Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Availability factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The availability factor of a power plant is the amount of time that it is able to produce electricity over a certain period, divided by the amount of the time in the period. Occasions where only partial capacity is available may or may not be deducted. Where they are deducted, the metric is titled equivalent availability factor (EAF). The availability factor should not be confused with the capacity factor. The capacity factor for a given period can never exceed the availability factor for the same period. The difference arises when the plant is run at less than full capacity, in which case the capacity factor is less than the availability factor.

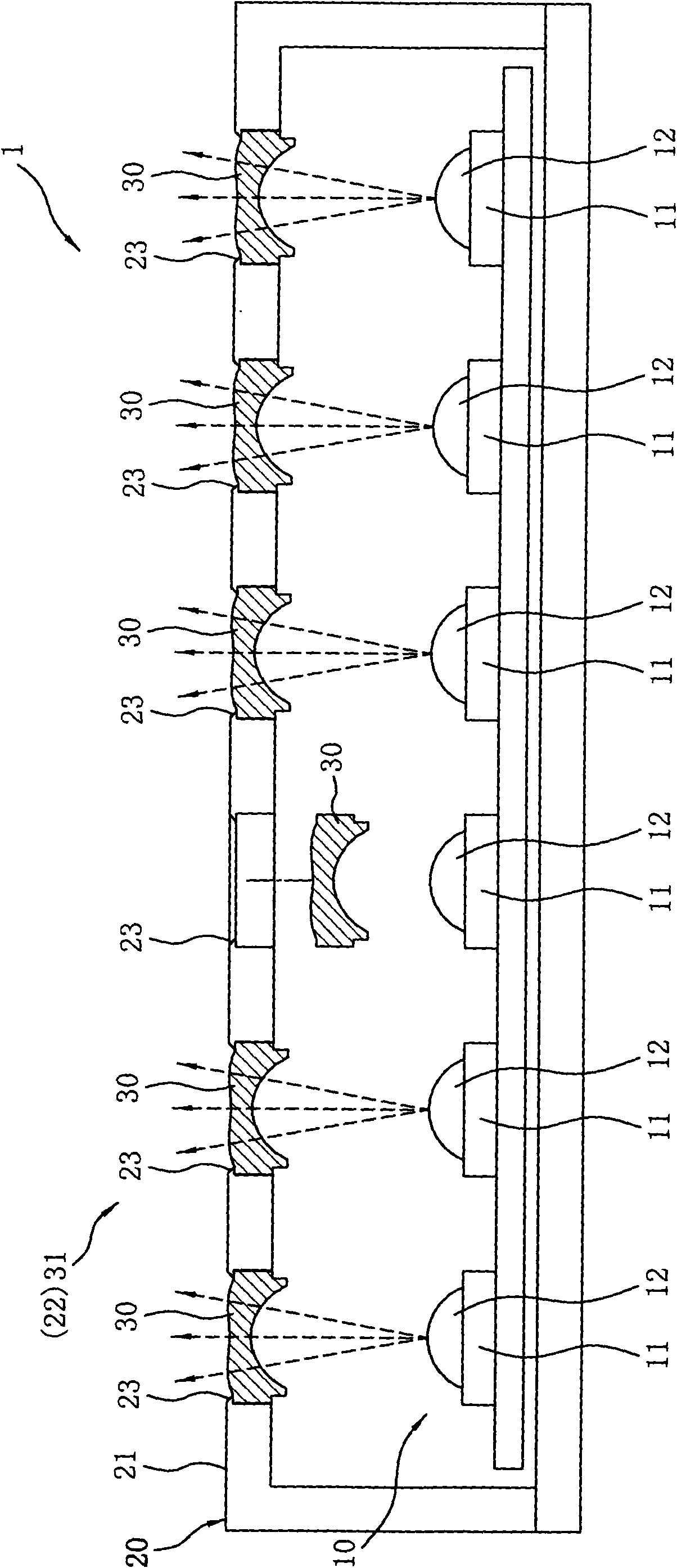

Particle beam irradiation system

ActiveUS7141810B2Improve usabilityIncreased availability factorRadiation/particle handlingElectrode and associated part arrangementsParticle beamProton

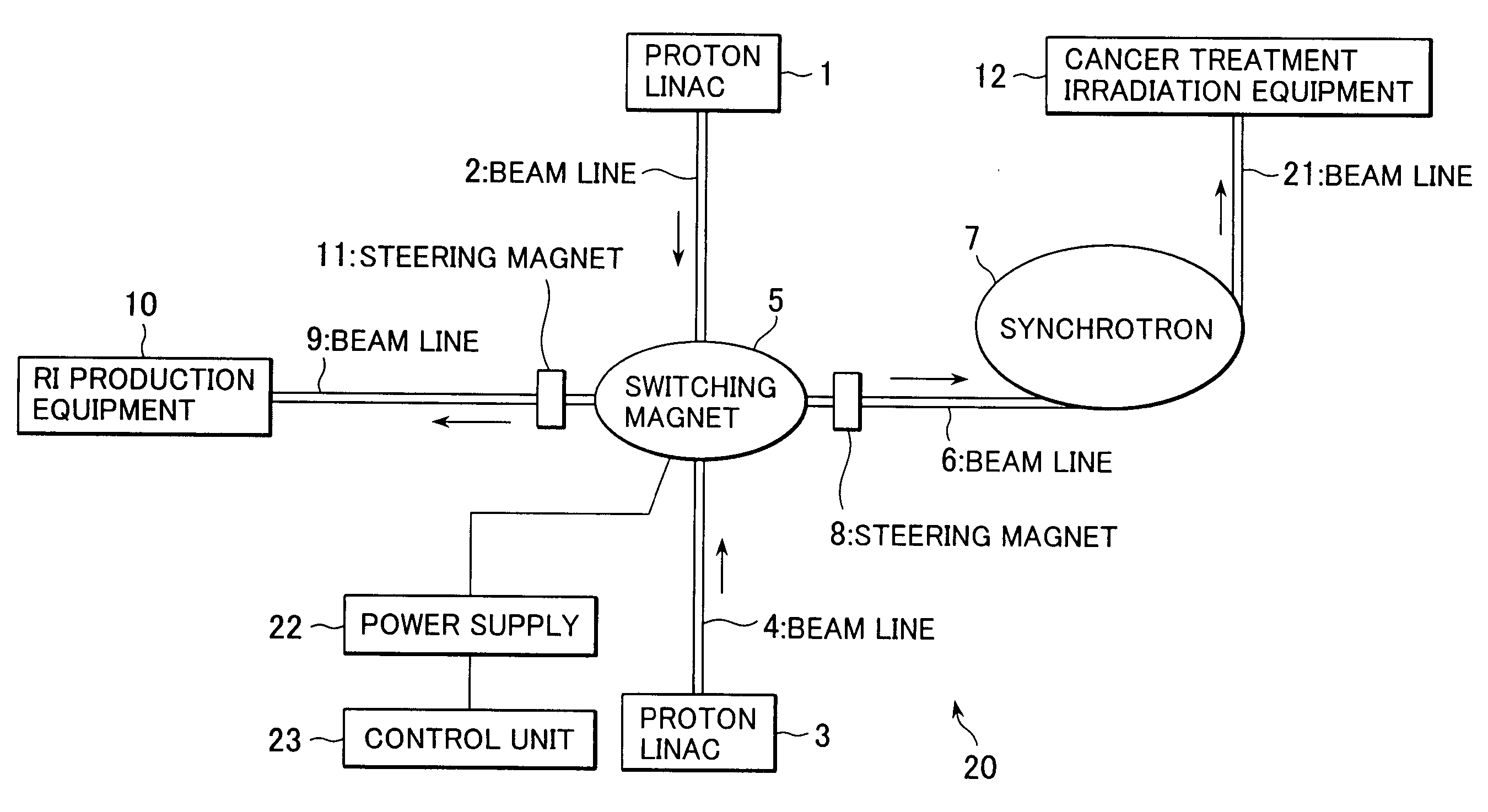

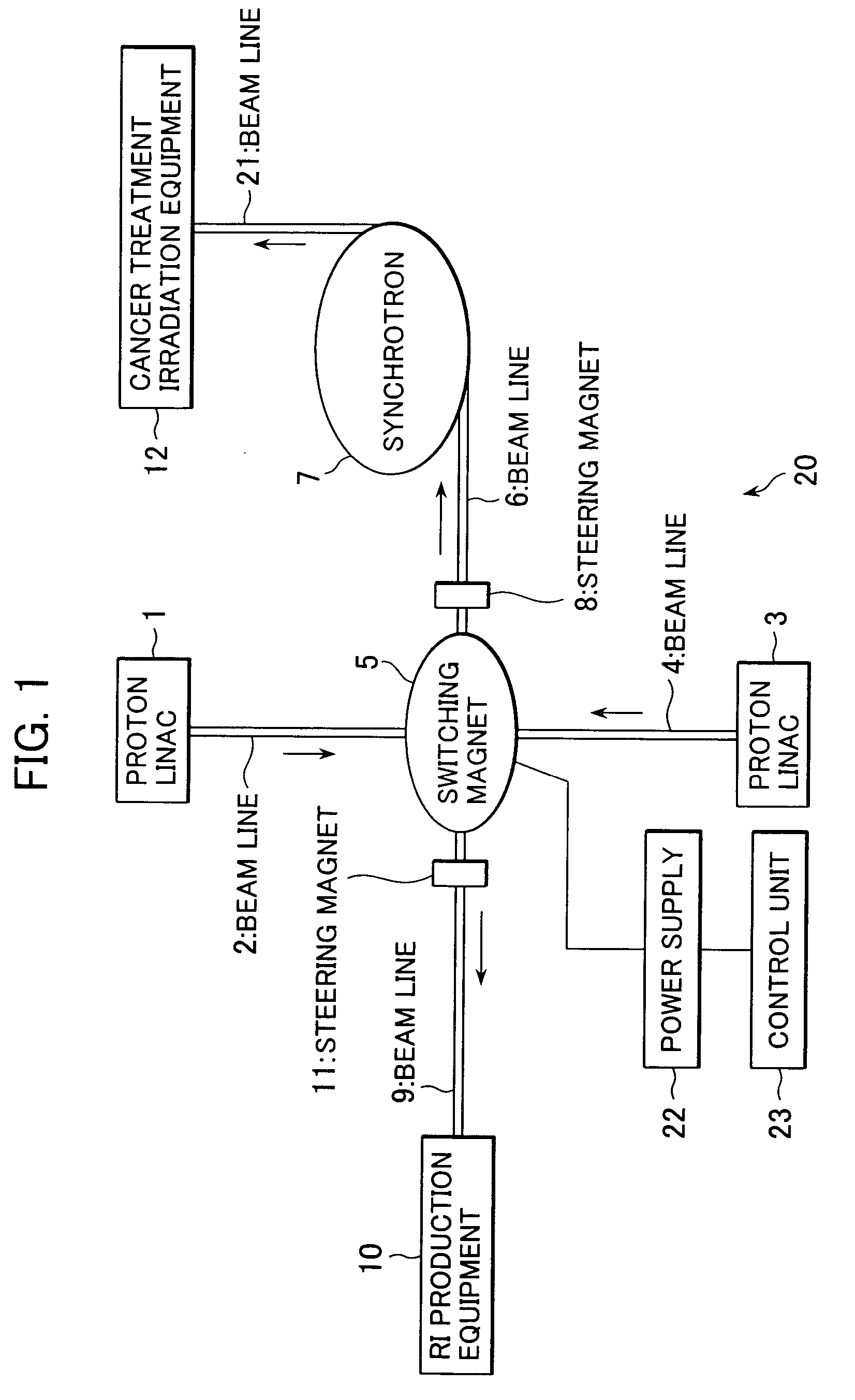

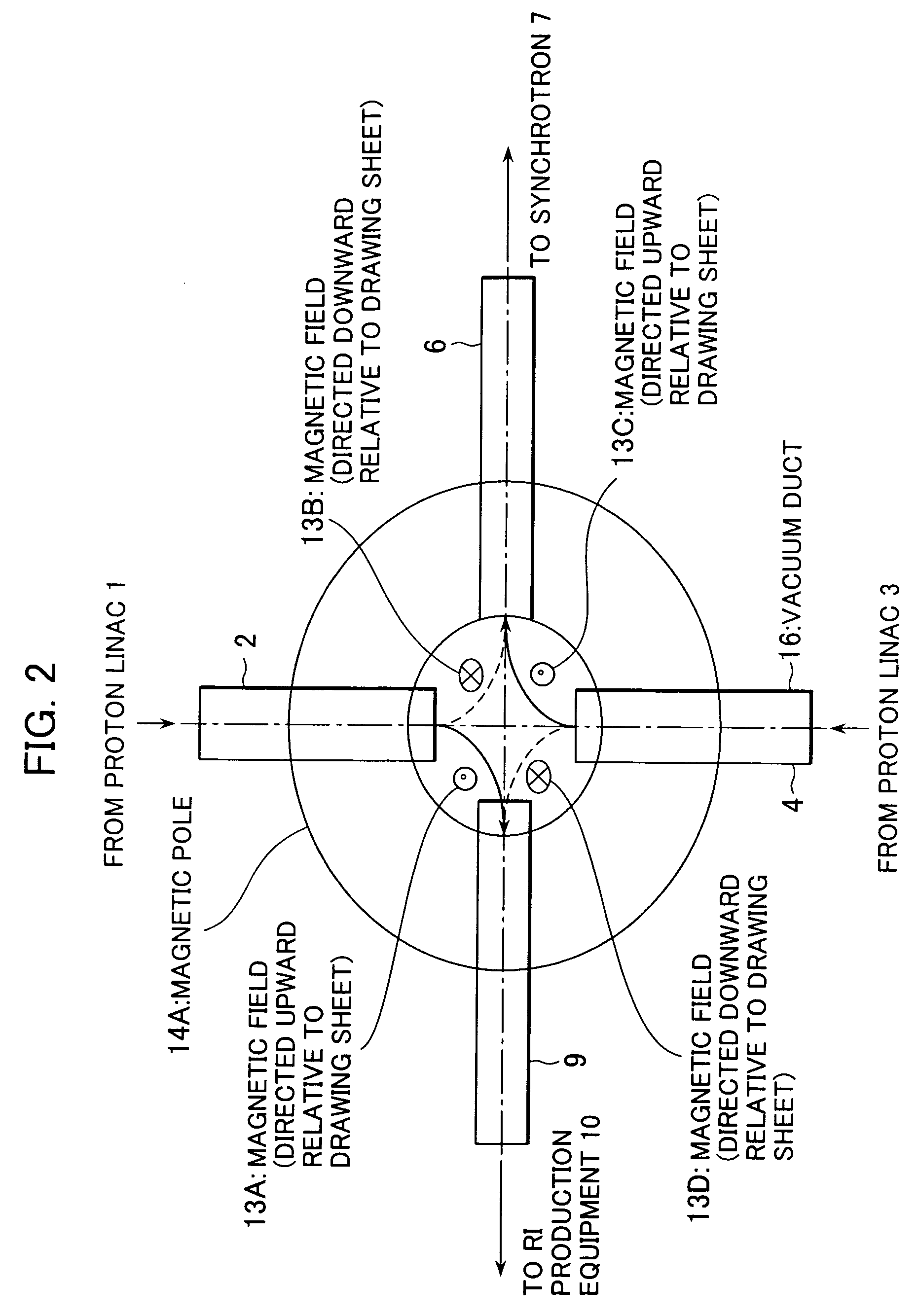

A particle beam irradiation system which can increase an availability factor. An ion beam extracted from one proton beam linac is bent at 90 degrees by a switching magnet and is introduced to RI production equipment through a beam line. In the RI production equipment, a RI is produced using the introduced ion beam. An ion beam extracted from the other proton beam linac is bent at 90 degrees by the switching magnet and is introduced to a synchrotron through a beam line. The ion beam extracted from the synchrotron is irradiated to a patient from irradiation equipment. If one proton beam linac comes into an abnormal state, the one proton beam linac is stopped in operation and checked. During the check, the ion beam extracted from the other proton beam linac is selectively introduced to the RI production equipment and the synchrotron by the switching magnet.

Owner:HITACHI LTD

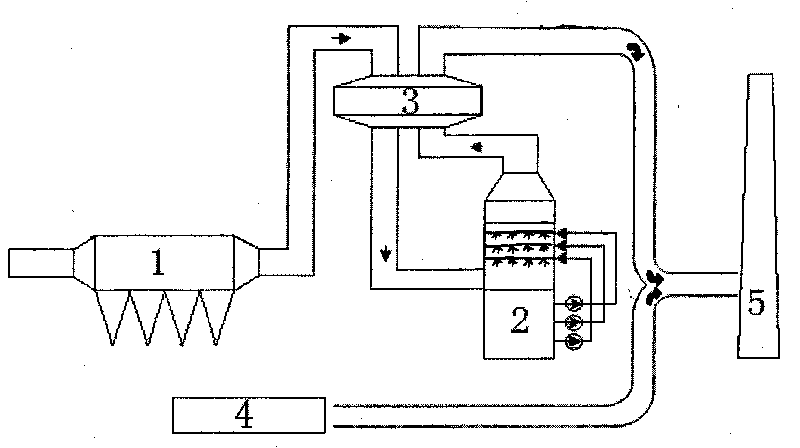

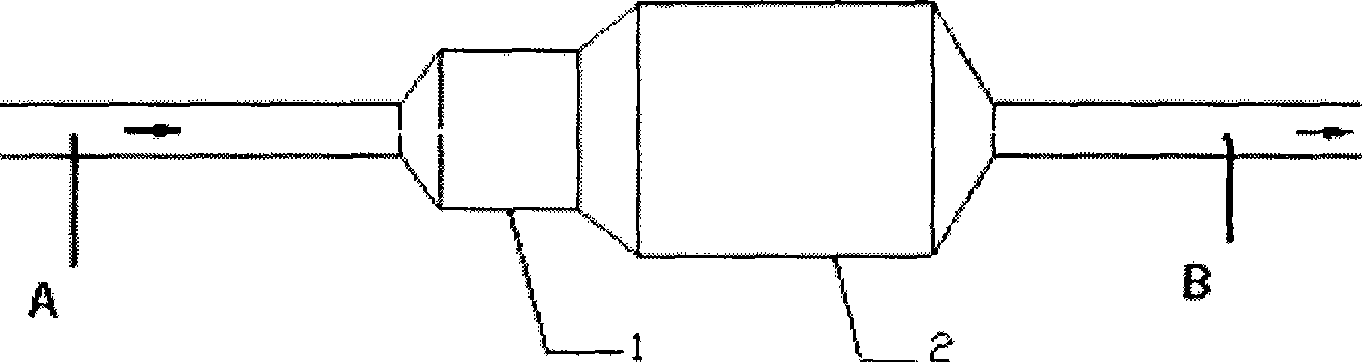

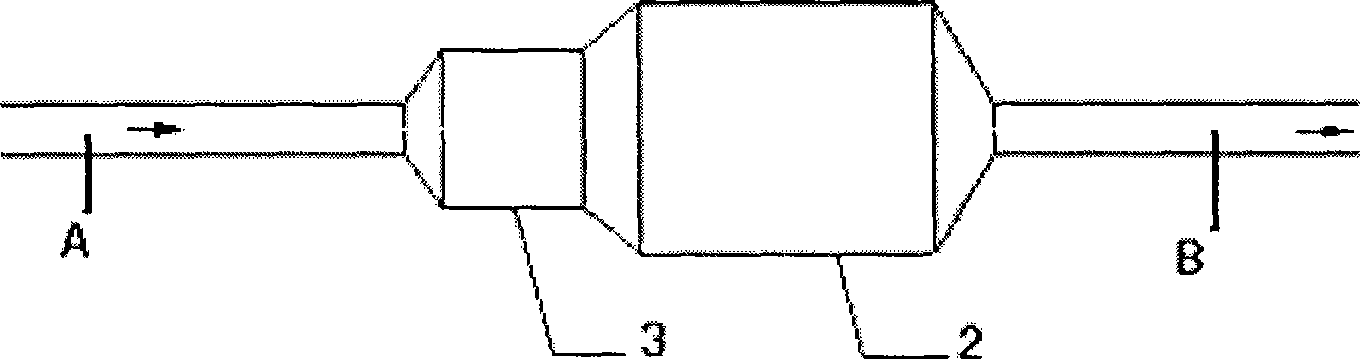

Exhaust gas treating device

InactiveUS6969250B1Efficiently captured and absorbedWear minimizationGas treatmentDispersed particle separationFiberCombustion chamber

A waste gas treatment system having a burner part and a combustion chamber provided at a downstream side of the burner part. Combustion flames are formed from the burner part toward the combustion chamber, and a waste gas is introduced into the combustion flames, thereby oxidatively decomposing the waste gas. The combustion chamber is formed from an inner wall made of a fiber-reinforced ceramic material. Therefore, the wear of the inner wall due to heat and corrosion is minimized, and thermal stress cracking is also reduced. Consequently, the lifetime of the system increases, and the cost of equipment and the availability factor can be improved. In addition, because the inner wall exhibits no catalytic effect, the formation of thermal NOx is suppressed, and it is possible to achieve environmental preservation and to simplify the treatment equipment.

Owner:EBARA CORP

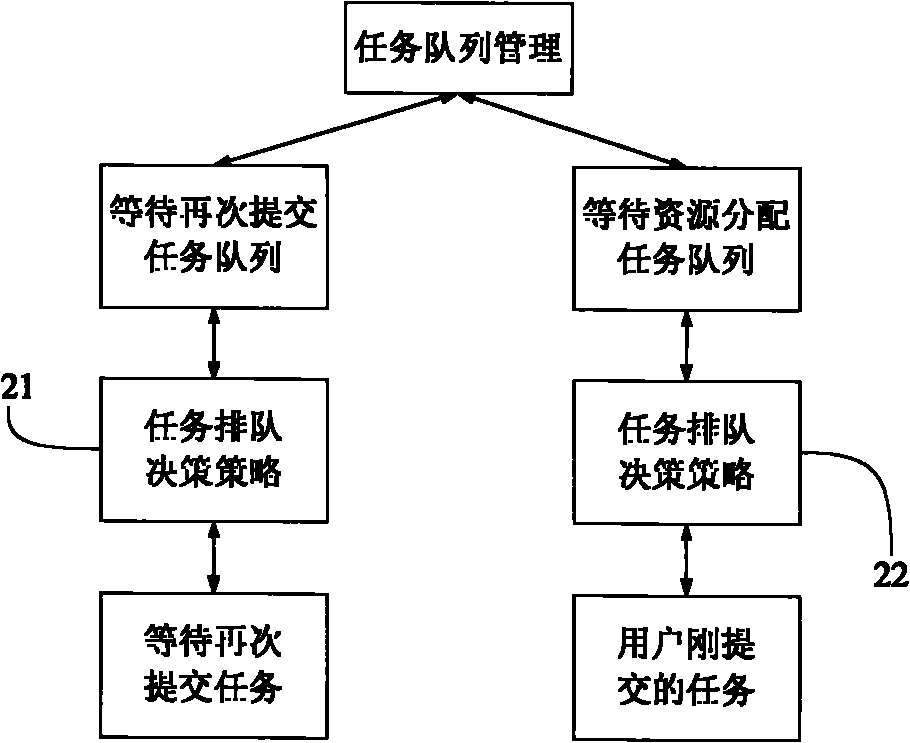

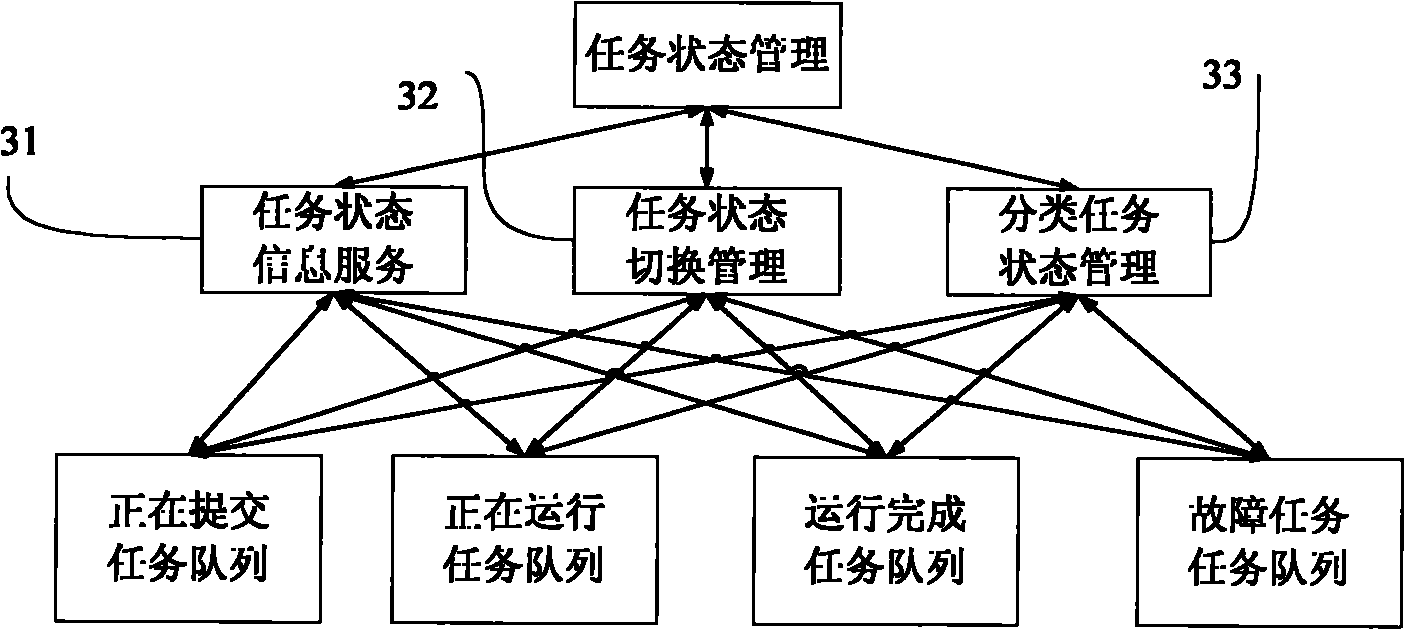

Cluster task dispatching manager used for multi-grid access

InactiveCN101958808AGuaranteed right of priorityTake advantage ofData switching networksWireless communicationCluster systemsResource allocation

The invention discloses a cluster task dispatching manager used for multi-grid access. Tasks on a cluster system are divided into local tasks and grid tasks, and a grid corresponding to the grid task is determined.Priority classification is carried out on the tasks, so as to ensure that cluster resource is allocated to the tasks according to task priority while the tasks are submitted. Meanwhile local task reservation resource occupying strategy is adopted, so as to ensure that the task from the grid can not contend cluster resource with the local task within valid reservation holding time when the local task has a great demand on resource. On the basis, a task dispatching and resource allocation strategy algorithm is provided, so as to ensure that required resource is timely and effectively allocated to the task. The invention can cause cluster task dispatching and management to be adaptive to that a cluster is simultaneously accessed by multiple grid systems, availability factor of cluster resource is fully improved, and task dispatching and management of cluster system are more flexible and convenient.

