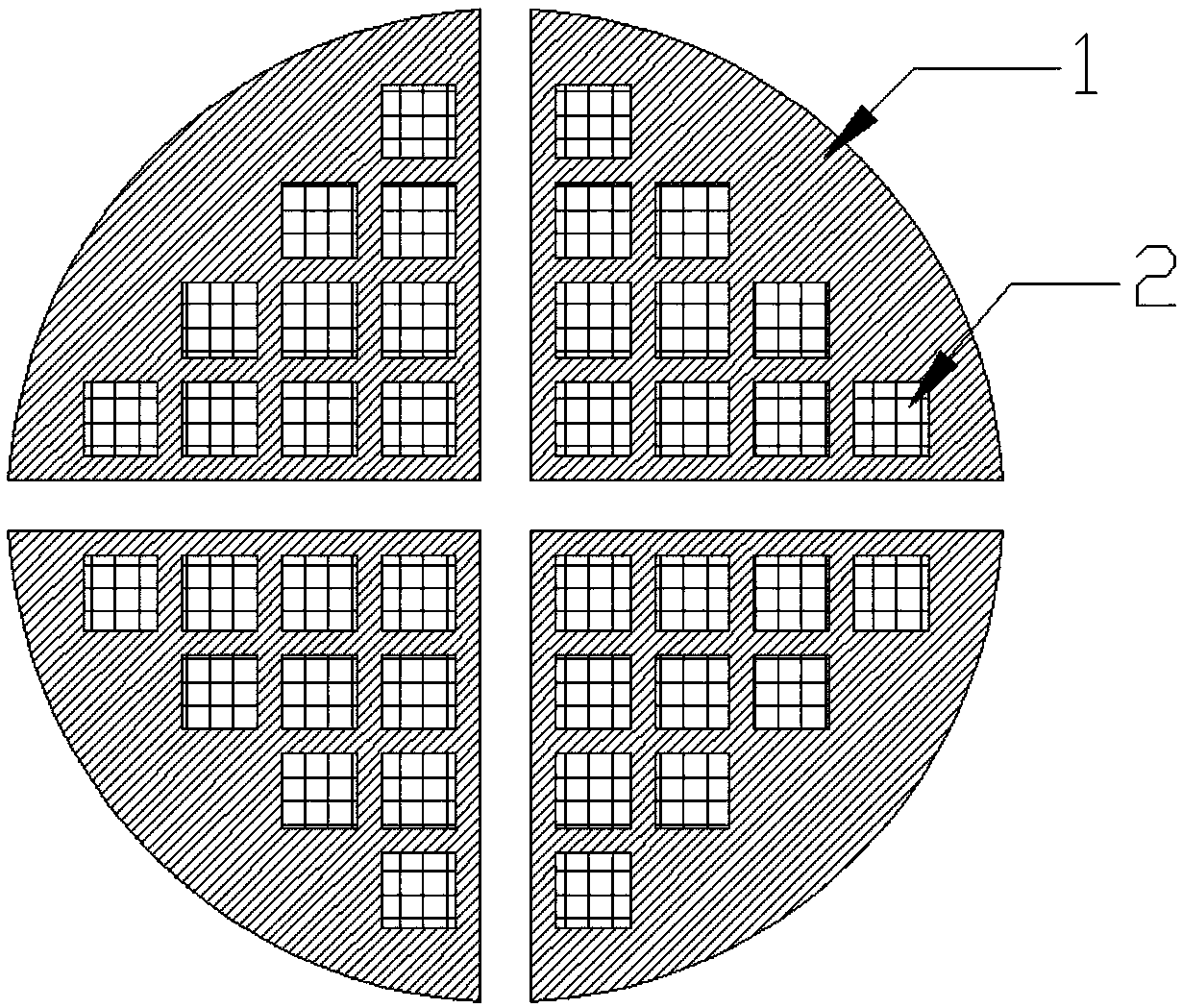

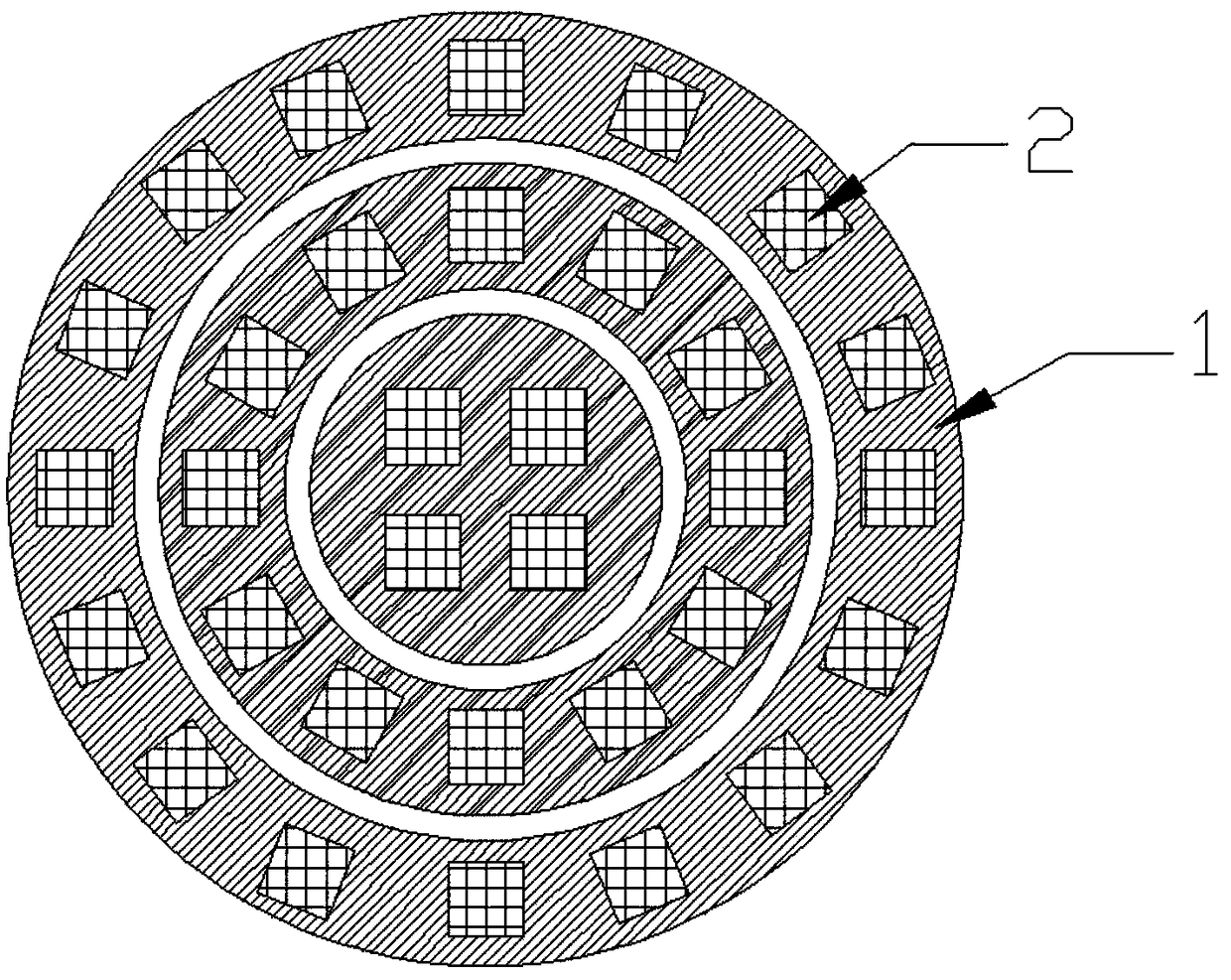

Temperature control device for substrate tables of MPCVD equipment and temperature control method

InactiveCN109402610AConsistent temperatureConsistent growth rateChemical vapor deposition coatingTemperature controlEngineering

