Temperature control device for substrate tables of MPCVD equipment and temperature control method

A temperature control device and a technology for a substrate stage, which are applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of uncontrollable heat dissipation of the substrate stage, uncontrollable temperature change of the substrate stage, and the like. Conducive to mass production, consistent growth rate and quality, and basically consistent growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

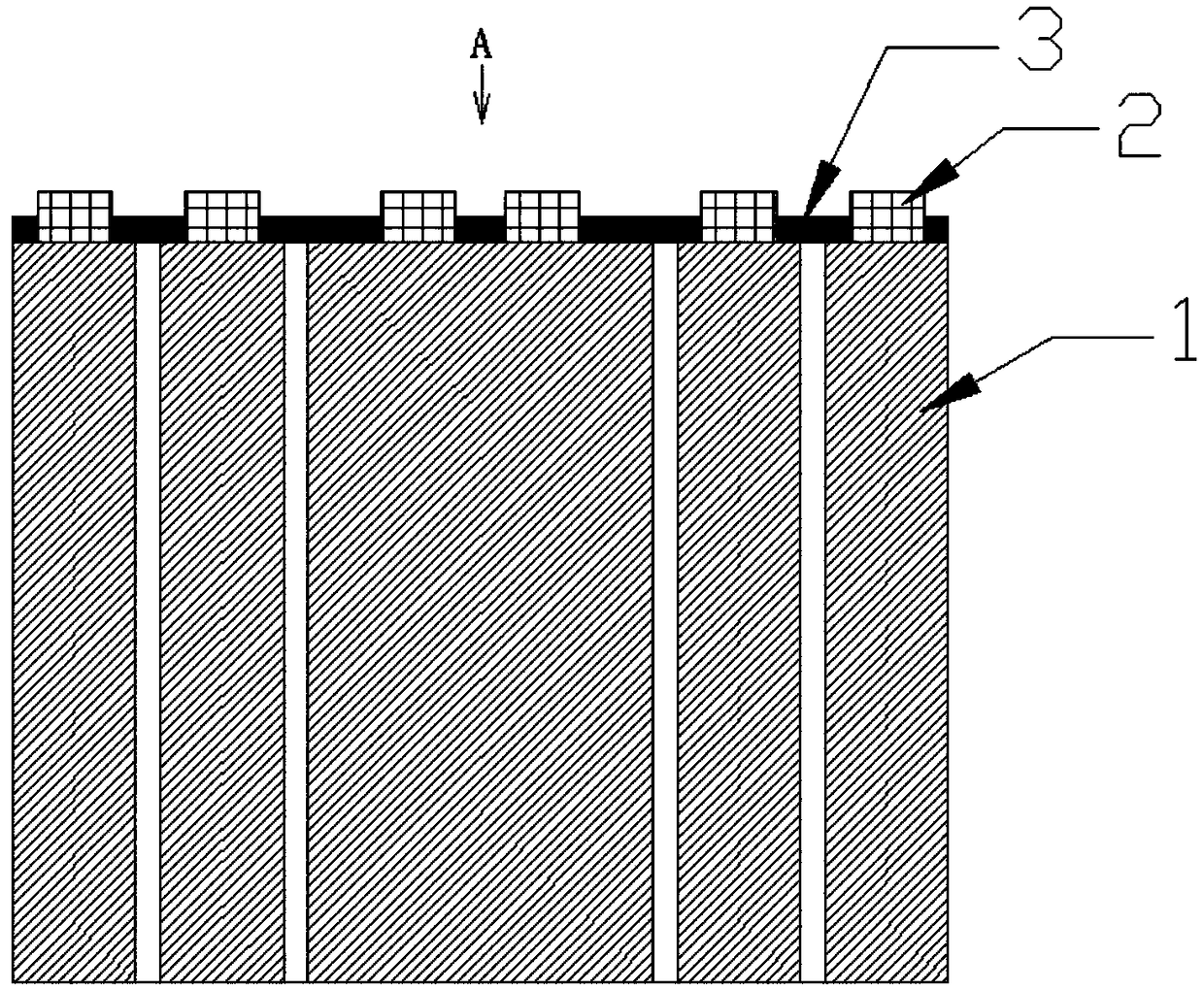

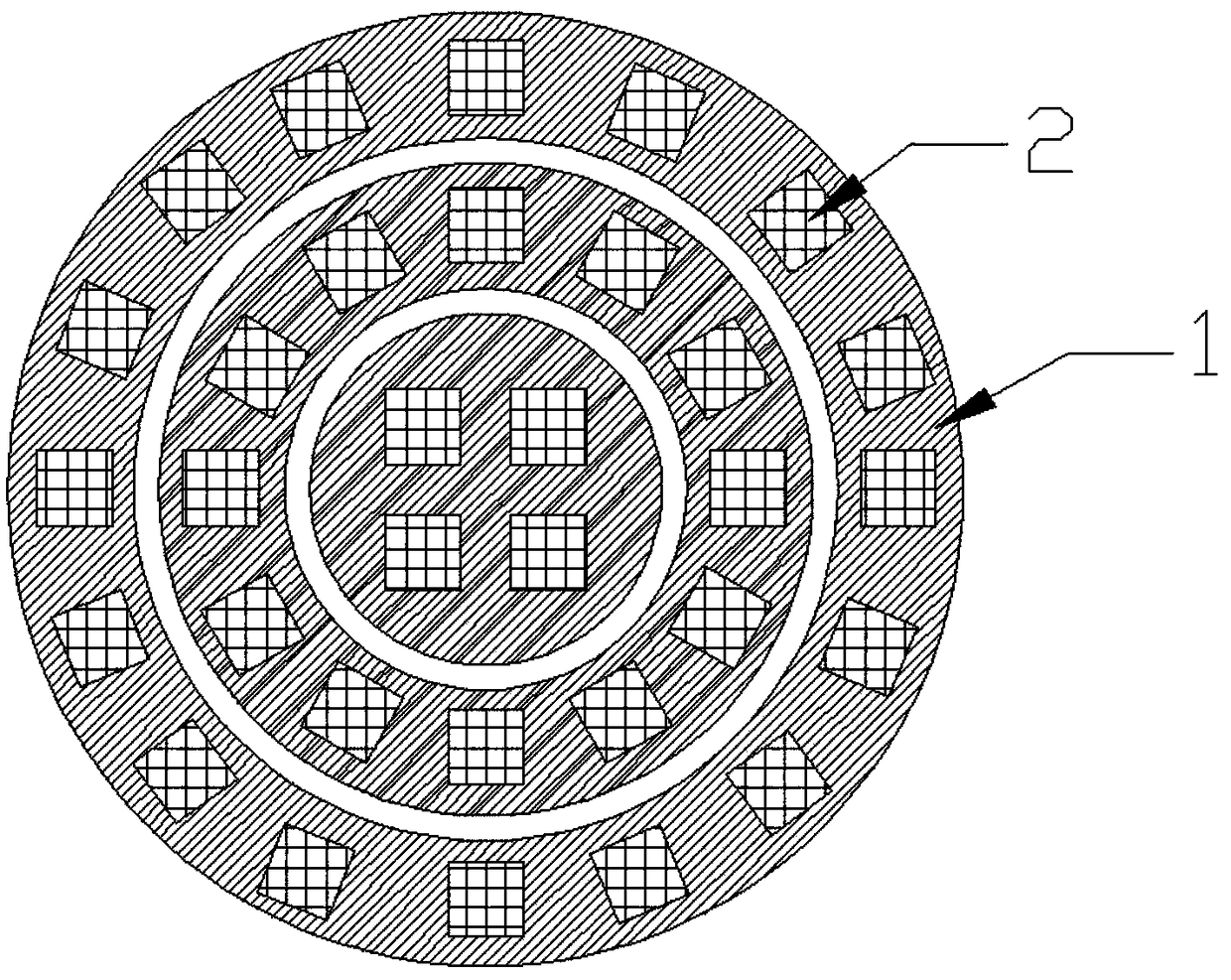

[0031] Refer to attached Figure 1-Figure 5 , the temperature control device of the present invention comprises a central circular substrate stage and a plurality of concentric annular substrate stages, the circular substrate stage and the plurality of concentric annular substrate stages have the same central axis, adjacent The distance between the substrate stages is 1mm, and each substrate stage is equipped with a separate cooling channel (including water inlet and outlet channels). The chip platform cooling medium cooling flow channel surrounds the annular substrate platform, the water inlet and the water outlet are close to each other, the water inlet is connected to the water pipe from bottom to top, and the water outlet is connected to the water pipe from top to bottom. The cooling medium cooling flow The channel can control the cooling speed of the substrate table by controlling the flow rate of the cooling medium from 0L / min to 10L / min. Each cooling medium is connecte...

example 2