Owner:EAST CHINA JIAOTONG UNIVERSITY

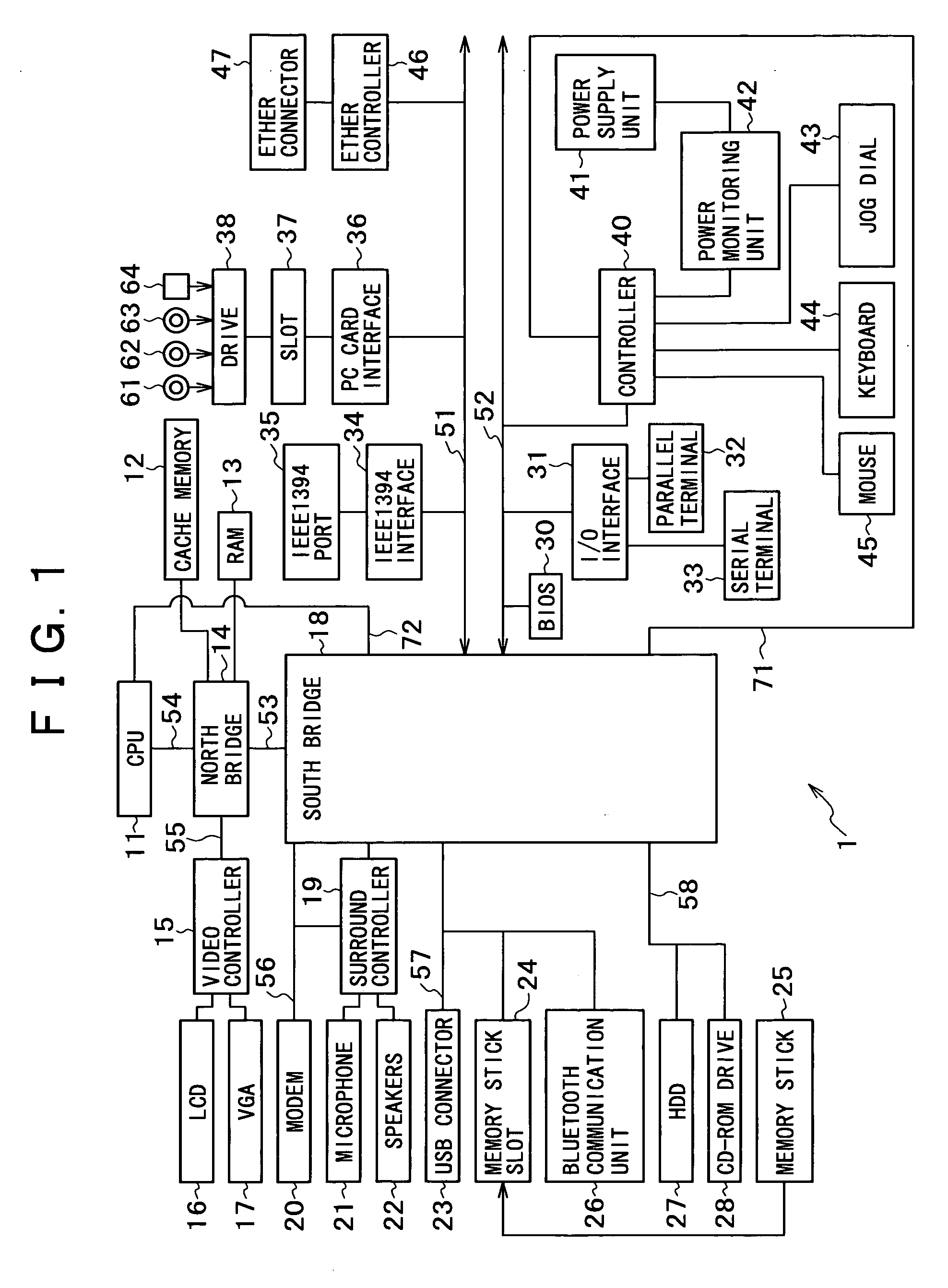

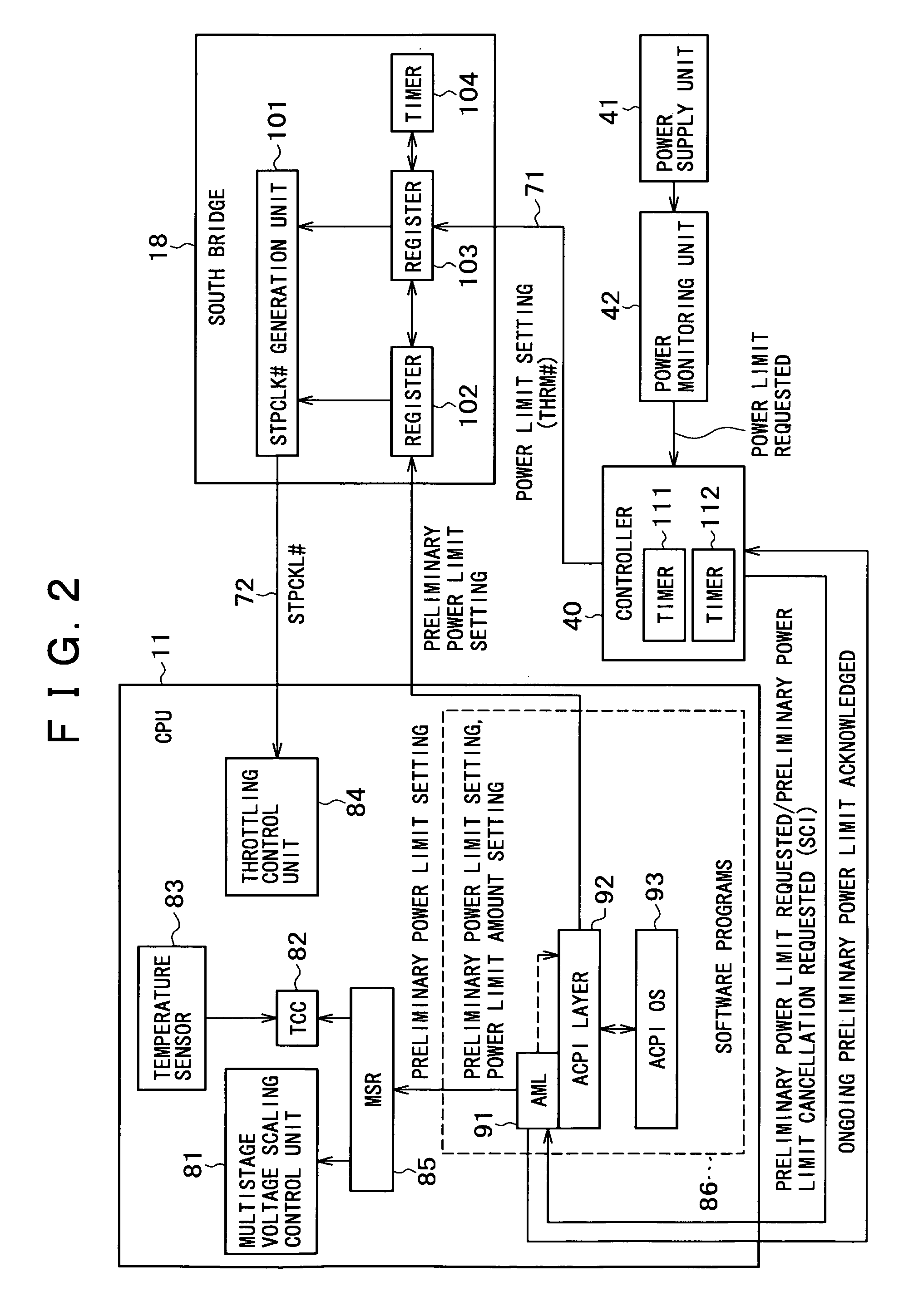

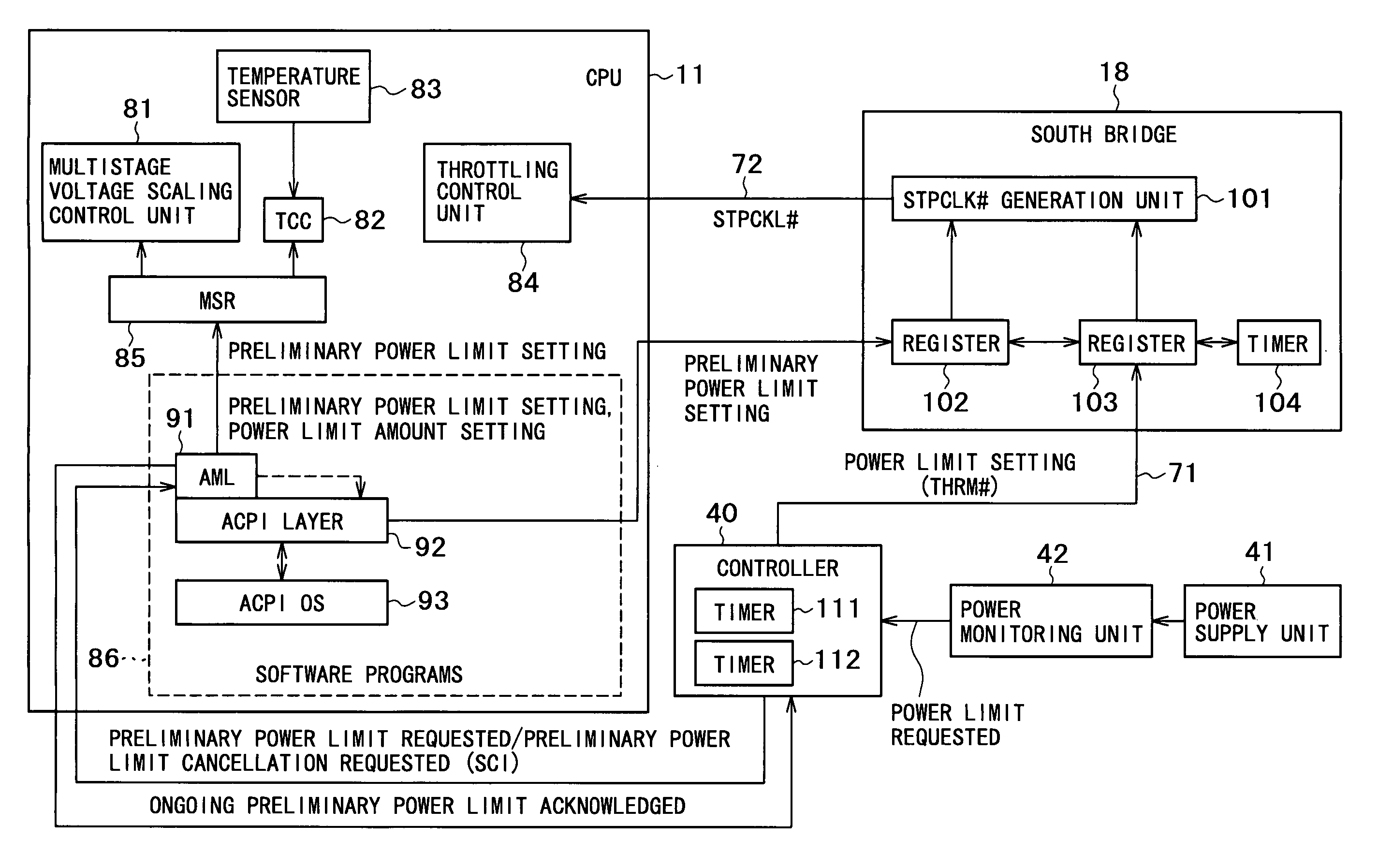

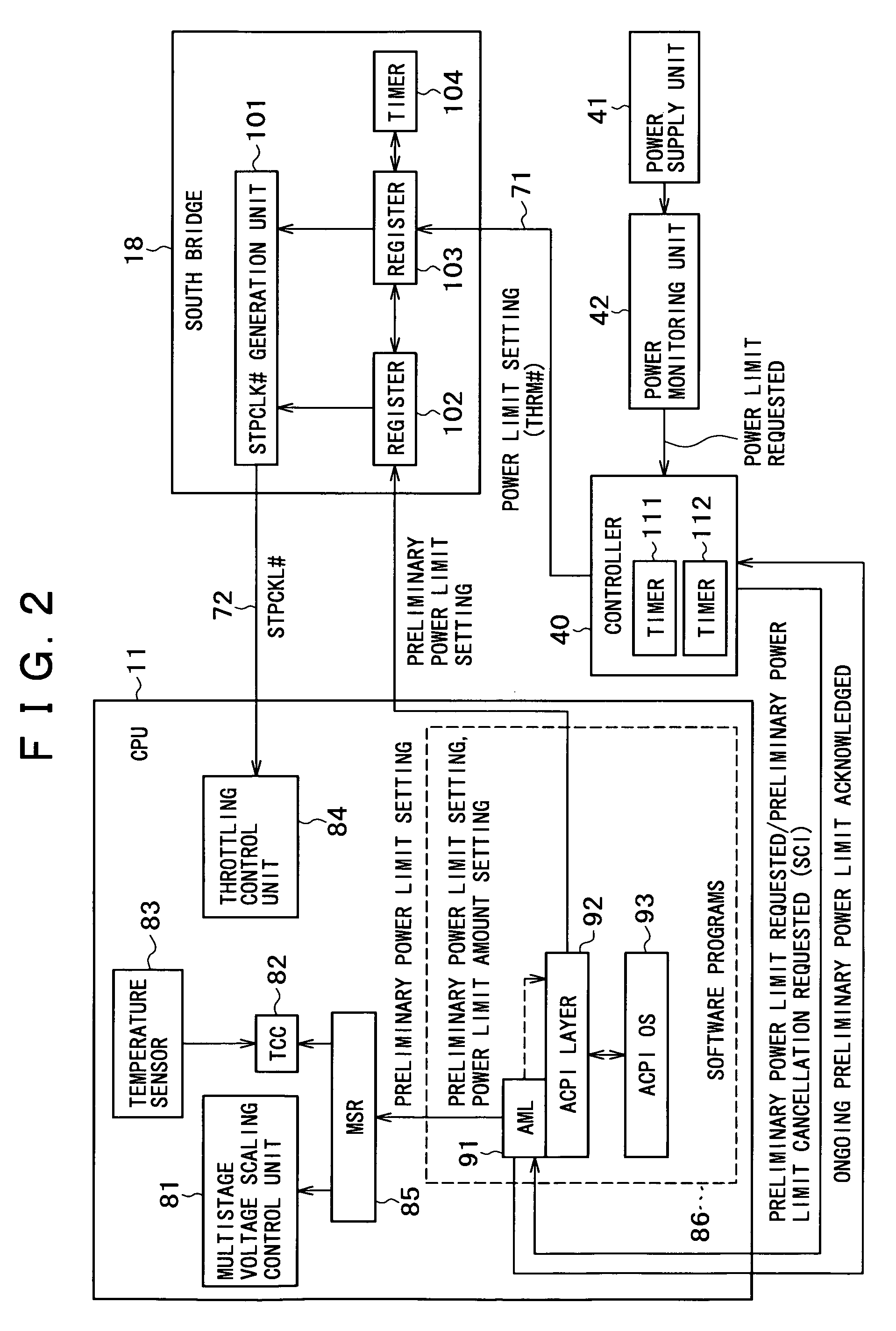

Information processing apparatus, information processing method, and program

InactiveUS20050022043A1Easy to shipImprove standardizationVolume/mass flow measurementHardware monitoringInformation processingControl set

An information processing apparatus having a processor is disclosed. The apparatus includes power monitoring means for monitoring power consumed by the information processing apparatus. The power monitoring means further outputs a power limit request demanding a limit to the power when the power being monitored exceeds a predetermined threshold. The apparatus also includes first setting means for setting a first control for limiting an availability factor of the processor as a limit to the power when the power monitoring means outputs the power limit request; second setting means for setting a second control for limiting the availability factor of the processor as a limit to the power when the power monitoring means outputs the power limit request; first controlling means for executing the first control set by the first setting means; and second controlling means for executing the second control set by the second setting means.

Owner:SONY CORP

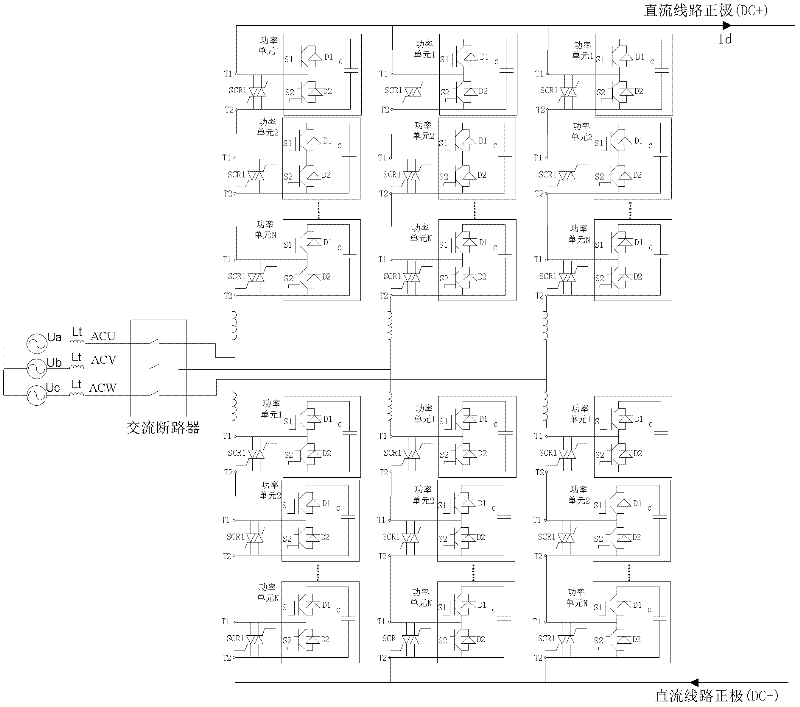

Method for protecting direct current line transient short-circuit fault of modular multiple-level converter

InactiveCN102403886AProtection securitySo as not to damageEmergency protective arrangements for limiting excess voltage/currentPower conversion systemsPower flowLevel converter

The invention relates to a method for protecting a direct current line transient short-circuit fault of a modular multiple-level converter, belonging to the technical field of direct current transmission. A group of two-way thyristor switch is connected on alternating current ports of each power unit of the modular multiple-level converter in parallel, when a direct current line has a transient short-circuit fault, control pulses of all of the power units are closed, and all of the two-way thyristor switches are triggered to be switched on at the same time, so that the short-circuit point of the direct current line is in natural arc extinction and disappears. When short-circuit current of the direct current line is detected to be zero, all of the two-way thyristor switches are controlled to be switched off, and the control pulses of all of the power units are opened, so that the converter runs again. With the adoption of the method, a switch device of the converter can be quickly protected from damage during a failure, and the direct current short-circuit point is in the natural arc extinction after failure, therefore, the device can automatically run again, thereby avoiding the complete off-stream of the device and greatly improving the reliability and the availability factor of the device.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

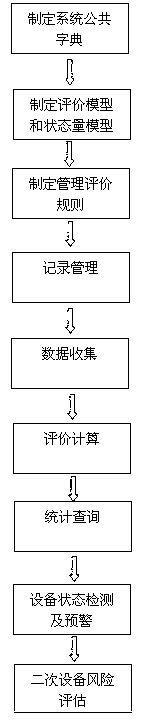

Secondary equipment intelligence state evaluation diagnostic system and method thereof

InactiveCN103218695APromote collaborationReduce downtimeResourcesSystems managementRecords management

The invention relates to secondary equipment, and in particular relates to a secondary equipment intelligence state evaluation diagnostic system and a method of the system. The secondary equipment intelligence state evaluation diagnostic system is specially characterized by comprising a system management module, a standard management module, an evaluation rule management module, a record management module, a data collection module, an evaluation management module, a statistical query module, an equipment state detecting and pre-warning module and a risk evaluation module. The secondary equipment intelligence state evaluation diagnostic system disclosed by the invention has the beneficial effects that the secondary equipment intelligence state evaluation diagnostic system firstly can reduce the outage time of the equipment, increases the reliability and availability factor of the equipment, reduces the recondition expense of the equipment, improves the operation performance of the equipment and increases the economical benefit. The secondary equipment intelligence state evaluation diagnostic system further can enhance cooperation between the operation department and the overhaul department, cancels unnecessary procedures, saves the management cost, reduces the operation and maintenance cost, and can quickly take recondition measures to eliminate failures of the equipment, thereby providing necessary technical conditions for promotion of large operation and overhauling.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

