Thermomagnetic power plant

A power device and thermo-magnetic technology, applied in the field of thermo-magnetic power device, can solve the problems of low energy utilization rate of internal combustion engine and complex mechanical structure, and achieve the effect of simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

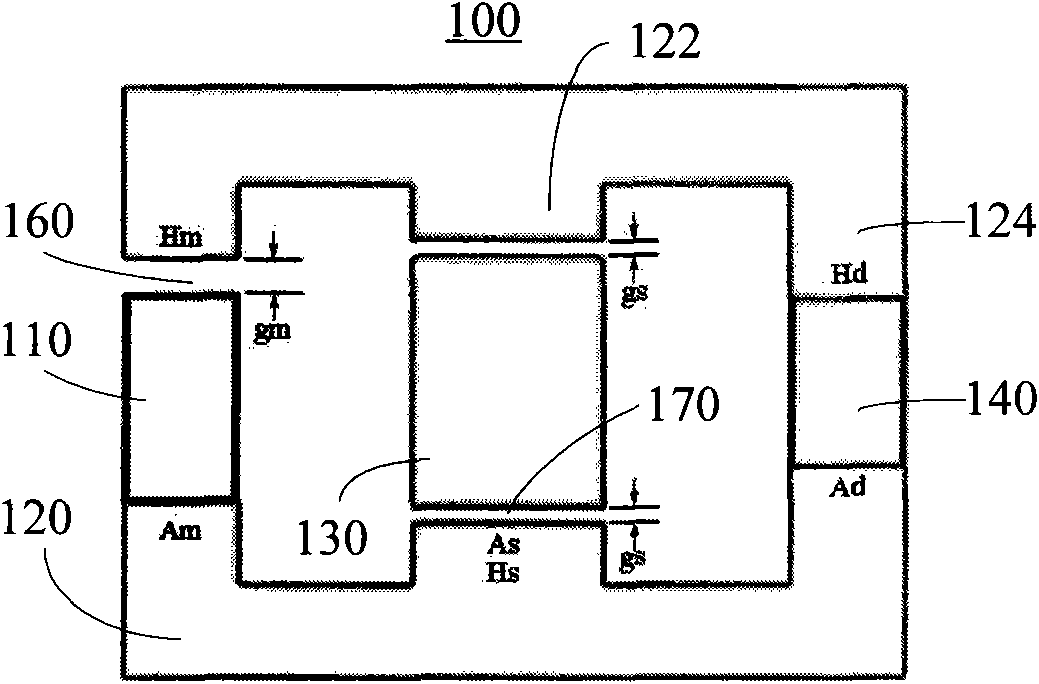

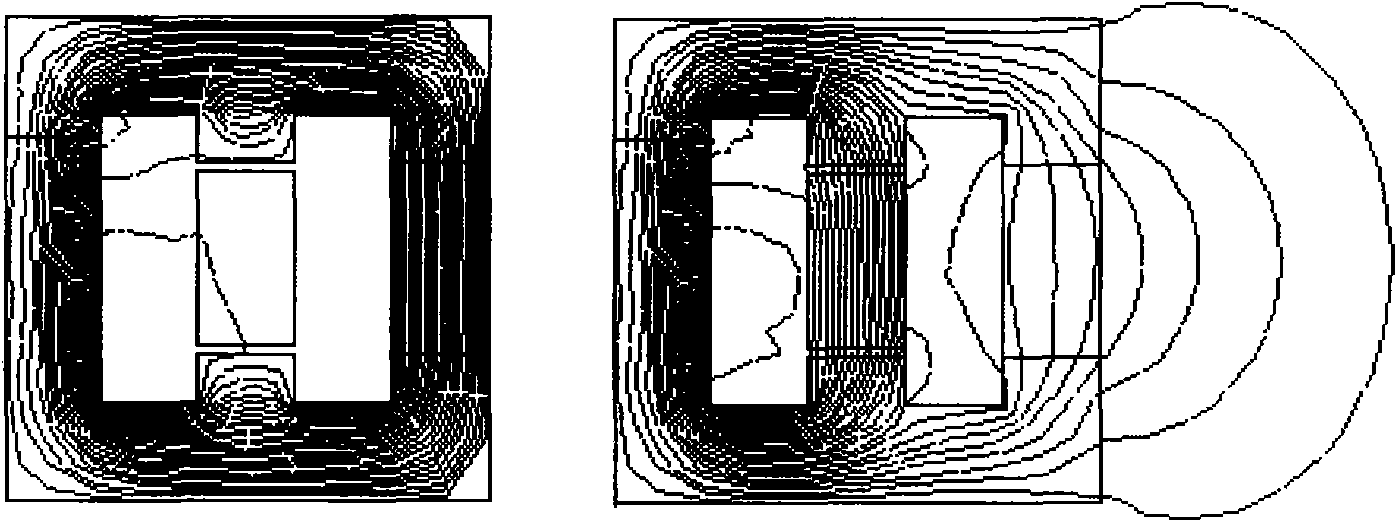

[0060] Such as Figure 4 , 5 Shown are the front view and perspective view of the first embodiment of the thermomagnetic motor of the present invention, respectively. The thermomagnetic motor 30 mainly includes a first stator 31 , a second stator 32 , a third stator 33 and a rotor 34 . The first stator 31, the second stator 32 and the third stator 33 are respectively fixed on the housing (in order to simplify the structure, Figure 4 , 5 not shown in). The first stator 31, the second stator 32 and the third stator 33 are all composed of the same components. Taking the first stator 31 as an example, it mainly includes a first stator magnet 311, a first stator yoke 312, two first stator salient poles 3123 and two oppositely disposed on the first stator yoke 312. 3125, and the first stator thermal magnet 314. There is a rotor air gap 343 between the rotor 34 and the first stator salient poles 3123 and 3125 .

