Preparation method of directional high-thermal-conductivity diamond/metal-based composite material

A composite material and high thermal conductivity technology, which is applied in metal material coating process, metal processing equipment, coating, etc., can solve problems such as high temperature heating, achieve control, achieve high thermal conductivity, avoid thermal damage and graphitization effect of propensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this example, the supersonic laser deposition technology is firstly used to deposit a diamond / Cu high thermal conductivity composite material with a diamond volume fraction of 60% on the substrate, and then deposit pure iron powder. A single-layer deposition material is prepared with pure iron powder as the filling phase, and then a composite material with a certain thickness is prepared by layer-by-layer accumulation. The process parameters of supersonic laser deposition are as follows: the spraying distance is 30mm, the scanning speed is 30mm / s, the carrier gas is nitrogen, the carrier gas preheating temperature is 600°C, the pressure is 4MPa, the laser power is 600W, and the powder feeding volume is 40g / min.

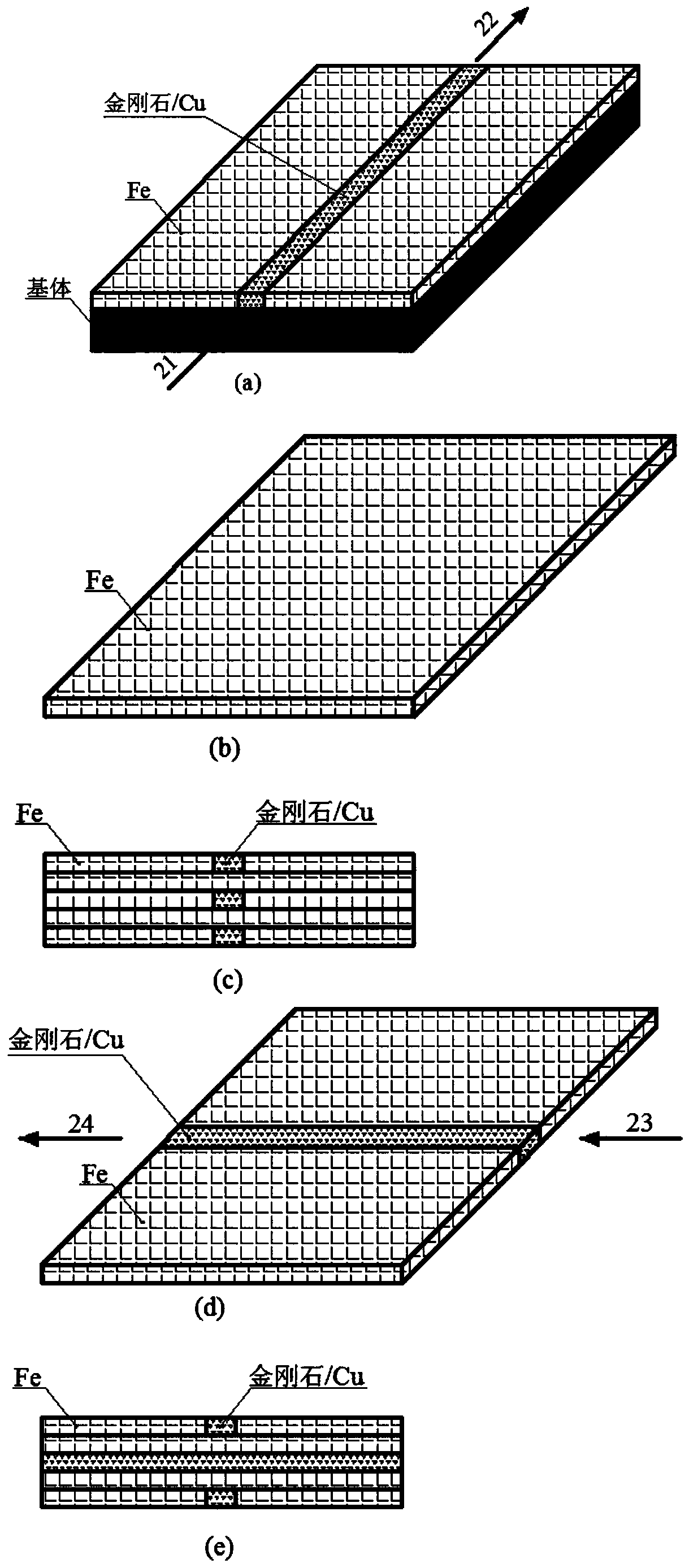

[0041] Such as figure 2 - As shown in (a), the deposition track of diamond / Cu on the substrate is single-channel single-layer linear deposition, and the direction of directional heat conduction is from 21 to 22. At this time, the temperature field of dire...

Embodiment 2

[0043] In this example, the material was deposited in the same manner as in Example 1, except that the diamond / Cu deposition trajectory was different.

[0044] Such as image 3 -As shown in (a), the deposition of diamond / Cu is changed from single-pass single-layer deposition in Example 1 to multi-pass overlapping single-layer deposition, forming a thin surface of diamond / Cu, and when the heat is directed from 31 to 32, Conduction is also performed along the 30 direction. At this time, the temperature field of directional heat transfer can be regarded as two-dimensional, that is, two-dimensional plane heat transfer. Similarly, the heat transfer direction of directional heat conduction can be controlled by changing the deposition material and the deposition track of diamond / Cu during the deposition process of the second layer and the third layer, which is the same as the embodiment in Example 1. Such as image 3 -As shown in (b), the second layer is deposited as pure iron pow...

Embodiment 3

[0046] In this example, supersonic laser deposition technology is used to deposit and prepare diamond / Al high thermal conductivity composite material on the substrate, and stainless steel powder is used as the filling phase. The deposition method is the same as in Example 1, the diamond / Al is deposited first, and then the stainless steel powder is deposited.

[0047] The morphology of the first layer deposited on the substrate is as follows Figure 4 - As shown in (a), after depositing several layers in this way of deposition, and then Figure 4 - Depositing several layers of the single-layer deposition morphology in (b), and then depositing several layers in the deposition mode of the first layer, after removing the matrix material, finally obtaining the spatial three-dimensional pattern of the composite material containing diamond / Al The cross-sectional diagram is as Figure 4 -shown in (c). At this time, the temperature field of directional heat transfer can be regarded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com