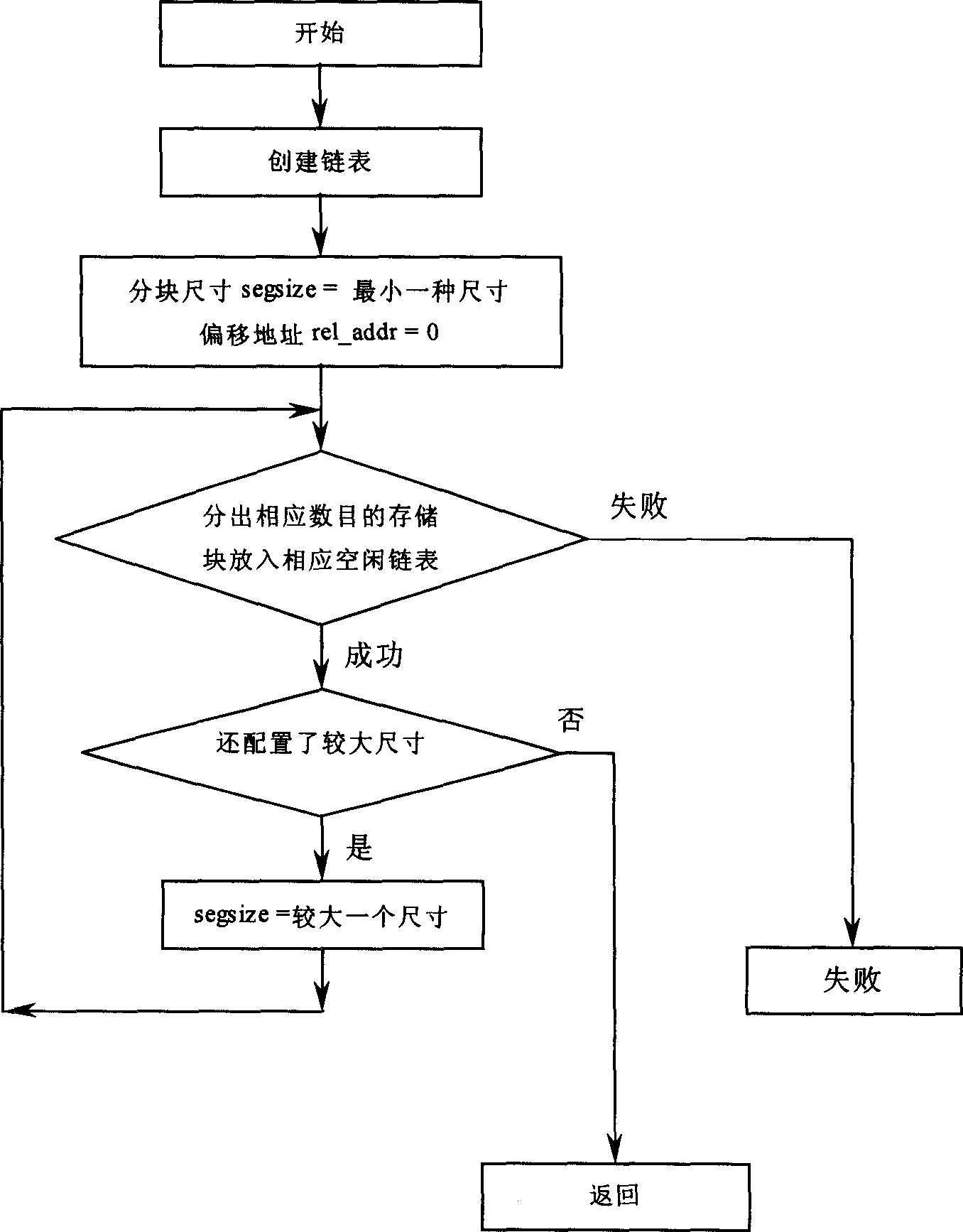

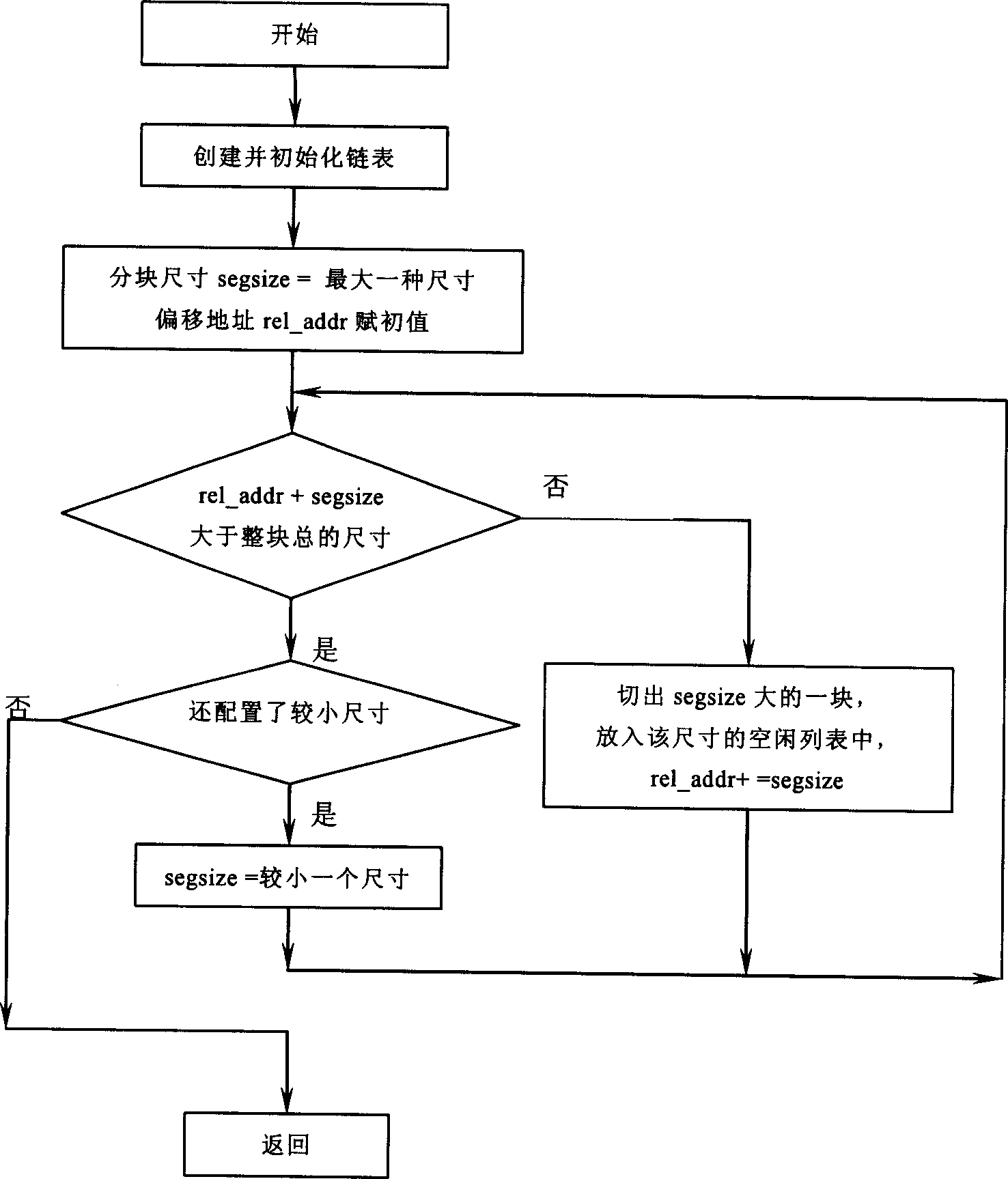

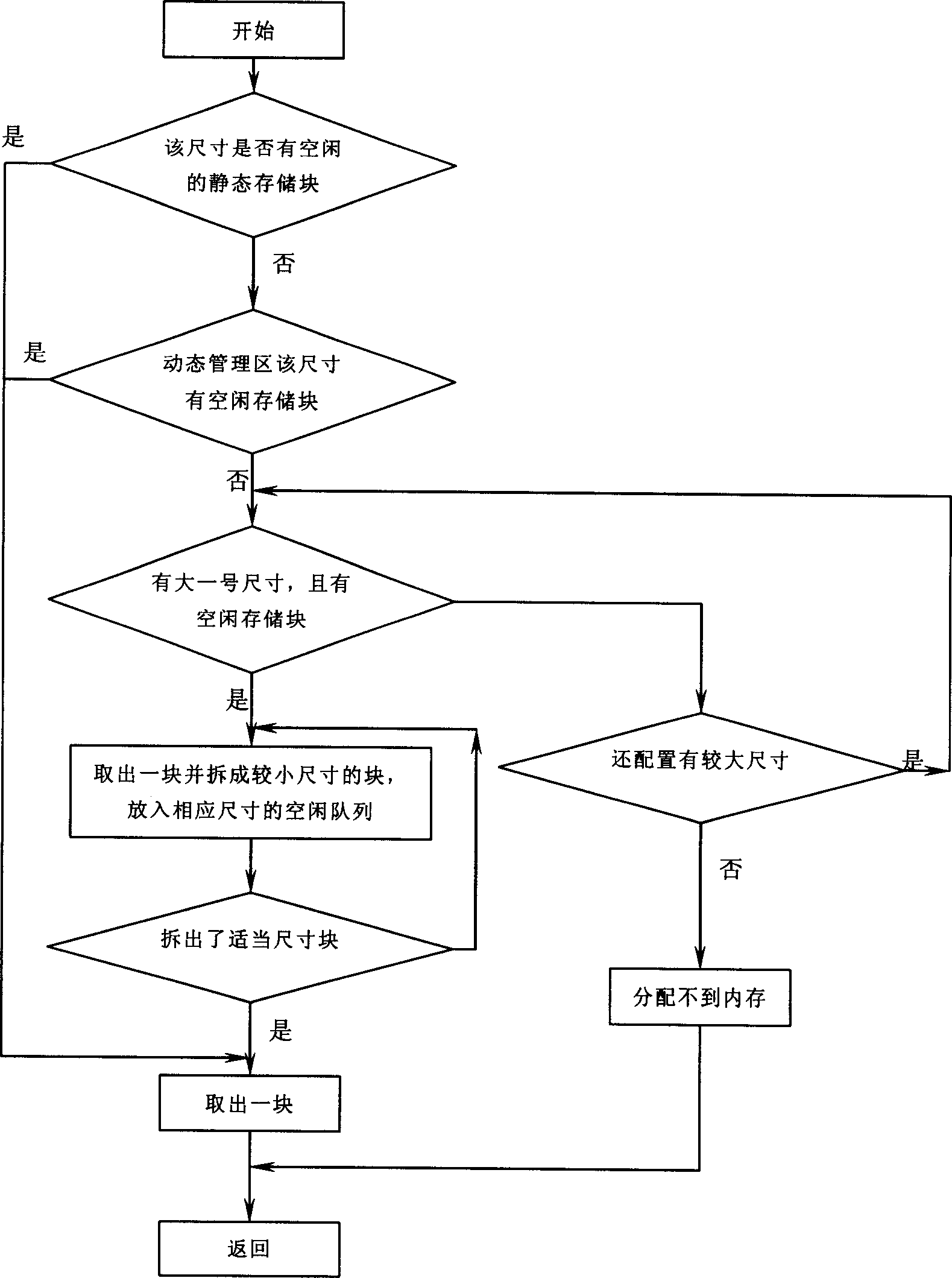

Method for storage area management with static and dynamic joint

InactiveCN1489334AReduce tensionMitigation efficiencyData switching networksSelection arrangementsLimited resourcesDynamic storage

The method divides the memory area into two portions: one portion is partitioned into static memory blocks in several sizes defined in advance; the other portion is shared dynamic memory area. In static memory, certain number of blocks is allocated for different memory sizes, and blocks will not be split or mergered. The shared dynamic memory area can be allocated dynamically. It is guaranteed that each memory block in various sizes possesses a minimum quantity in order to meet basic application. Meanwhile, limited resources of memory area are utilized fully. The invention assures service efficiency and utilization rate of memory area, solves conflict between shortage of memory area and low availability factor, as well as avoids complex maintenance in operation. The method is applied to management for each memory, data table and periphery memory area, as well as can manages multiform or / and multiple memory areas.

Owner:ZTE CORP

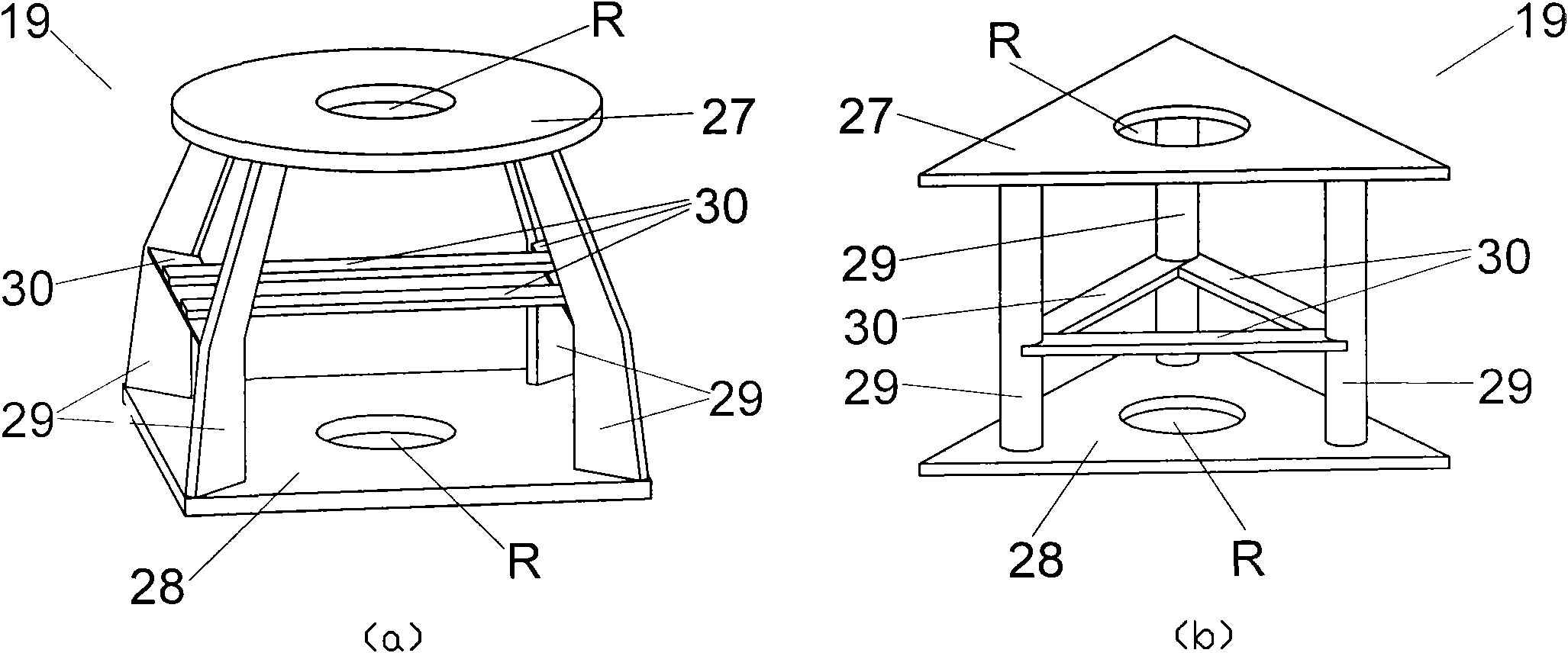

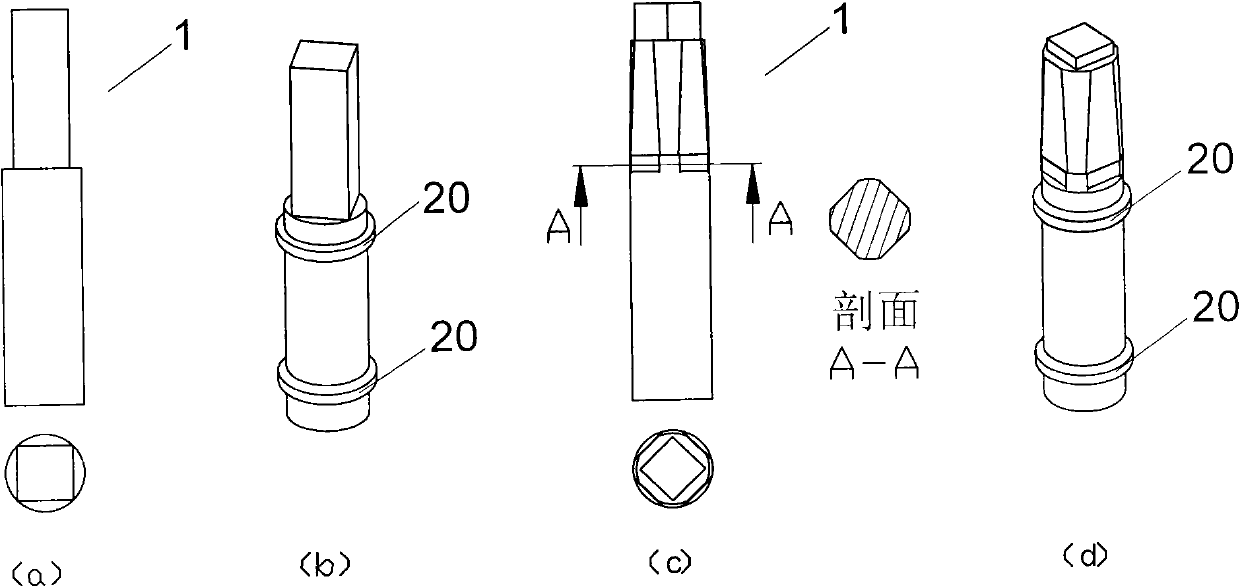

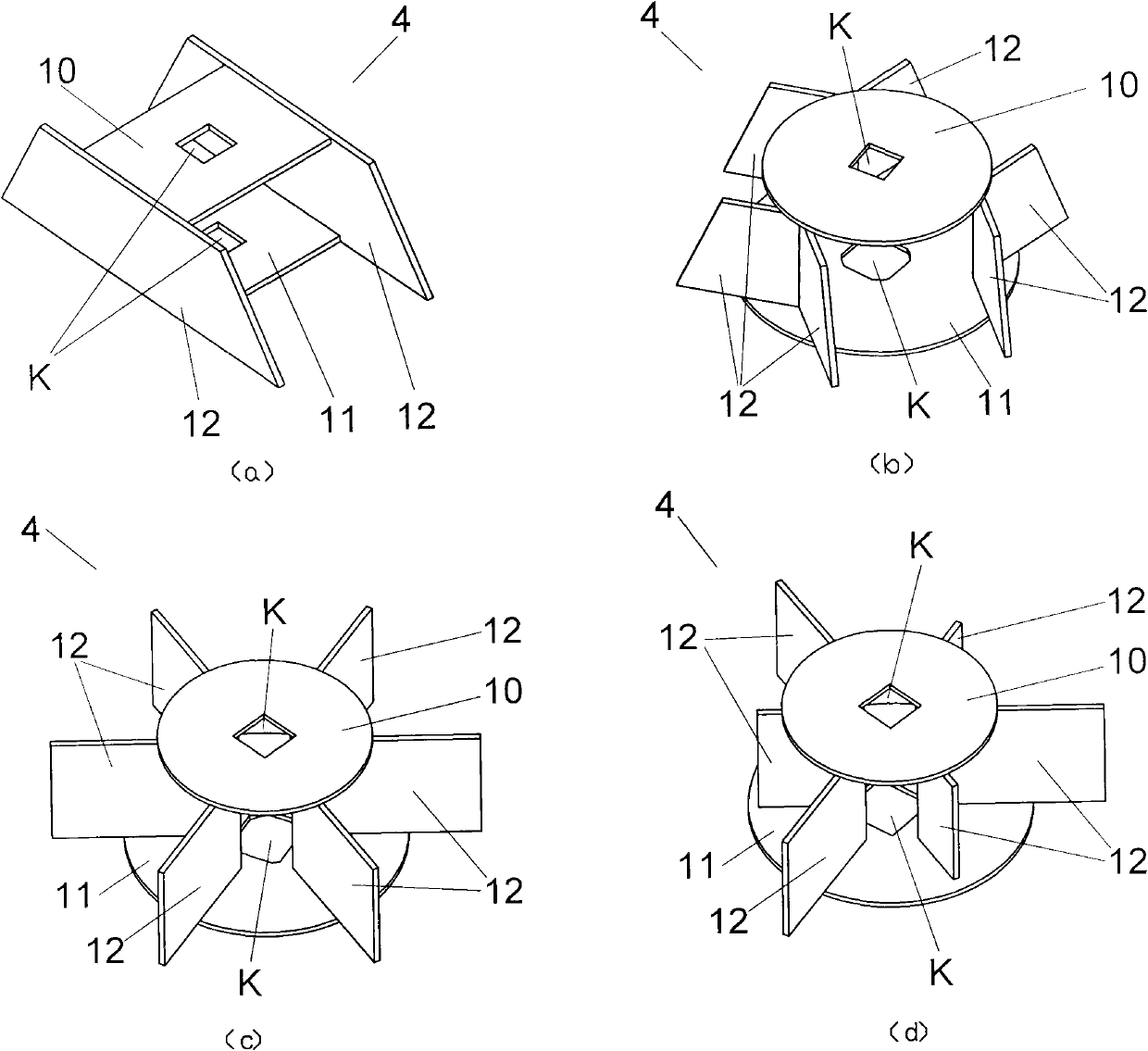

Vertical shaft fan of wind generating set

ActiveCN102213180AReduce installation costsReduce manufacturing costMachines/enginesWind energy generationEngineeringUltimate tensile strength

The invention discloses a novel vertical-shaft fan structure of vertical shaft wind generating set, wherein the novel vertical-shaft structure is designed according to the unique blade operation characteristic of a vertical-shaft fan. In the invention, by virtue of the direct correlation among blades, a compact main shaft assembly, an installation mode and other construction, the availability factor of a wind wheel support part is exponentially improved, the power transmission paths of the blades are scattered, and the length of the arm of force of a transmission component is decreased, so that the stress uniformity is improved, the vibration source of the blades is removed, thus the intensity requirement of the wind wheel support part is exponentially reduced, and the intensity requirement of a hub and a main shaft is reduced at the same time, and the transportation and installation of the fan are convenient. Therefore, the fan structure in the invention has the advantages of small centrifugal load, light weight, easiness for installation, easiness for transport and low cost.

Owner:李锋

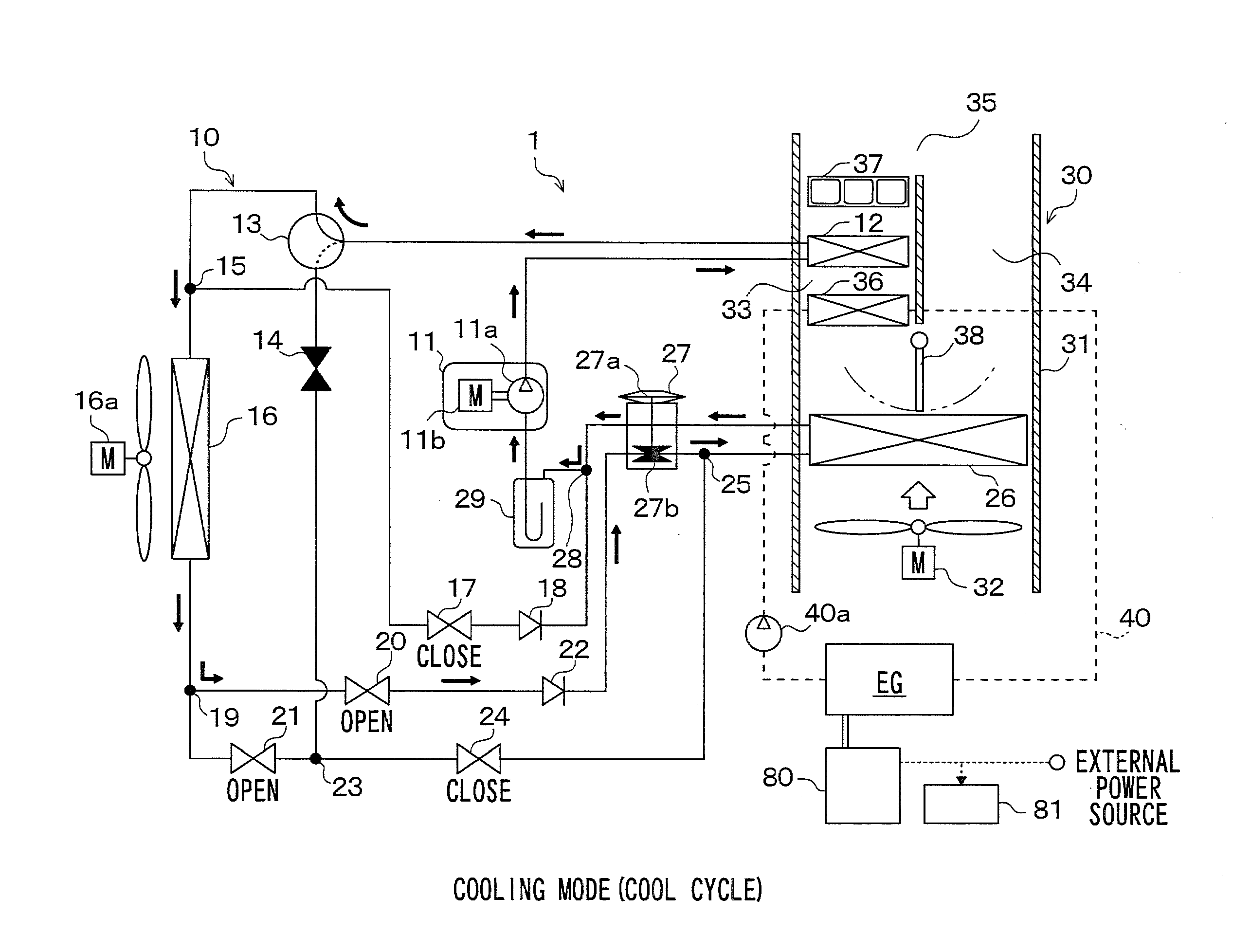

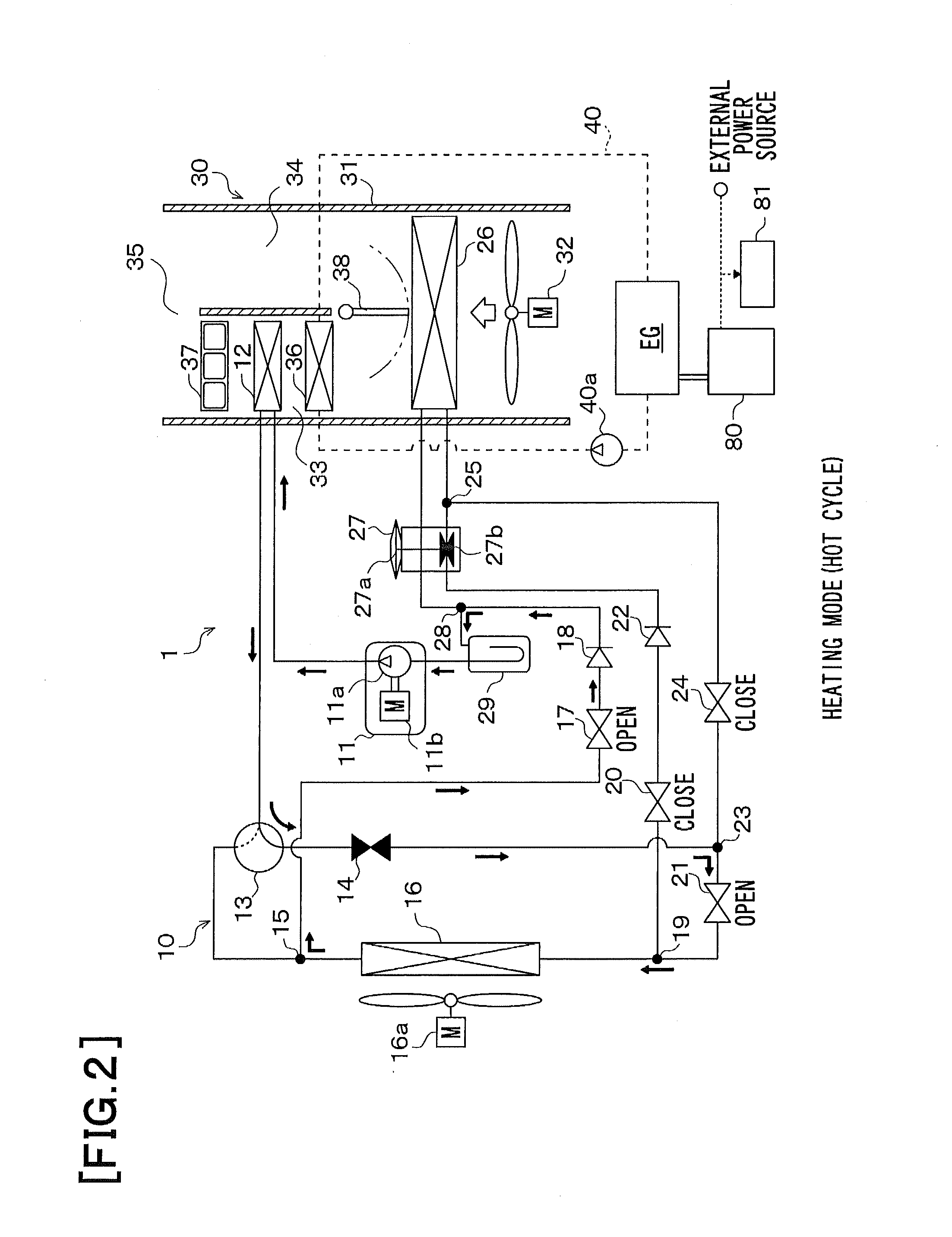

Air conditioner for vehicle

InactiveUS20140102666A1Reduced availabilityReduce power consumptionAir-treating devicesCoolant flow controlPower conditionerEngineering