[0061] In a preferred embodiment, there is a gap 316 between th...

no. 2 approach

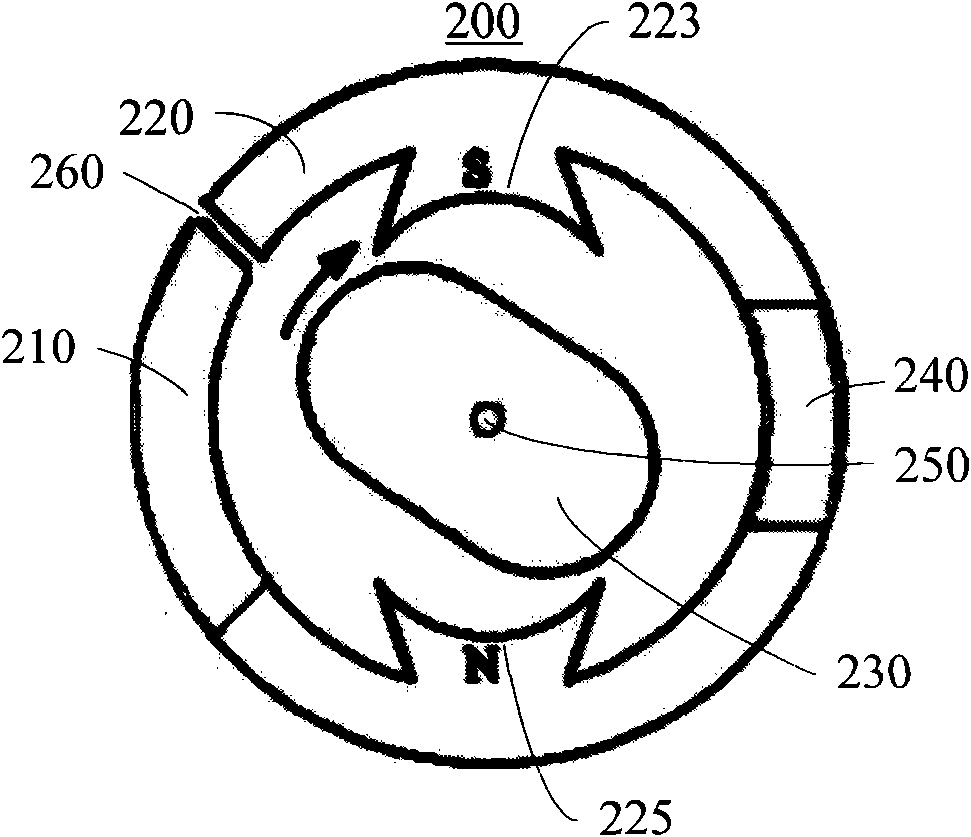

[0080] Such as Figure 12 , 13 Shown are the front view and perspective view of the second embodiment of the thermomagnetic motor of the present invention, respectively. In this embodiment, the thermomagnetic motor 40 includes stators 41 , 42 , 43 and a rotor 44 . The stators 41, 42, and 43 have the same structure, and the stator 41 is taken as an example to illustrate its structural composition. Similar to the structure of the first embodiment of the present invention, the stator 41 mainly includes a first stator magnet 411, a first stator yoke 412, and two first stator protrusions that are oppositely arranged on the first stator yoke 412. Magnetic poles 4123 and 4125 , and first stator thermomagnet 414 . Wherein the stator magnet 411 can be a permanent magnet or an electromagnet instead. A gap 416 is provided at both ends or one end of the stator magnet 411, and the gap 416 can be filled with materials with relatively low magnetic permeability such as air, copper, and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com