Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

168 results about "3-Hydroxybutanoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

BUTYRIC ACID substituted in the beta or 3 position. 3-Hydroxybutanoate is one of the ketone bodies produced in the liver. from MeSH 3-hydroxybutyrate is a hydroxy fatty acid anion that is the conjugate base of 3-hydroxybutyric acid , obtained by deprotonation of the carboxy group; major species at pH 7.3.

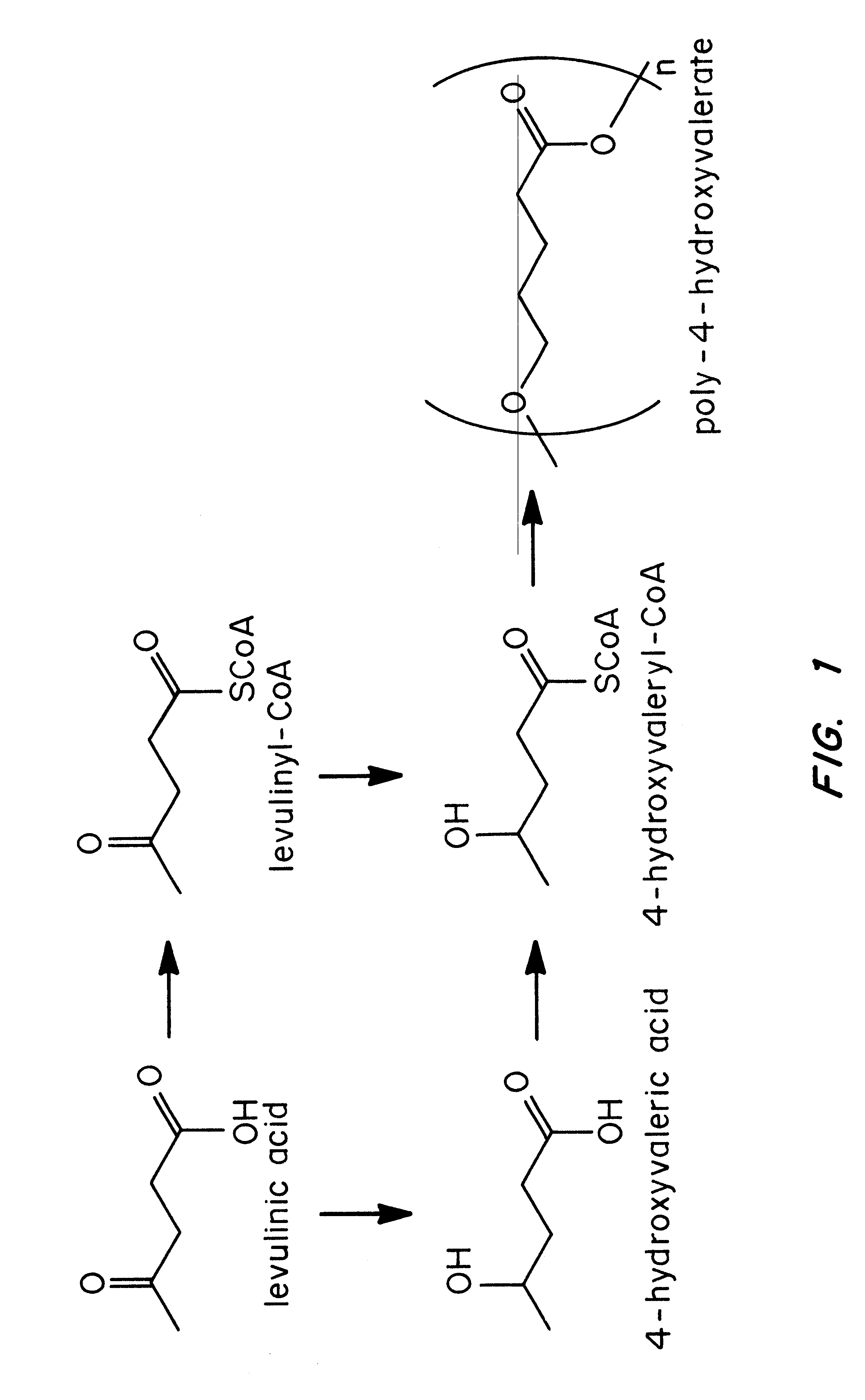

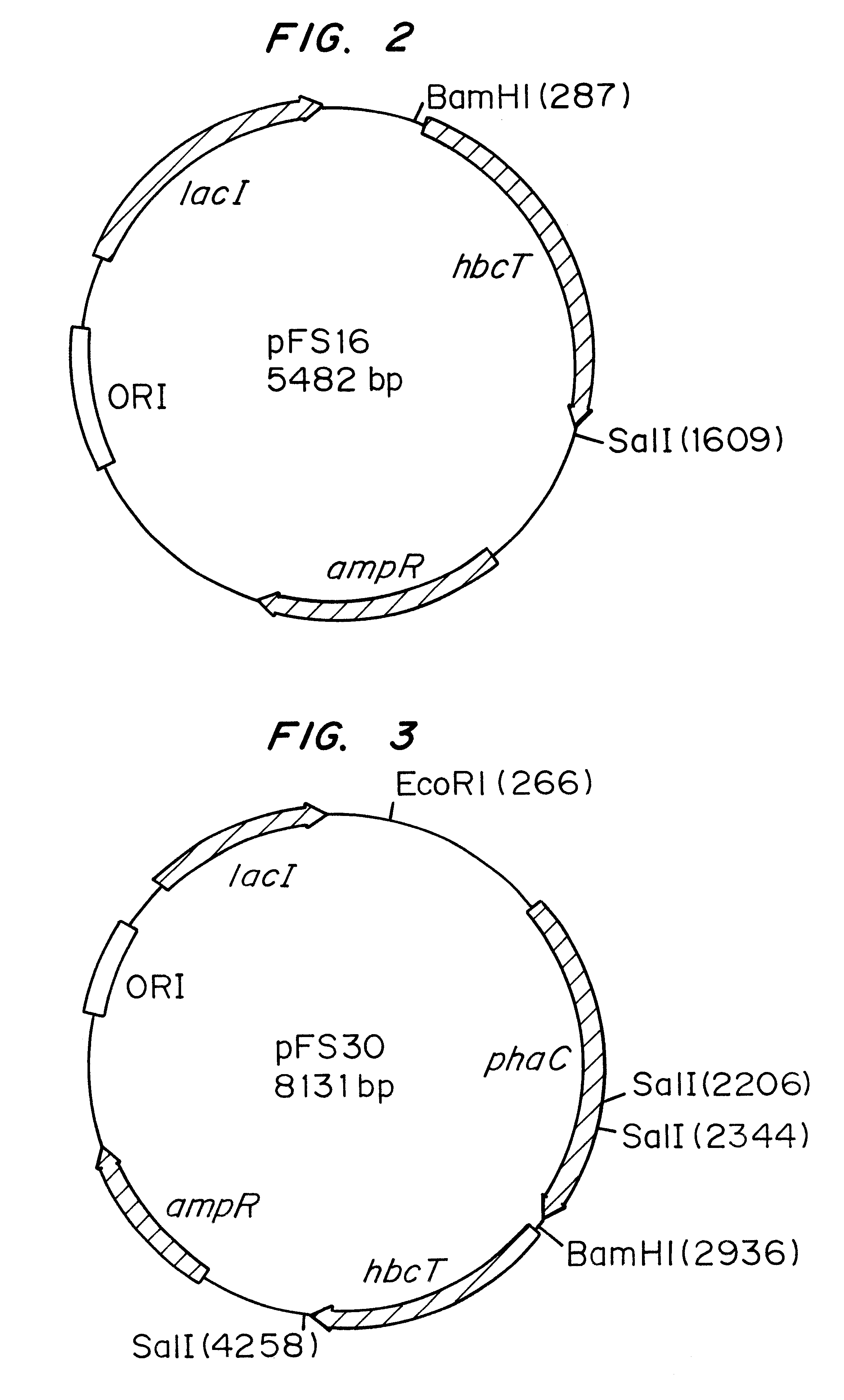

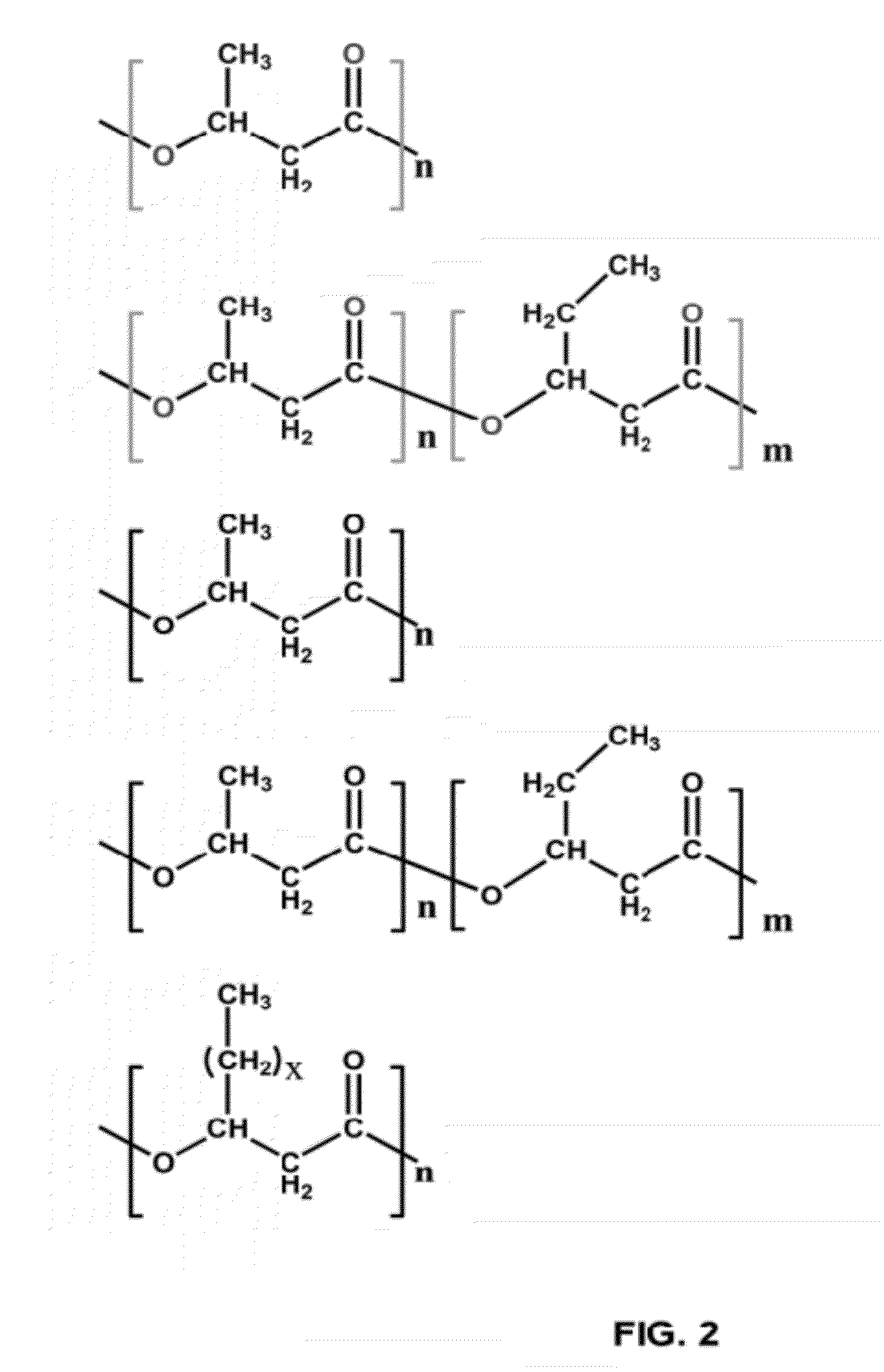

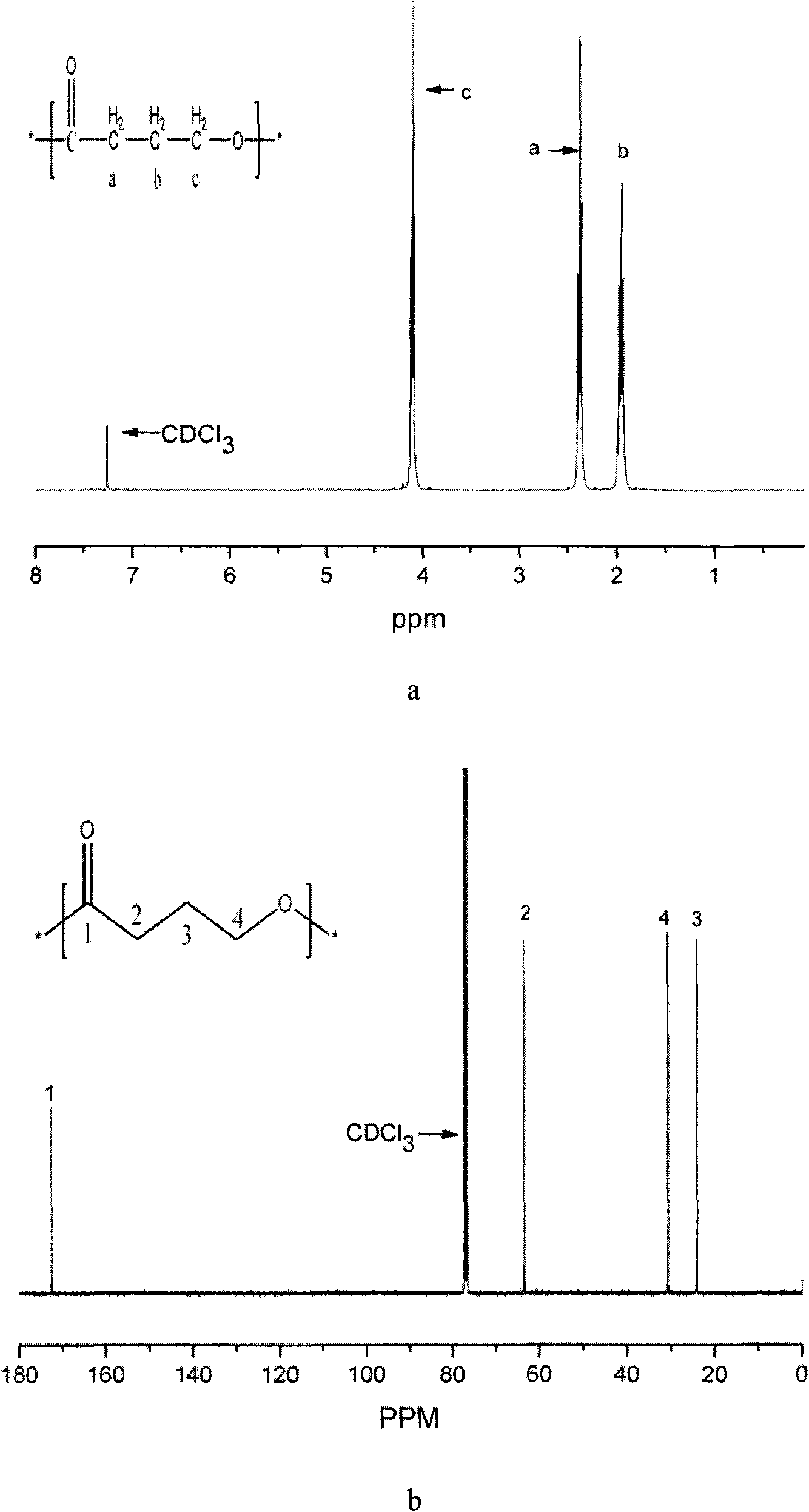

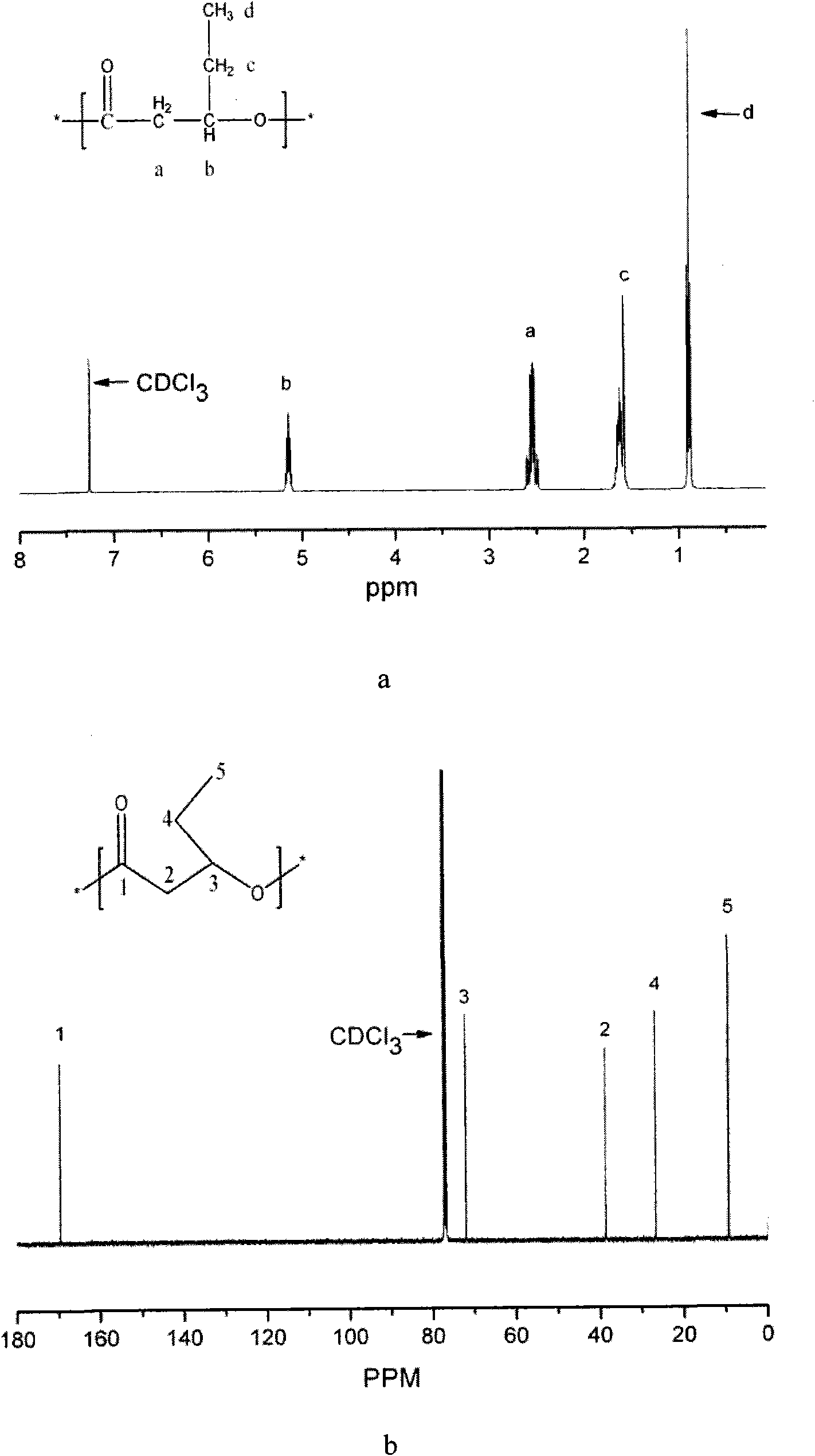

Polyhydroxyalkanoate biopolymer compositions

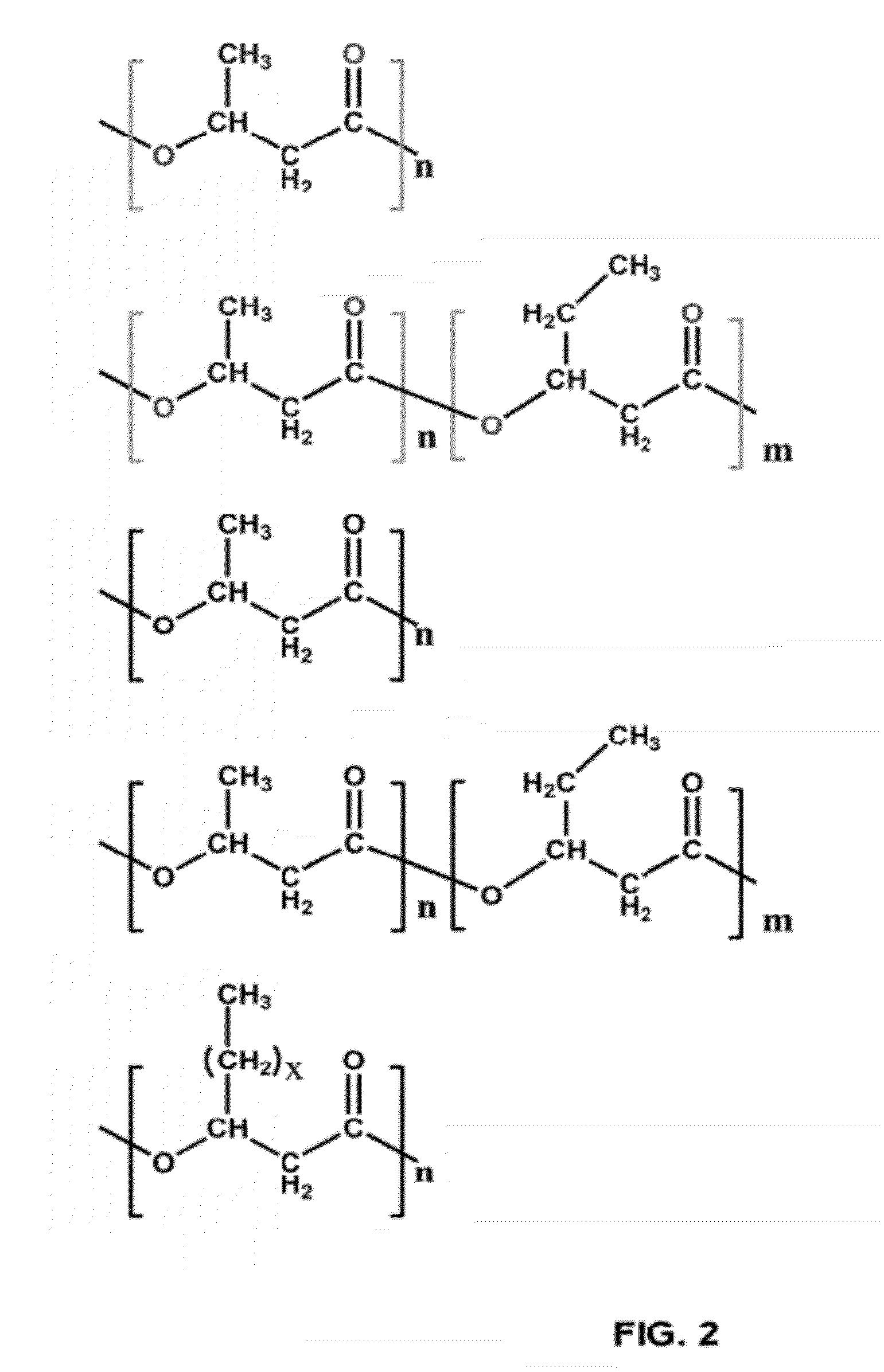

Several novel PHA polymer compositions produced using biological systems include monomers such as 3-hydroxybutyrate, 3-hydroxypropionate, 2-hydroxybutyrate, 3-hydroxyvalerate, 4-hydroxybutyrate, 4-hydroxyvalerate and 5-hydroxyvalerate. These PHA compositions can readily be extended to incorporate additional monomers including, for example, 3-hydroxyhexanoate, 4-hydroxyhexanoate, 6-hydroxyhexanoate or other longer chain 3-hydroxyacids containing seven or more carbons. This can be accomplished by taking natural PHA producers and mutating through chemical or transposon mutagenesis to delete or inactivate genes encoding undesirable activities. Alternatively, the strains can be genetically engineered to express only those enzymes required for the production of the desired polymer composition. Methods for genetically engineering PHA producing microbes are widely known in the art (Huisman and Madison, 1998, Microbiology and Molecular Biology Reviews, 63: 21-53). These polymers have a variety of uses in medical, industrial and other commercial areas.

Owner:METABOLIX

Biodegradable card base

InactiveUS6350530B1High strengthReduce rigidityDecorative surface effectsDuplicating/marking methodsPolyesterPolymer science

The present invention provides a card base which is degradable by microbes in natural environment. The card base is excellent in properties necessary for card bases, such as tensile strength, impact strength, flex temperature, heat resistance, resistance to thermal expansion and contraction, blocking resistance and humidity resistance, and has rigidity, bending resistance and durability. The card base contains, as essential components, a 3-hydroxybutylate / 3-hydroxyvalerate copolymer and a lactic acid polymer, and, where necessary, a polycaprolactone or a high-molecular aliphatic polyester. The card base has a single-layer structure, or a sandwich structure further having overlay layers comprising a composition containing, as essential components, a lactic acid polymer and either or both of a polycaprolactone and a high-molecular alphatic polyester.

Owner:GUNZE LTD

Degradable mulch film and preparation method thereof

InactiveCN102850626AFast degradationHigh strengthPlant protective coveringsPolyolefinPolymer science

The invention provides a degradable mulch film and a preparation method thereof, which belongs to the technical field of high polymer materials. The degradable mulch film comprises, by weight, 10 to 20 parts of polyethylene, 10 to 20 parts of polypropylene, 2 to 3 parts of polyvinyl alcohol, 1 to 2 parts of poly propylene carbonate, 3 to 5 parts of polylactic acid, 1 to 2 parts of poly(3-hydroxybutyrate-co-4-hydroxybutyrate), 4 to 6 parts of chitosan, 2 to 4 parts of methyl-polyolefin resin, 2 to 4 parts of polypropylene glycol, 0.5 part of nanometer titanium dioxide, 0.5 part of a photolysis agent, 5 to 15 parts of an inorganic filling material and 5 to 15 parts of starch. The degradable mulch film provided by the invention has the following advantages: 1, a fast degradation fast, and a fast degradation rate of more than 35% within 120 d; 2, high strength, transverse tensile strength of more than 16 MPa and vertical tensile strength of more than 17 MPa.