An air conditioner for a vehicle includes a blower that generates blown air; a heating heat exchanger that heats the blown air by heat exchange between the blown air and a heat medium; a target temperature setup device that sets a target temperature for a passenger compartment in accordance with an operation performed by an occupant; and a control device that determines the availability factor of the blower in accordance with the temperature of the heat medium wherein the control device increases the availability factor of the blower as the target temperature increases.

Owner:TOYOTA JIDOSHA KK

Resource state-based virtual machine structure adjustment method and adjustment system

InactiveCN102331948AAdjust in timeIncrease profitResource allocationSoftware simulation/interpretation/emulationResource poolWeb application

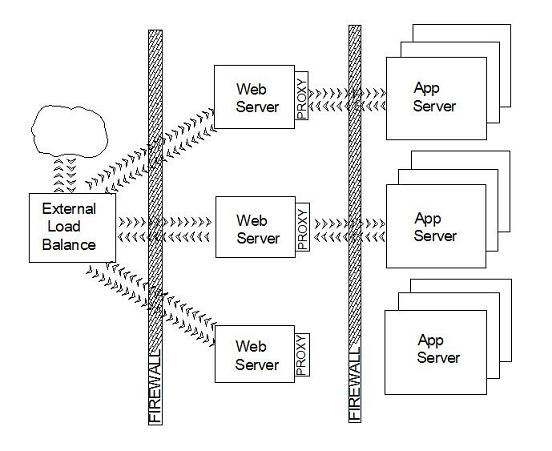

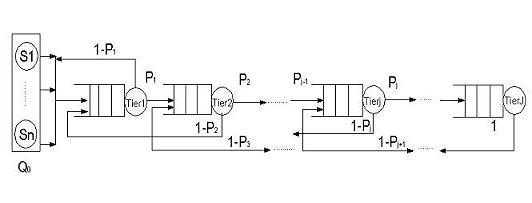

The invention relates to a resource state-based virtual machine structure adjustment method and adjustment system. A corresponding virtual machine mechanism is obtained by calculating the minimum value of a cost function at the current stage of multi-layer Web application; further, various types of virtual machines can be configured by realizing the minimum cost at the current stage of the multi-layer Web application; when a client request of the multi-layer Web application changes, a virtual machine structure which is distributed to the application in a cloud resource pool is timely adjusted, so that the technical effects of optimizing cloud resources and modifying the utilization ratio of the entire cloud platform resource are achieved; meanwhile, reliable response time and availability factor can be provided for a tenant. That is to say, a cloud platform service provider can meet a cloud tenant requirement with the minimum cost through the technical scheme provided by the invention.

Owner:HANGZHOU WANYUN COMPUTING TECH

Fan of vertical shaft wind generating set

ActiveCN102213180BImprove the uniformity of forceIncrease centrifugal loadMachines/enginesWind energy generationEngineeringUltimate tensile strength

Owner:李锋

Heating process of low-temperature flue gas with wetting flue gas desulphurization

InactiveCN101701717AEasy to liftImprove diffusivityLighting and heating apparatusAir preheaterFlue gas

Owner:XIAN THERMAL POWER RES INST CO LTD

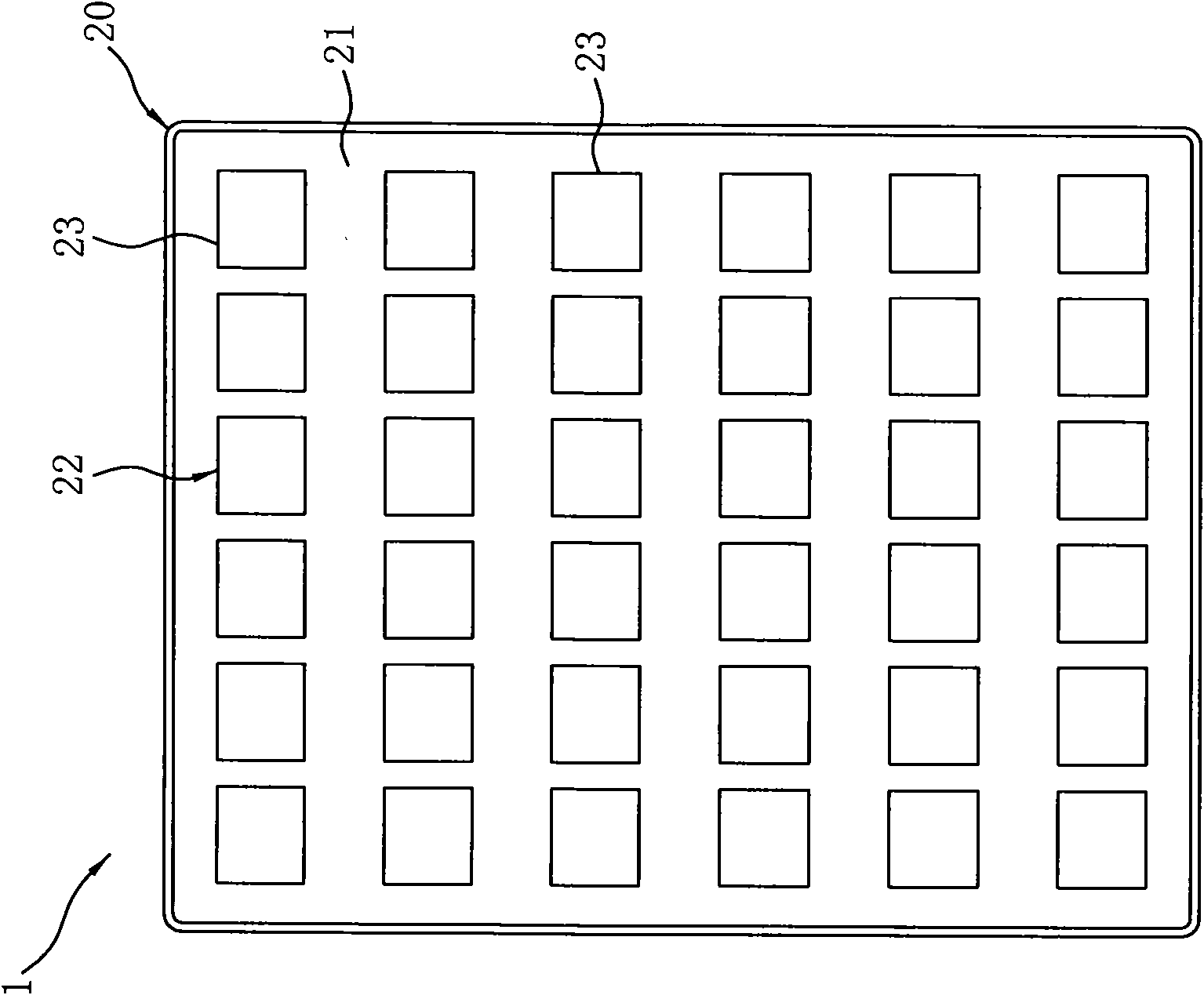

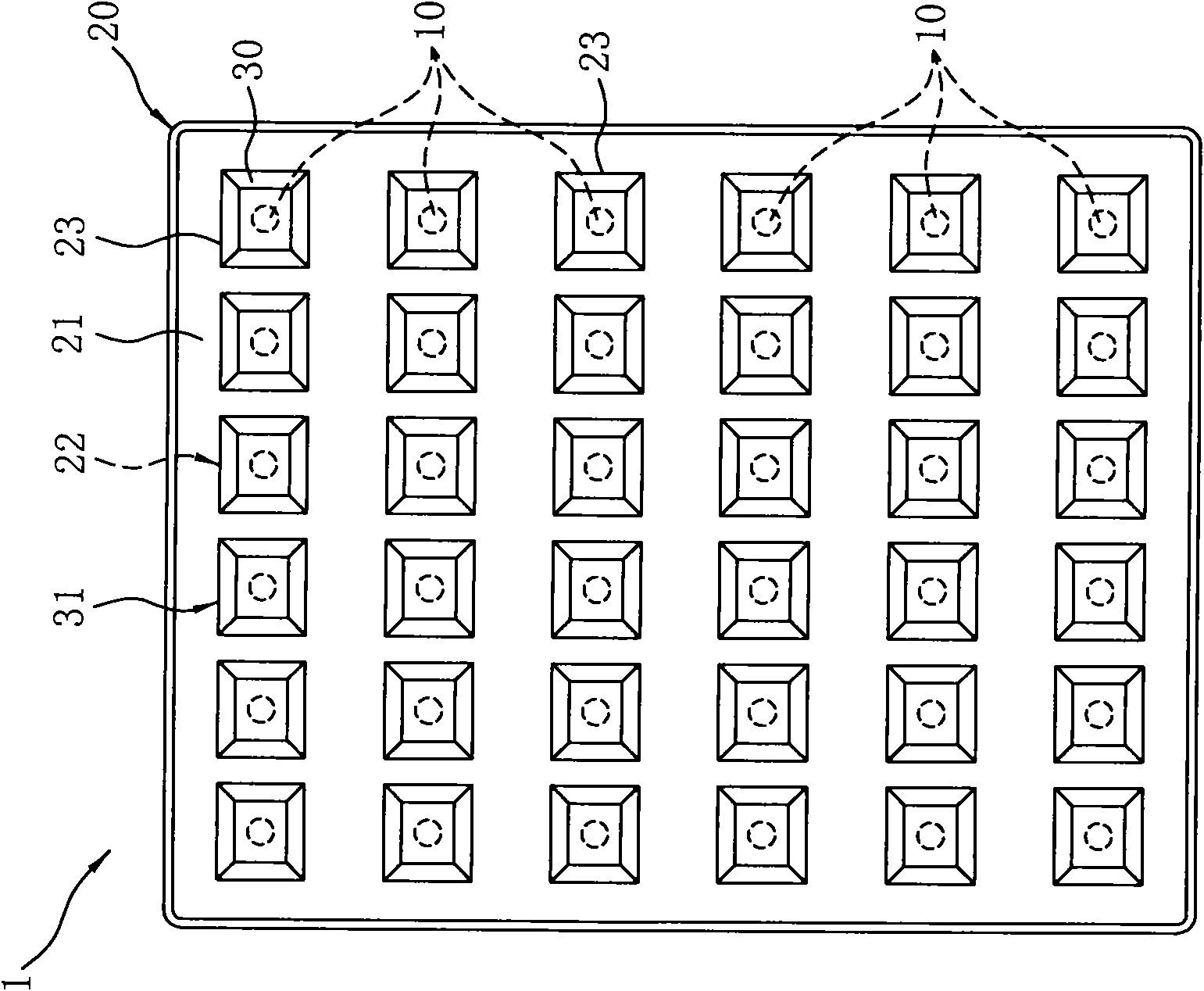

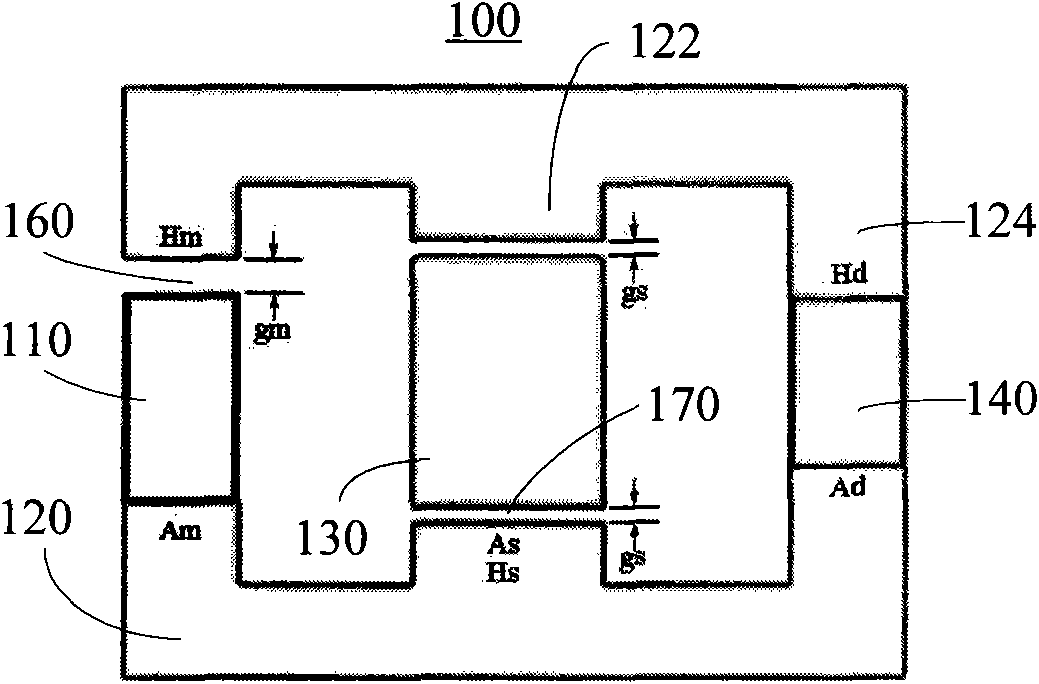

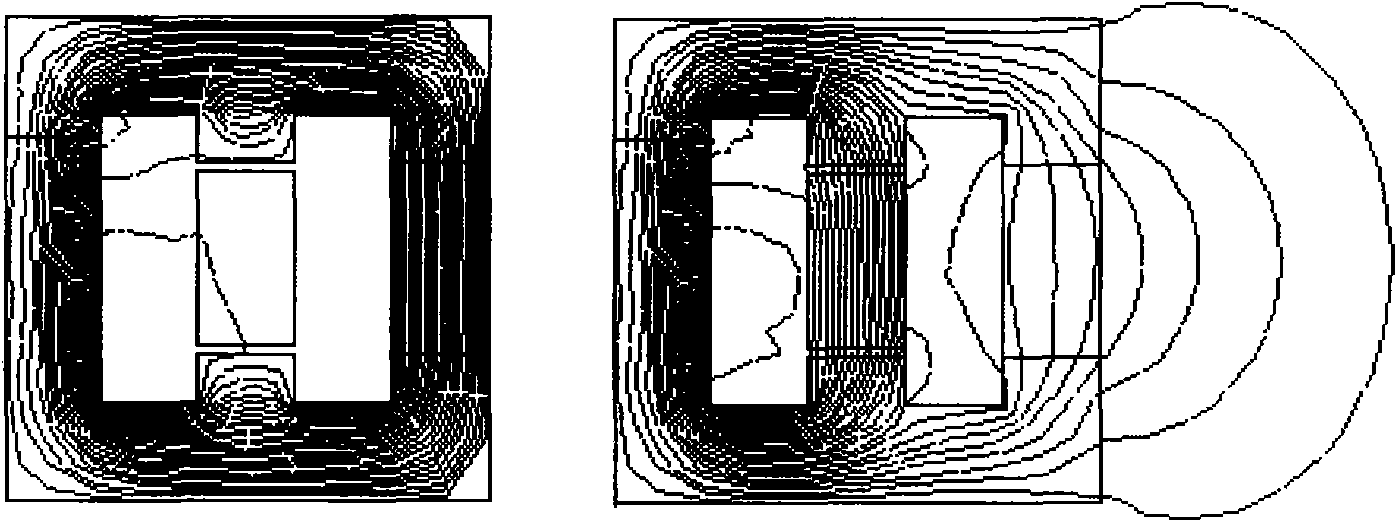

Light emitting diode lighting device

The invention discloses a light emitting diode (LED) lighting device, which comprises a light emitting diode (LED) array and an external holder. The LED array is formed by arraying a plurality of light emitting diodes (LED) in a certain pattern; and the external holder is hermetically covered on the front periphery of the LED array, prevents water and protects the LED array. A hole slot array is arranged on a corresponding plate surface of the external holder facing the LED array. A plurality of 2nd lenses used together with the LEDs are correspondingly embedded in hole slots of the hole slot array respectively and are combined with the hole slot array to form a second lens array so as to outwards project the LED light generated by the LED array by the second lens array. The lighting device has multiple functions of reducing loss in the use process, improving effective illumination level, simplifying assembly, improving optical efficiency, enhancing availability factor and the like.

Owner:CREATE ELECTRONICS OPTICAL

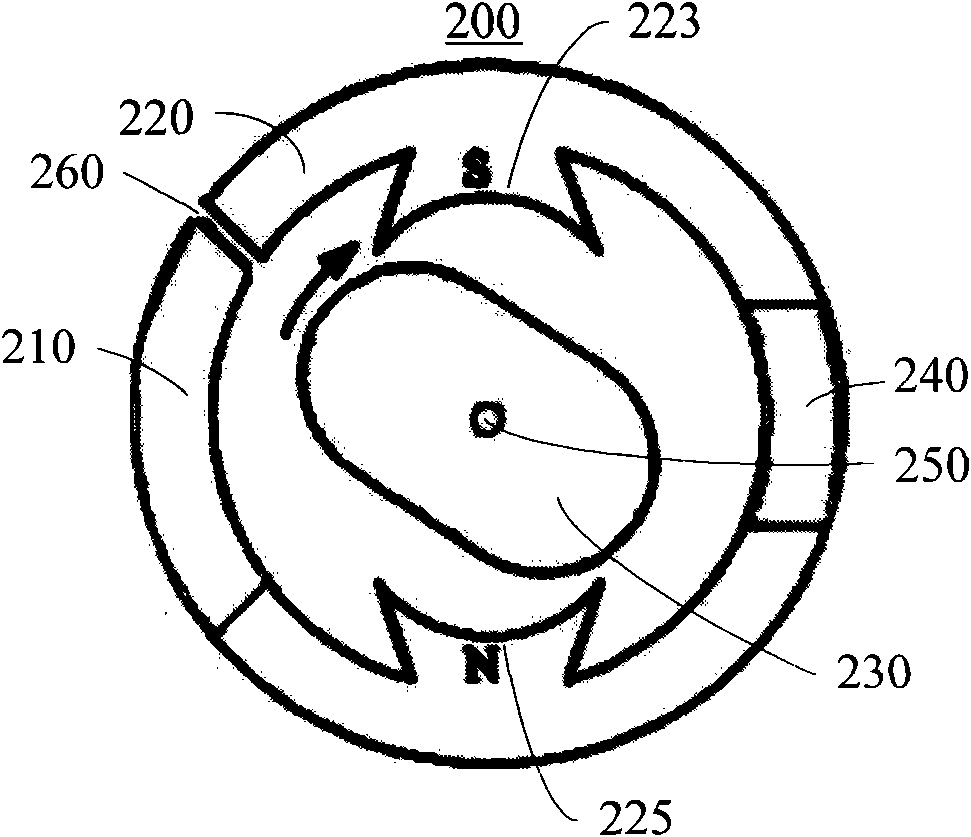

Thermomagnetic power plant

Owner:方李明

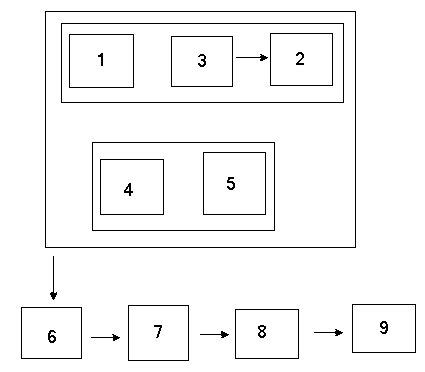

Multi-factor application selection

InactiveCN1736080AQuality improvementSpecial service provision for substationNetworks interconnectionMobile deviceMultiple factors

A method for selecting an application to deliver content in a networked consumer environment ( 12 ) is based on multiple factors. Generally, application selection is based on factors associated with a desired content to be communicated and / or rendered, a desired location and certain capabilities and conditions of applications and consumer electronic (CE) devices in a network ( 18 ). In various embodiments, the method is based on any combination of equivalent content, content type, sink resource, content source, preference, and resource availability factors. In another aspect of the invention, a consumer environment for multi-factor application selection includes a network with various combination of sink resources ( 22 ), source resources ( 24 ), processing resources ( 26, 30 ), and external communication resources ( 28, 32 ). The network ( 18 ) may also include mobile devices ( 34 ).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

