Temperature control device and method for MPCVD equipment

A temperature control device and equipment technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the temperature difference of diamond substrate, uneven distribution of plasma, uncontrollable temperature change of substrate table, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

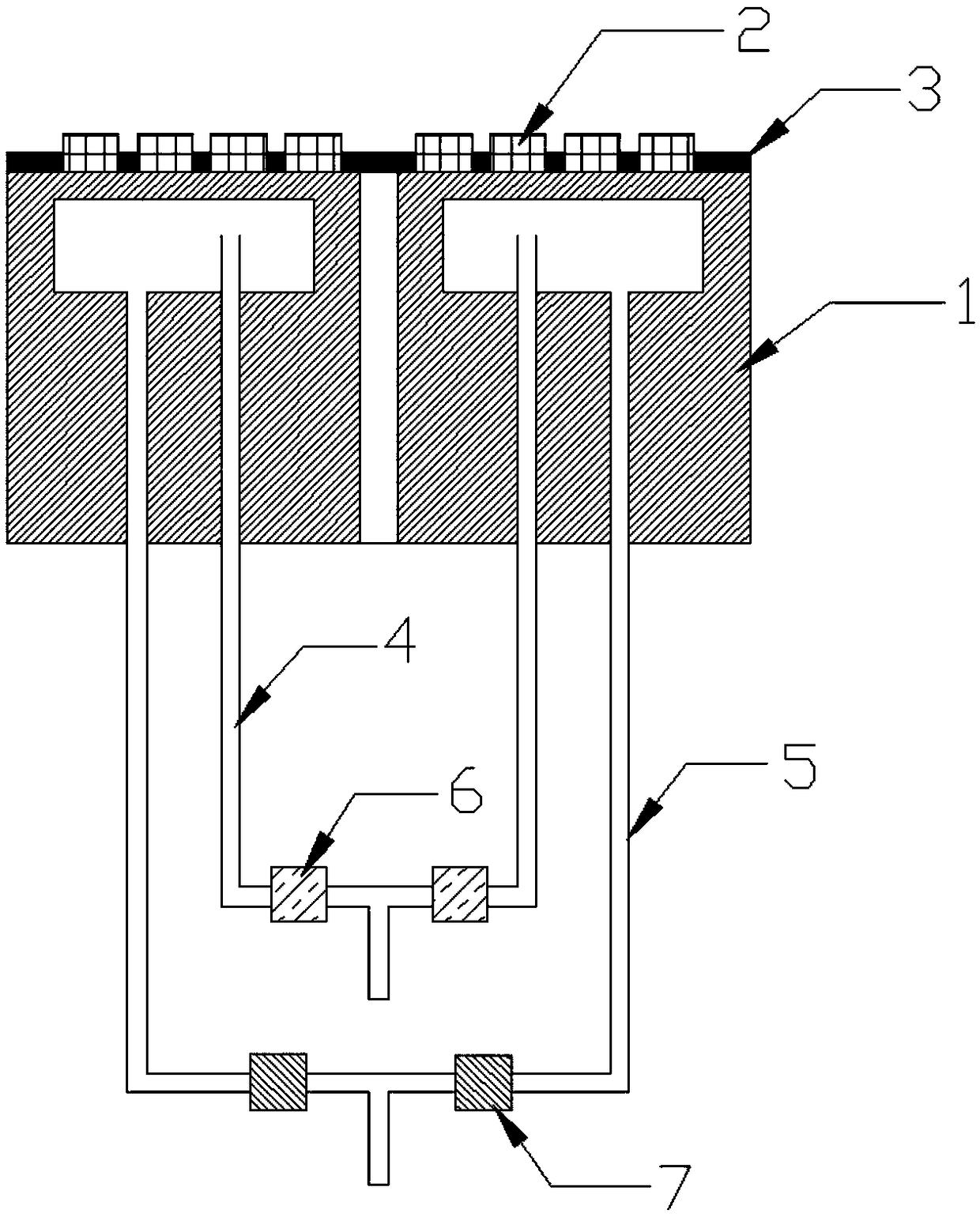

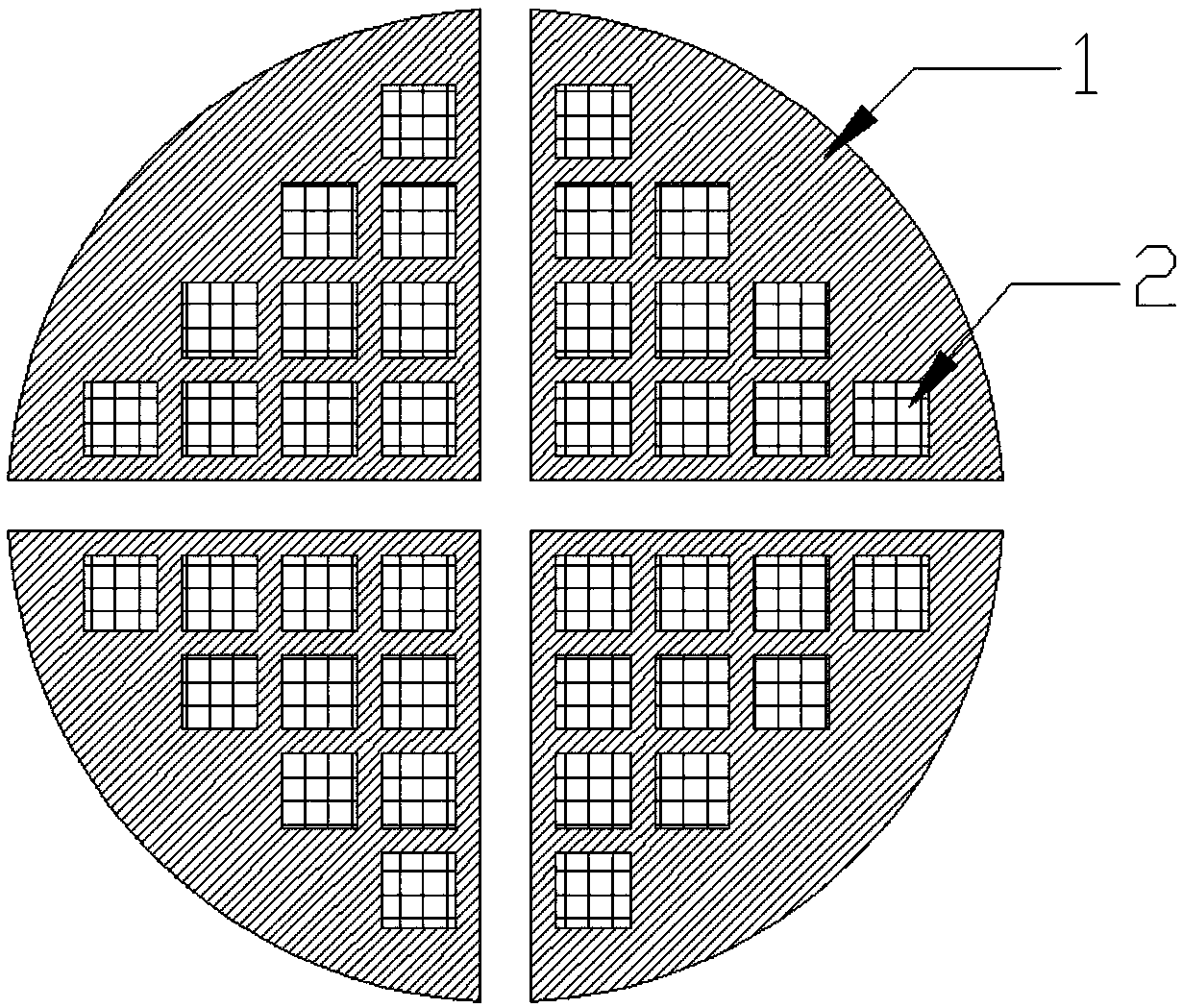

[0031] Refer to attached Figure 1-Figure 5 , the temperature control device of the present invention comprises four substrate stages, each substrate stage is a 1 / 4 cylinder, assembled to form a cylinder, the distance between adjacent substrate stages is 1 mm, and each substrate stage is configured A separate cooling channel (including water inlet and outlet), the cooling channel is a conventional cooling channel, which can uniformly cool the surface of the substrate table; the cooling channel can control the flow rate of the cooling medium to 0L / min -10L / min, to control the cooling rate of the substrate table. Each cooling medium is connected with a separate flow valve, and the size of the cooling medium water inlet can be controlled by adjusting the flow valve, thereby controlling the flow of the cooling medium.