Owner:苏州市德莱尔建材科技有限公司

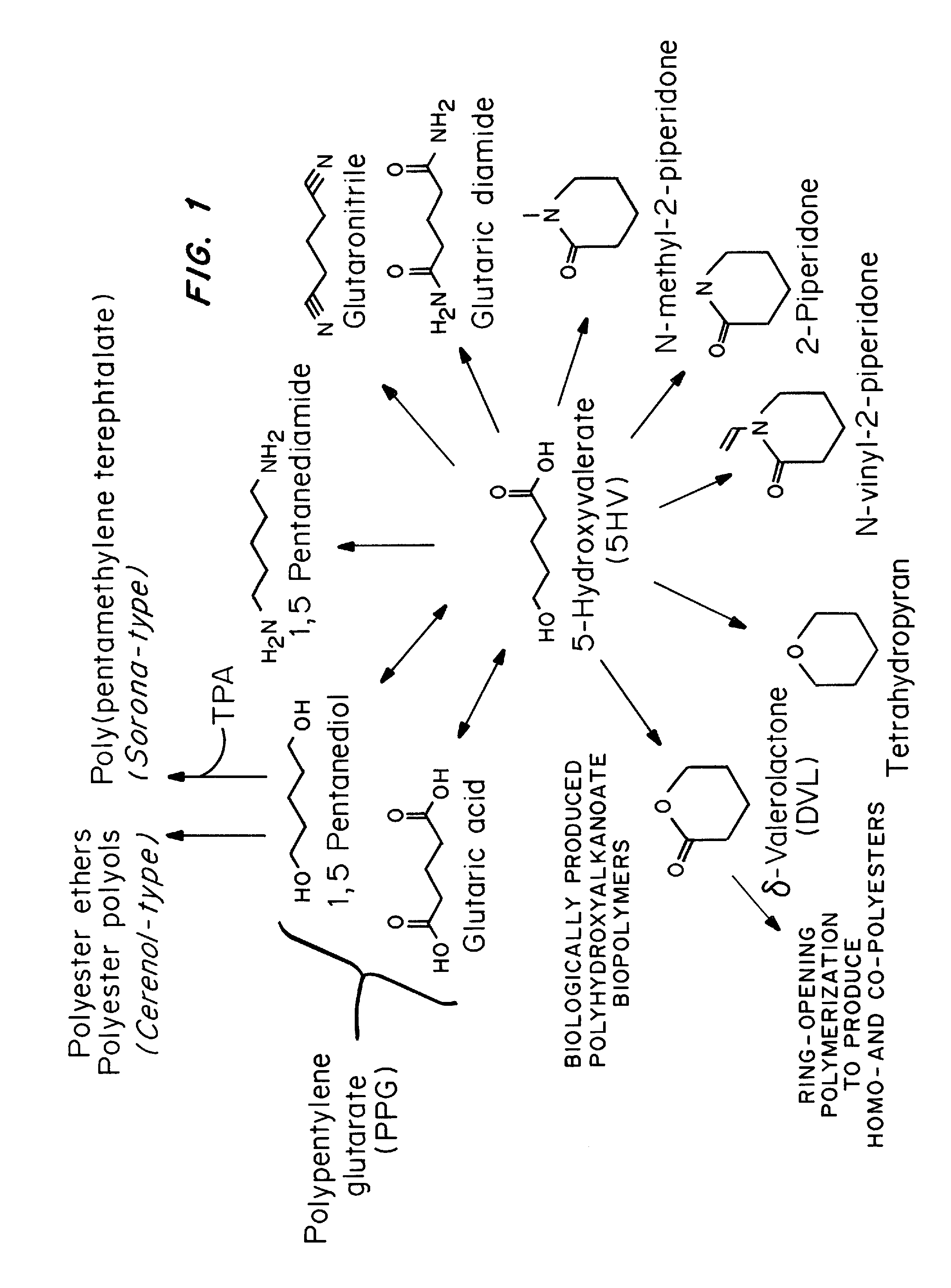

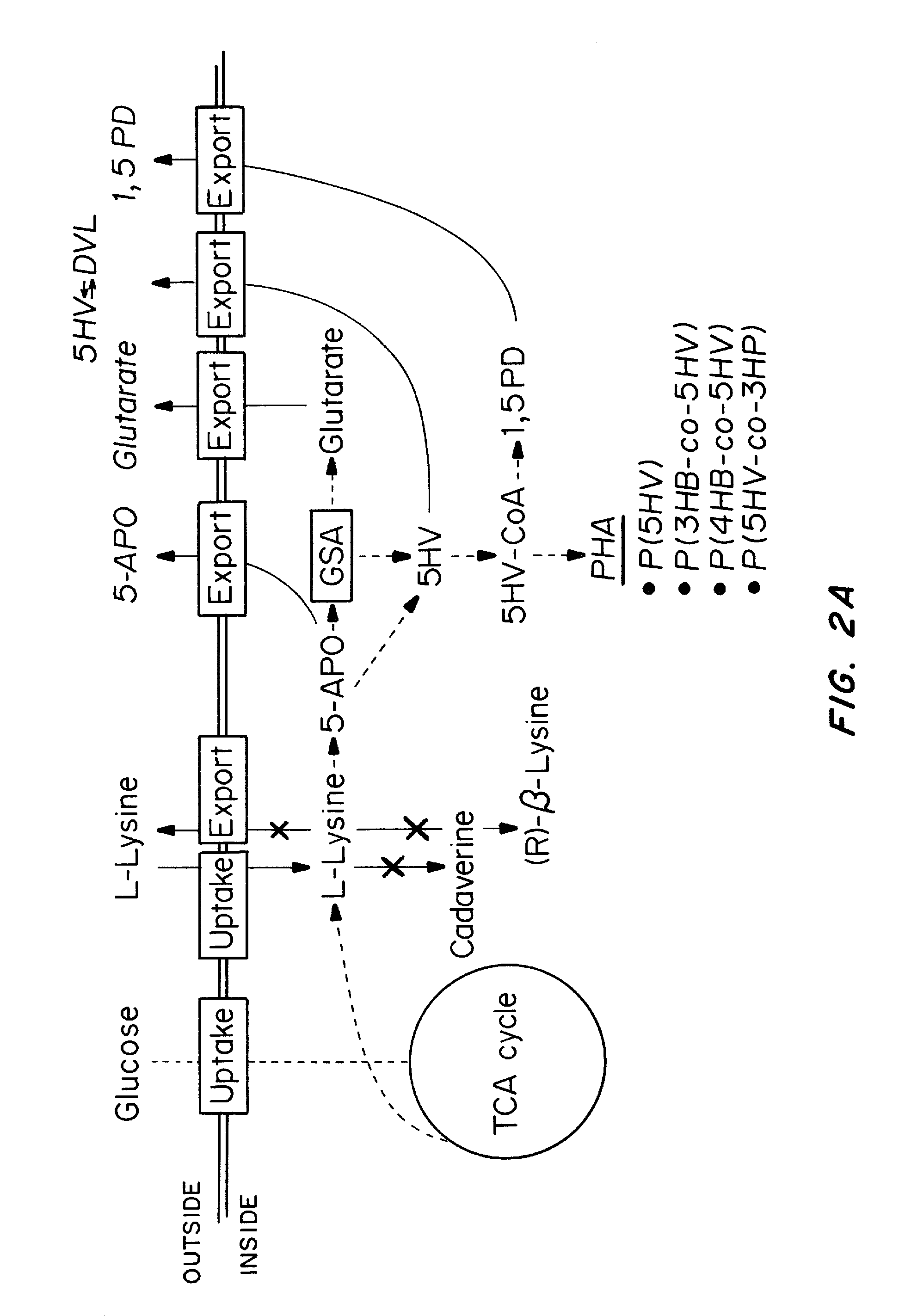

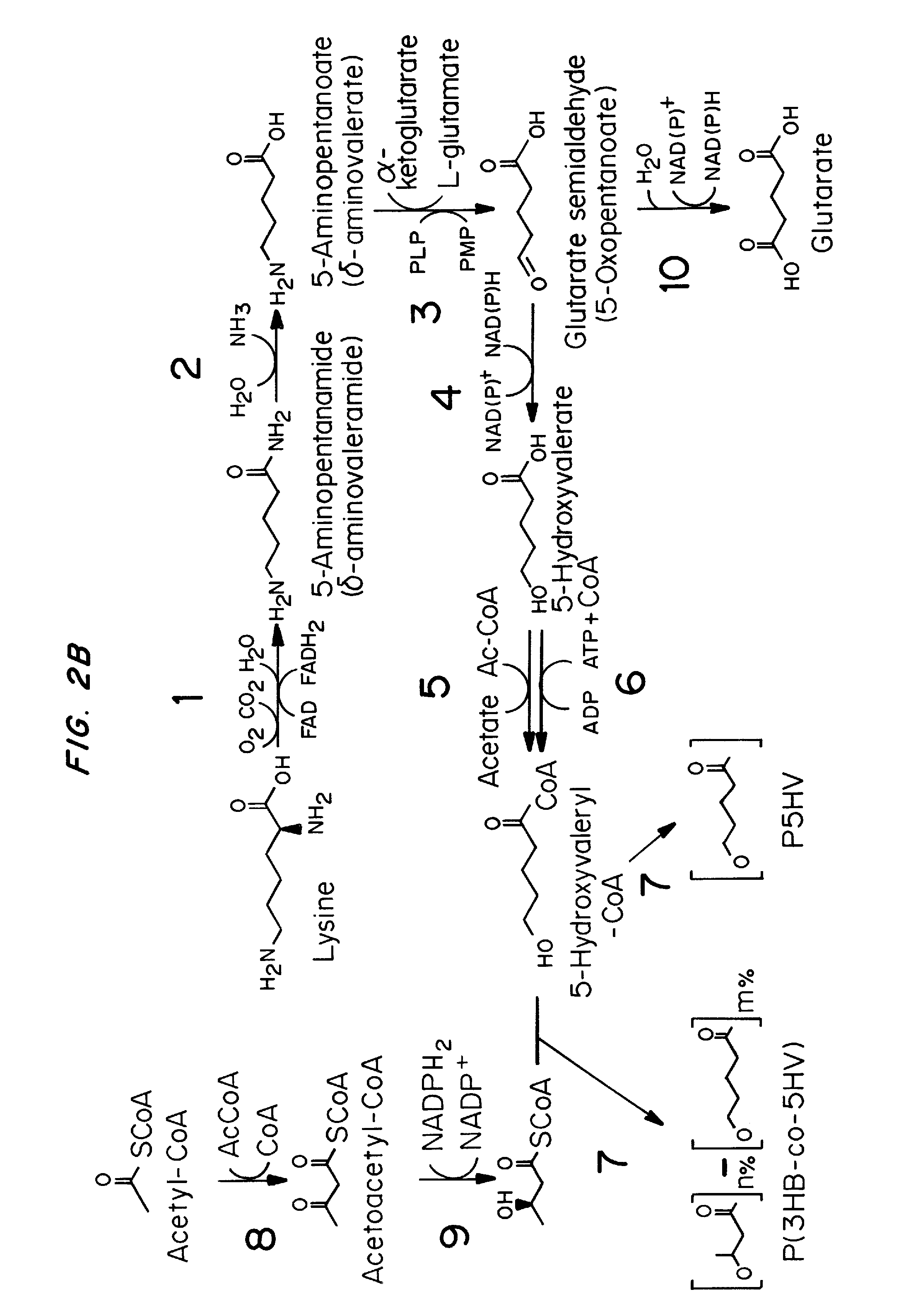

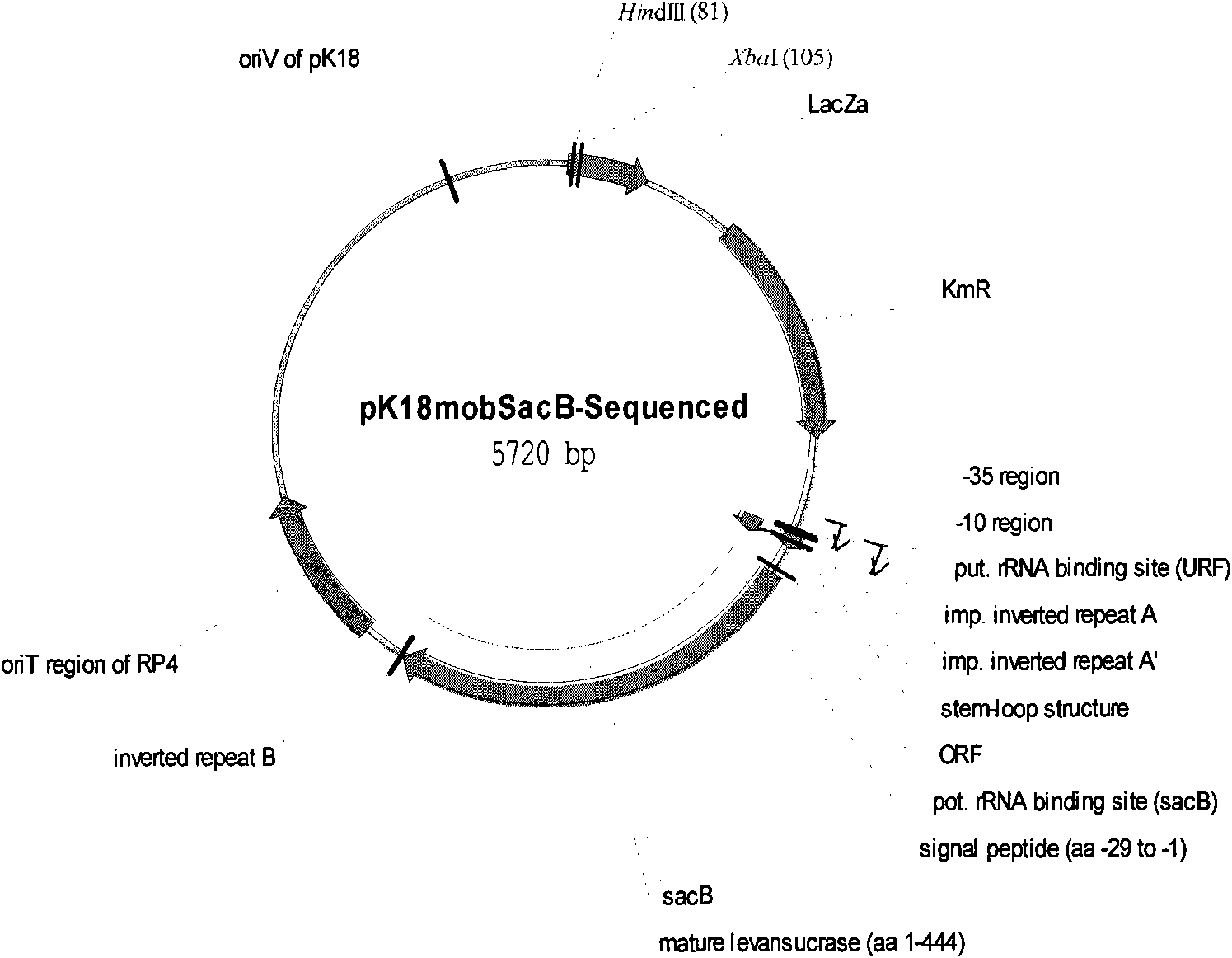

Green process and compositions for producing poly(5HV) and 5 carbon chemicals

Recombinant hosts for producing polyhydroxyalkanoates and methods of producing polyhydroxyalkanoates from renewable carbon substrates are provided. Certain recombinant hosts that produce 5 carbon chemicals such as 5-aminopentanoate (5AP), 5-hydroxyvalerate (5HV), glutarate, and 1,5 pentanediol (PDO) are also provided. One embodiment provides a recombinant host expressing a gene encoding a heterologous enzyme selected from the group consisting of a polyhydroxyalkanoate synthase and a 5-hydroxyvalerate-CoA (5HV-CoA) transferase, wherein the host produces a polymer containing 5-hydroxyvalerate. Preferably, the host expresses both a polyhydroxyalkanoate synthase and a 5HV-CoA transferase. The host can be prokaryotic or eukaryotic. A preferred prokaryotic host is E. coli. The polymers produced by the recombinant hosts can be homopolymers or copolymers of 5-hydroxyvalerate. A preferred copolymer is poly(3-hydroxybutyrate-co-5-hydroxyvalerate).