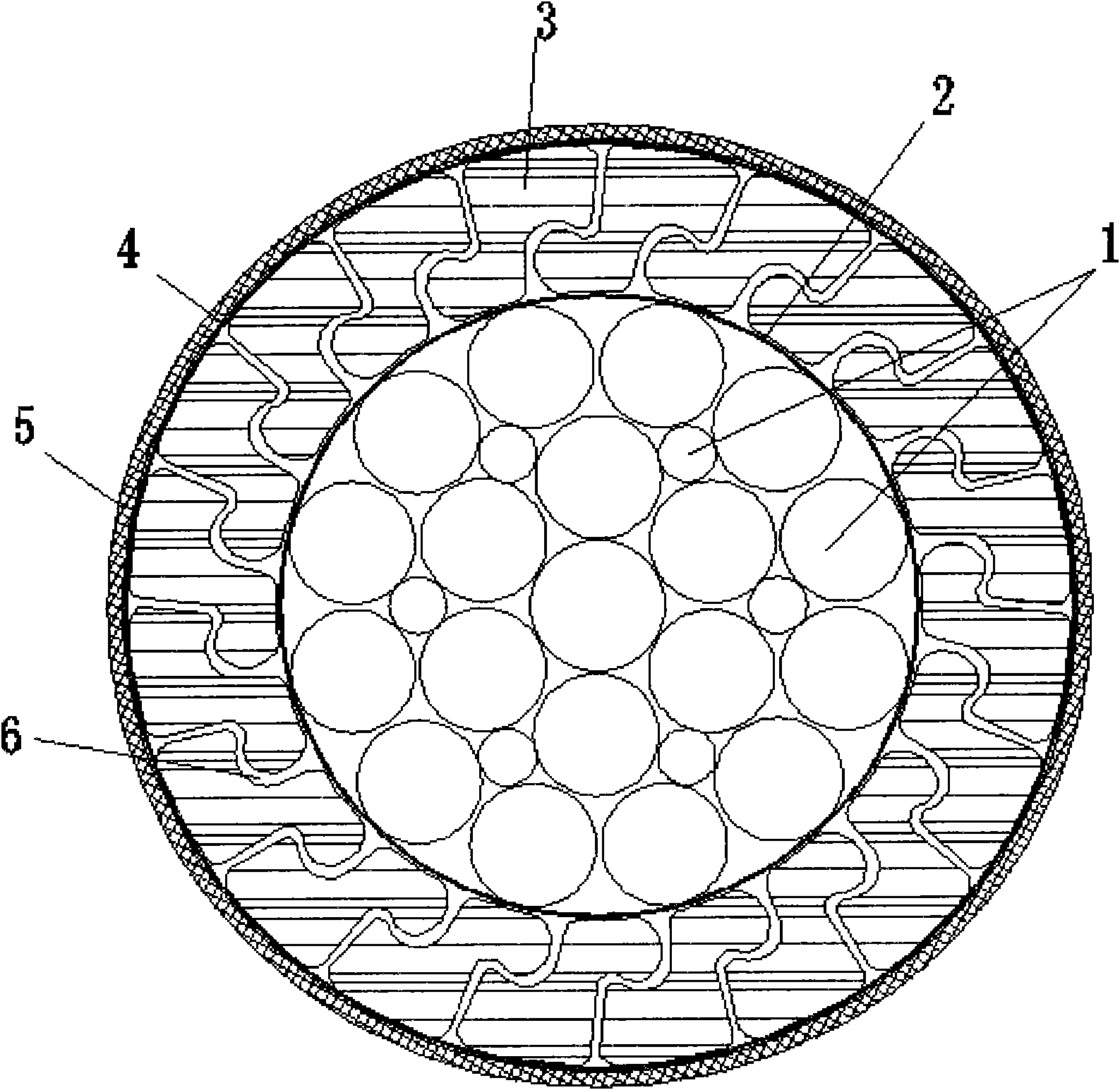

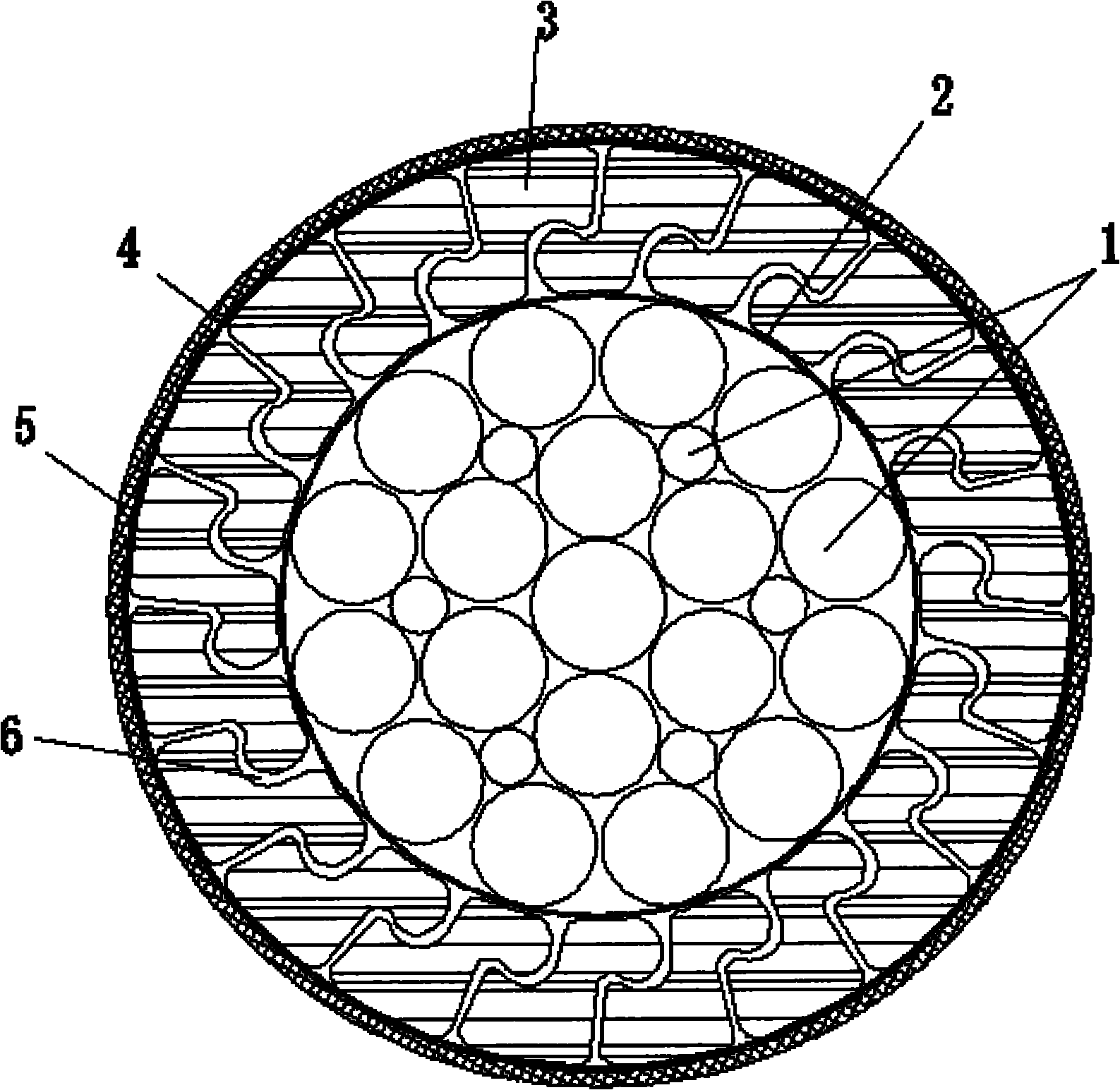

Composite inhaul cable with totally-closed carbon fiber wires and high-strength steel wire

InactiveCN101806037AEffective protectionAvoid enteringBridge structural detailsTextile cablesFiberPolyester

The invention relates to a novel cable body structure of a composite inhaul cable with totally-closed carbon fiber wires and a high-strength steel wire, which is mainly used for inhaul cables in large-span structures such as cable rope bearing bridges and cable-strut tension structures. A high-strength steel wire (1) of the composite inhaul cable is positioned at the core part of the composite inhaul cable; an inner-layer polyester fiber high-strength wrapping tape (2) winds around the high-strength steel wire (1); Z-shaped carbon fiber wires (3) of which the outer parts are occlusive mutually wrap the inner-layer polyester fiber high-strength wrapping tape (2); an outer-layer polyester fiber high-strength wrapping tape (4) winds outside the Z-shaped carbon fiber wires (3) of which the outer parts are occlusive mutually; and a peripheral high-density polyethylene sheath (5) wraps the outer-layer polyester fiber high-strength wrapping tape (4). The novel cable body structure can ensure that a totally-closed carbon fiber wire layer can still prevent harmful substances such as water and gas from entering the steel wire cable body of which the core part zinc-coated wire when plastic sheaths of the inhaul cable are damaged unexpectedly or cracks with aging after the plastic sheaths are used for years, and can reduce the dead weight of the cable body and improve the availability factor of the inhaul cable.

Owner:SOUTHEAST UNIV

Information processing apparatus, information processing method, and program

InactiveUS7171572B2Easy to shipWithout running the risk of quality defectsVolume/mass flow measurementHardware monitoringControl setInformation processing

An information processing apparatus having a processor is disclosed. The apparatus includes power monitoring means for monitoring power consumed by the information processing apparatus. The power monitoring means further outputs a power limit request demanding a limit to the power when the power being monitored exceeds a predetermined threshold. The apparatus also includes first setting means for setting a first control for limiting an availability factor of the processor as a limit to the power when the power monitoring means outputs the power limit request; second setting means for setting a second control for limiting the availability factor of the processor as a limit to the power when the power monitoring means outputs the power limit request; first controlling means for executing the first control set by the first setting means; and second controlling means for executing the second control set by the second setting means.

Owner:SONY CORP

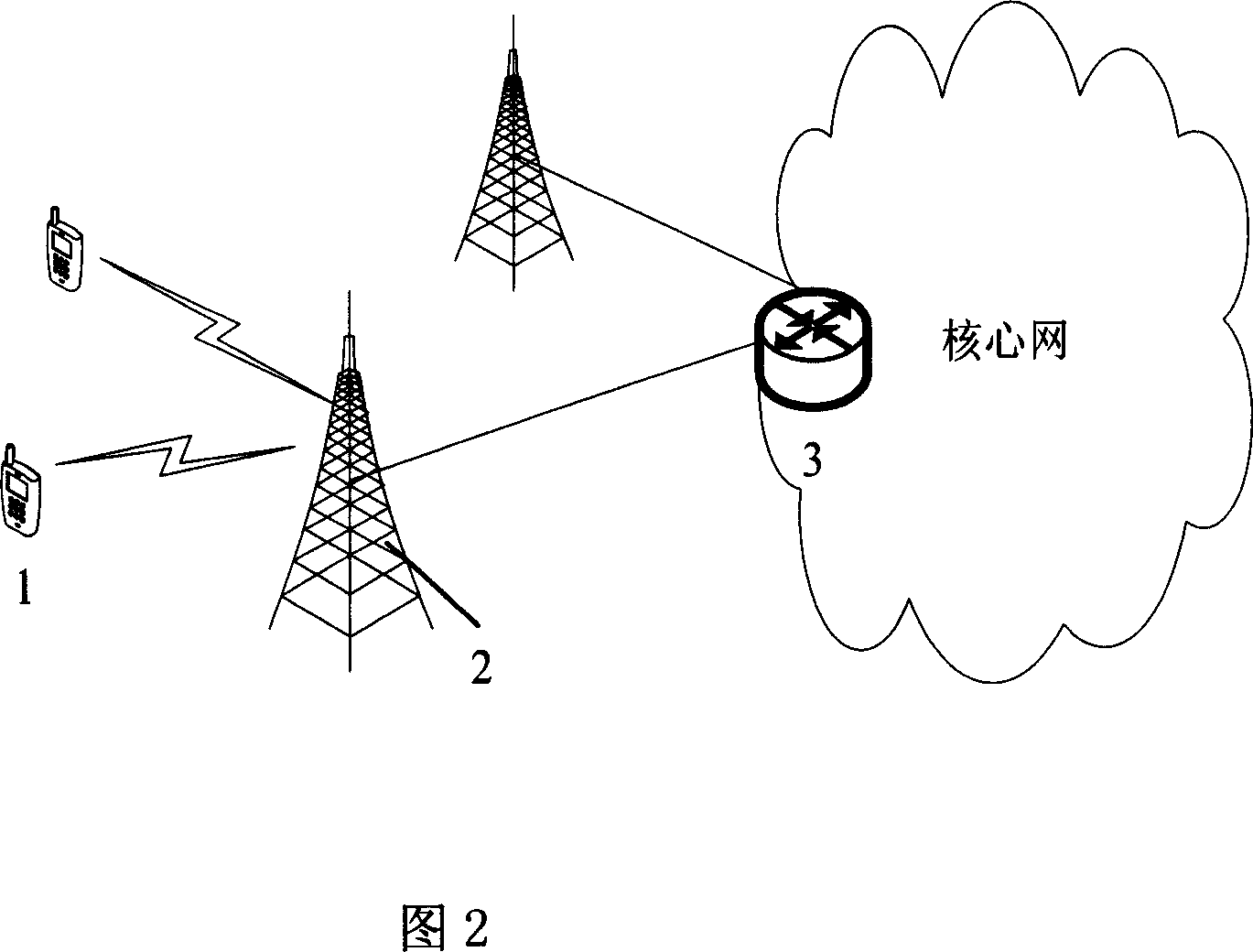

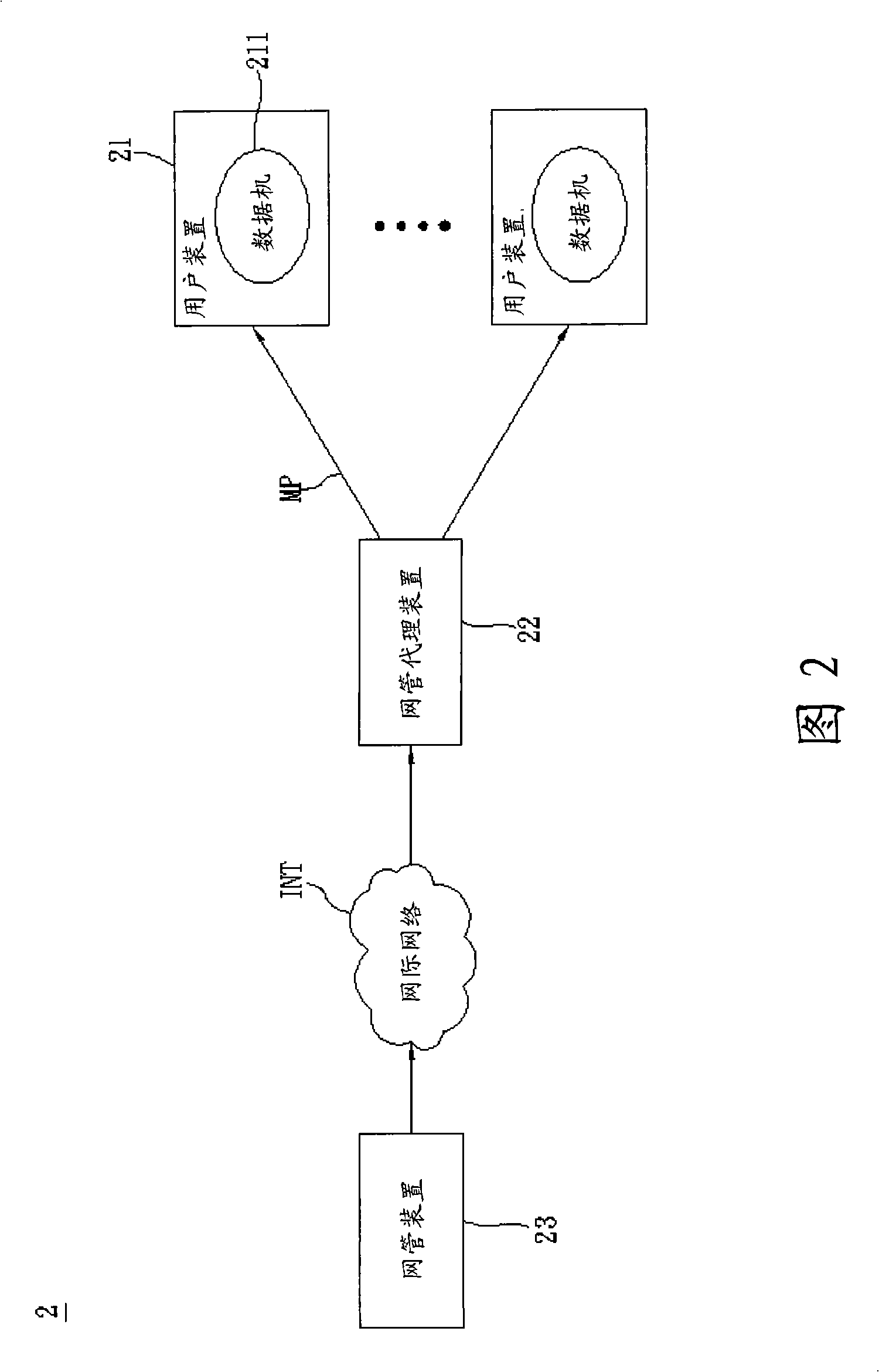

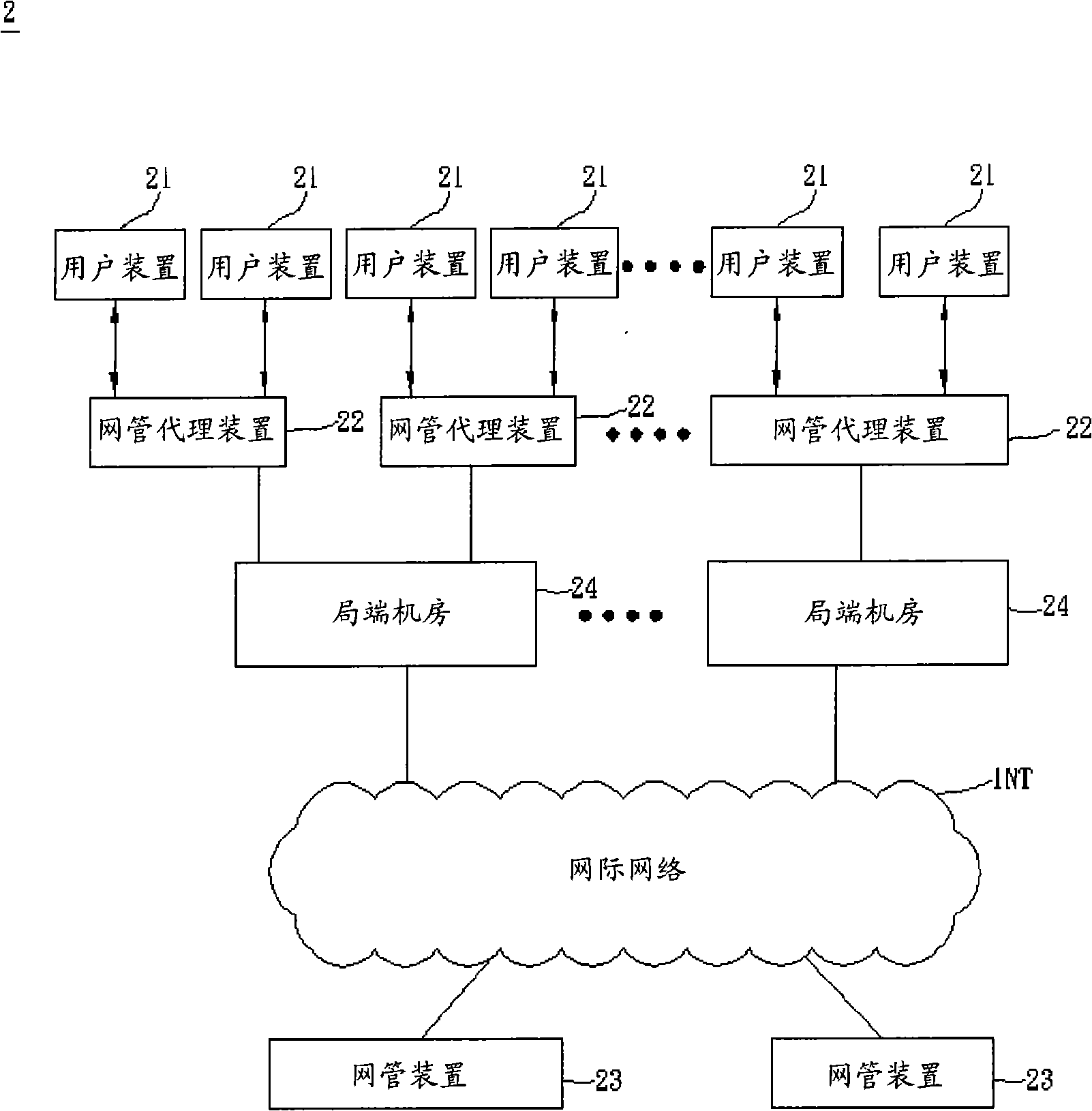

Communication Network, Communication Network Management Method, and Management System

InactiveUS20170310581A1Low costImprove convenienceData switching networksNetwork managementDistributed computing

Disclosed is a communication network management method provided with a plurality of communication devices and a management system to transmit packets between a plurality of communication devices through a communication path established by the management system. The management system establishes a communication path for a first service necessitating a guarantee of an availability factor on the basis of a first establishment policy in which communication paths that share the same route even in a part of the communication network are consolidated. The management system establishes a communication path for a second service that does not necessitate a guarantee of an availability factor on the basis of a second establishment policy in which the routes to be used are distributed over the entire communication network. The establishment policy is changed depending on a service type.

Owner:HITACHI LTD

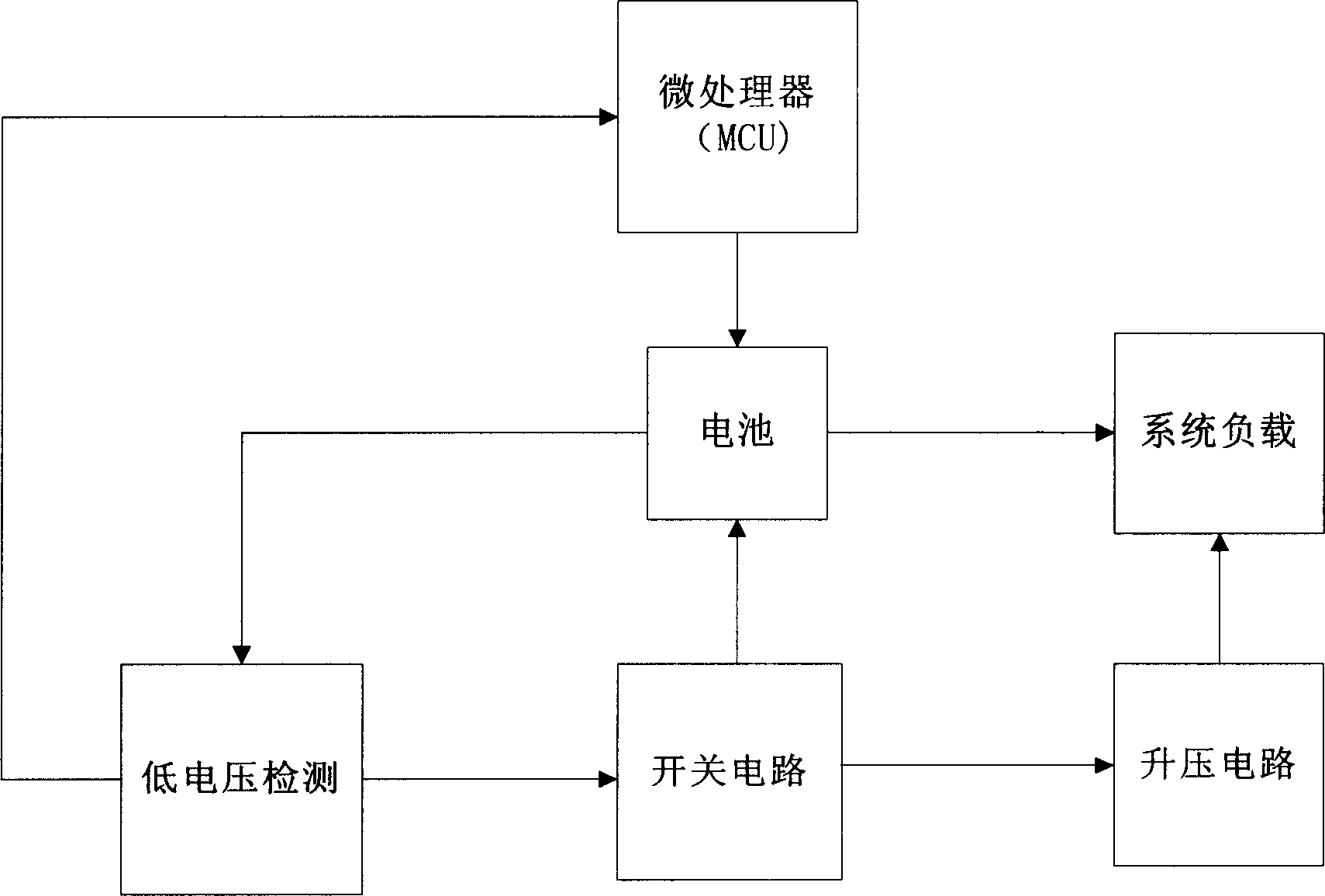

Method for improving battery availability factor

InactiveCN1734826ATake advantage ofExtended use timePrimary cell maintainance/servicingElectrical testingElectrical batteryLow voltage

This invention provides a method to improve battery utility, which comprises steps as follows: inputting battery voltage into portable system, setting separately direct supplying and outputted duplex feeding after lifting voltage; when using, detecting and determining the low voltage for battery; when it is larger than normal operating voltage, using direct supplying type; or else, taking lift voltage operation firstly then supplying power; starting automatic shut-down battery voltage detection to control work state of device. The invention can make good use of battery voltage, prevents from sudden shut down, prolongs service time, and is convenient to realize and spread.

