Method and device for automatic layer exchange during irradiation of goods containers

A technology for irradiation and cargo, which is applied in the field of automatic layer change of irradiated cargo boxes, can solve problems such as uneven radiation absorption dose, achieve the effect of solving the difficulty of product layer change and improving energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

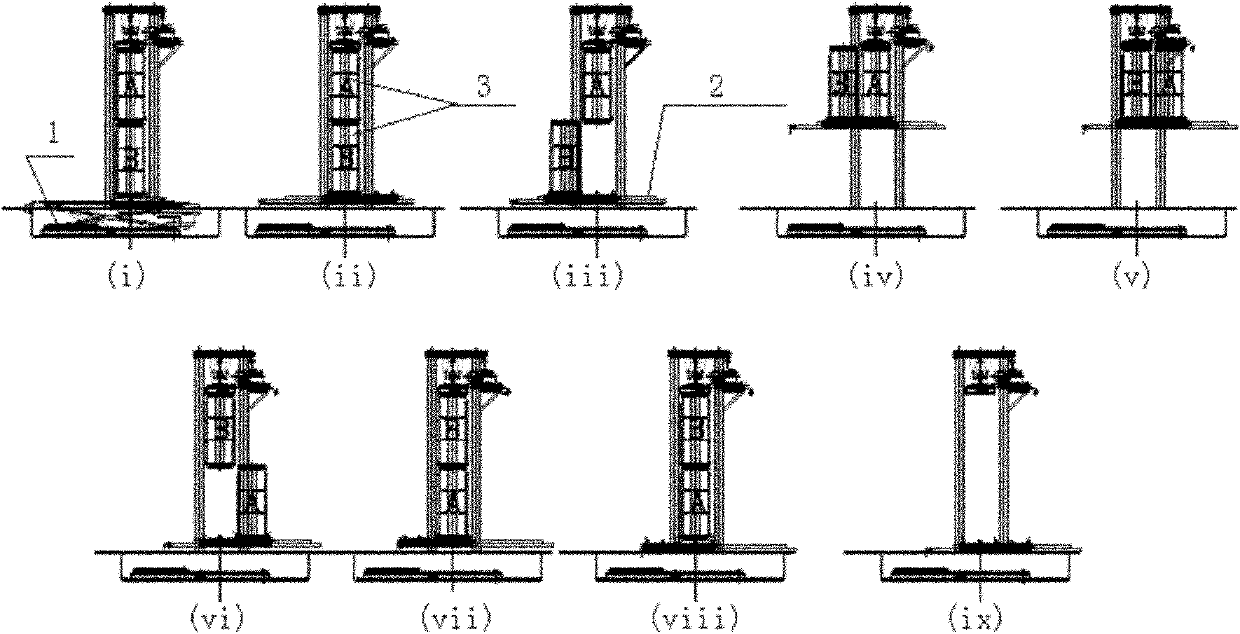

[0024] like figure 1 The shown automatic layer changing device used in the method for automatic layer changing of irradiated cargo suspension boxes of the present invention is located in the cargo loading and unloading hall, and consists of a suspension conveyor system 8, a hydraulic lift 1, a mobile working platform 2, a crane Box 3 (including the upper hanging box A and the lower hanging box B) and positioning pin 4, the mobile working platform 2 is connected with the hydraulic lift 1, the upper hanging box A and the lower hanging box B are connected through the positioning pin 4, and the conveyor system is suspended The conveying chain of 8 is connected with upper floor hanging box A by positioning pin 4. Among them, the mobile working platform 2 includes: a variable frequency motor 5, a sprocket and a chain 6, a limit travel switch 7 and a conveying roller shaft 9, such as figure 2 shown.

[0025] use figure 1 The automatic layer-changing device shown is used for the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com