Owner:CJ CHEILJEDANG CORP

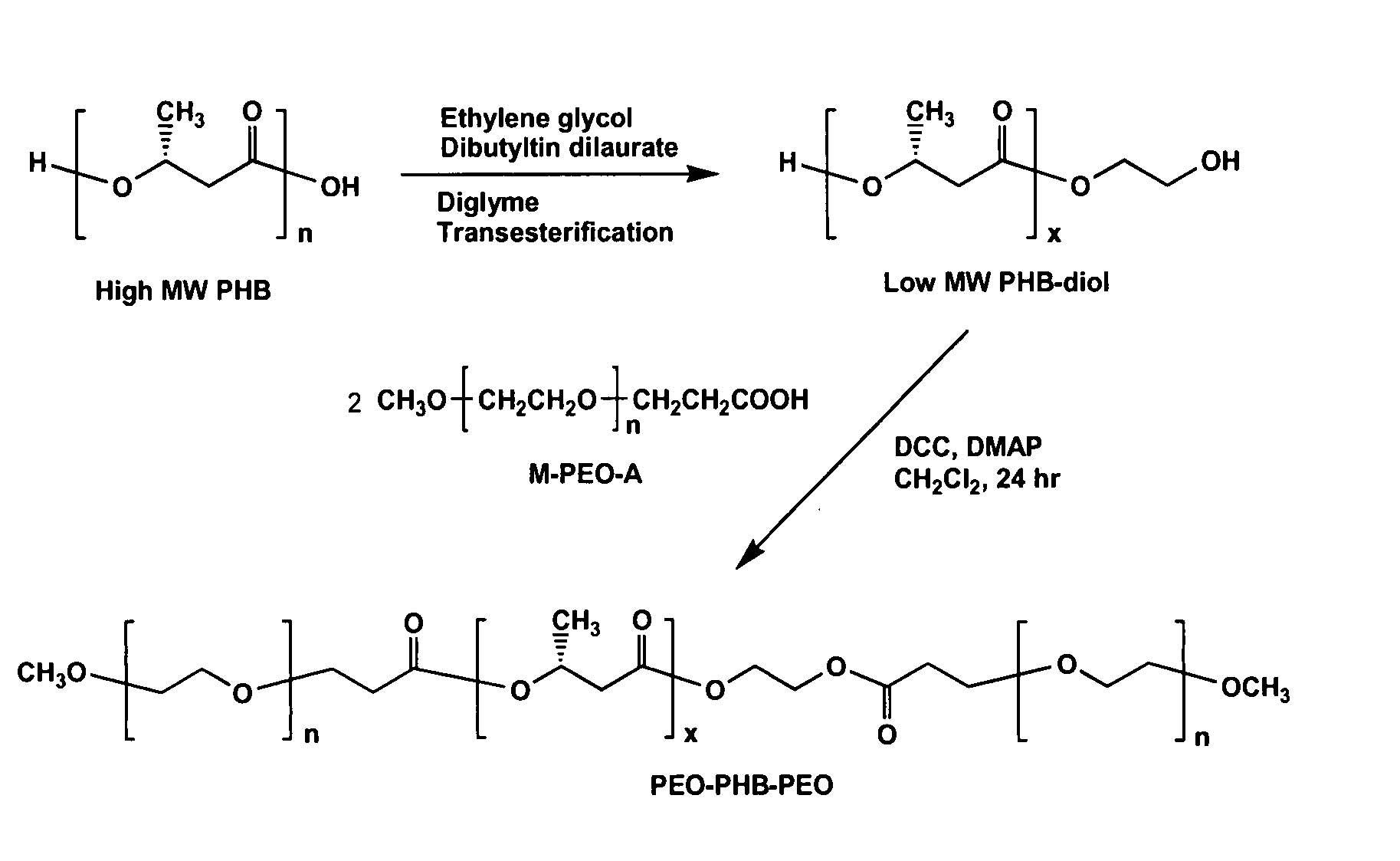

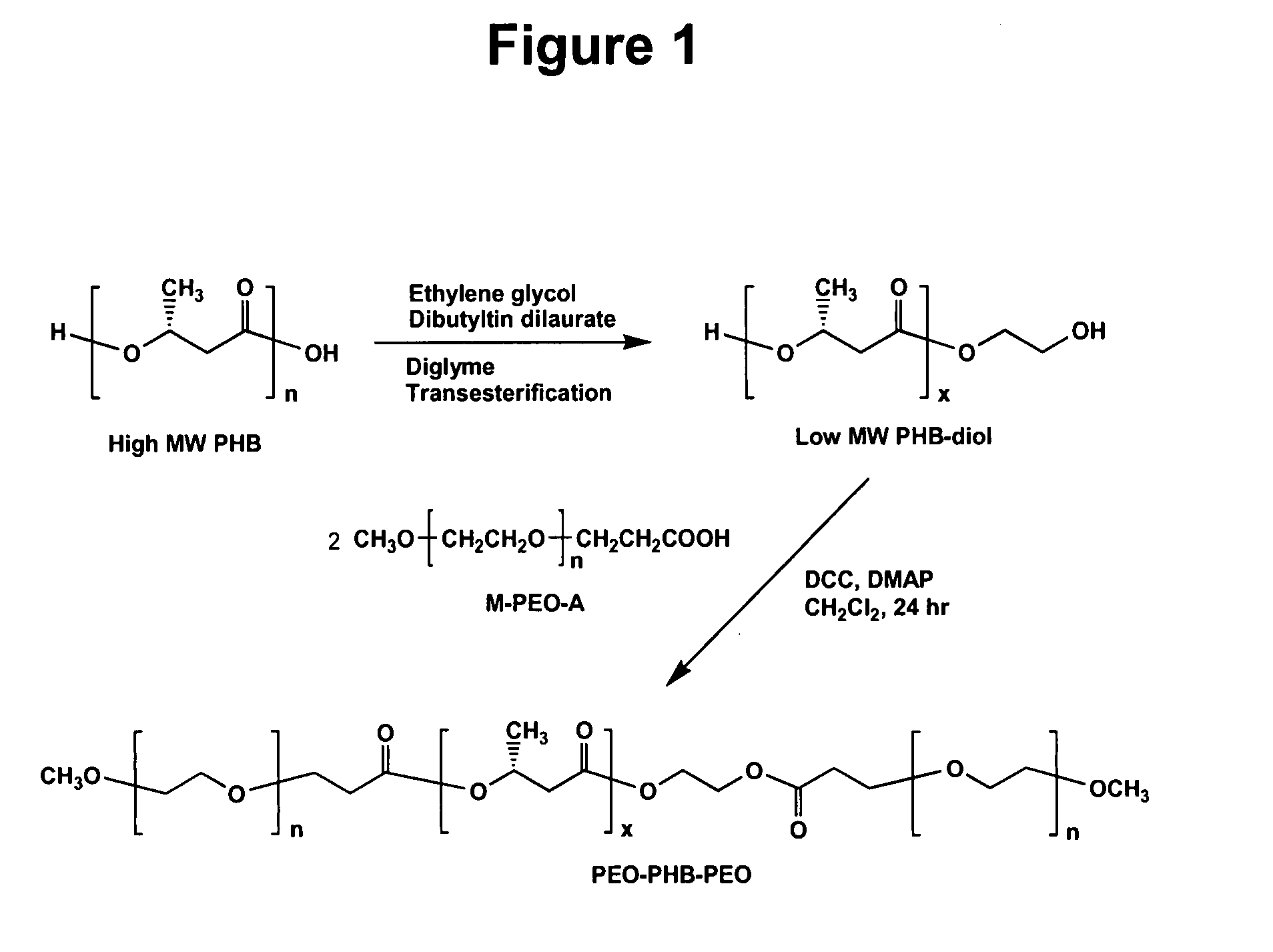

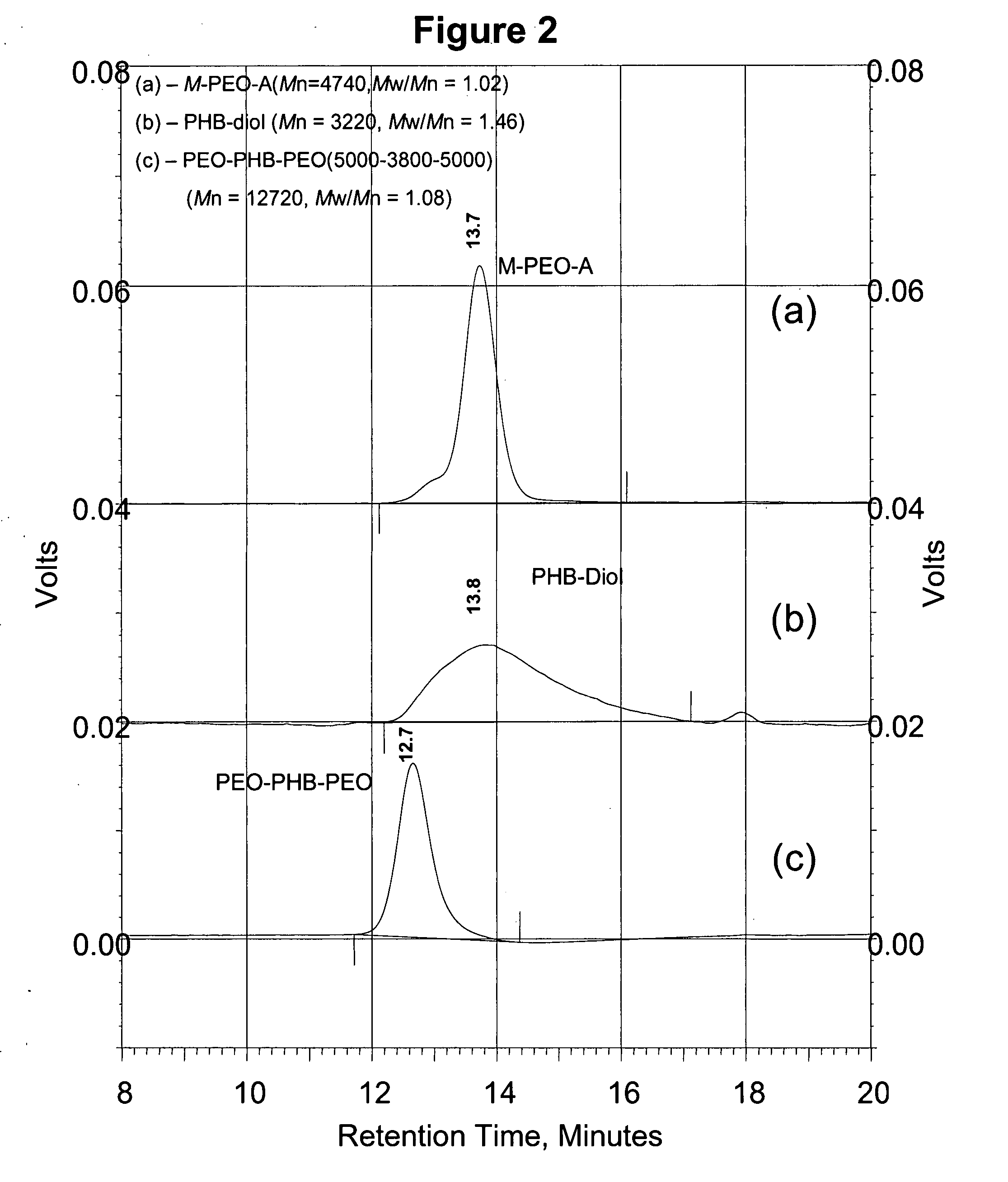

Biodegradable triblock copolymers, synthesis methods therefore, and hydrogels and biomaterials made there from

InactiveUS20080057128A1Interesting propertyVivo degradation ratePowder deliveryPeptide/protein ingredientsPolymer scienceSynthesis methods

A drug delivery system that includes micelles formed from an amphiphilic copolymer that includes an A polymer block comprising a poly(alkylene oxide) and a B polymer block comprising a poly(hydroxyalkanoate), and a therapeutically effective amount of at least one therapeutic agent intimately contained within the micelles. In one preferred embodiment of the invention, the A polymer block is poly(ethylene oxide) (PEO) and the B polymer block is poly[(R)-3-hydroxybutyrate] (PHB), and the copolymer is the triblock ABA copolymer PEO-PHB-PEO. A method of synthesizing the amphiphilic triblock copolymer is also provided.