Owner:上海贝豪通讯电子有限公司

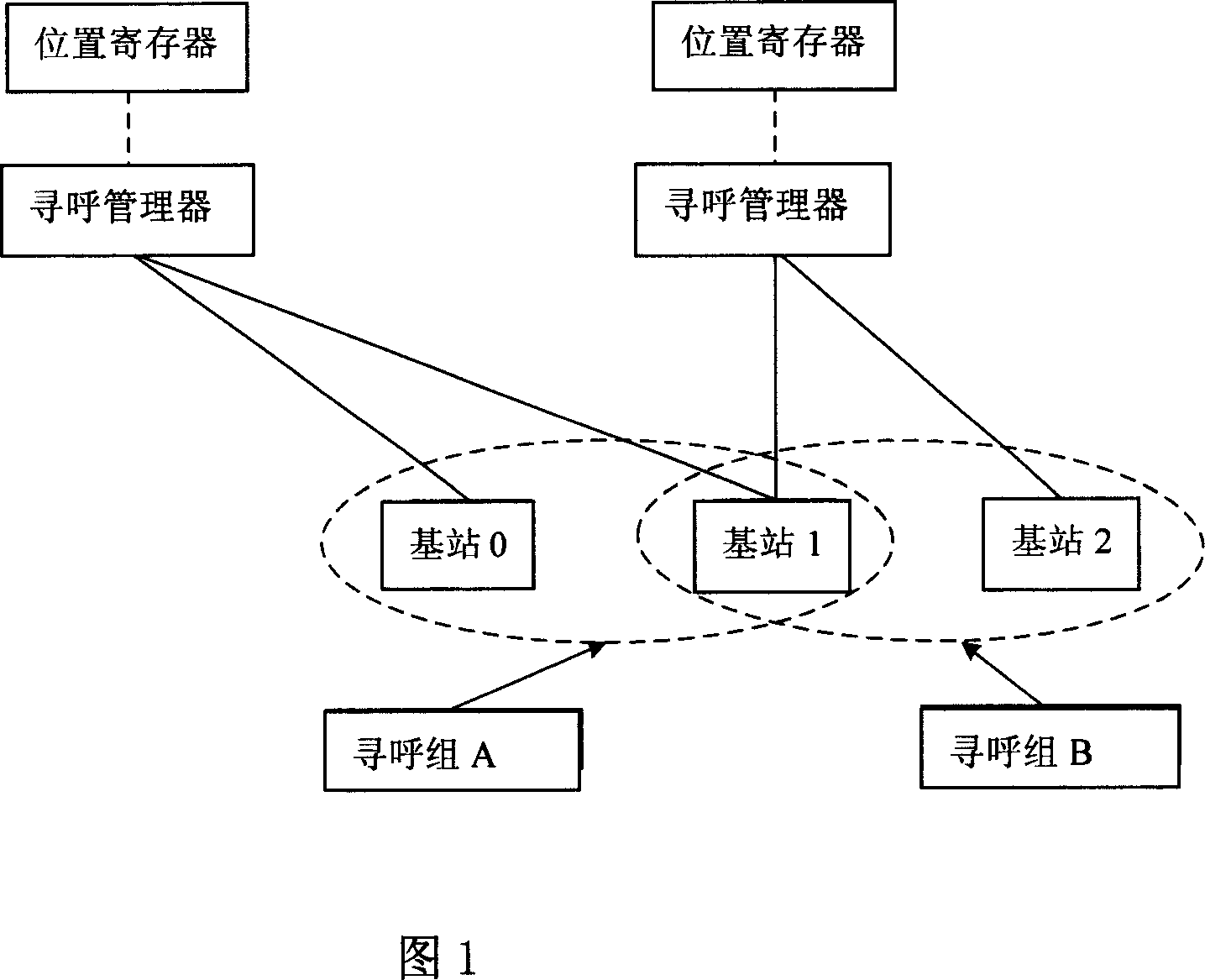

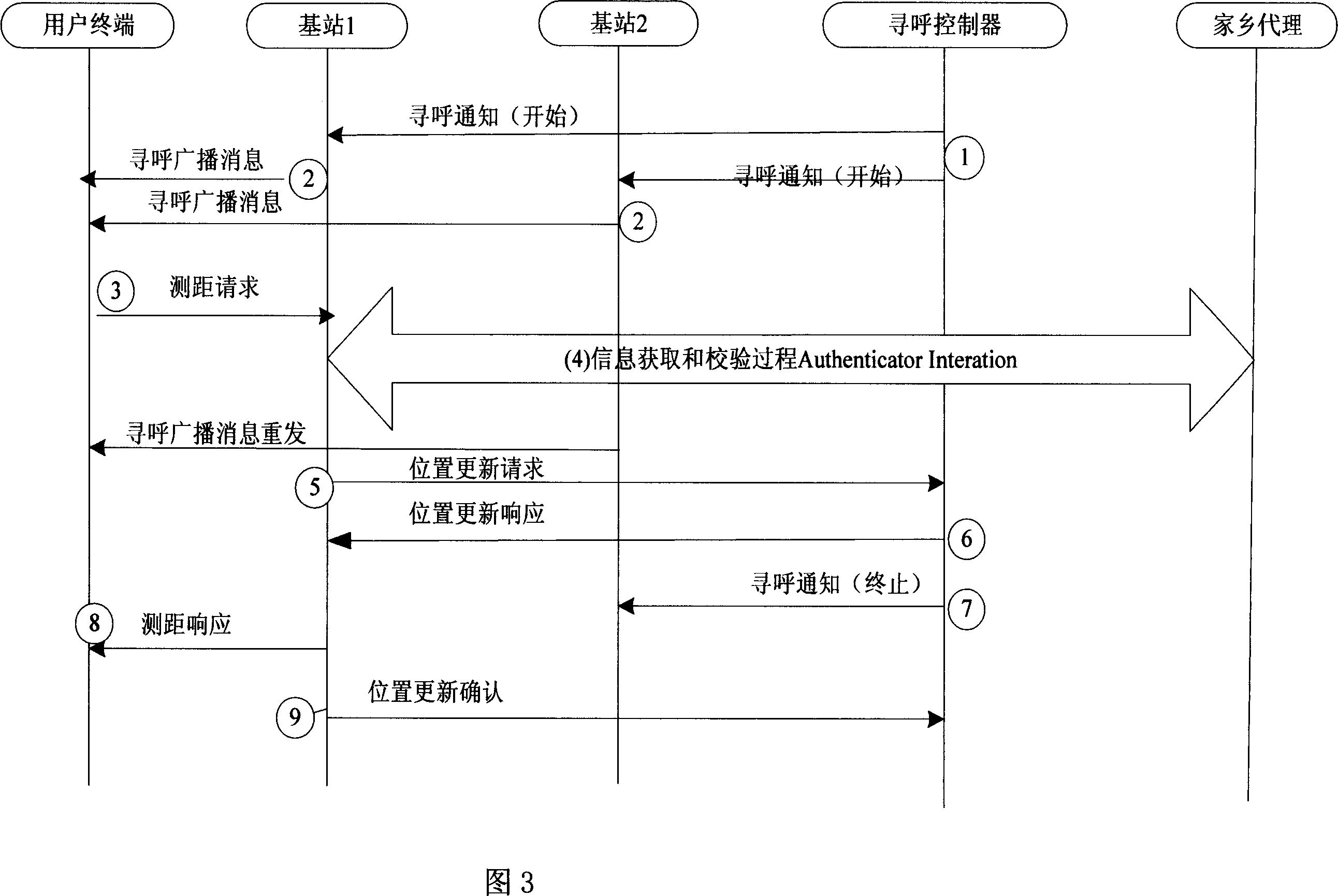

Method for improving system performance in mobile wideband wireless access system

InactiveCN101064933AReduce occupancyImprove performanceRadio/inductive link selection arrangementsWireless communicationAccess networkBroadband

The invention discloses a method to improve system performance in wireless access system of mobile broad band, which is invented to solve the problem that the base station which does not receive the response from terminal can not terminate to transmit the messages of seeking broadcast. Said method includes: accessing network sends the messages of seeking broadcast to require the terminal to act following the requirement, and the terminal begins according to the requirement of network, after the network receives the response, and it can inform the relative node to stop transmitting broadcast messages to reduce the occupancy of air source and system source, and improves the availability factor of wireless source and system source, and at the same time, the chance which is chosen in reason can ensure the success rate of seeking.