[0036]The temperature control device of the present invention comprises a circular substrate stage located in the center and a plurality of concentric annular substrate stages, the circular substrate stage and the plurality of concentric annular substrate stages have the same central axis, and adjacent substrate stages The distance between the stages is 1 mm, and each substrate stage is equipped with a separate cooling medium cooling flow channel, which can control the cooling rate of the substrate stage by controlling the flow rate of the cooling medium.

[0037] It also includes a gas source, the gas (air) in the gas source passes into the cooling medium cooling channel, and the cooling medium cooling channel can control the cooling of the substrate table by controlling the flow rate of gas mixed into the cooling medium speed.

[0038] The annular substrate stage cooling medium cooling passage surrounds the annular substrate stage, and the circular substrate stage cooling me...

example 3

[0042] The temperature control device of the present invention comprises a circular substrate stage located in the center and a plurality of concentric annular substrate stages, the circular substrate stage and the plurality of concentric annular substrate stages have the same central axis, and adjacent substrate stages The distance between the stages is 1 mm, and each substrate stage is equipped with a separate cooling medium cooling flow channel, which can control the cooling rate of the substrate stage by controlling the flow rate of the cooling medium.

[0043] It also includes a gas source, the gas (air) in the gas source passes into the cooling medium cooling channel, and the cooling medium cooling channel can control the cooling of the substrate table by controlling the flow rate of gas mixed into the cooling medium speed.

[0044] The annular substrate stage cooling medium cooling passage surrounds the annular substrate stage, and the circular substrate stage cooling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com