Owner:OMEROS CORP

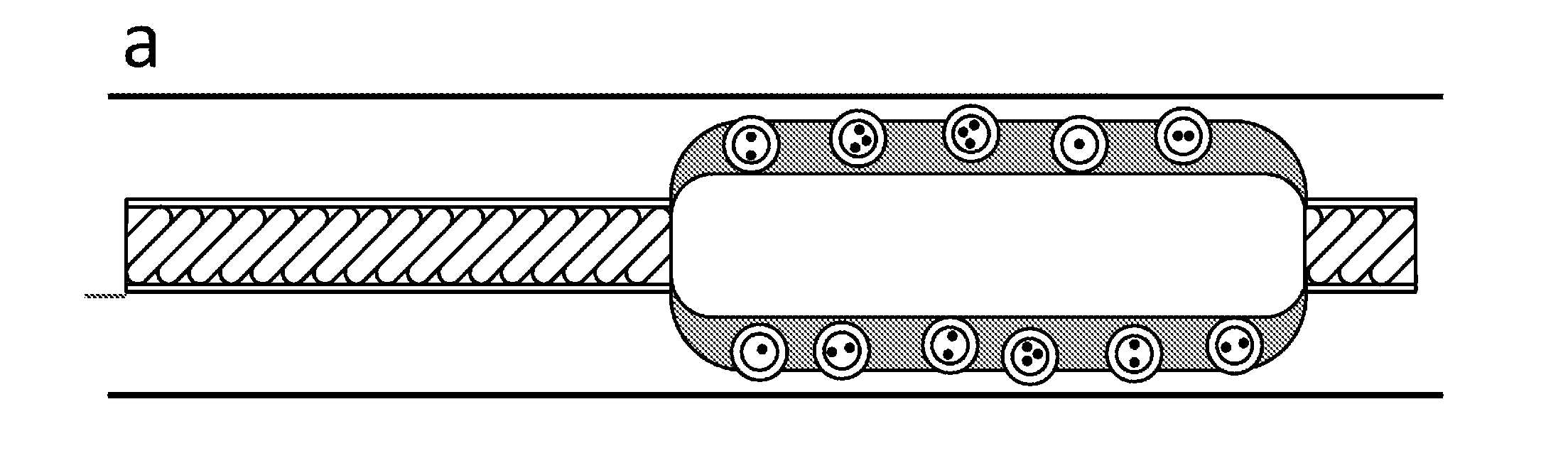

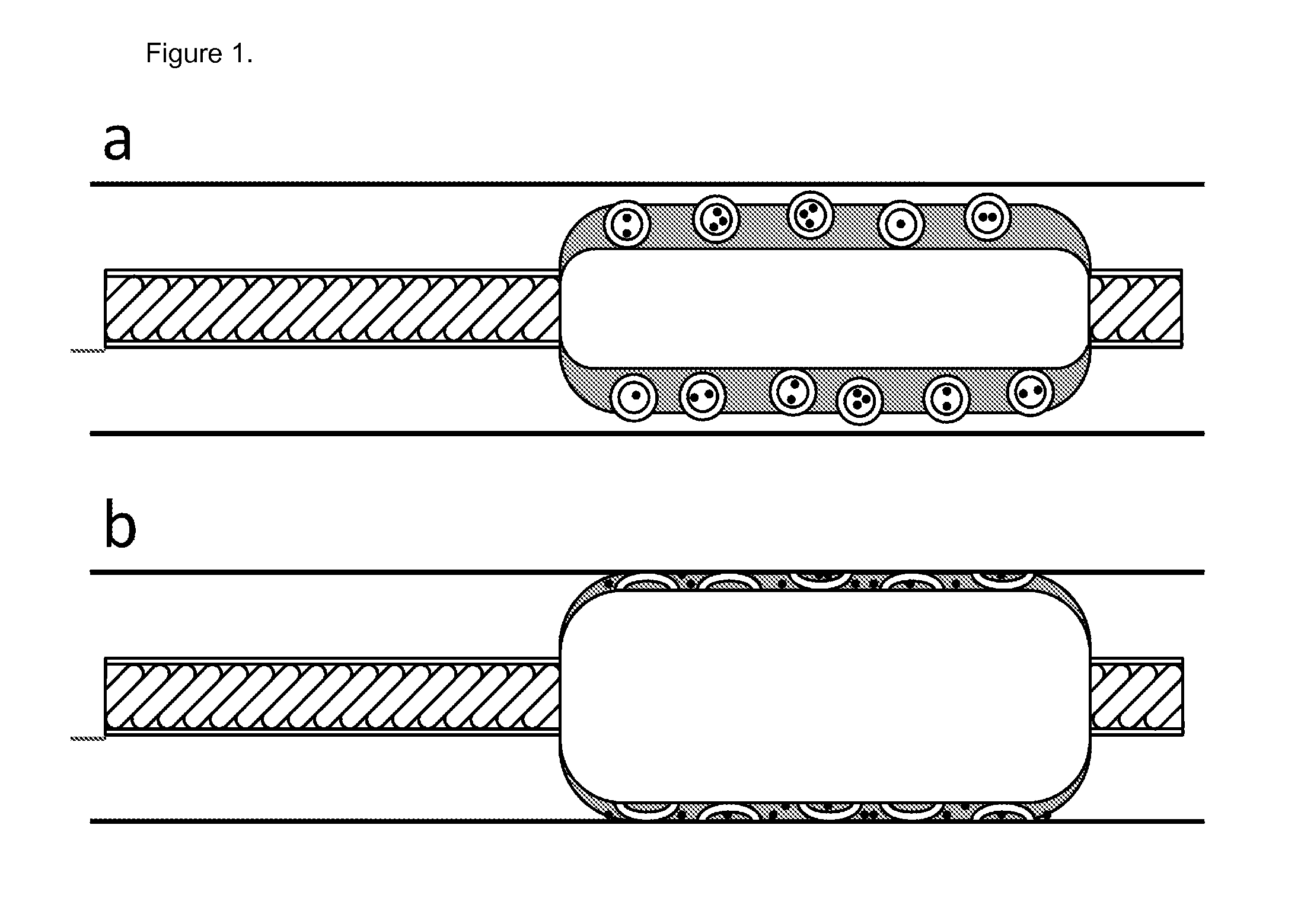

Balloon catheter comprising pressure sensitive microparticles

InactiveUS20120083734A1Improve brittlenessEffective treatmentSurgeryDilatorsPolyesterPoly(N-isopropylacrylamide)

The invention provides a solution to the above mentioned problem in that it provides a catheter balloon comprising a flexible coating on its outer surface wherein a plurality of microparticles are contained wherein said coating comprises a material selected from the group consisting of poly(N-vinyl-pirrolidone, poly(N-vinyl-pirrolidone-co-butylacrylate), poly(-vinyl pyridine), polyacrylamides, e.g. poly(N-isopropylacrylamide), poly(amido-amines), poly(ethylene imine), poly(ethylene oxide-block-propylene oxide), poly(ethylene oxide-block-propylene oxide-block-ethylene oxide), poly(styrene-block-isobutylene-block-styrene), poly(hydroxystyrene-block-isobutylene-block-hydroxystyrene), polydialkylsiloxanes, polysaccharides, polyacrylates and polyalkylmethacrylates, e.g. polymethylmethacrylate and poly(2-hydroxyethylmethacrylate) and wherein said microparticles comprise a material selected from the group consisting of polyesters, e.g. poly(lactic acid), poly(lactic-co-glycol acid), poly(glycolic acid), poly(3-hydroxybutyrate), poly(3-hydroxyvalerate), poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and polycaprolactone, polyamides, polysaccharides, polyurethanes, polyalkylmethacrylates and polyacrylates, e.g. polymethylmethacrylate and poly(2-hydroxyethylmethacrylate) and wherein the microparticles comprise a pharmaceutically active compound.

Owner:ENCAPSON

Fibers, nonwoven fabrics, and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate

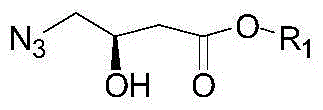

InactiveUS6013590AProtect and promote and control plant growthHigh elongationBaby linensAdhesivesPolymer scienceBiodegradable copolymers

The present invention relates to fibers, and nonwovens comprising said fibers, comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid previous topsheet, a biodegradable liquid impervious backsheet comprising the above fibers and / or nonwovens, and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