The invention discloses a temperature control device for substrate tables of MPCVD equipment. The temperature control device comprises the circular substrate table located at the center and the multiple concentric annular substrate tables, the same central shaft is arranged between the circular substrate table and the multiple concentric annular substrate tables, the spacing distance between everytwo adjacent substrate table is 1-10 mm, each substrate table is provided with a separate cooling water path, and the cooling water paths can control the cooling speeds of the substrate tables by controlling the flow rate and the flow of injected cooling water. By controlling the temperatures of the substrate tables, the temperatures of substrates in the diamond growing process are regulated andcontrolled, and then the temperatures of base plates are controlled in the diamond deposition process. In the diamond growing process, the surface temperatures of diamonds are controlled by controlling heat dissipation, so that the surface temperatures of all the diamonds in the deposition process are approximate, in this way, the growing rates and the quality of the diamonds produced at the samebatch are consistent, and batch production is facilitated.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

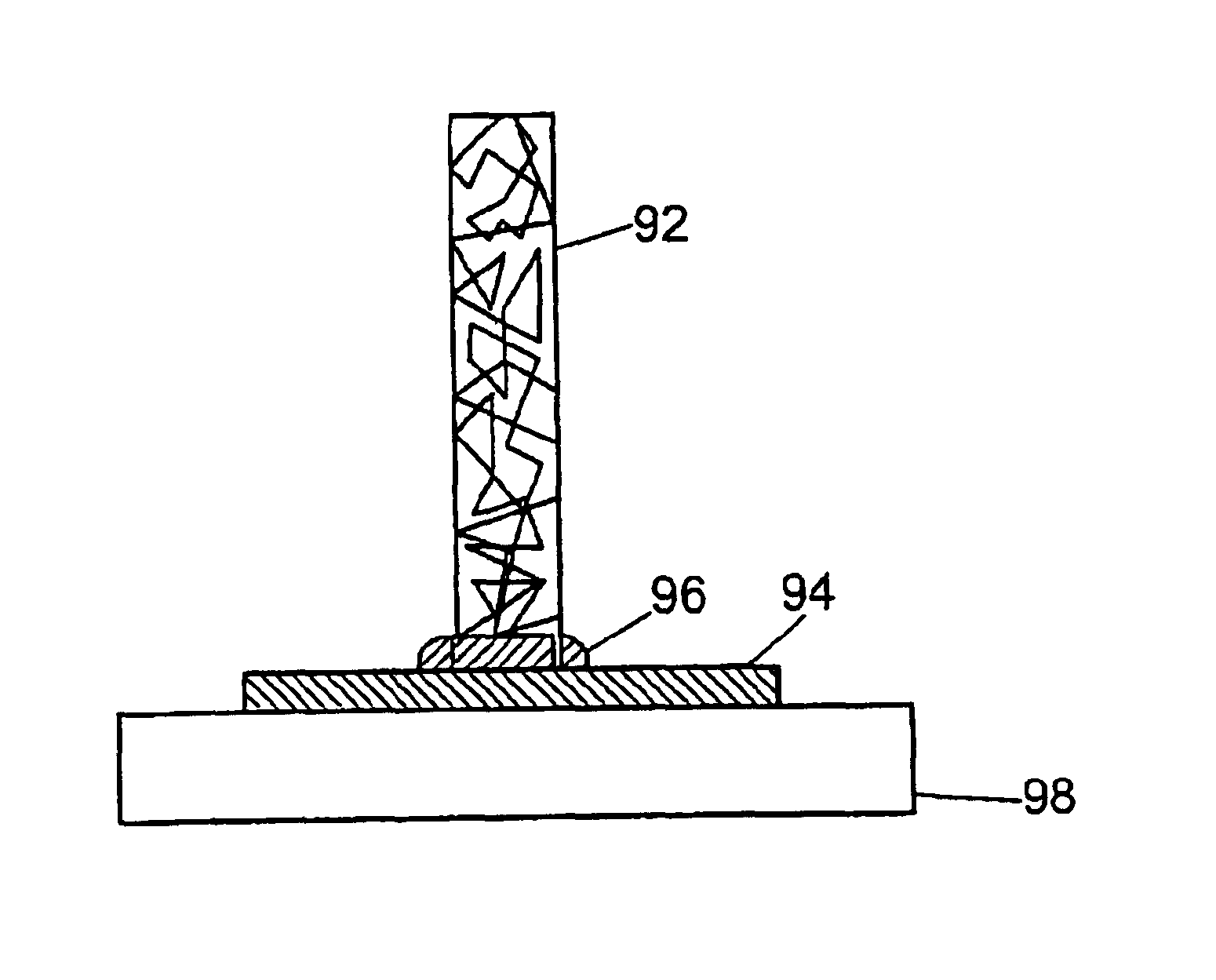

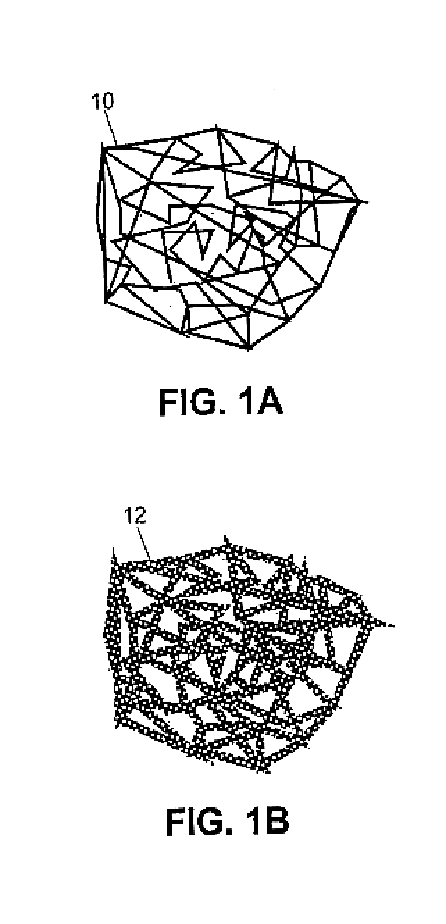

Diamond coated article bonded to a body

InactiveUS6902808B2Coin-freed apparatus detailsSoldering apparatusFilling materialsDiamond deposition

A diamond foam article comprises diamond deposited material on a substrate having an open contiguous structure at least partially filled with a filler material. Methods for forming a diamond foam article comprise providing a foam substrate; preparing the foam substrate for diamond deposition; depositing diamond material on the foam substrate by one of several diamond deposition methods; and at least partially filling the diamond foam article with a filler material. Diamond foam articles are bonded to other components.

Owner:P1 DIAMOND

Cast diamond tools and formation thereof by chemical vapor deposition

InactiveUS20050122189A1Impedence networksPiezoelectric/electrostriction/magnetostriction machinesEtchingGas phase

The present invention provides diamond tools, and a method for the formation thereof, using CVD techniques. In one aspect, a mold is provided which has an interface surface configured to inversely match a configuration intended for the working surface of a diamond layer in a tool. After the mold is provided, various CVD techniques may be used to deposit diamond layers upon the diamond interface surface of the mold. Following diamond deposition upon the diamond interface surface, the mold may be removed by various means, such as chemical etching, or the mold may be left intact for certain applications, such as SAW filters. Thus, the working surface of the diamond receives a shape which inversely corresponds to the configuration of the mold's diamond interface surface. The diamond layer may then be incorporated into a tool, if such incorporation has not yet taken place.

