Vertical shaft fan of wind generating set

A fan and vertical shaft technology, applied in the design and manufacture of vertical shaft wind turbine fans, can solve the problems of endangering the living environment of birds, poor performance, low cantilever time efficiency, etc., and achieve the effect of reducing manufacturing cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

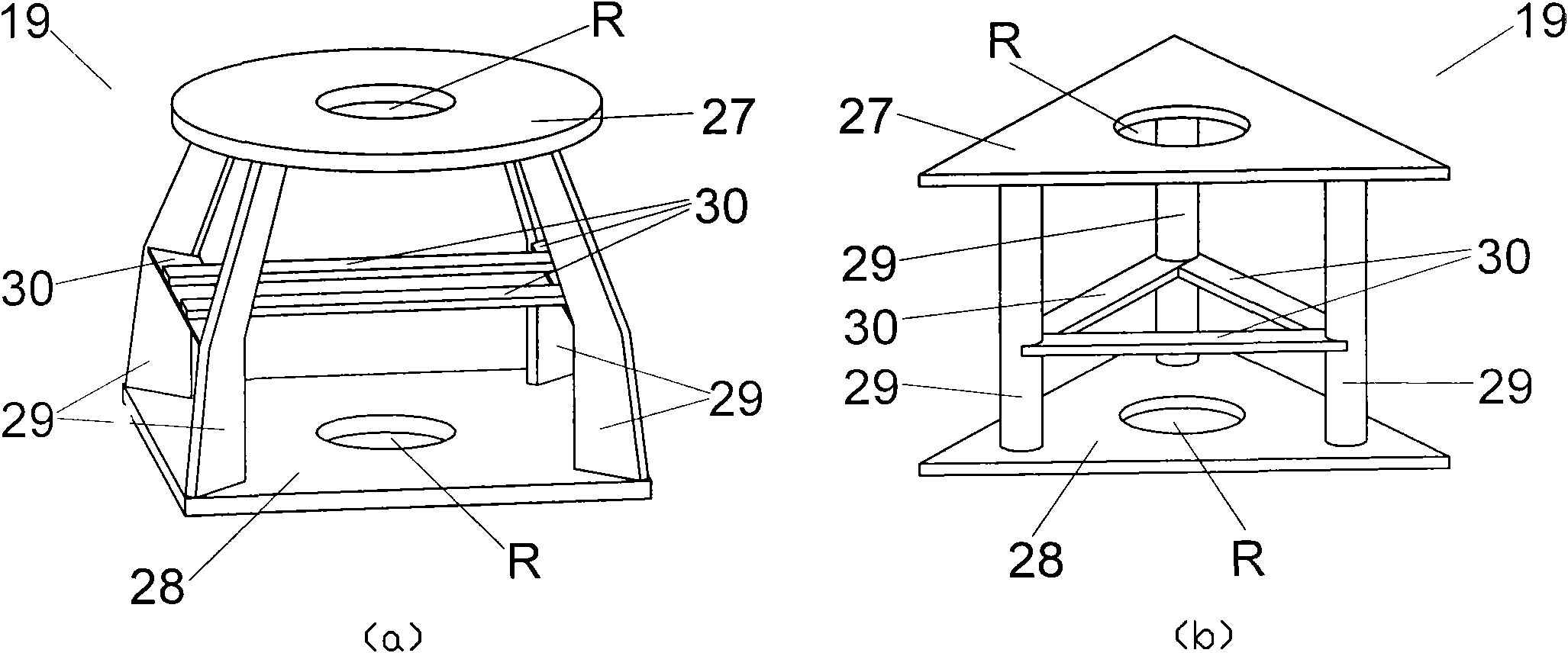

[0048] Figure 13 is a structural schematic diagram of Embodiment 1 of the present invention, which consists of Figure 5 (a) the tower shown in 2, two Figure 9 The vane unit 31 shown in (a) and Figure 11 The support unit 32 shown in (a) combines the wind wheel 3 and Figure 4 The main shaft assembly 18 shown in (a) forms a fan, and the fan together with a drive shaft 36, a transmission or torque converter 37 and a generator 38 form a vertical-axis wind power generator. Figure 5 The tower frame 2 of (a) is a square structure. Figure 9 The blade unit 31 of (a) is by two blades 9, two transverse arms 8 and four Figure 8 The connecting block 13 shown in (a) forms; The connection between cross arm 8 two ends and connecting block 13 is shown in Figure 8 (b), the blade 9 is installed on the connection block 13 . Figure 11 The support unit 32 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com