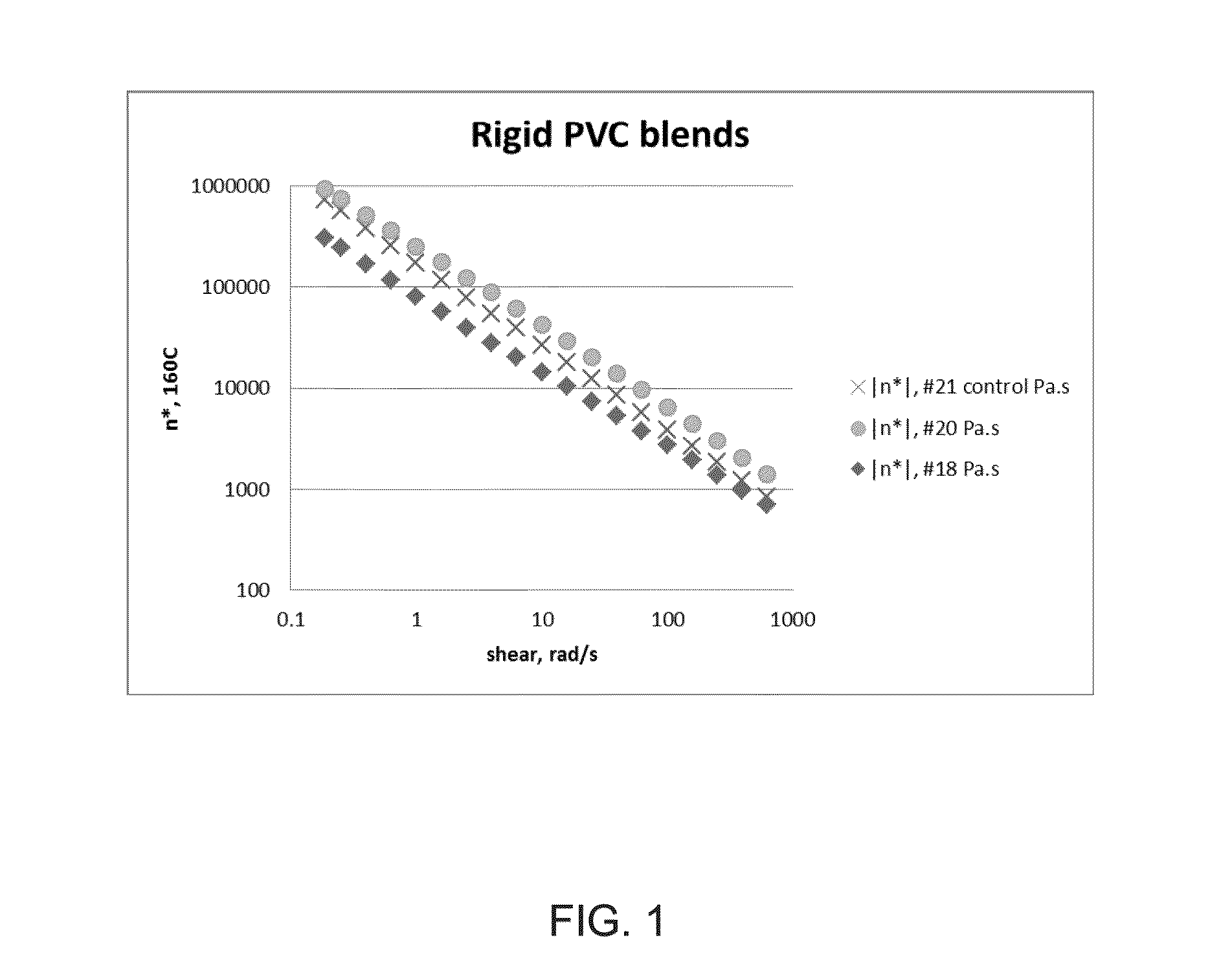

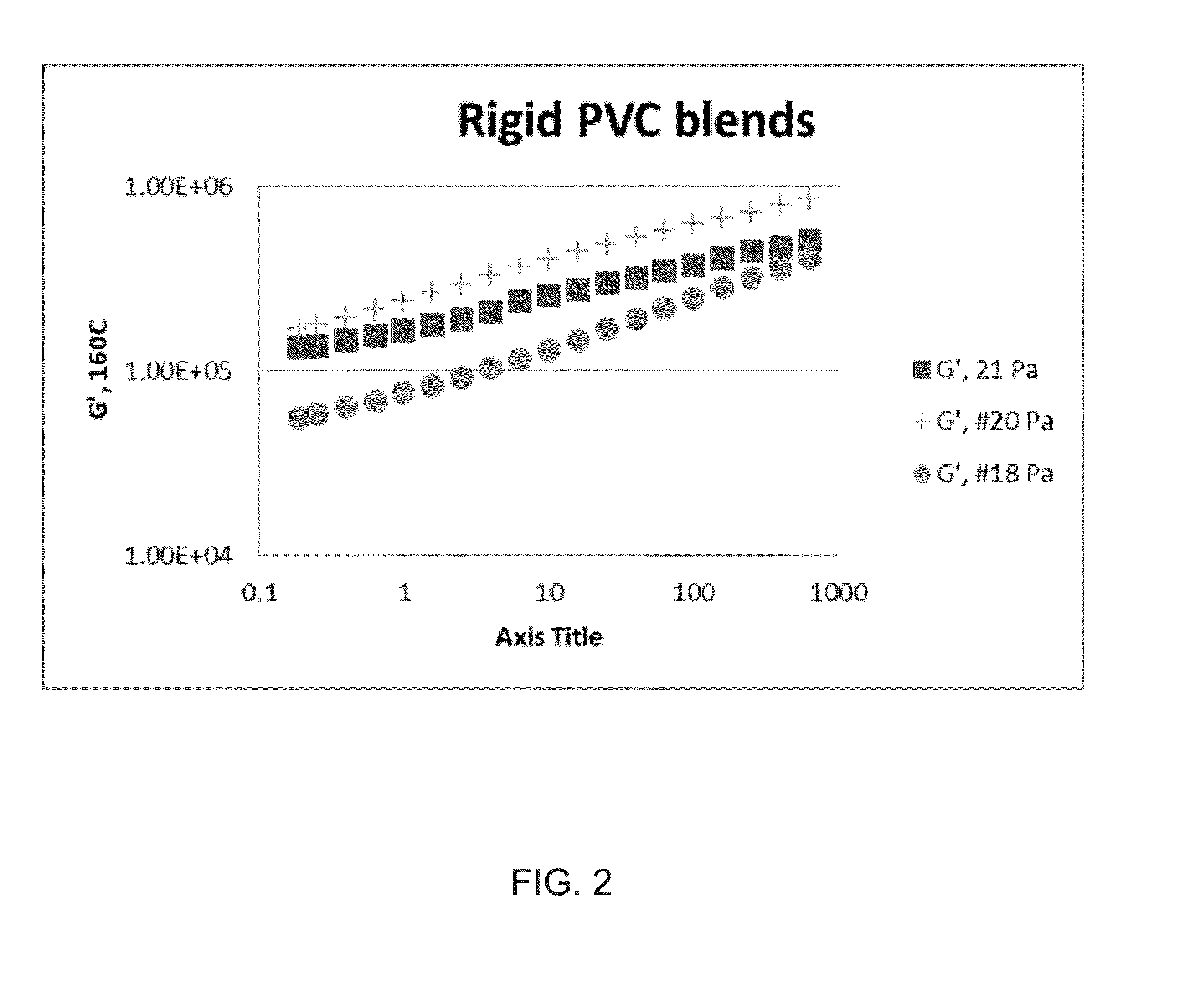

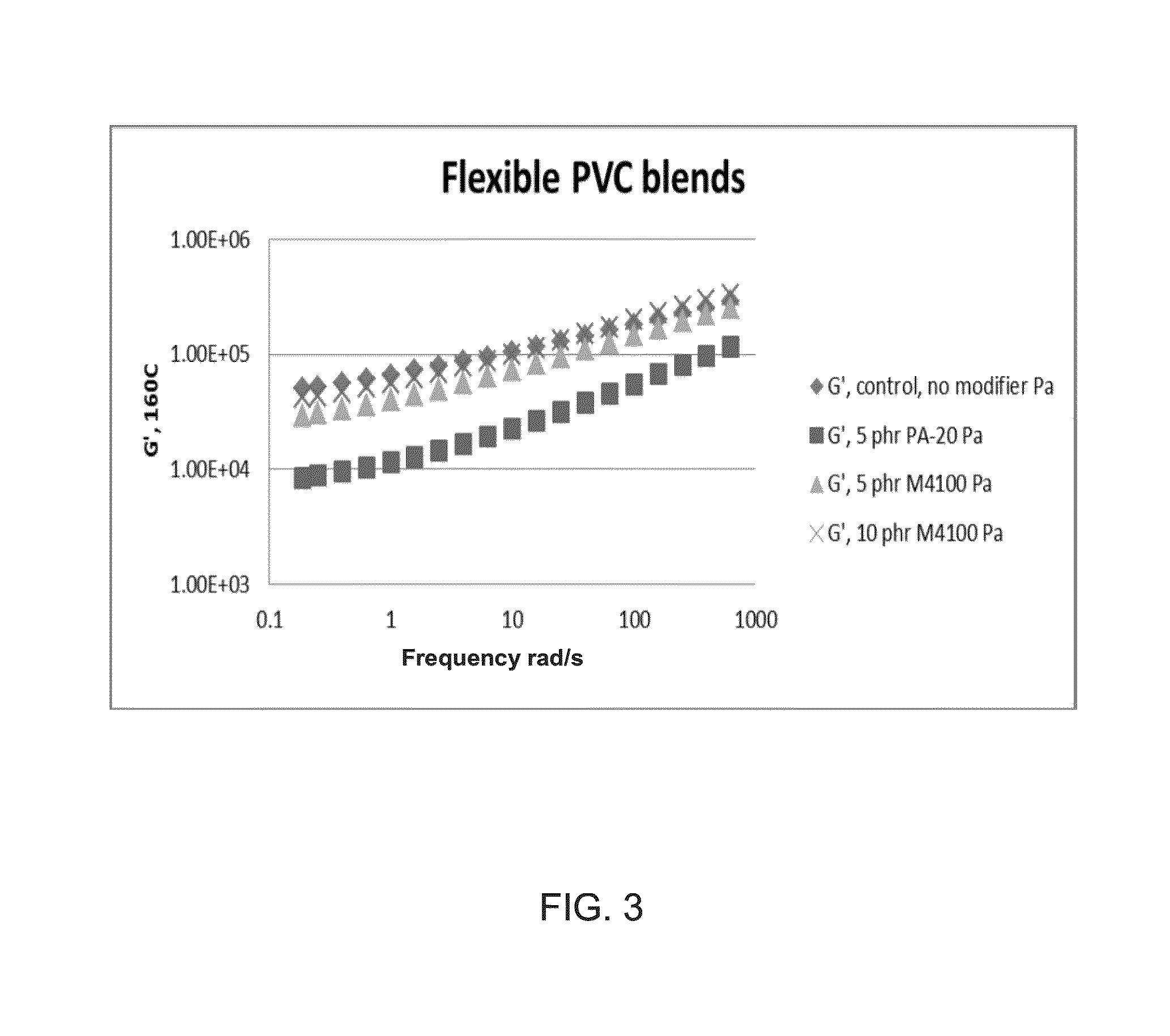

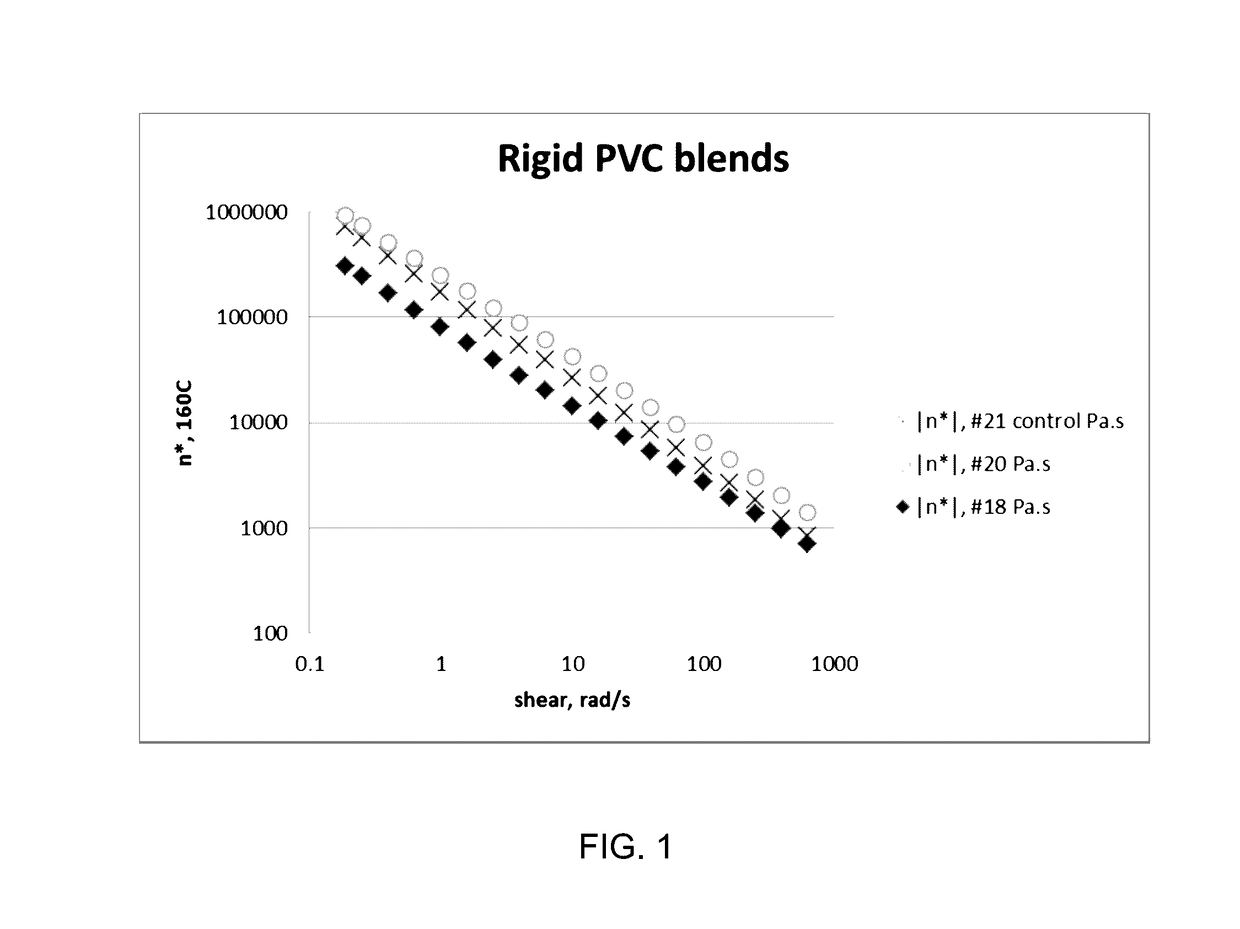

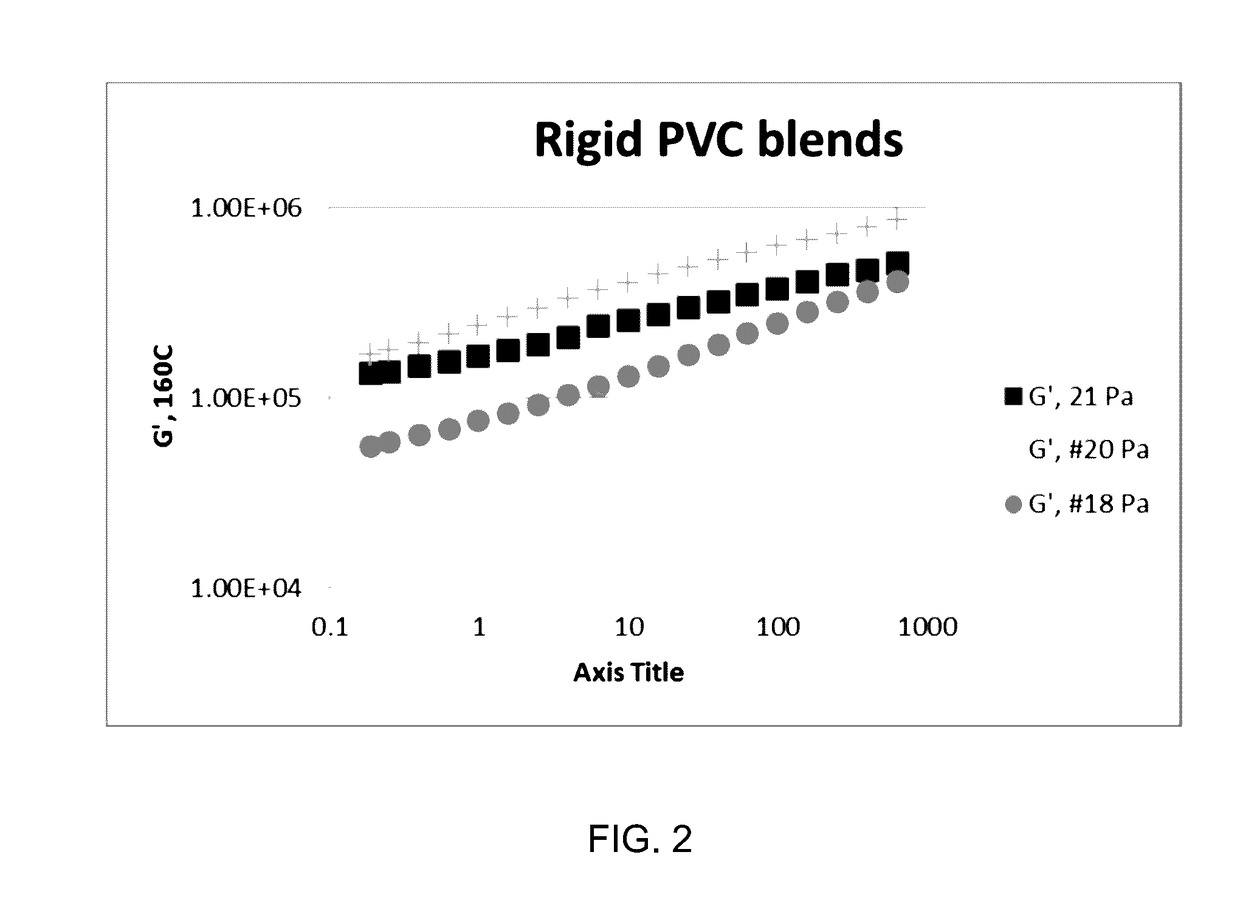

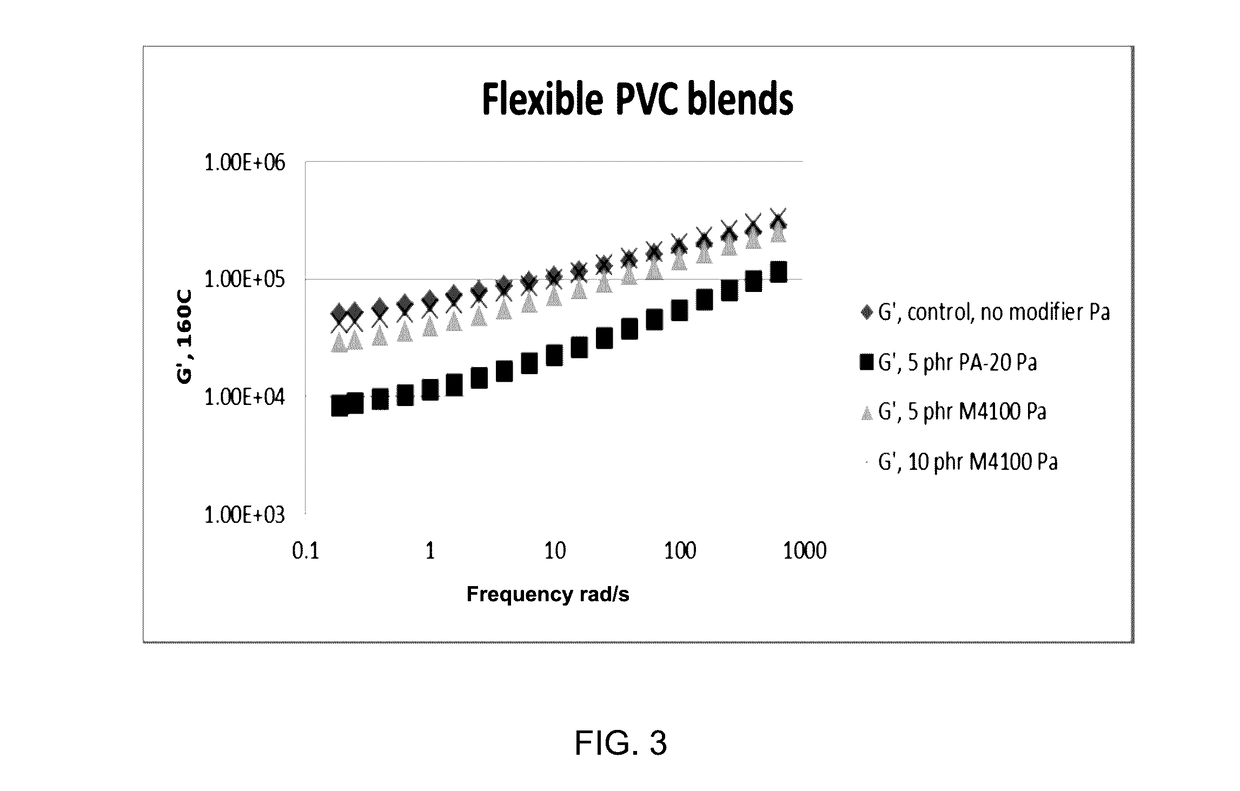

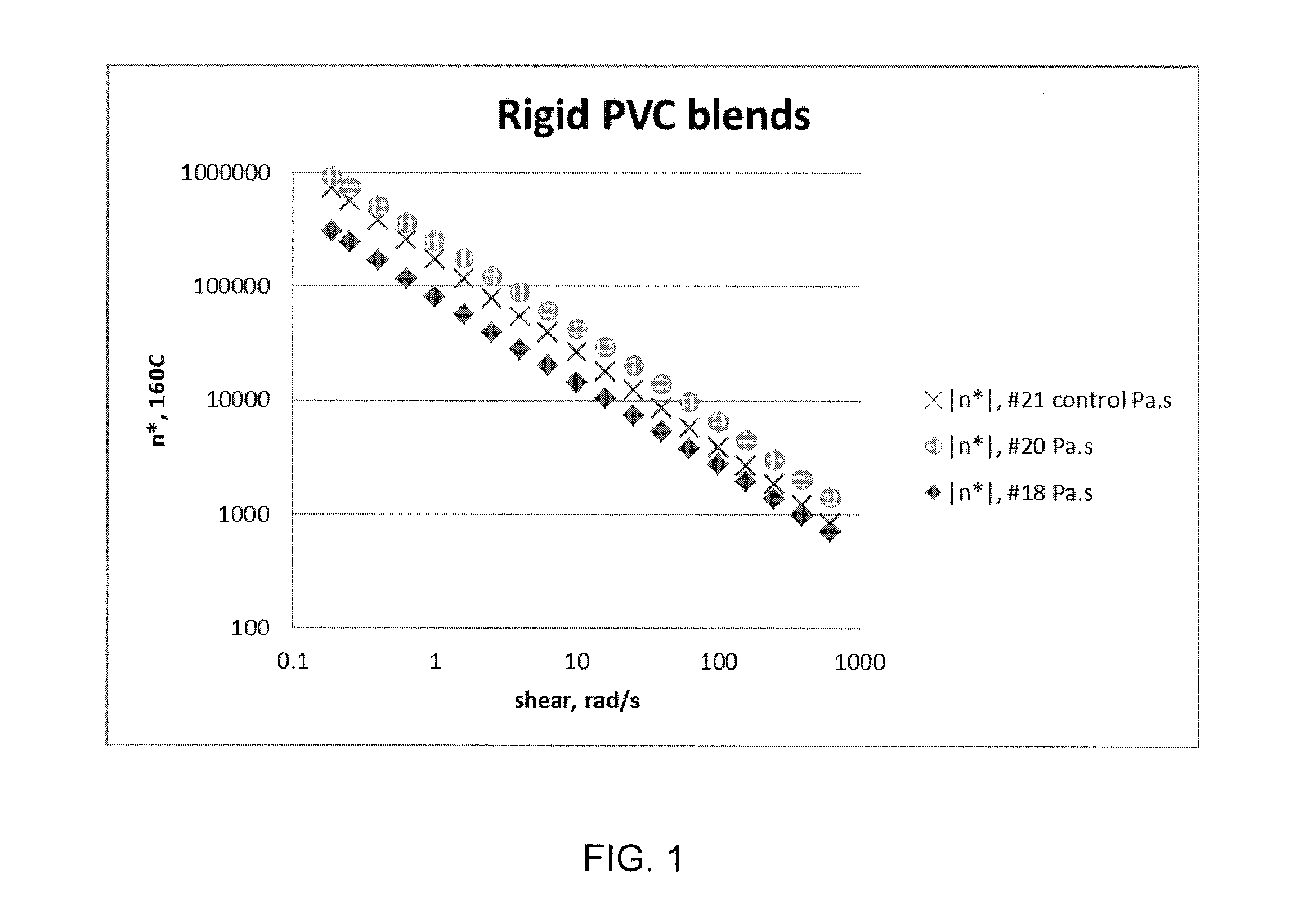

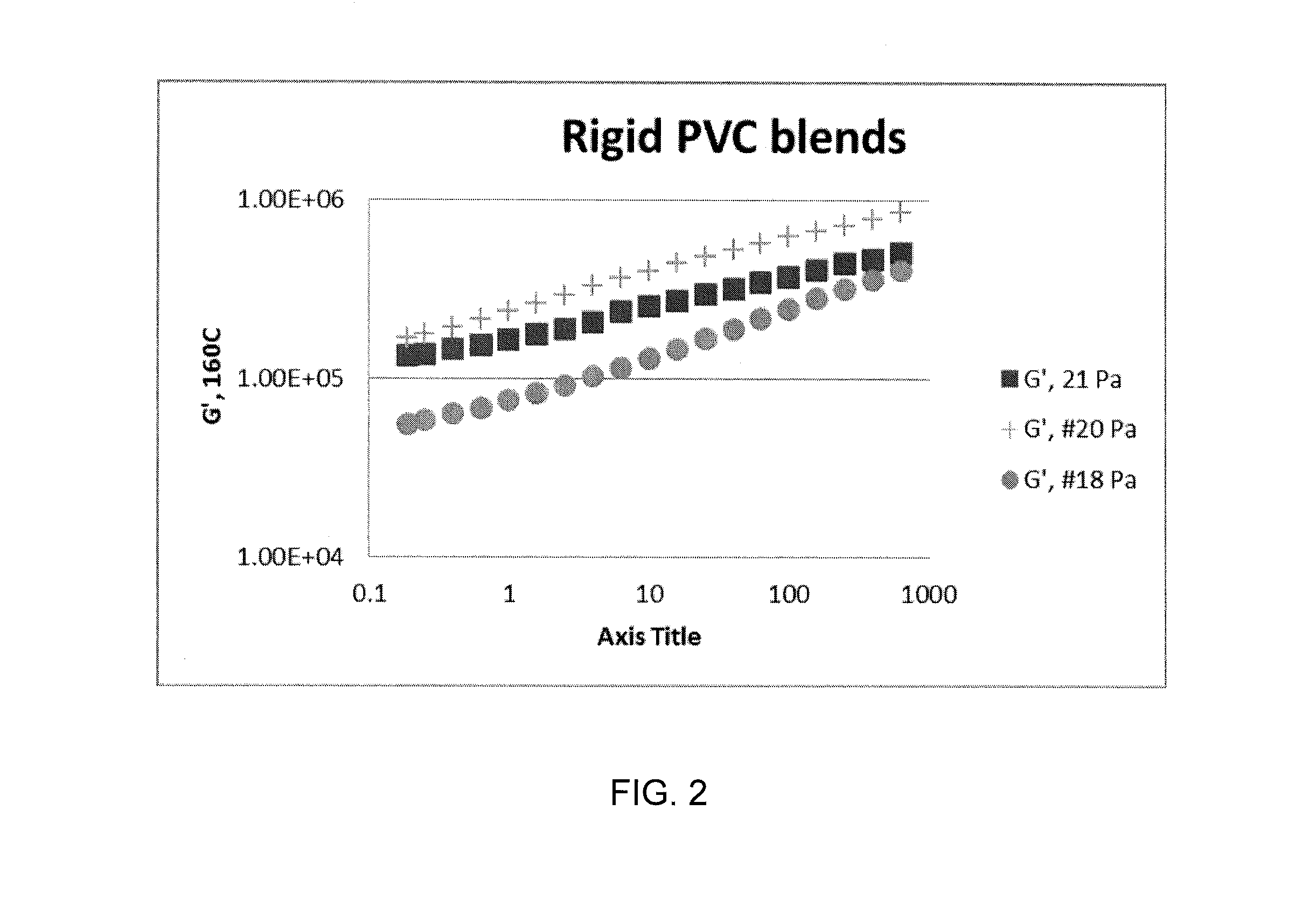

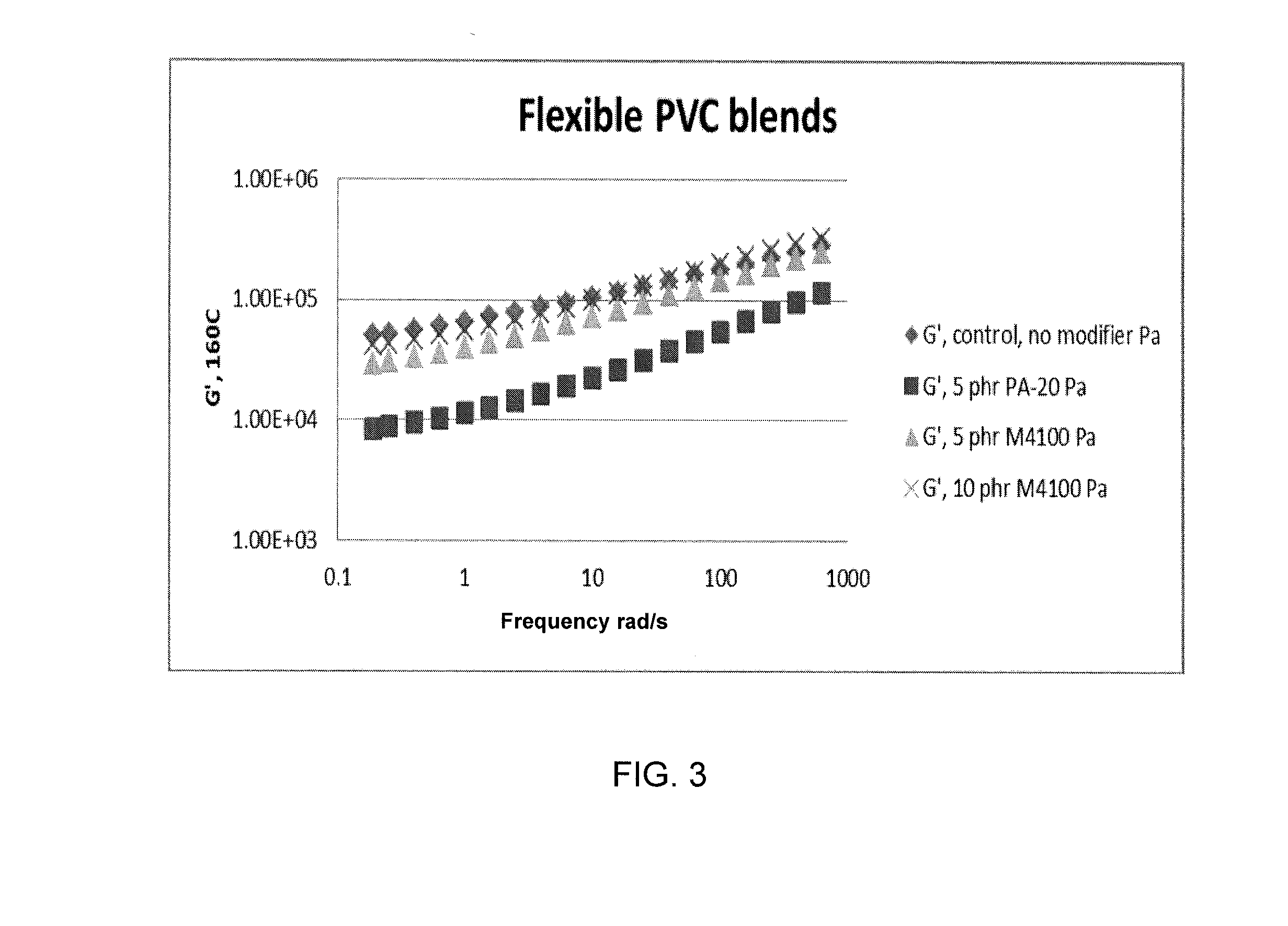

Biobased modifiers for polyvinylchloride blends

Compositions of polymer blends of polyvinylchloride (PVC), a low molecular weight plasticizer and polyhydroxyalkanoate (PHA) are described. In certain embodiments, the PHA is a poly-3-hydroxybutyrate-co-4-hydroxybutyrate copolymer having a weight percent 4-hydroxybutyrate of 30-45%. In other embodiments the PHA is a multiphase P3HB-4HB copolymer blend having one phase fully amorphous. The PHA is mixed with the PVC and low molecular weight plasticizer to optimize the PVC's optical, thermal and mechanical properties. In certain embodiments, the polymer is branched with optionally additives that improve properties. Methods of making the compositions of the invention are also described. The invention also includes articles, films and laminates comprising the compositions.

Owner:CJ CHEILJEDANG CORP

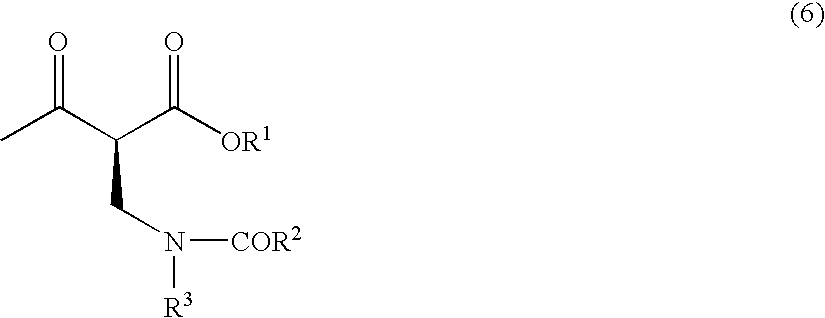

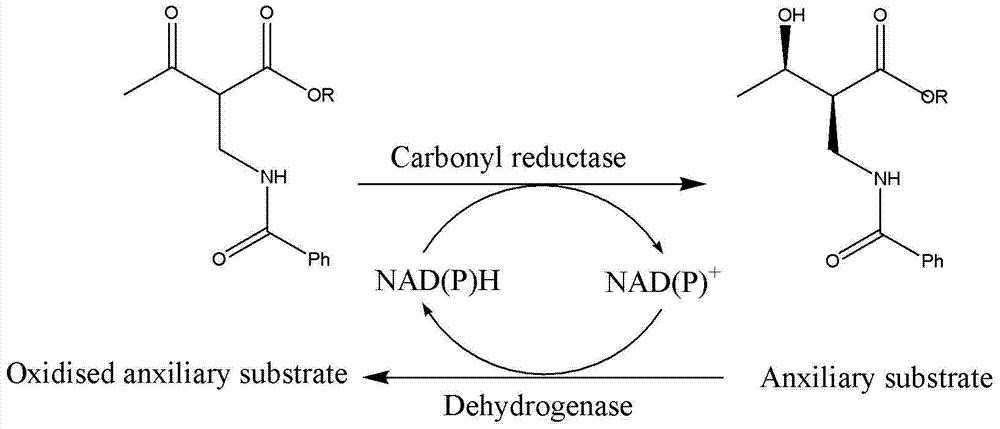

Method for producing optically active 2-(n-substituted aminomethyl)-3-hydroxybutyric acid ester

The present invention relates to a method for producing optically active 2-(N-substituted aminomethyl)-3-hydroxybutyric acid esters wherein a 2-(N-substituted aminomethyl)-3-oxobutyric acid ester is treated with an enzyme source capable of stereoselectively reducing said ester to the corresponding optically active 2-(N-substituted aminomethyl)-3-hydroxybutyric acid ester having the (2S,3R) configuration. The present invention provides an efficient method for industrially producing optically active 2-(N-substituted aminomethyl)-3-hydroxybutyric acid esters, in particular such compounds having the (2S,3R) configuration, which are useful as intermediates for the production of medicinal compounds, among others.

Owner:KANEKA CORP

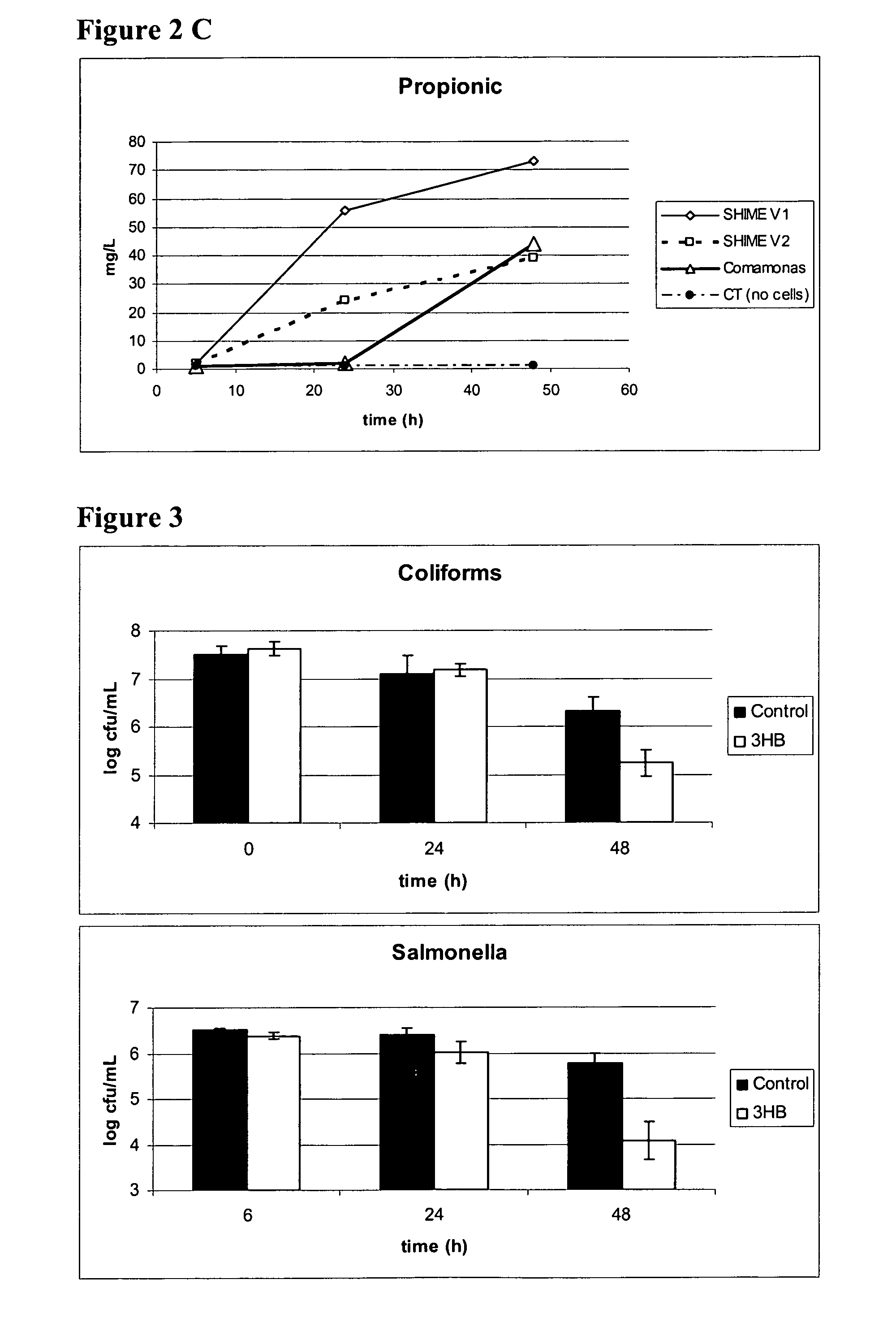

Hydroxybutyrate and poly-hydroxybutyrate as components of animal feed or feed additives

ActiveUS20100093860A1Optimized formulaSmall particlesAntibacterial agentsBiocideEscherichia coliFood additive

This invention relates to the use of hydroxybutyrate and poly hydroxybutyrate as components of animal feed or feed additives, as well as to compositions, feed additives and feed containing them. The inventors surprisingly found that hydroxybutyrate and poly-hydroxybutyrate, preferably 3-hydroxybutyrate and poly-3-hydroxybutyrate, have a great potential for use in animal feed for modulation of the gut flora. More precisely, it has been found that poly-3-hydroxybutyrate or a microbial strain capable for producing poly-3-hydroxybutyrate can be used as a potential growth promoter or gut flora modulator by releasing SCFA, preferably 3-hydroxy butyric acid, in the gut micro flora. Further, the inventors found that 3-hydroxybutyrate and poly-3-hydroxybutyrate have a great potential for suppressing or inhibiting pathogenic bacteria in the gastro intestinal tract, e.g. have a antimicrobial activity against strains of Vibrio, E. coli and Salmonella.

Owner:UNIV GENT

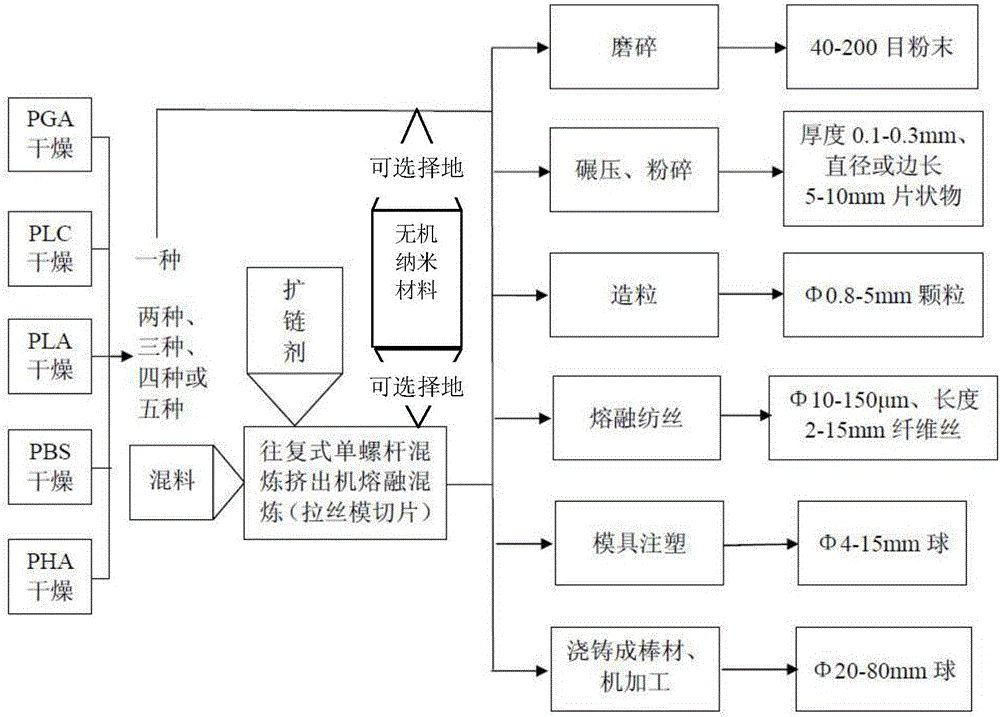

Degradable material for oil and gas field operation and preparation method thereof

InactiveCN105295321ALess intrusiveReduce harmFluid removalDrilling compositionAcid fracturingPoly-3-hydroxybutyrate