[0032] It also includes a gas source, the gas (usually air) in the gas source is passed into the cooling flow channel, and the cooling flow channel can control th...

example 2

[0036] The temperature control device of the present invention includes four substrate stages, each substrate stage is a 1 / 4 cylinder, assembled to form a cylinder, the distance between adjacent substrate stages is 1mm, and each substrate stage is configured A separate cooling flow channel, the cooling flow channel can control the cooling rate of the substrate table by controlling the flow rate of the cooling medium.

[0037] It also includes a gas source, the gas (air) in the gas source passes into the cooling channel, and the cooling channel can control the cooling rate of the substrate table by controlling the flow of gas mixed into the cooling medium.

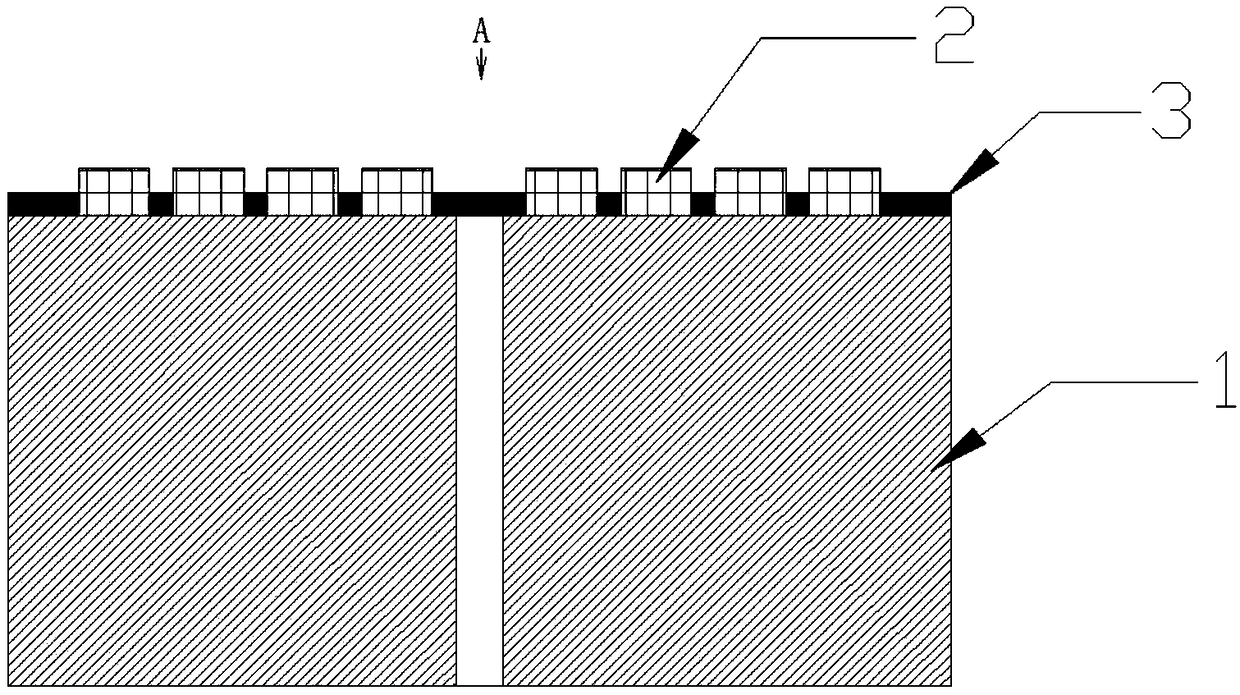

[0038] The upper surfaces of each substrate stage are flush, and molybdenum sheets with openings are placed. The size and position of the openings correspond to the diamond seeds placed on the substrate stage during the deposition process. The gaps between the plurality of substrate stages Covered by molybdenum sheet.

[0...

example 3

[0041] The temperature control device of the present invention includes four substrate stages, each substrate stage is a 1 / 4 cylinder, assembled to form a cylinder, the distance between adjacent substrate stages is 1mm, and each substrate stage is configured A separate cooling flow channel, the cooling flow channel can control the cooling rate of the substrate table by controlling the flow rate of the cooling medium.

[0042] It also includes a gas source, the gas (air) in the gas source passes into the cooling channel, and the cooling channel can control the cooling rate of the substrate table by controlling the flow of gas mixed into the cooling medium.

[0043] The upper surfaces of each substrate stage are flush, and molybdenum sheets with openings are placed. The size and position of the openings correspond to the diamond seeds placed on the substrate stage during the deposition process. The gaps between the plurality of substrate stages Covered by molybdenum sheet.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com