Preparation process of composite coating layer based on machining tool

A technology for processing cutting tools and composite coatings, which is applied in metal material coating technology, coatings, gaseous chemical plating, etc., can solve the problems of short service life and rough surface of processing tools, and achieve not easy to fall off, good adhesion, even texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

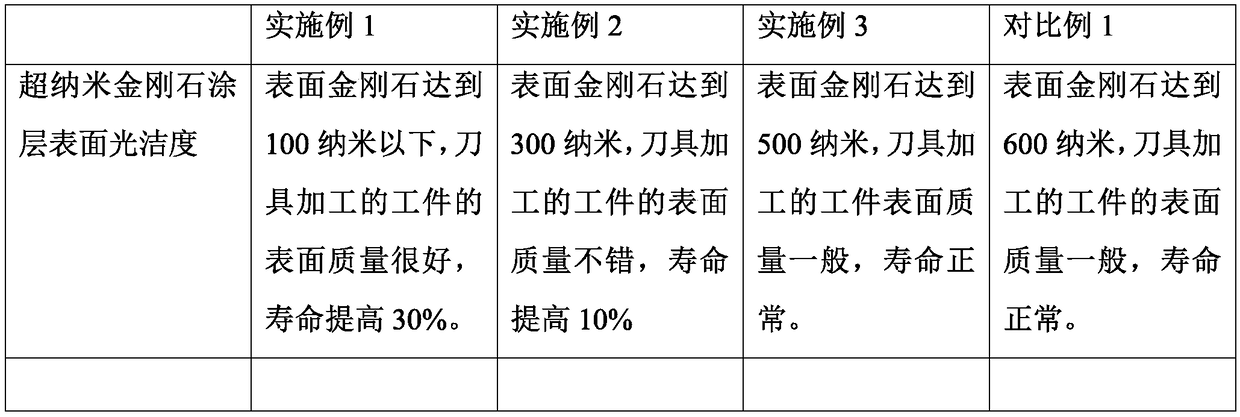

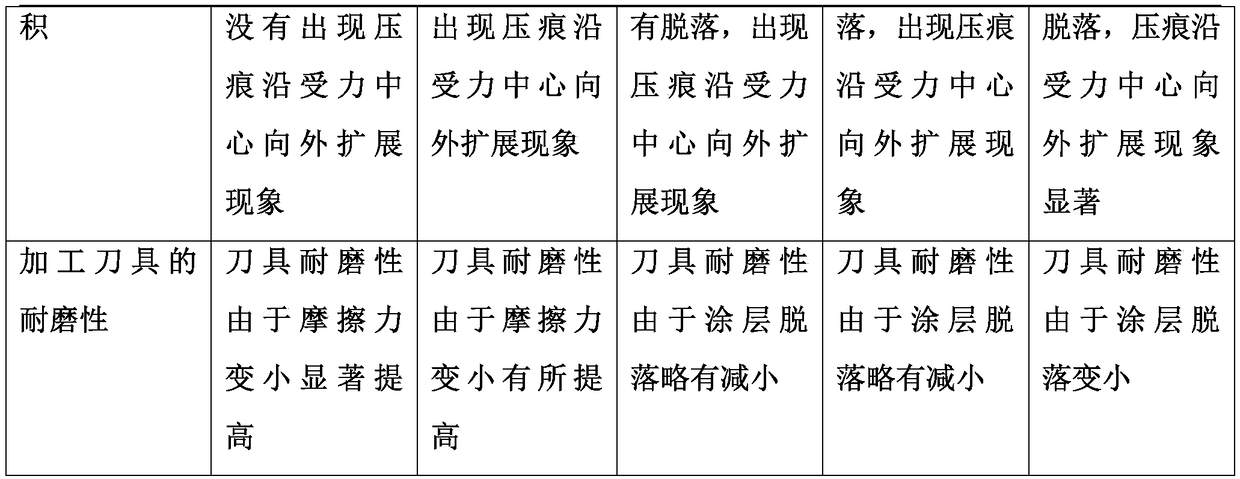

Embodiment 1

[0020] A composite coating preparation process based on a processing tool, including processing the internal CVD diamond coating of the processing tool and the ultra-nano-diamond coating on the outer surface of the CVD diamond coating; wherein,

[0021] Machining the internal CVD diamond coating of the tool includes the following steps:

[0022] Step 11: The processing tool is subjected to cleaning pretreatment and cobalt removal pretreatment in sequence, and the processing tool after decobalt pretreatment is cleaned and dried for use; it should be noted that the pre-cleaning treatment refers to the organic Dirt removal. Can be treated with alcohol or acetone. Decobalt pretreatment is to remove the cobalt on the surface of the machined tool to improve the adhesion of the later composite coating. Cobalt removal pretreatment includes alkali etching with inorganic alkali solution for 2-20 minutes, cleaning after alkali etching, and then putting in inorganic acid solution for ac...

Embodiment 2

[0027] A composite coating preparation process based on a processing tool, including processing the internal CVD diamond coating of the processing tool and the ultra-nano-diamond coating on the outer surface of the CVD diamond coating; wherein,

[0028] The processing steps of the CVD diamond coating inside the tool are the same as in Example 1;

[0029] The processing of ultra-nano-diamond coating on the outer surface of CVD diamond coating includes the following steps:

[0030] Step 21: Adjust the pressure in the CVD diamond deposition furnace to -105KPa, keep CH 4 、H 2 The air flow rate ratio remains unchanged, and then Ar is introduced into the CVD diamond deposition furnace, and the Ar air flow rate is linearly increased to 1000sccm, and the linear increase time is 60min, and the CH 4 、H 2 , The gas flow rate ratio of Ar is 1:200:200, the pressure in the CVD diamond deposition furnace is maintained at -100.5KPa, the temperature of the surface of the processed tool is c...

Embodiment 3

[0032] A composite coating preparation process based on a processing tool, including processing the internal CVD diamond coating of the processing tool and the ultra-nano-diamond coating on the outer surface of the CVD diamond coating; wherein,

[0033] The processing steps of the CVD diamond coating inside the tool are the same as in Example 1;

[0034] The processing of ultra-nano-diamond coating on the outer surface of CVD diamond coating includes the following steps:

[0035] Step 21: Adjust the pressure in the CVD diamond deposition furnace to -100.5KPa, keep CH 4 、H 2 The air flow rate ratio remains unchanged, and then Ar is introduced into the CVD diamond deposition furnace, and the Ar air flow rate is linearly increased to 1000sccm, and the linear increase time is 90min, and the CH 4 、H 2 , The gas flow rate ratio of Ar is 1:200:200, the pressure in the CVD diamond deposition furnace is maintained at -100.5KPa, the temperature of the tool surface is controlled to be 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com