The invention provides a degradable material for oil and gas field operation and a preparation method thereof. The preparation method of the degradable material for oil and gas field operation comprises the step of carrying out melting mixing reaction on two, three, four, or five polymers of polyglycolic acid, polycaprolactone, polylactic acid, poly butylene succinate and poly-3-hydroxybutyrate and a chain extender, so as to obtain resin alloy, namely, the degradable material for oil and gas field operation. The degradable material for oil and gas field operation can be prepared into shapes such as pieces, powder, particles and balls, or can be prepared from one of polyglycolic acid, polycaprolactone, polylactic acid, poly butylenes succinate and poly-3-hydroxybutyrate into shapes such as pieces, powder, particles and balls through the method, is used for temporary plug and filtration reduction for protecting a reservoir, and temporarily plugging shot holes, constructed layer sections, and the like during various operation (drilling, well completion, well repair and acid fracturing) in the oil and gas field, and has the advantages of being completely degradable and harmless to the stratum.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

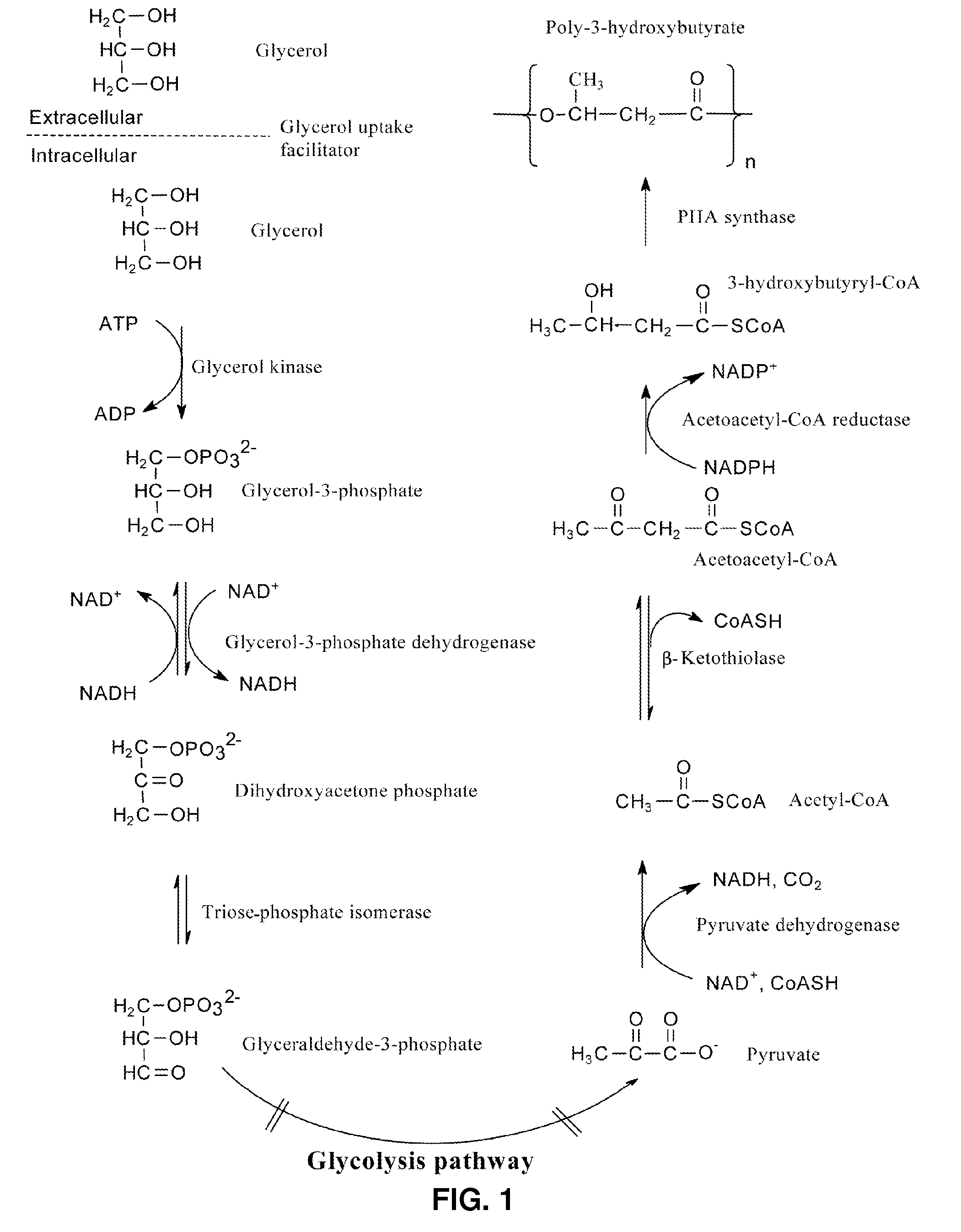

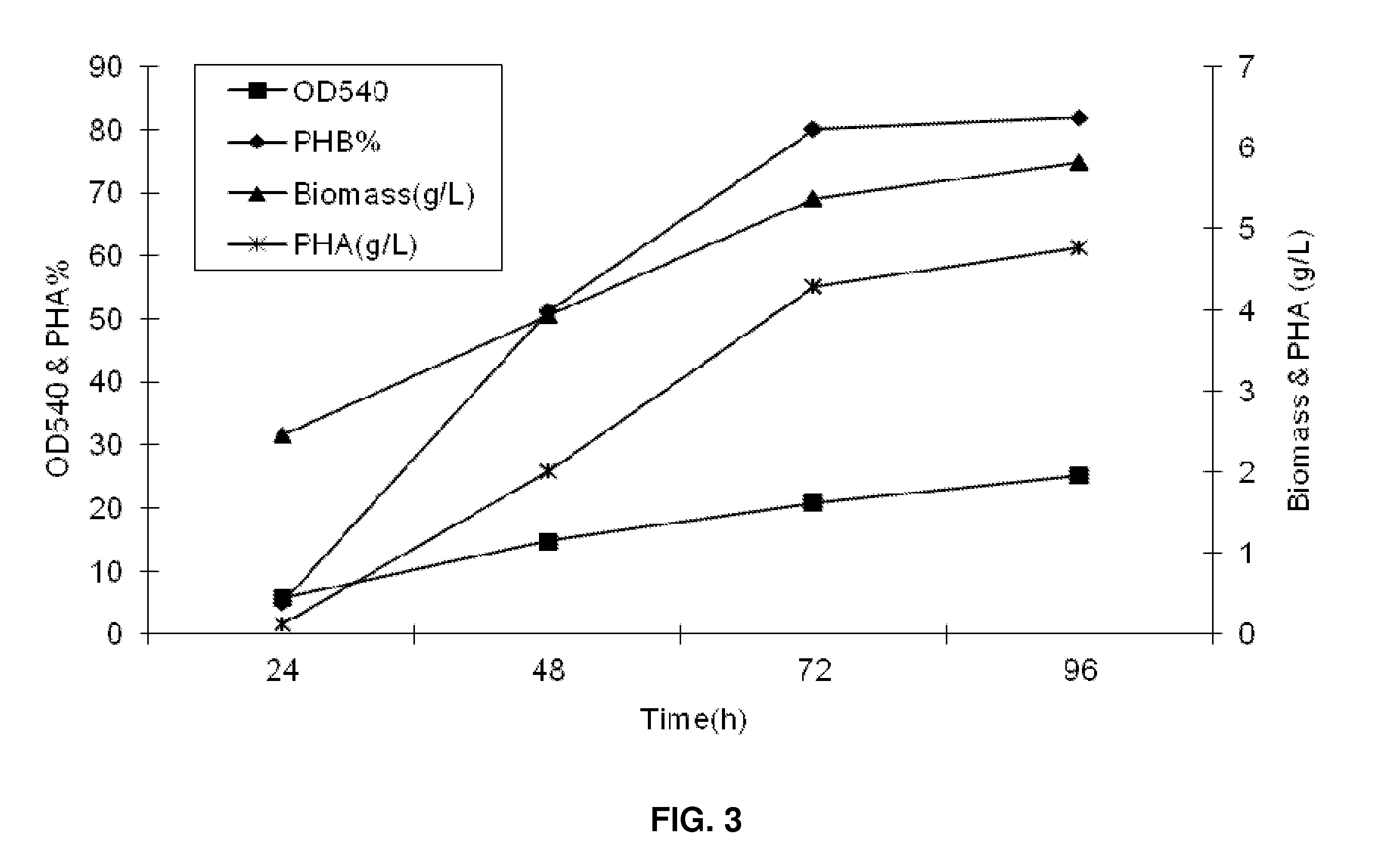

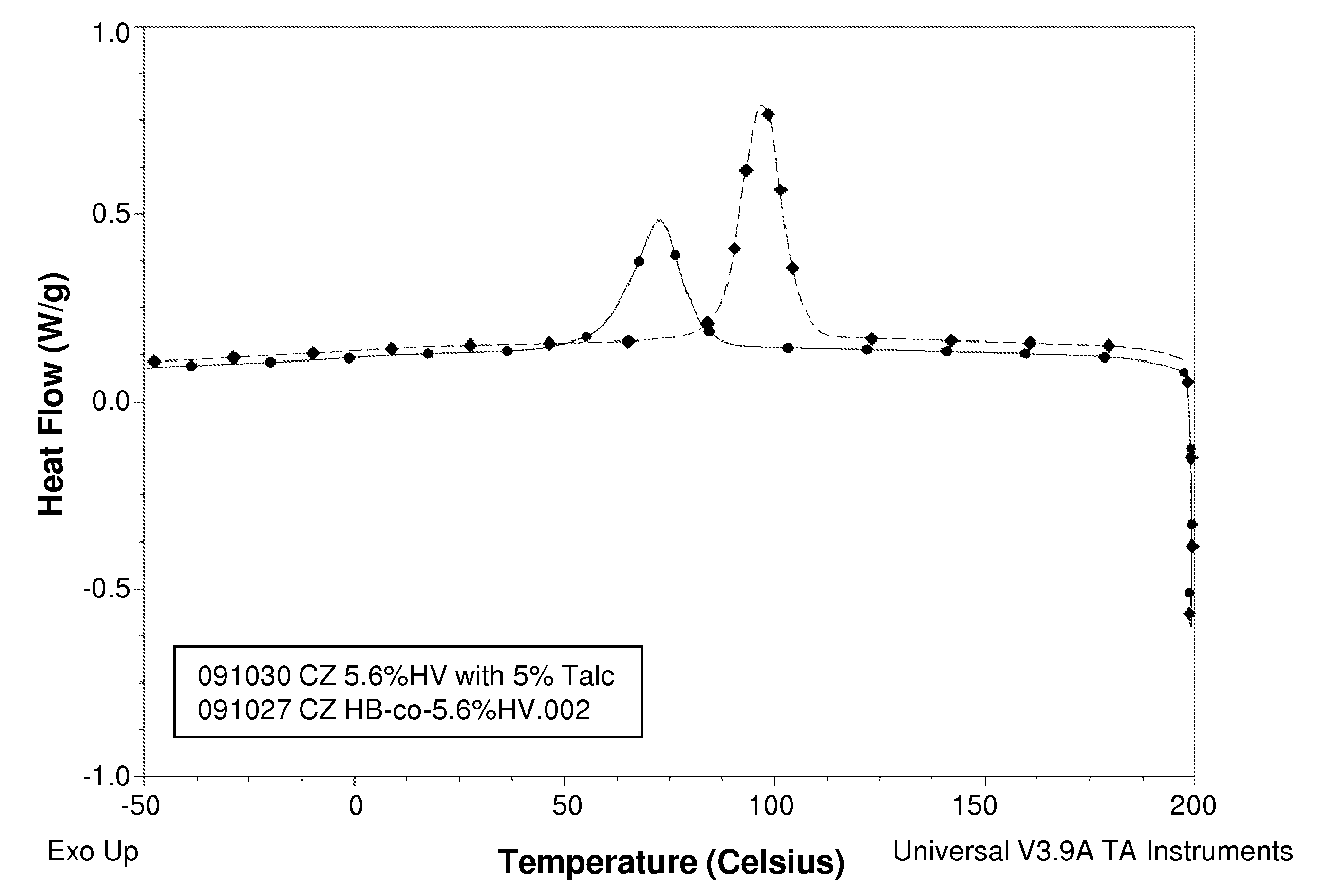

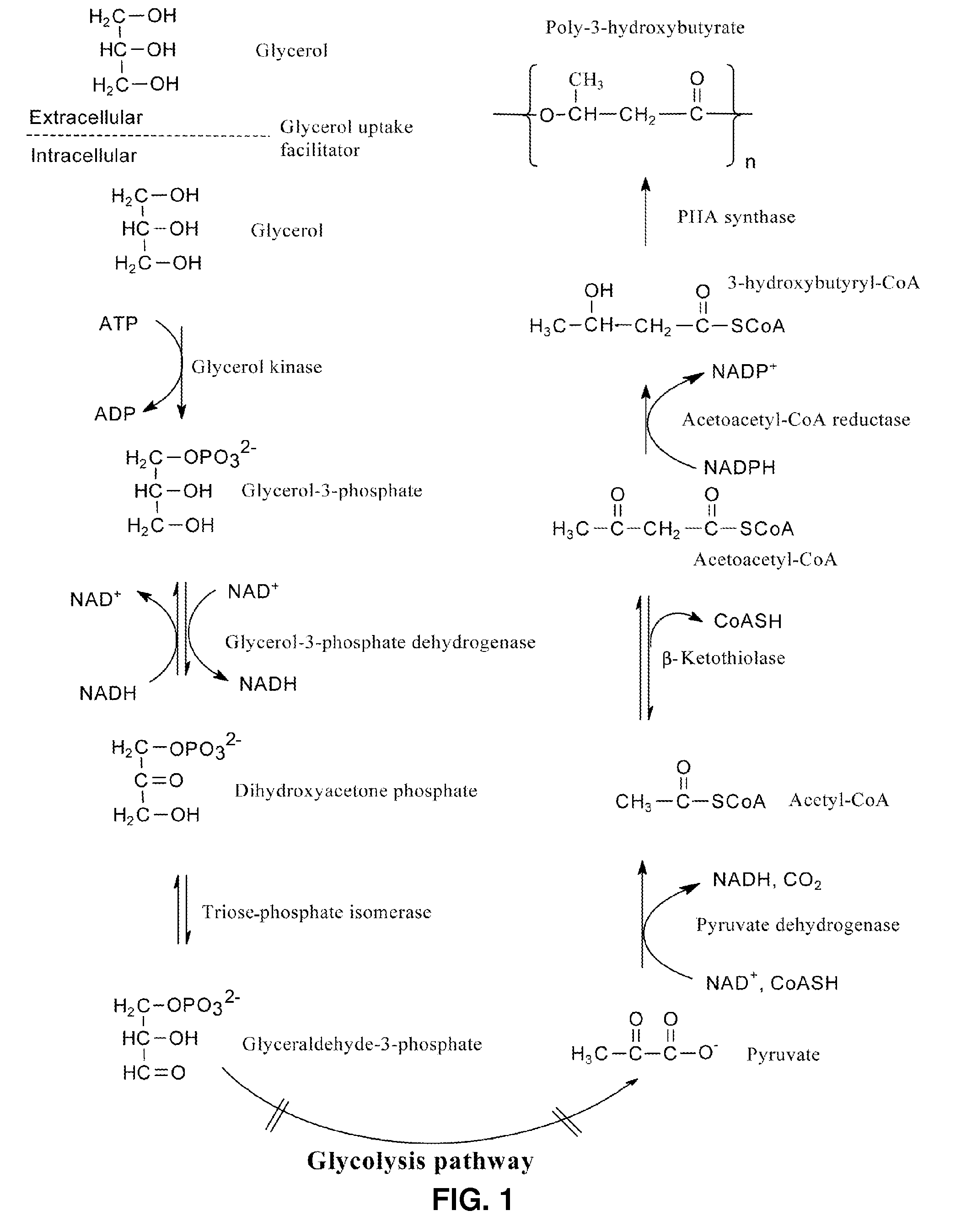

Methods for producing polyhydroxyalkanoates from biodiesel-glycerol

Methods are provided for producing biodegradable polyhydroxyalkanoates (PHAs) with desired geometry, molecular mass, mechanical and / or physical-chemical properties from glycerol, an inexpensive carbon source and byproduct of the biodiesel industry. Microorganisms capable of converting carbon to PHA can be used to convert biodiesel-glycerol to poly-3-hydroxybutyrate (PHB) or other monomer or copolymer PHAs via fermentation. The microorganisms are cultured in a medium comprising glycerol as a primary carbon source and one or more low molecular mass organic acids as a secondary carbon source. Biomass can be harvested from the culture medium and crude PHA extracted and purified, thereby recovering purified PHA with the desired property. After PHA isolation, a nucleating agent can be added to improve certain physical-chemical properties of the PHA, e.g., crystallization temperature, to enhance performance of the PHA during injection molding.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