Owner:KINIK

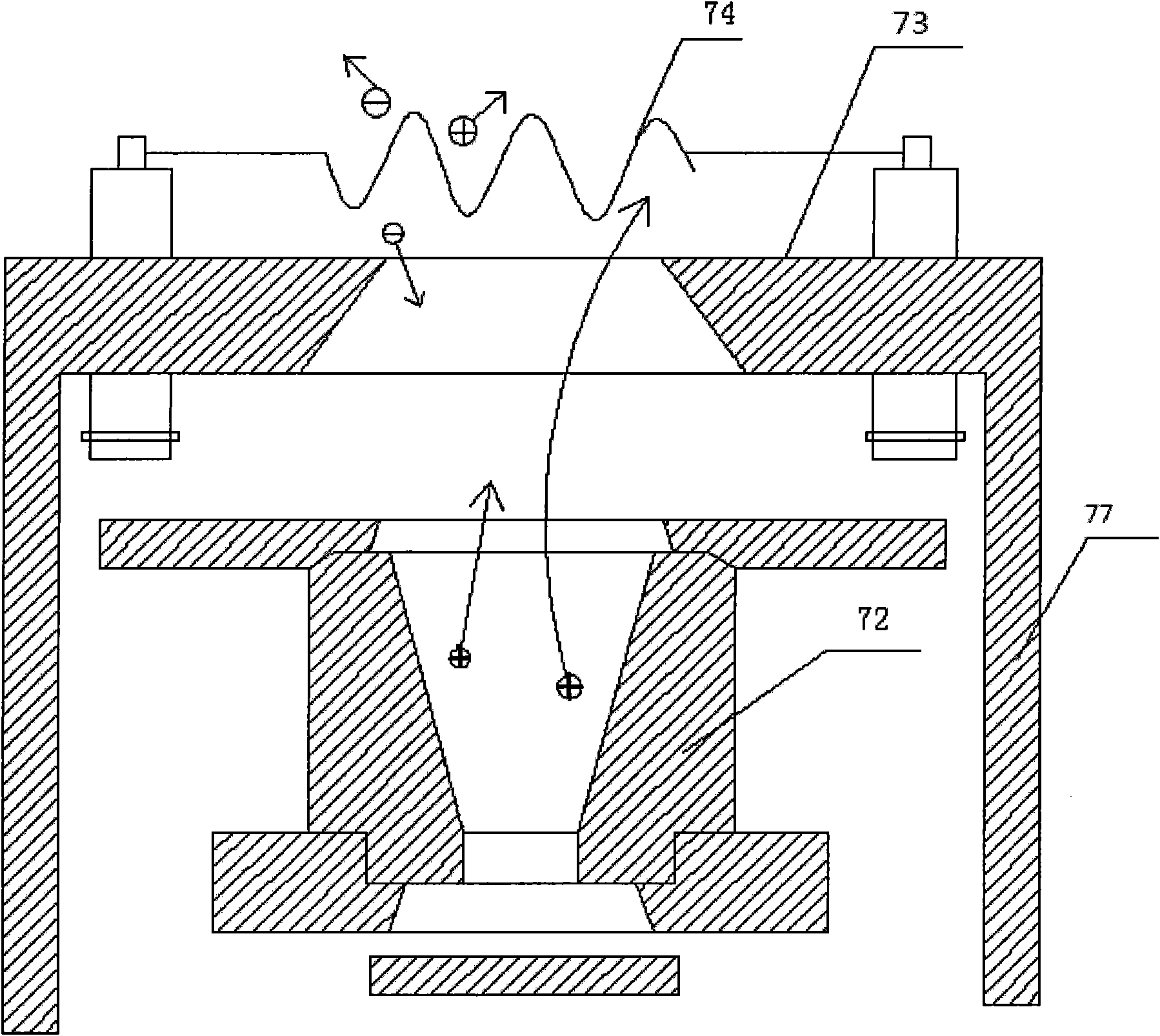

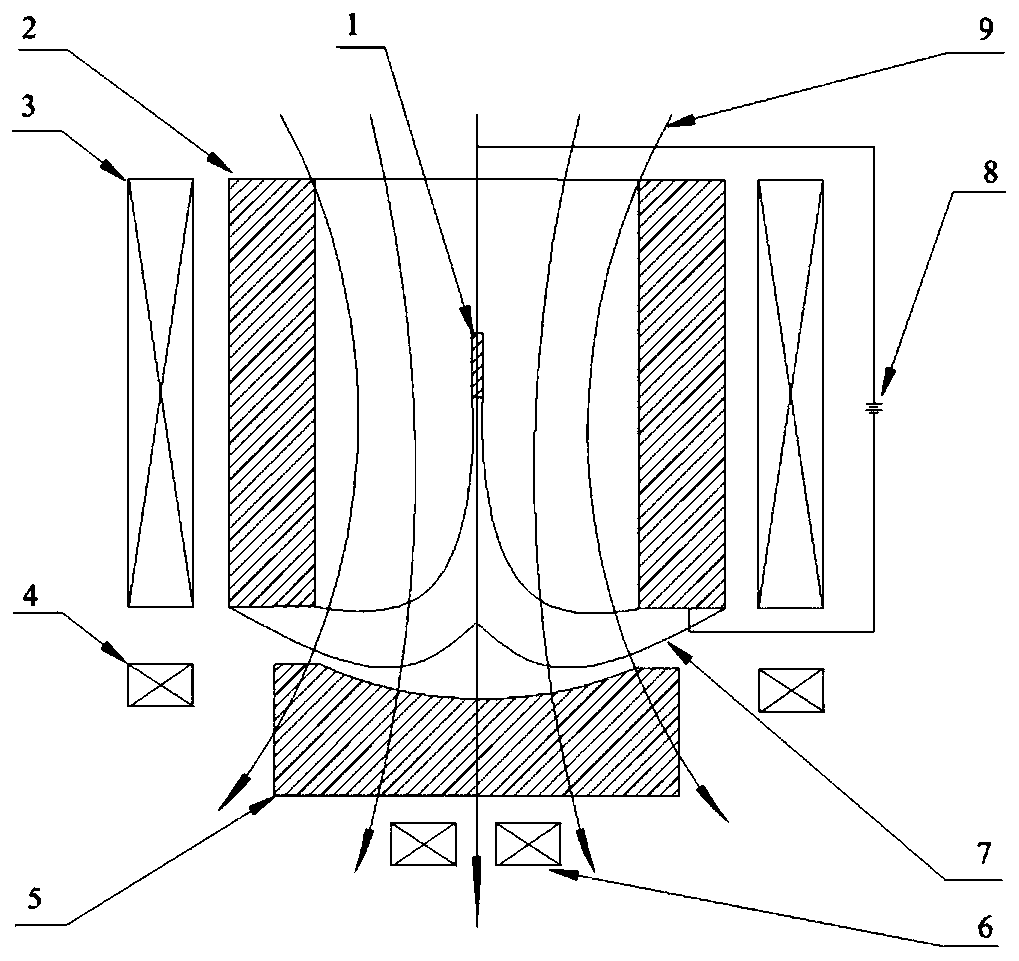

Plasma arc deposition device and method for diamond film

ActiveCN111005065ALarge deposition areaUniform depositionPolycrystalline material growthFrom chemically reactive gasesHeat sinkCondensed matter physics

The invention discloses a plasma arc deposition device and method for a diamond film, and belongs to the technical field of diamond material preparation. A large-area conformal diamond film is deposited by adopting a direct-current arc plasma device with multi-stage magnetic field control; stable control on a rotating plasma arc is realized through a magnetic field generated by an arc-stabilizingmagnetic field coil; an extended arc coil further stabilizes the arc, and the extended rotating arc adapts to the size of a substrate, so that the large-area stable rotating guide of the arc to the substrate is realized. Meanwhile, a guide magnetic field coil at the bottom of the substrate realizes movement of the plasma arc towards the concave part of the substrate, and uniform deposition of diamonds on the surface of the conformal substrate is realized. Three magnetic field coils expand and guide the electric arc to enlarge the diamond deposition area while achieving generation and stabilization of the rotating electric arc, interference of anode carbon deposition on the electric arc is avoided, and long-term stable growth of a diamond film with a uniform thickness is achieved. The obtained conformal diamond film can be used as a heat sink or window material with high heat flux and rapid heat dissipation.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com