Owner:ZTE CORP

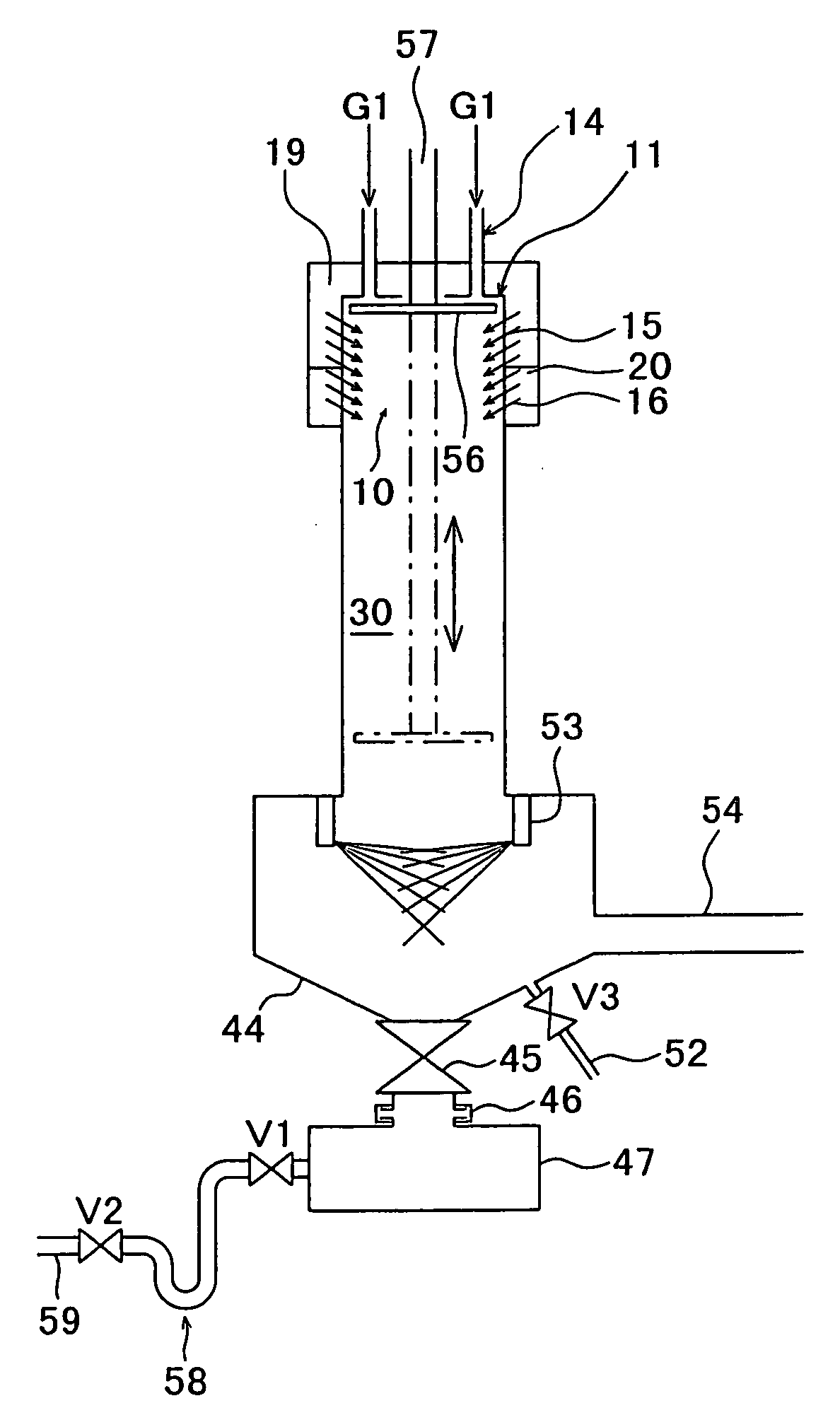

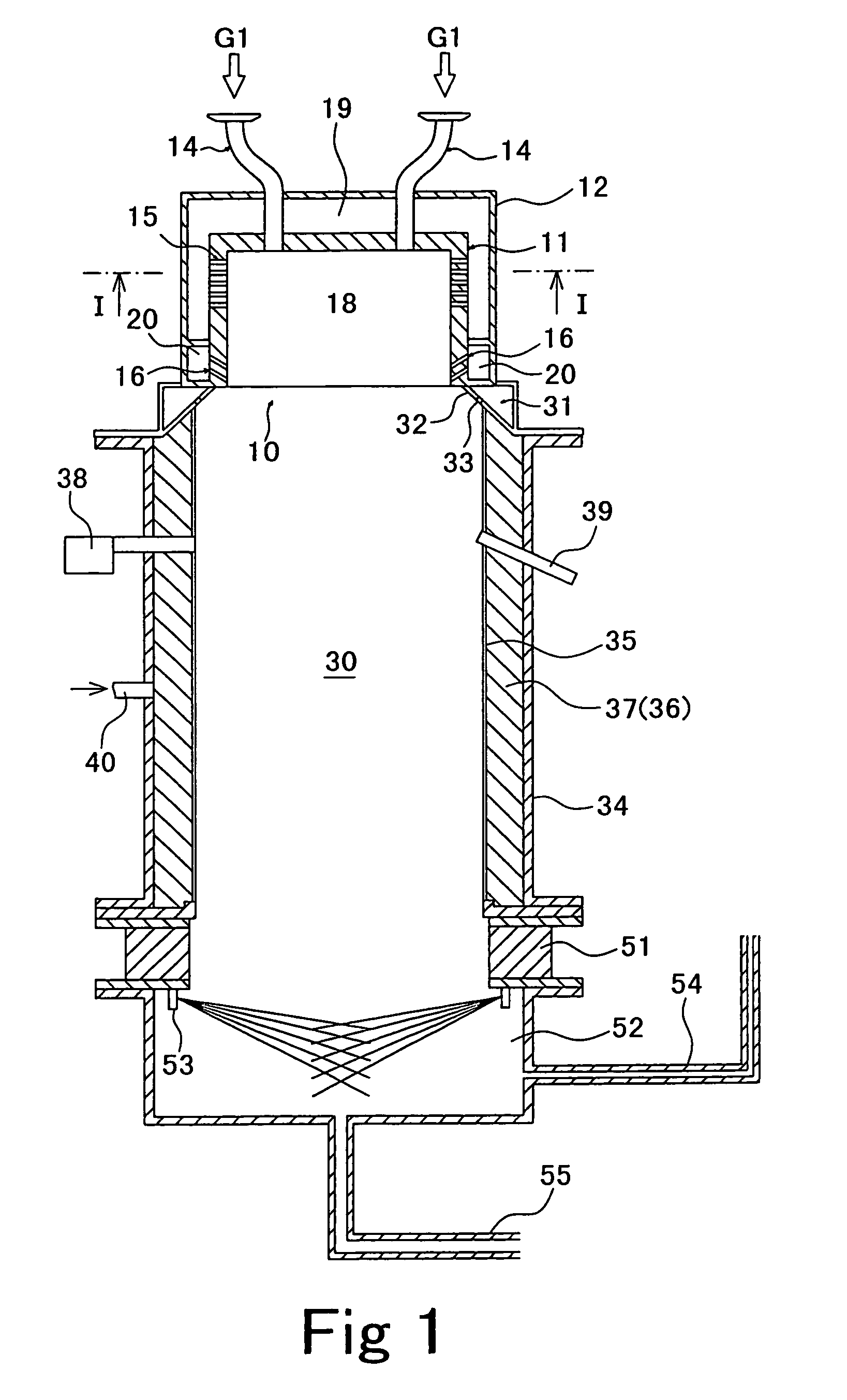

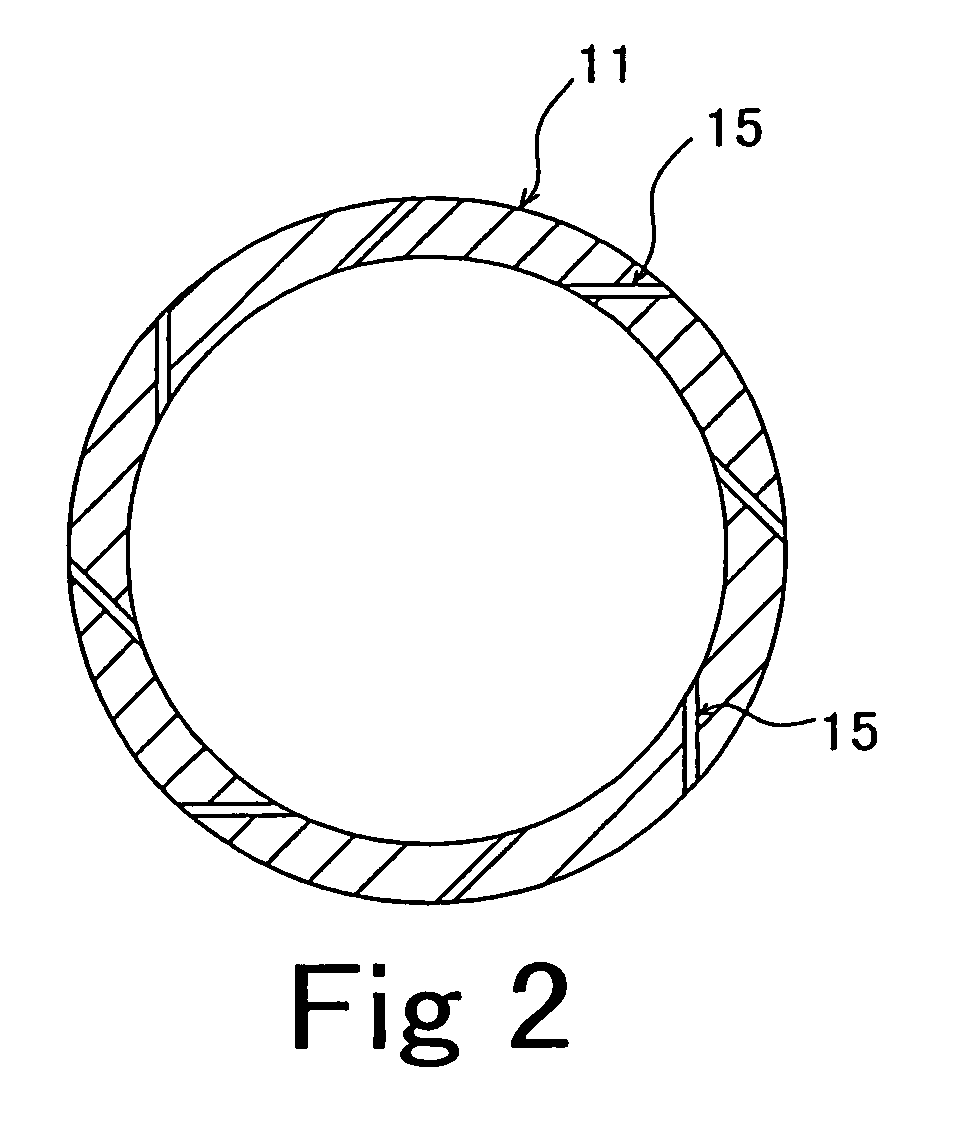

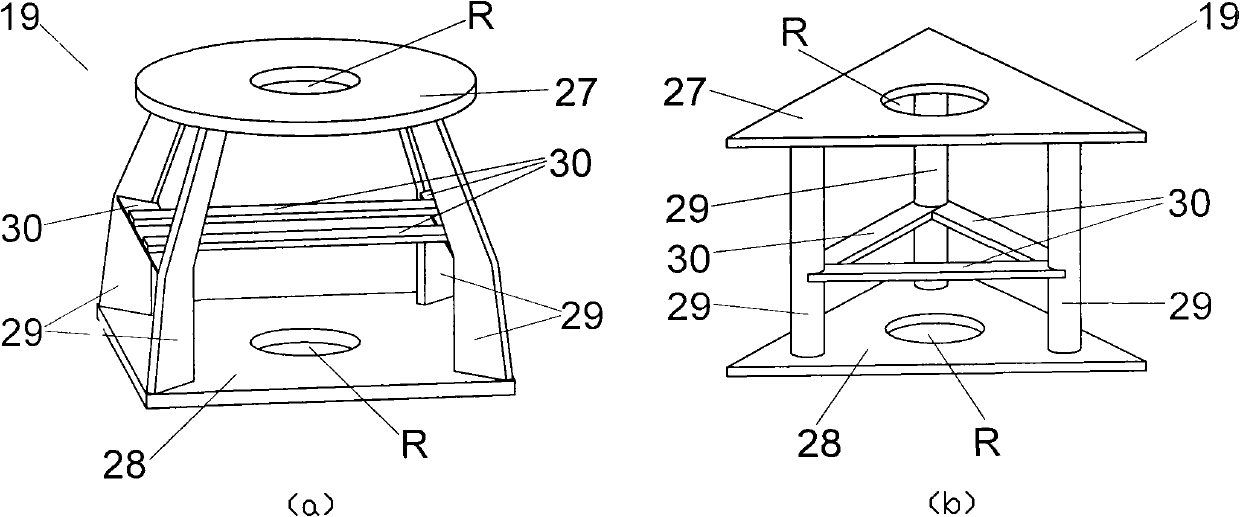

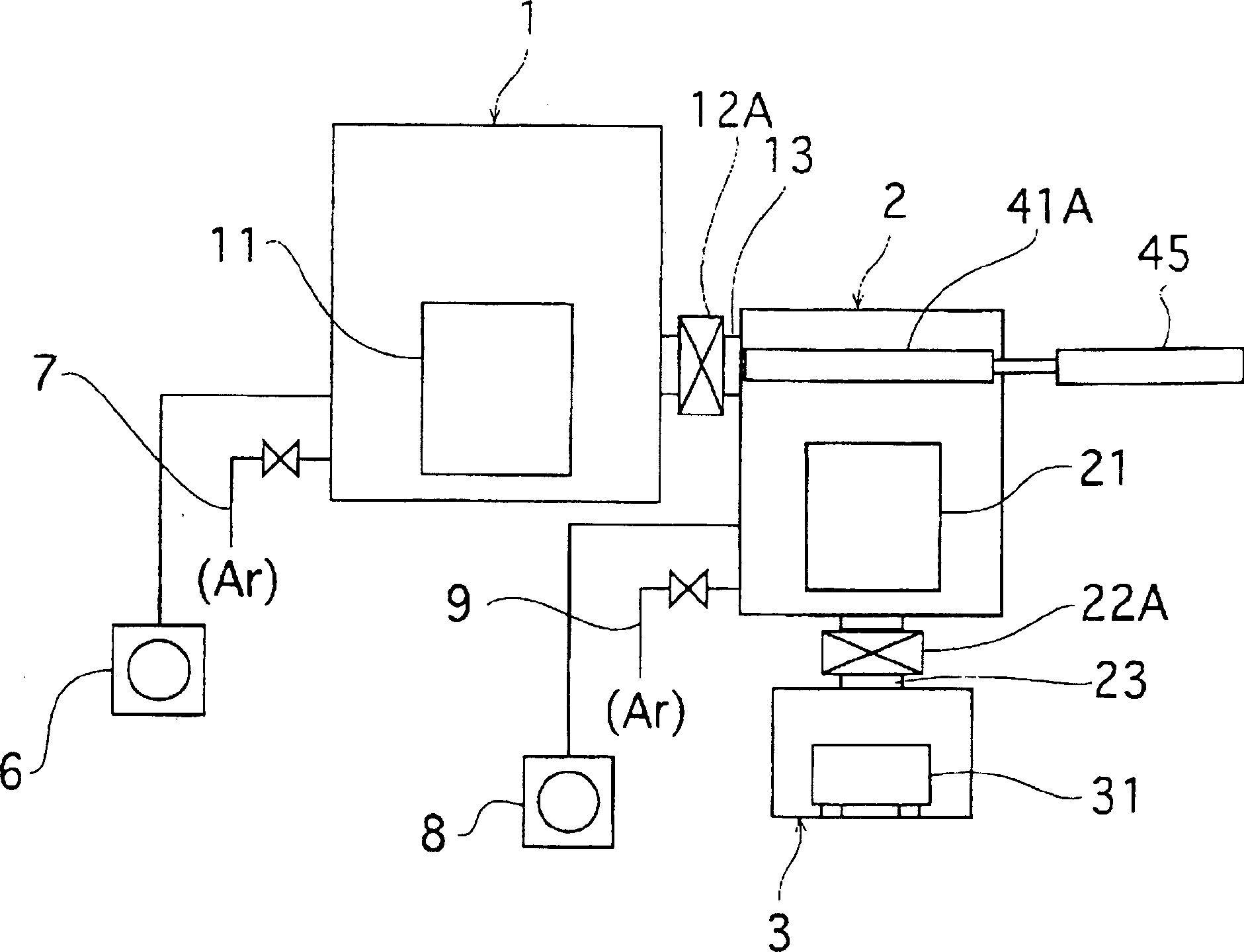

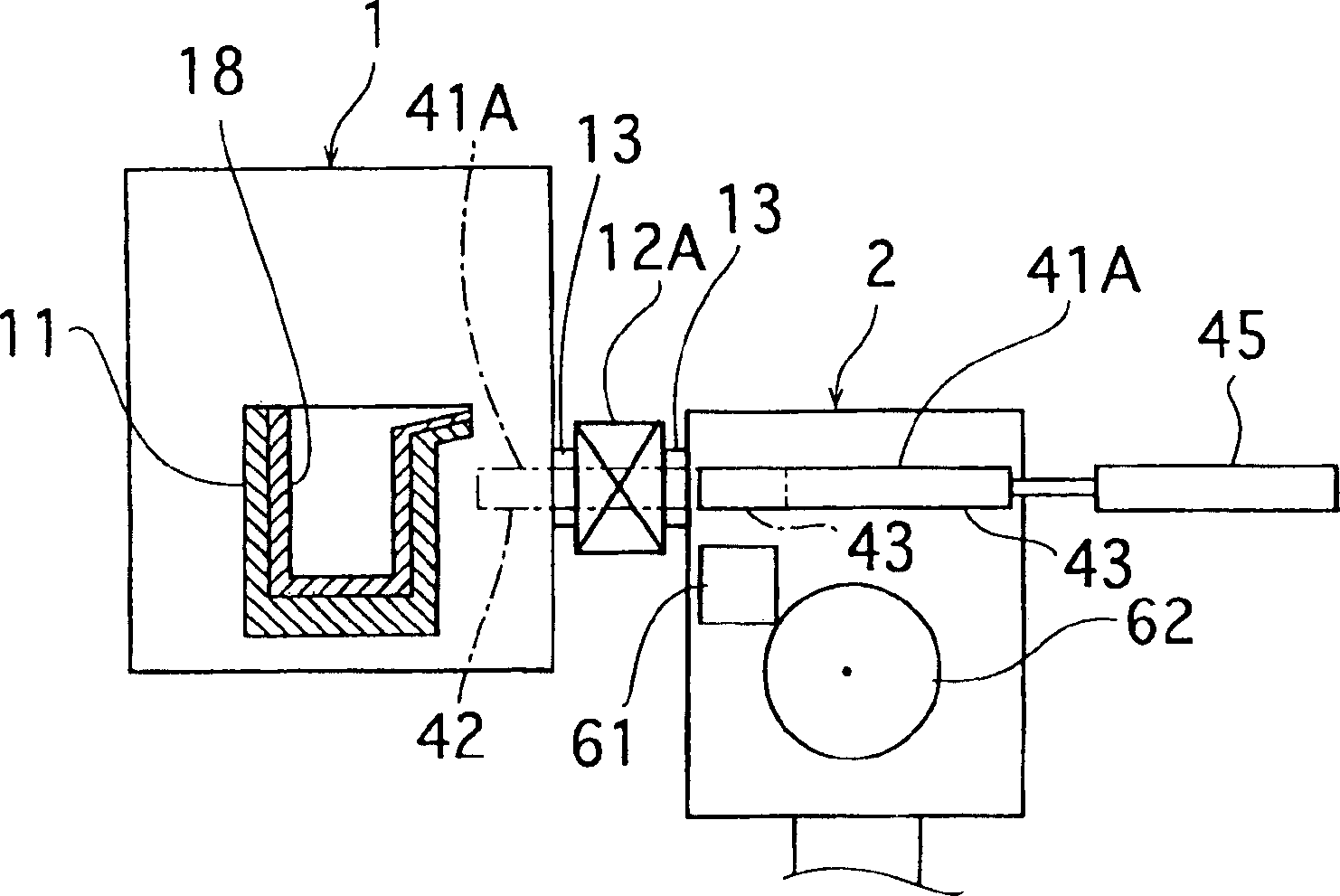

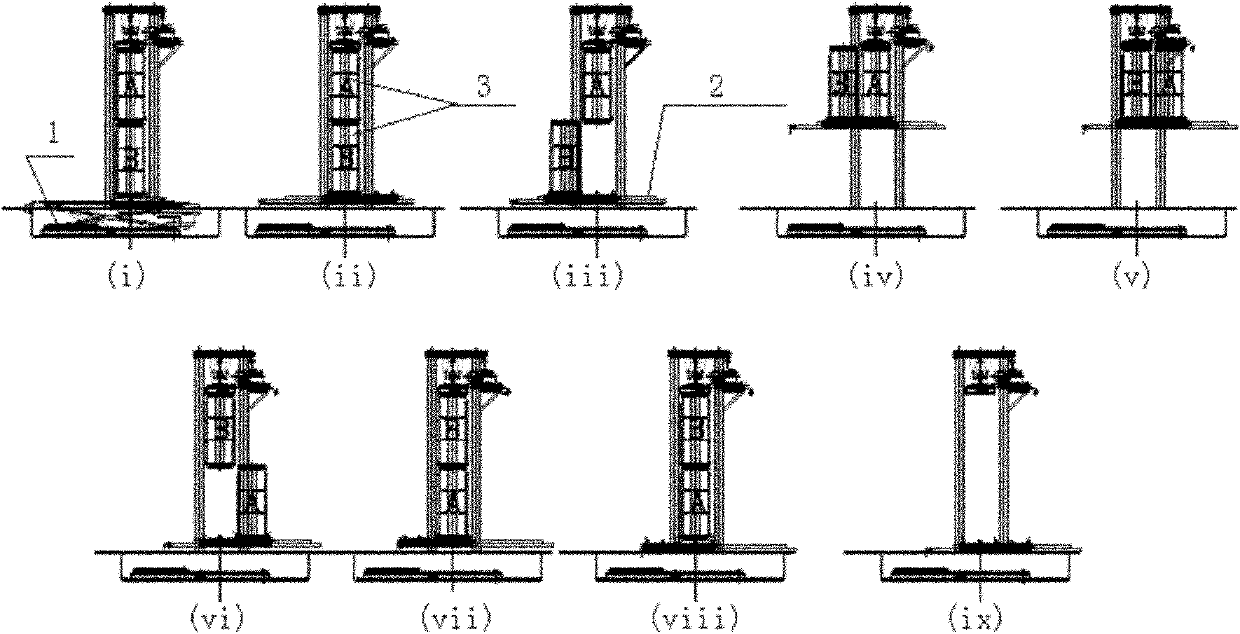

Vacuum casting appts.

To provide a vacuum melting and casting apparatus, which can improve its availability factor by making the apparatus compact and by increasing the number of cycles of melting and casting, and further can cope with a variety of requirements by selecting each process of melting, casting, and collecting of castings among a plurality of processes. The apparatus is divided into a melting chamber 1, a casting chamber 2, and a collecting camber 3, and the volumes of the respective chambers are reduced. The melting chamber 1 and the casting chamber 2 are connected via a first closed passage 13 having a first gate valve 12, which can be vacuum-sealed even when a degree of vacuum in any chamber is high. A flap valve 99, which opens and closes the end portion of the downstream side of a second closed passage 23 in the collecting chamber 3, is provided between the casting chamber 2 and the collecting chamber 3. When the molten metal is to be poured, the opened first gate valve 12 and the first closed passage 13 are advanced, and the molten metal is poured from a melting furnace 11 of the melting chamber 1 into a rectangular pipe shape rounder 41 provided to pour the molten metal to a tundish 61 of the casting chamber 2. When the molten metal is not to be poured, the first gate valve 12 and the first closed passage 13 are retracted, and then the first gate valve 12 is closed. (C)2004,JPO.

Owner:ULVAC INC

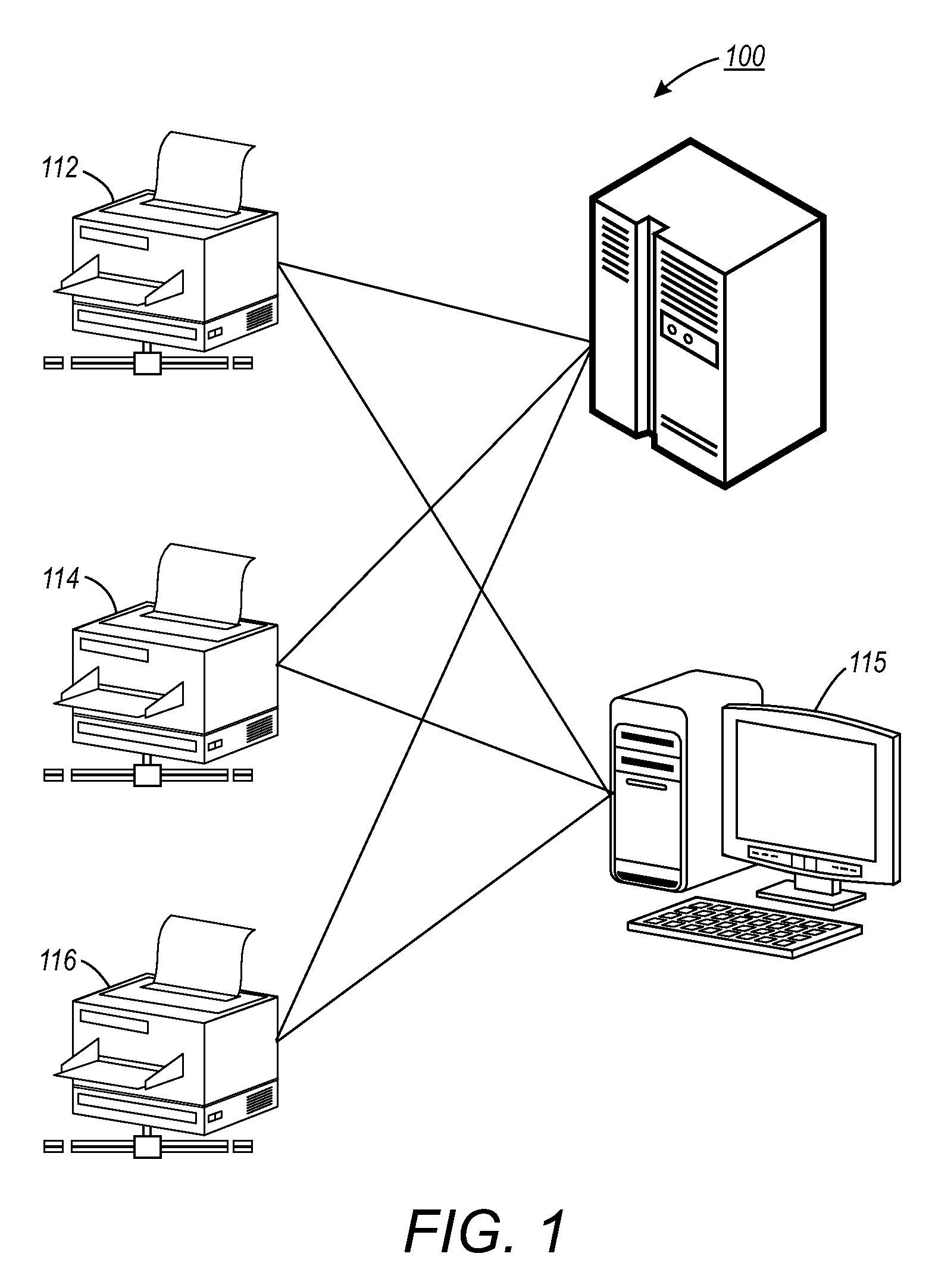

Method and system for automatic sharing and customization in a fleet of multi-function devices

InactiveUS20100328705A1Eliminating inconsistent informationEliminating race conditionMultiple digital computer combinationsTransmissionCorporate policyDevice Grid

A method and system for enabling automatic service sharing and custom user interface features in a fleet of multi-function devices. EIP (Extensible Interface Platform) services can be registered via a peer-to-peer discovery subsystem associated with a multi-function device grid infrastructure. EIP service registration information can be submitted and stored in the grid infrastructure. The multi-function devices can be equipped with an enterprise EIP client, which can query the discovery subsystem and apply a corporate policy. The discovery subsystem detects the optimal instance of the service based on loading and availability factors and then returns a reference with respect to the services that allows access to enhanced services. Such an approach enables a fleet of multi-function devices to dynamically discover EIP services and auto populate service options to provide increased capability, reduced complexity, and improved speed.

Owner:XEROX CORP

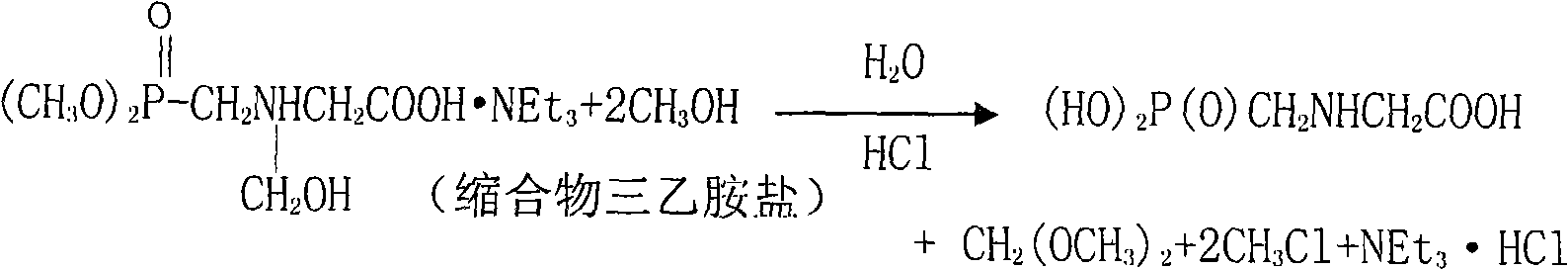

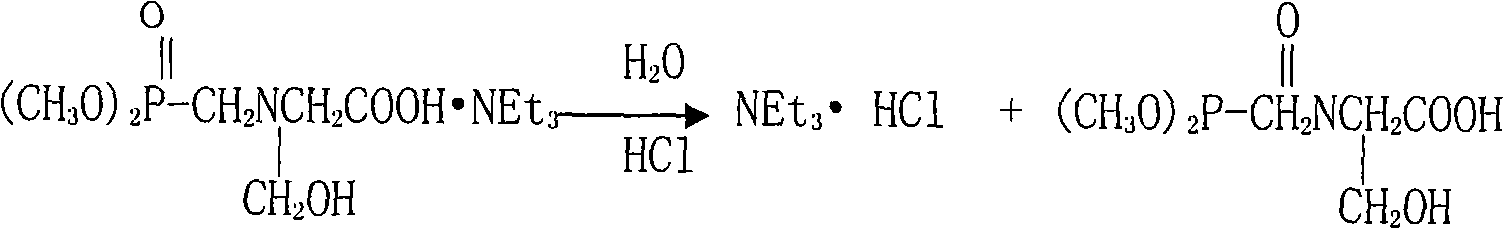

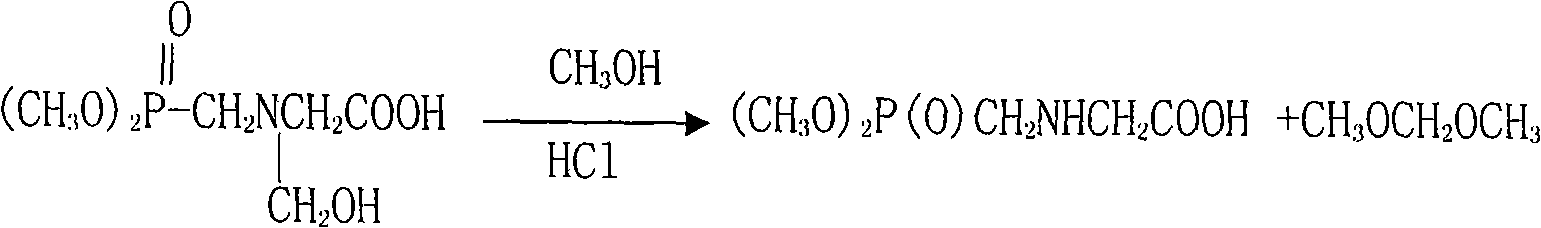

Hydrolyzation post-processing technique during preparation of glyphosate through glycin method

ActiveCN101671363AIncrease surface areaShorten the timeGroup 5/15 element organic compoundsDistillationHydrolysis

The invention relates to a hydrolyzation post-processing technique during preparation of glyphosate through a glycin method, which includes the steps of implementing reduced pressure distillation andseparation to a hydrolyzation liquor under the temperature between 80 and 110 DEG C and the pressure equal to or less than 0.05MPa after the condensation reaction and hydrolysis reaction for preparingglyphosate through the glycin method are finished, depickling and then crystallizing to obtain the glyphosate products. The hydrolyzation post-processing technique during preparation of glyphosate through the glycin method recovers hydrochloric acid by reducing the pressure, which can lead the recovery rate of hydrochloric acid to be more than 4 percent; and hot water is added for crystallizing after the hydrochloric acid is removed, thus effectively improving the availability factor of a crystallization kettle; and meanwhile, as no caustic soda liquor is added during hydrolyzation, the totalamount of a mother liquor and the content of sodium chloride are reduced as well, the energy consumption for recovering triethylamine through rectifying the mother liquor is reduced, and the total yield of the finally obtained solid glyphosate reaches 73-75 percent.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

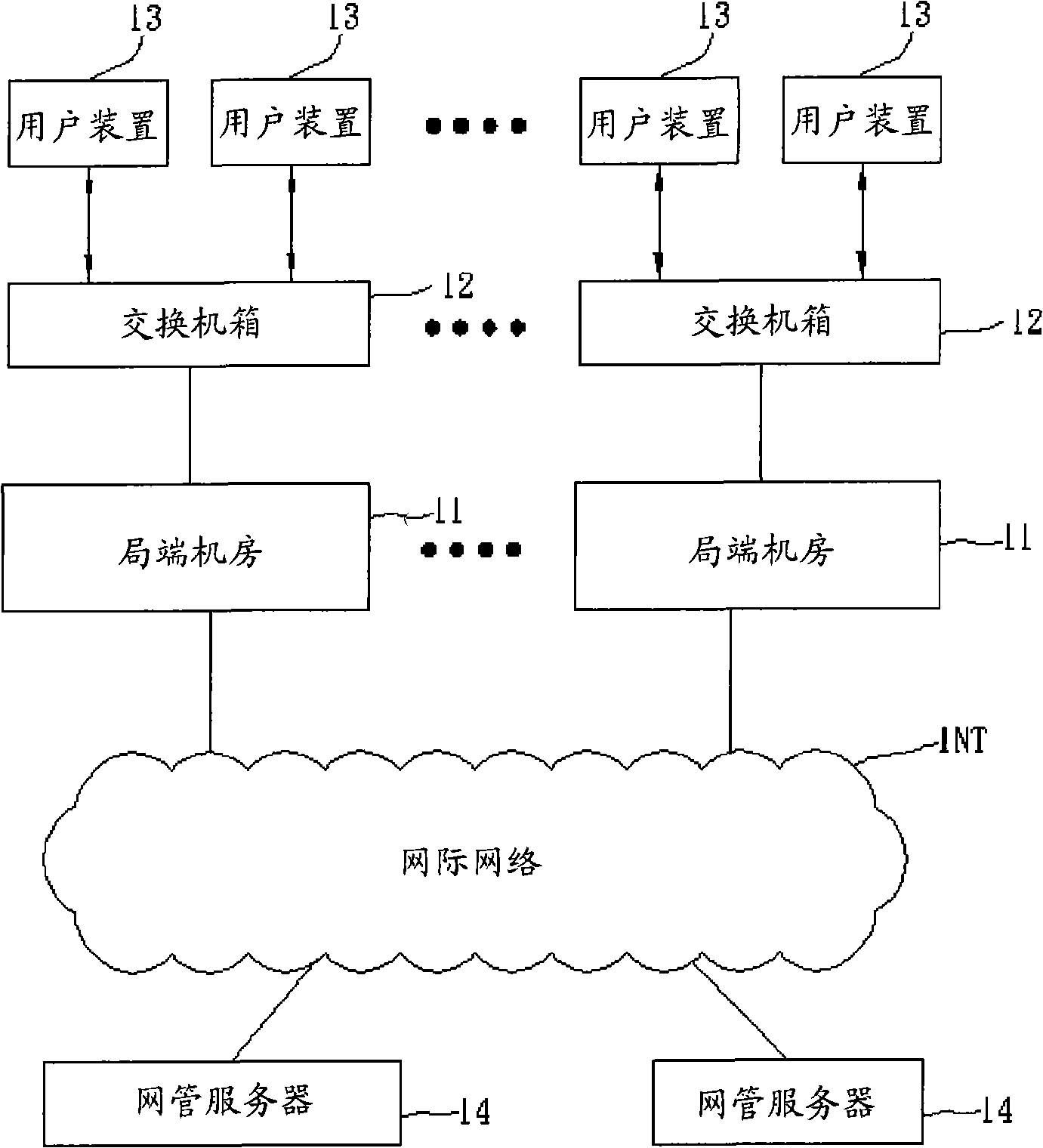

Network management system and management method

InactiveCN101299675AIncrease transfer speedImprove network management performanceNetworks interconnectionEthernet protocolWorkload

The invention discloses a network manager system and management method thereof. The network management system includes at least a user apparatus and a network management agent apparatus. The network management agent apparatus is connected with the user apparatus, and transmits a management package to the user apparatus through a data link layer according to an Ethernet protocol, wherein, the management package at least carries an information string which is set by network management protocol in at least one hierarchy outside the data link layer. The network management method is applied in the network in the network management system. The invention can reduce the network management workload of the network management to the user apparatus, in order to boost the efficiency of the user apparatus and increase the availability factor of the frequency width, thereby largely improving the network transmission velocity and integral network management efficiency in combination with the Ethernet.

Owner:ACCTON TECHNOLOGY CORPORATION

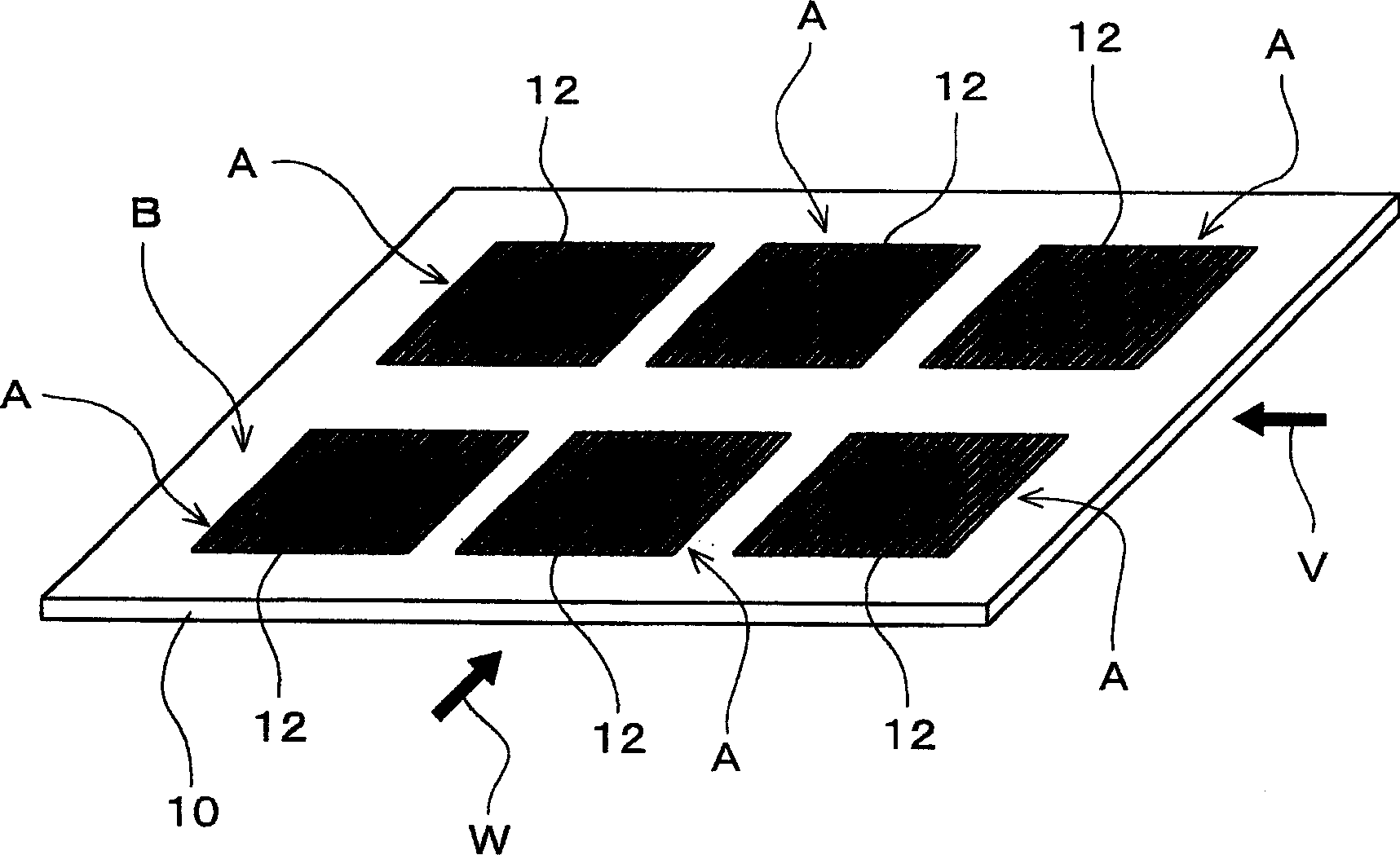

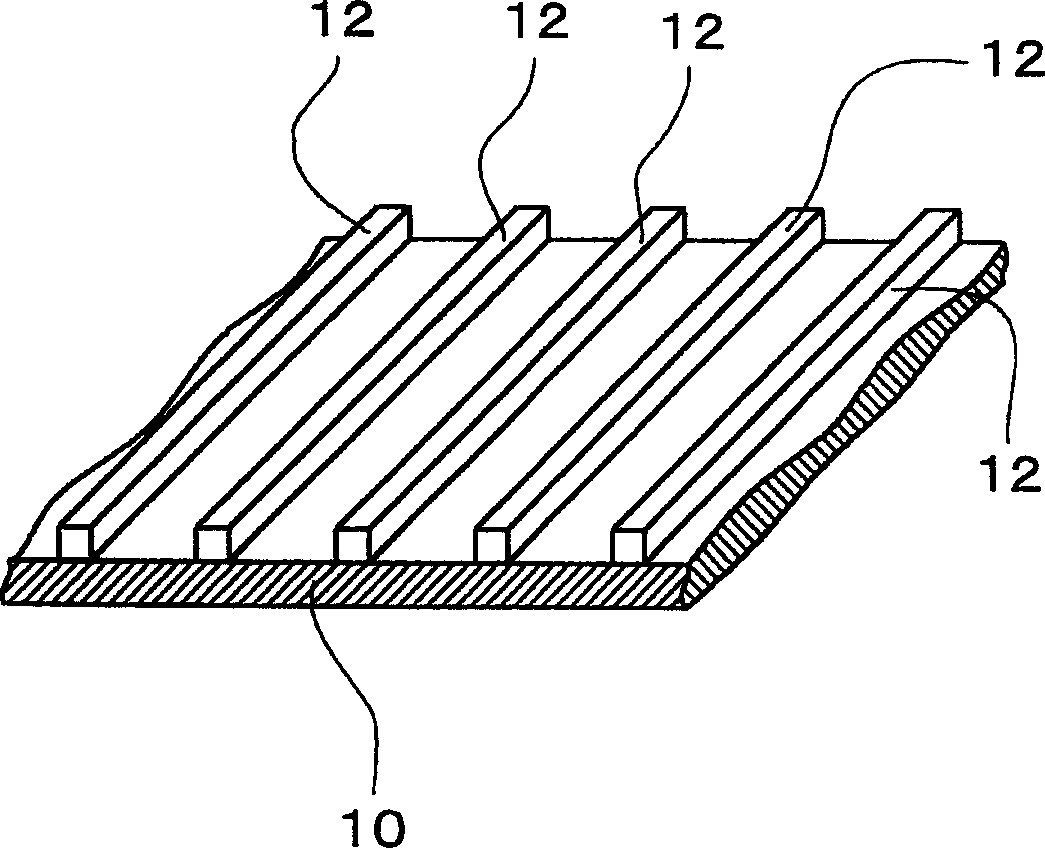

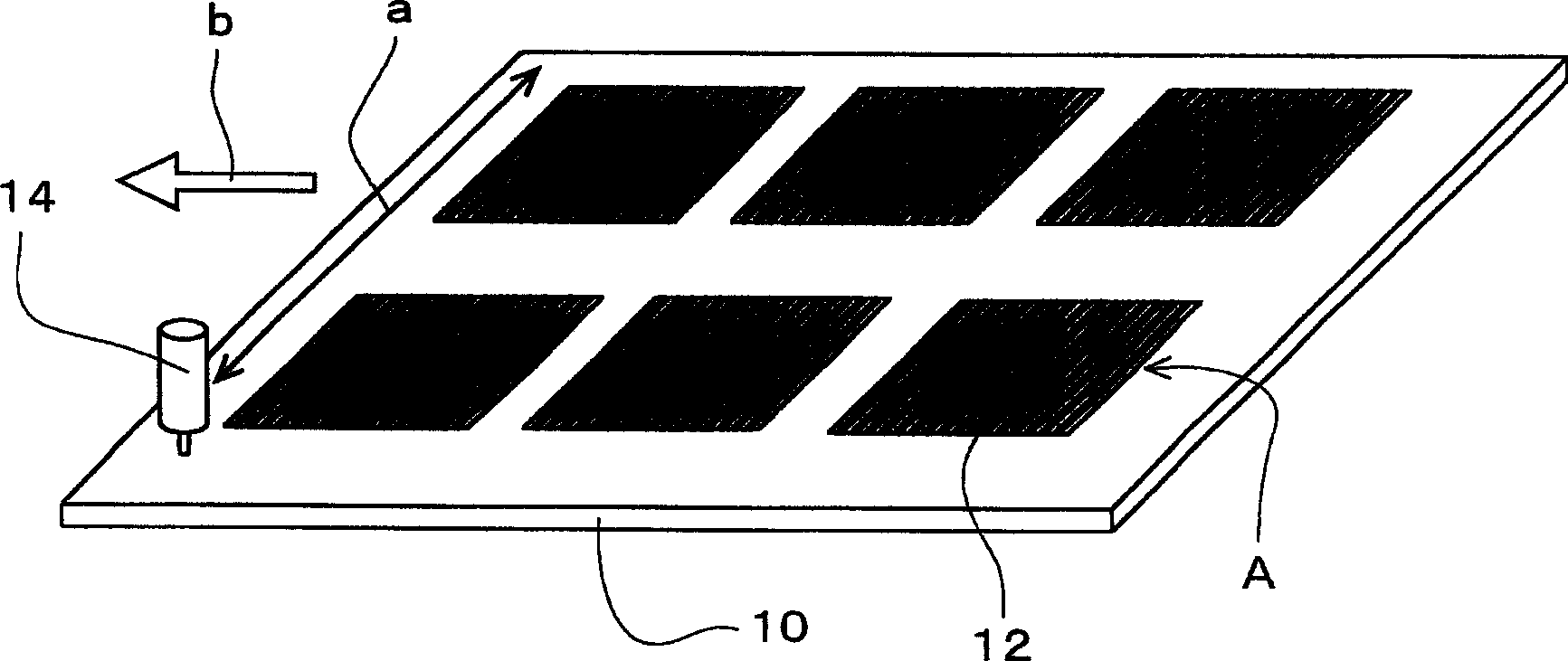

Manufacturing method of color filter

InactiveCN1825145ACoating high precisionInhibition lossPhotomechanical apparatusPrintingSpray nozzleEngineering

Provided is a manufacturing method of color filter capable of improving the availability factor of material, simplifying processes and forming high-definition colored pattern. The manufacturing method of color filter comprises a process of applying coloring material between banks 12 on a glass substrate by delivering the coloring material from a nozzle 14 while scanning the nozzle for the glass substrate 10 on which the light-shielding banks 12 of a prescribed pattern are formed and intermittently feeding the glass substrate with a prescribed pitch in the direction orthogonal to the scanning direction, a process of aligning and laminating a mask plate on which a light transmission part corresponding to an available part of the color filter is formed, on the back surface side of the glass substrate, exposing light from the back surface side of the glass substrate via the mask plate and curing the color material applied on the part corresponding to the available part of the color filter and a process of developing the surface side of the glass substrate and dissolving and removing the coloring material which is applied on the part corresponding to non-available part of the color filter and is left uncured.

Owner:DAINIPPON SCREEN MTG CO LTD

Method and device for automatic layer exchange during irradiation of goods containers

InactiveCN102001527AQuickly switch layers up and downIncrease the amount of irradiationLifting devicesStacking articlesEngineeringIrradiation

The invention discloses a method and device for automatic layer exchange during irradiation of goods container. The method comprises the following steps of: conveying a spreader into or out of an irradiation room by a suspension conveyor system; and carrying out layer exchange on an upper-layer suspension box and a lower-layer suspension box on the spreader by a hydraulic lifter and a movable working platform. The device is arranged in a goods handling hall, and consists of the suspension conveyor system, the hydraulic lifter, the movable working platform, the upper-layer suspension box, the lower-layer suspension box and a positioning pin. The method and the device have high automation, save time and labor, are convenient to maintain, cab be used for quickly exchanging the upper-layer suspension box and the lower-layer suspension box to make the uniformity of irradiation absorption dose of goods meet requirements, and increases energy availability factor of a radioactive source and the quantity of irradiated goods.

Owner:ZHEJIANG YINDU IRRADIATION TECH

Postprocessing system of diesel engine

InactiveCN101457681AImprove energy utilizationReduce internal meltingExhaust apparatusSilencing apparatusRegenerative processCoupling

The invention relates to a diesel engine post treatment system comprising a tight coupling partial flow metal filter and a wall flow ceramic filter, wherein, a first stage tight coupling partial flow metal filter is arranged at the outlet of an exhaust manifold, a first stage wall flow ceramic filter is arranged behind the first stage tight coupling partial flow metal filter, and the partial flow metal filter and the wall flow ceramic filter are respectively covered with oxidation catalyst. The energy availability factor of the entire post treatment system is higher, and the burning-out or the cracking and other failure risks in the post treatment system in the active regenerative process are greatly reduced, thereby increasing the reliability of the system.

Owner:CHERY AUTOMOBILE CO LTD

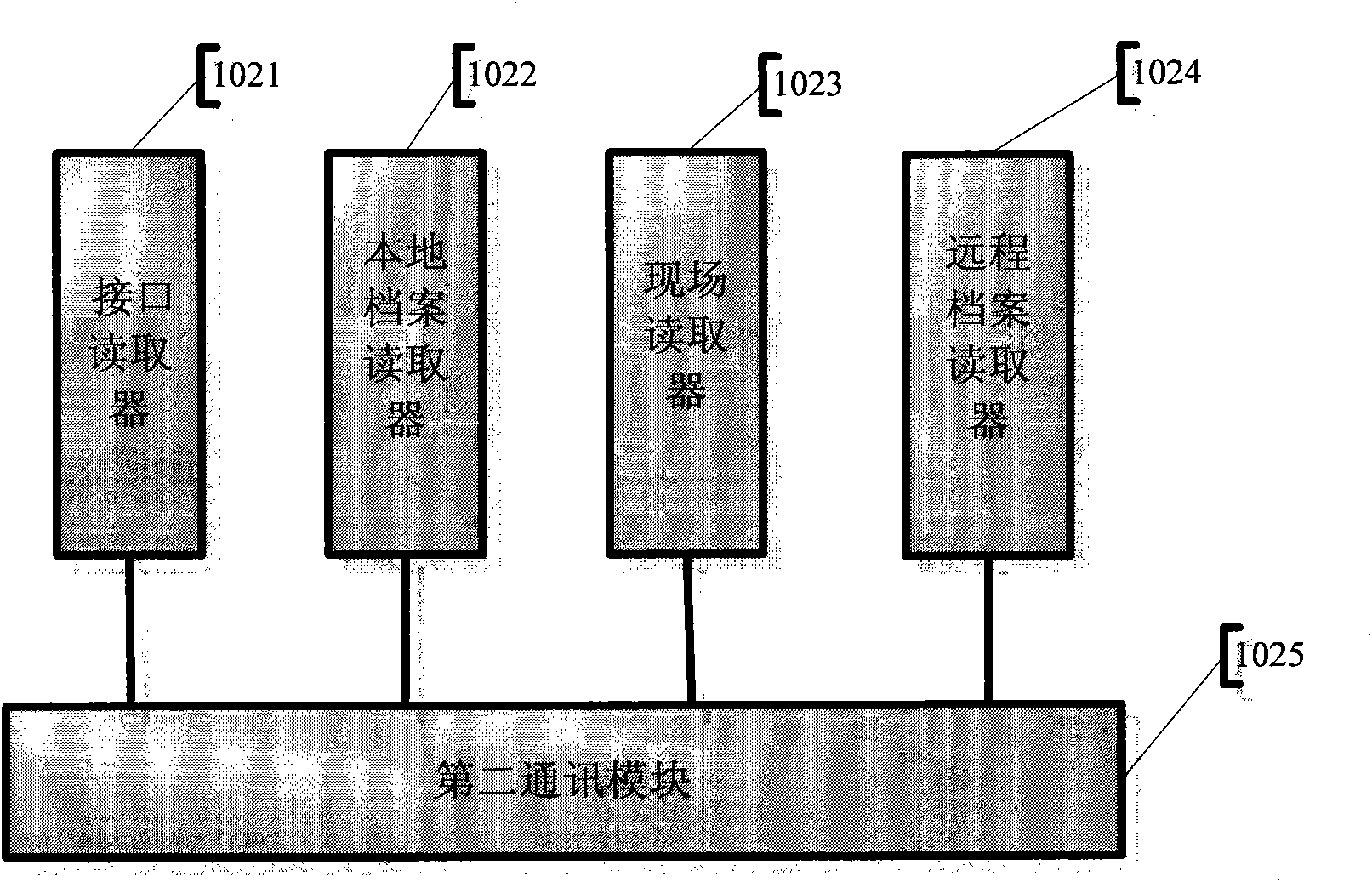

Device and method for performing remote medical treatment

InactiveCN101873353AImprove trustImprove accuracyData switching networksInformation objectMedical institution

The invention provides a device and a method for performing remote medical treatment. The device comprises a first reading and processing unit, a second reading and processing unit, a third reading and processing unit and a remote medical treatment server, wherein the first reading and processing unit is used for reading one of or more items of identification information from an identification information carrying object, generating and sending an identification information verification request, and starting a remote medical treatment logic after the verification is passed; the second reading and processing unit is used for reading and sending local medical file and examination information of a patient, accessing and receiving remote medical treatment file information; the third reading and processing unit is used for reading the medical treatment information and sending the medical treatment information to the remote medical treatment server; and the remote medical treatment server is used for receiving the medical treatment information through a network, saving identification information and medical treatment information which are reserved by an identification information object, processing request information and responding to the request information. Due to the adoption of the technology of the device and the method for performing the remote medical treatment, credible remote medical treatment can be realized without dependence on conventional medical institutions, unbalance medical treatment resource allocation is made up, the availability factor of the resource is improved, and the problem of difficulty and high cost of medical treatment is solved.

Owner:田小平

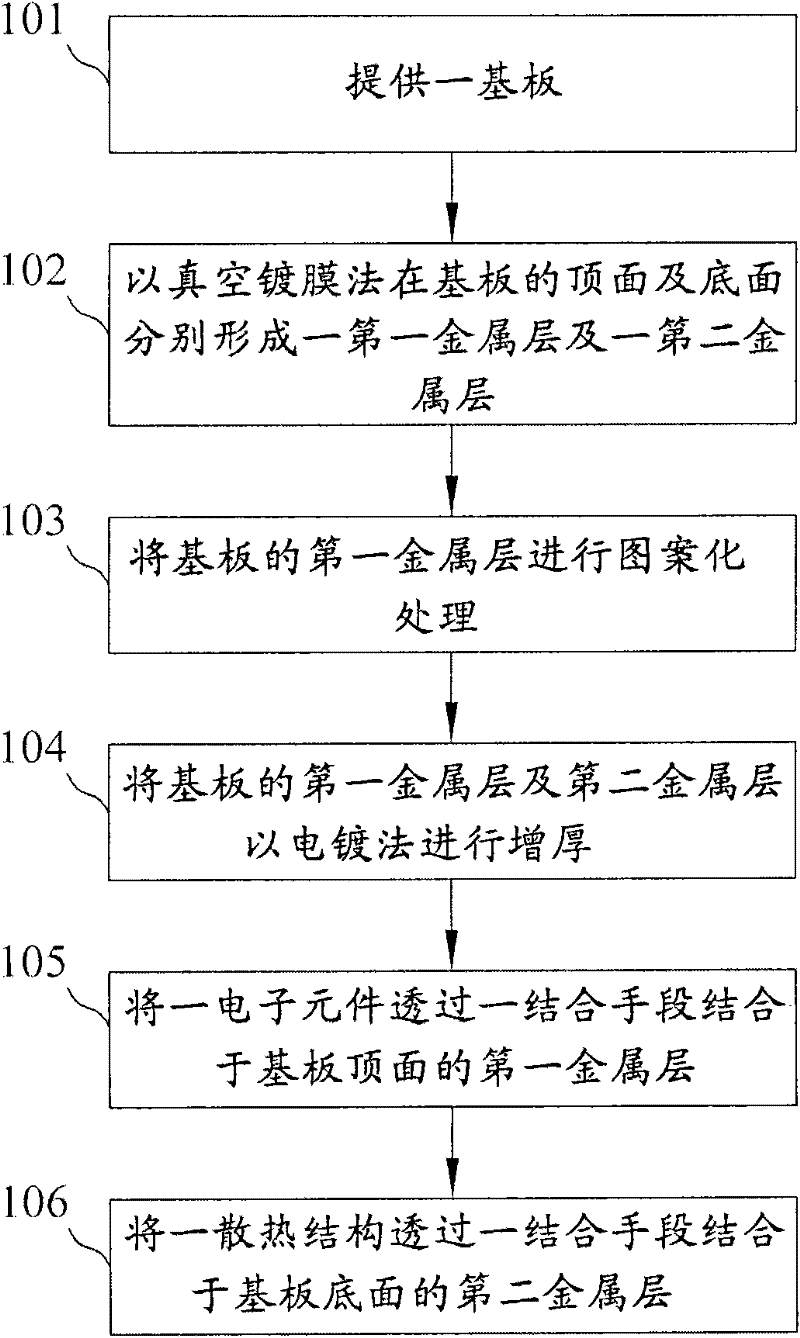

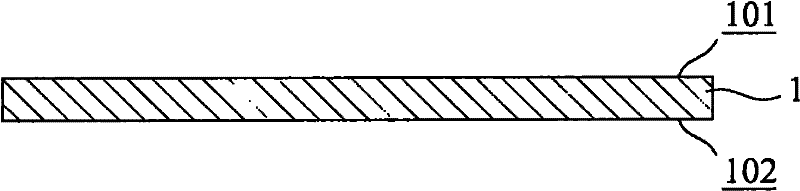

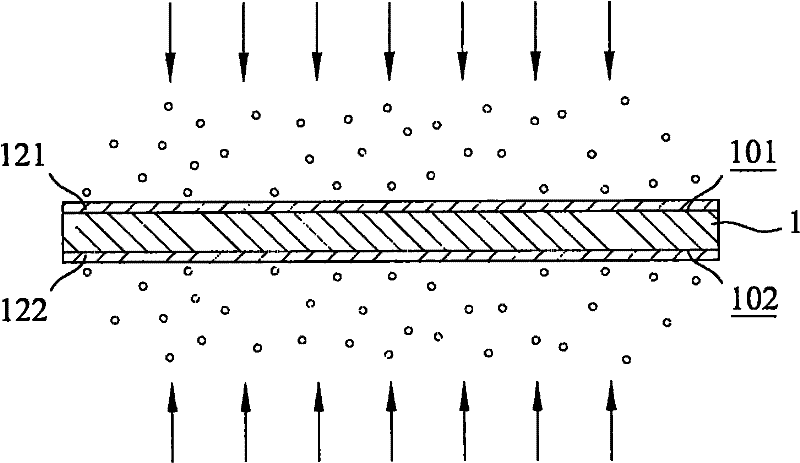

Improved combination structure and combining method of baseplate and heat dissipating structure

InactiveCN102447018AImprove bindingAddressing non-solderable featuresSemiconductor/solid-state device detailsSolid-state devicesAdhesiveLight-emitting diode

The invention discloses an improved combination structure and a combining method of a baseplate and a heat dissipating structure. The method comprises the following steps of: (a) providing the baseplate; (b) respectively forming a first metal layer and a second metal layer on the top surface and the bottom surface of the baseplate in a vacuum evaporation coating method; and (3) leading the heat dissipating structure to be combined on the second metal layer of the bottom surface of the baseplate by means of combination. According to the improved combination structure of the baseplate and the heat dissipating structure obtained by using the combining method, a heat source conductive interface of a ceramic baseplate or an aluminium baseplate can be converted into a metal interface with better heat transfer property through a high polymer adhesive by adopting a vacuum coating method, thereby the whole heat transfer coefficient is substantially increased, and the unweldable characteristic of the kind of baseplates is solved; and due to the increasing of thermal conductivity, the service life of the LED (Light-Emitting Diode) grain packaging is prolonged and the availability factor of the LED grain packaging is improved.

Owner:PARAGON TECH

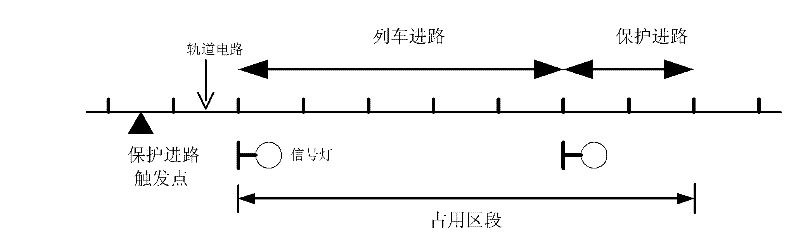

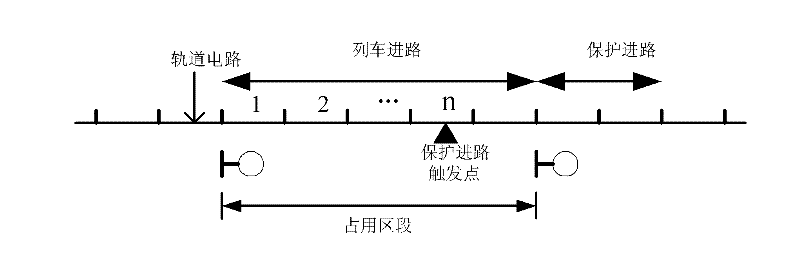

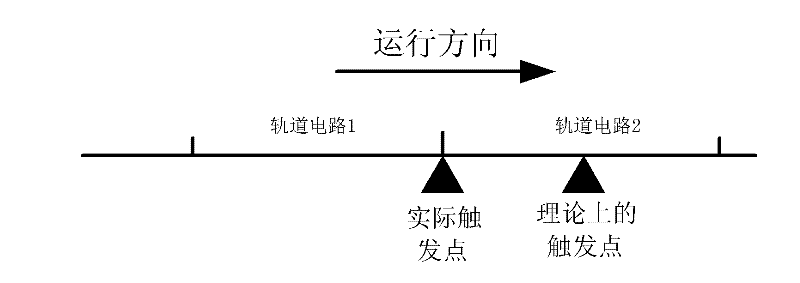

Interlock protective route trigger method for metrovehicle

ActiveCN102381339AImprove efficiencyNo increase in workloadSignal boxes station blockingEngineeringAvailability factor

An interlock protective route trigger method for metrovehicle provides each protective route trigger point in a corresponding train route and comprises the following specific steps: step one: an interlock system detects running position of a train according to an occupied condition of a track circuit; step two: when the train is detected to enter a train route, the system prepares a protective route with the arrangement being corresponded to the train route; step three: the train continuing running, when the train is detected to enter a zone in which the trigger point of the protective route is located, the interlock system starts the protective route; step four: the interlock discharges the protective route, and the train continues running. The interlock protective route trigger method for metrovehicle divides a zone occupied in one time into two times of occupations, then the interlock protective route trigger method for metrovehicle improves availability factor of zones and does not change the original interlock and opposite relationships, so the the interlock protective route trigger method for metrovehicle does not add extra amount of work.

Owner:CRRC NANJING PUZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com