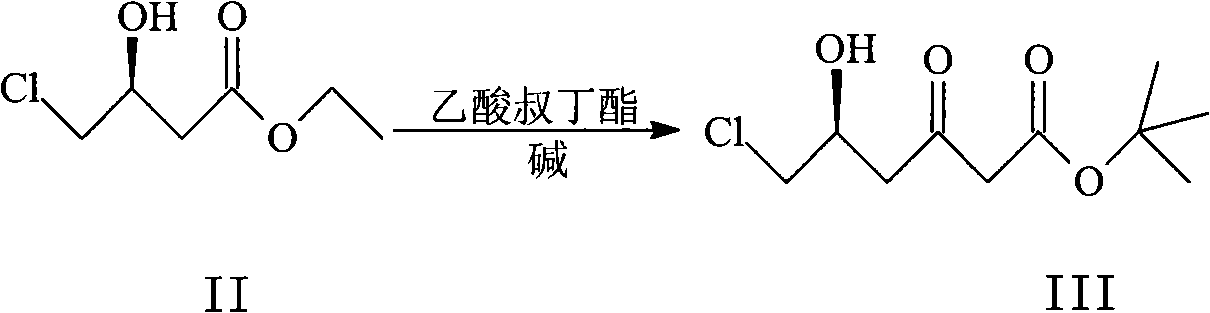

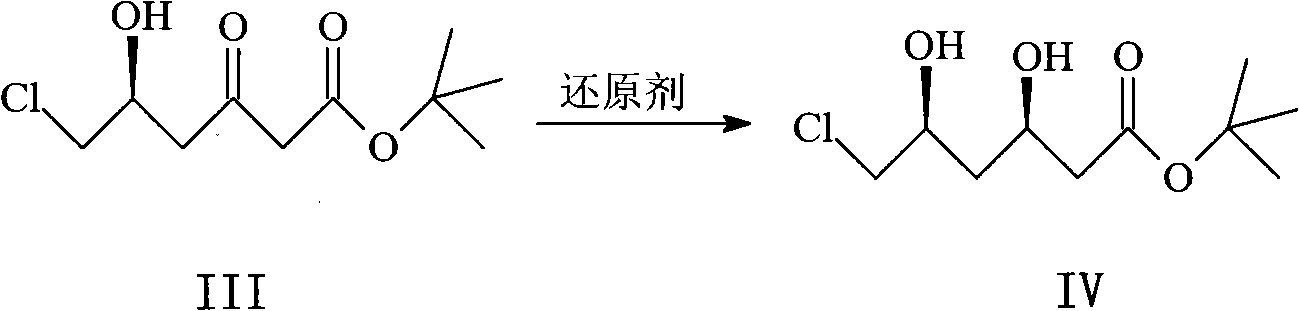

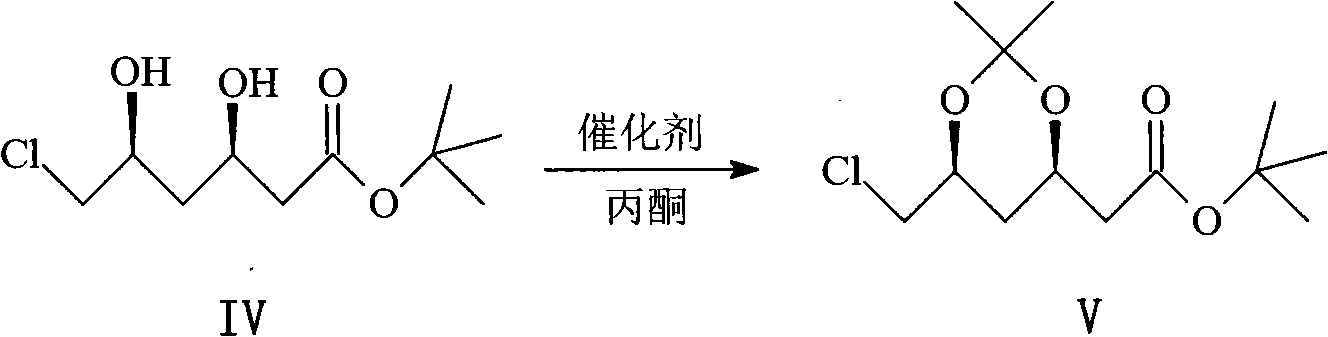

Preparation method of key intermediate of rosuvastatin calcium side chain

ActiveCN101624390AEase of industrial productionSimple and fast operationOrganic compound preparationCarboxylic acid esters preparationSide chainRosuvastatin Calcium

The invention provides a preparation method of a key intermediate of a rosuvastatin calcium side chain, comprising the following steps: using (S)-4-chlorine-3-hydroxybutanoate as an initial raw material; and preparing the key intermediate through four-step reactions of condensation, reduction, hydroxy group protection and condensation. The reaction process is simple to operate, the products in each step are easy to separate and purify, the purification and separation step is carried out without a silicagel column, and the yield is more than 80 percent, therefore, the intermediate with higher chemical purity and optical purity can be obtained. The GC determination shows that the chemical purity is more than or equal to 99.5 percent and the optical purity is more than or equal to 99.2 percent ee.

Owner:LUNAN PHARMA GROUP CORPORATION

Fibers, nonwoven fabrics and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate

InactiveUS6143947AProtect and promote and control plant growthHigh elongationEngine sealsBaby linensPolymer scienceBiodegradable copolymers

The present invention relates to fibers, and nonwovens comprising said fibers, comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a biodegradable liquid impervious backsheet comprising the above fibers and / or nonwovens, and an absorbent core positioned between the topsheet and the backsheet.

Owner:MEREDIAN

Films and absorbent articles comprising a biodegradable polyhydroxyalkanoate comprising 3-hydroxybutyrate and 3-hydroxyhexanoate comonomer units

InactiveUS6027787AEasily processed into filmPromote degradationSynthetic resin layered productsBaby linensBiodegradable copolymersPolymer chemistry

The present invention relates to a film comprising a biodegradable copolymer, wherein the copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU monomer unit has the structure and the second RRMU has the structure wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a biodegradable liquid impervious backsheet comprising the above film, and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

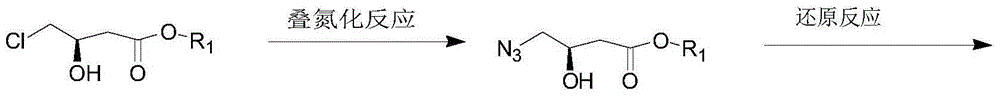

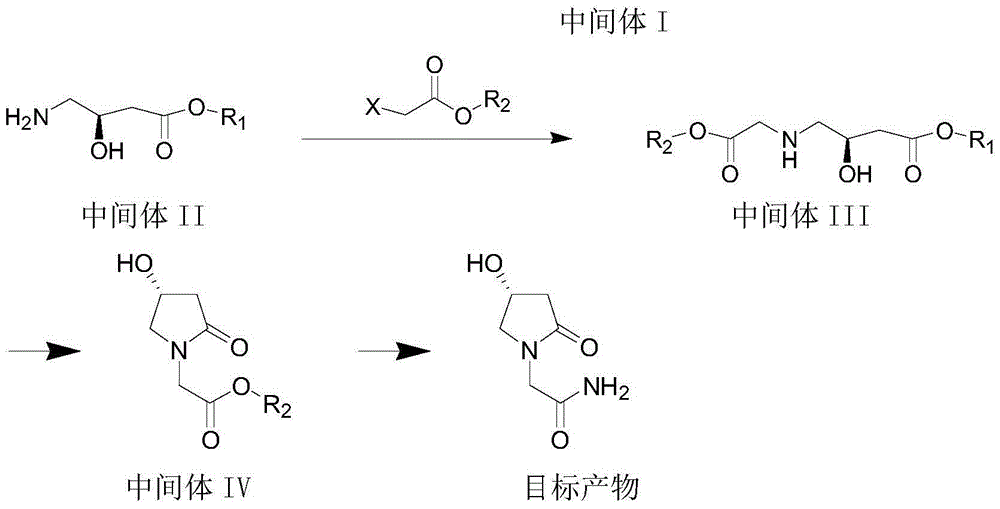

Preparation method for (R)-4-hydroxy-2-oxo-1-pyrrolidine acetamide

The invention provides a preparation method for (R)-4-hydroxy-2-oxo-1-pyrrolidine acetamide. The preparation method comprises the following steps: (1) with R-4-chloro-3-hydroxy butyrate as an initial raw material, subjecting the initial raw material and an azido reaction agent to an azido reaction so as to obtain an intermediate I; (2) subjecting the intermediate I to a reduction reaction so as to obtain an intermediate II; (3) subjecting the intermediate II and halogenated acetate to a condensation reaction so as to obtain an intermediate III; (4) subjecting the intermediate III to a ring closure reaction so as to obtain an intermediate IV; and (5) subjecting the intermediate IV to an aminolysis reaction so as to obtain (R)-4-hydroxy-2-oxo-1-pyrrolidine acetamide. The preparation method can prepare a (R)-4-hydroxy-2-oxo-1-pyrrolidine acetamide product with ideal yield of at least more than 38%, and a novel synthetic route is opened up for (R)-4-hydroxy-2-oxo-1-pyrrolidine acetamide.

Owner:CHONGQING RUNZE PHARM CO LTD

Methods for producing polyhydroxyalkanoates from biodiesel-glycerol

ActiveUS20120135480A1Increased elongation-to-breakIncreased resistance to breakingBiofuelsFermentationBiodieselGlycerol

Methods are provided for producing biodegradable polyhydroxyalkanoates (PHAs) with desired geometry, molecular mass, mechanical and / or physical-chemical properties from glycerol, an inexpensive carbon source and byproduct of the biodiesel industry. Microorganisms capable of converting carbon to PHA can be used to convert biodiesel-glycerol to poly-3-hydroxybutyrate (PHB) or other monomer or copolymer PHAs via fermentation. The microorganisms are cultured in a medium comprising glycerol as a primary carbon source and one or more low molecular mass organic acids as a secondary carbon source. Biomass can be harvested from the culture medium and crude PHA extracted and purified, thereby recovering purified PHA with the desired property. After PHA isolation, a nucleating agent can be added to improve certain physical-chemical properties of the PHA; e.g., crystallization temperature, to enhance performance of the PHA during injection molding.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Resource-renewable and biodegradable conductive fiber and preparation method thereof

ActiveCN102936761ARealize conductive functionLower percolation thresholdElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsFiber3-Hydroxypentanoic acid

The invention discloses resource-renewable and biodegradable conductive fiber and a preparation method thereof. The fiber consists of the following raw materials in parts by weight: 30-70 parts of polylactic acid (PLA), 30-70 parts of poly(3-hydroxybutyric acid-co-3-hydroxyvalerate (PHBV) and 0.05-8 parts of conductive filler. The preparation method of the conductive fiber comprises the following steps of: (1) proportionally pre-mixing PHBV (if PLA is not less than 50 parts) or PLA (if PLA is less than 50 parts) and the conductive filler, and performing melt blending and granulation to obtain the conductive master batch of the PHBV or PLA; (2) proportionally pre-mixing the PLA or PHBV and the conductive master batch of the PHBV or PLA, and performing melt blending and granulation to obtain composite conductive mater batches; and (3) spinning and drafting the composite conductive master batches one by one to obtain the conductive fiber. The conductive fiber disclosed by the invention can be used as the material for electrodes, static resistance, low-temperature heating, electromagnetic shielding, thermal sensitivity, gas sensitivity and the like.

Owner:JIANGNAN UNIV

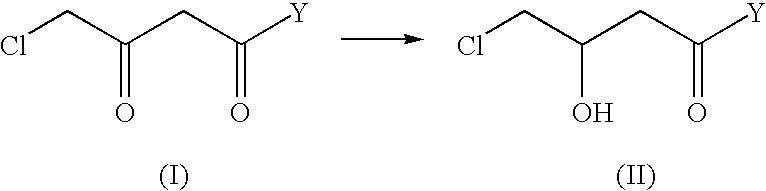

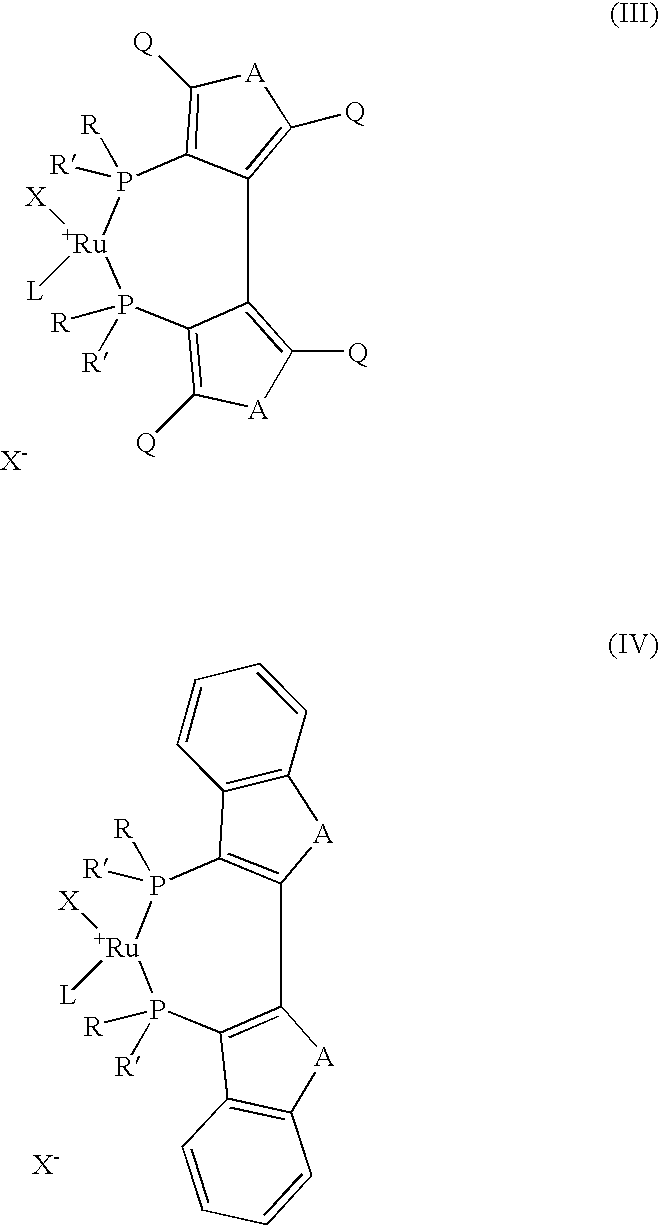

Industrial process for the production of L-carnitine

InactiveUS6566552B2Easily appilcable on an industrial scaleReduce productionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen pressureSubstrate concentration

The present invention describes a process for the industrial production of L-carnitine, comprising the enantioselective reduction of an alkyl 4-chloro-3-oxobutyrate or 4-chloro-3-oxobutyramide. The optically active 3-hydroxy derivative thus obtained is reacted with trimethylamine, obtaining crude L-carnitine, which is then finally purified. The catalyst used for the reduction is a complex of ruthenium bound to a penta-atomic bis-heteroaromatic system. The reduction reaction, performed in controlled conditions of hydrogen pressure, substrate concentration, temperature, and substrate: catalyst molar ratio, enables 4-chloro-3-hydoxybutyrate or 4-chloro-hydroxybutyamide to be obtained in a high yield. The process described, which leads to L-carnitine being obtained, is easily applicable on an industrial scale.

Owner:SIGMA TAU IND FARMACEUTICHE RIUNITE SPA

Method for preparing high-toughness degradable material by using melt-grafting blending method

The invention relates to a method for preparing a high-toughness degradable material by using a melt-grafting blending method, which comprises the following steps: (1) carrying out melt-grafting on polycaprolactone PCL, anhydride and an initiator, and then obtaining modified polycaprolactone by way of extrusion granulation, wherein the mass ratio of the polycaprolactone PCL to the anhydride to the initiator is 100: (1 to 10): 0.5; and (2) carrying out melt-grafting blending on poly (3-hydroxybutyrate-3-hydroxyvalerate) PHBV, the modified polycaprolactone, methyl acrylate and an initiator, and then obtaining the high-toughness PHBV-class degradable material by way of extrusion granulation, wherein the mass ratio of the poly (3-hydroxybutyrate-3-hydroxyvalerate) PHBV to the modified polycaprolactone to the methyl acrylate to the initiator is 100: (5 to 50): (0.5 to 10):0.5, the processing temperature is 100 to 170 DEG C, and the screw speed is 50-80 R.P.M. The method is simple in process, low in cost, and suitable for industrialization, and the elongation at break of the produced PHBV-class degradable material can reach 560 percent; therefore, the method of the invention has good application prospect.

Owner:DONGHUA UNIV

Biobased rubber modifiers for polymer blends

Compositions of polymer blends of polyvinylchloride (PVC) or polymethylmethacrylate (PMMA) or polyoxymethylene (POM) and polyhydroxyalkanoate (PHA) are described. In certain embodiments, the PHA is a poly-3-hydroxybutyrate-co-4-hydroxybutyrate copolymer having a weight percent 4-hydroxybutyrate of 30-45%. In other embodiments the PHA is a multiphase P3HB-4HB copolymer blend having one phase fully amorphous. The PHA is mixed with the PVC or PMMA or POM to optimize its optical, thermal and mechanical properties. In certain embodiments, the polymer is branched with optionally additives that improve properties. Methods of making the compositions of the invention are also described. The invention also includes articles, films and laminates comprising the compositions.

Owner:CJ CHEILJEDANG CORP

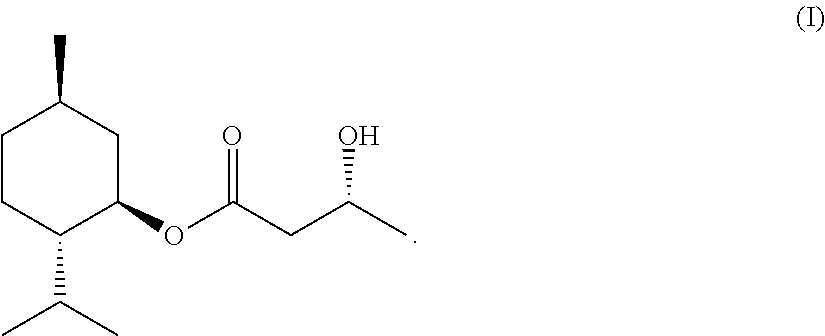

(3R)-L-menthyl 3-hydroxybutyrate, process for producing the same, and sensate composition comprising the same

InactiveUS8476472B2Increase cooling intensityBiocideCosmetic preparationsHydroxybutyratesFood science

Owner:TAKASAGO INTERNATIONAL CORPORATION

Method for preparing hydroxyalkanoate homopolymer and special bacteria thereof

ActiveCN101845414AHigh purityIncrease productionBacteriaMicroorganism based processesPseudomonas putidaCoenzyme A biosynthesis

The invention discloses a method for preparing hydroxyalkanoate homopolymer and special bacteria thereof. Recombinant pseudomonas putida is prepared by the method comprising the following steps of: depriving coding functions of 3-hydroxyfatty acyl-coenzyme A dehydrogenase coding gene and 3-ketoacyl coenzyme A thiolase coding gene in pseudomonas putida to obtain recombinant pseudomonas putida, and recording the recombinant pseudomonas putida as recombinant pseudomonas putida I. Experiments prove that the hydroxyalkanoate homopolymer, particularly medium and long-chain hydroxyalkanoate homopolymer (C4-C14), can be obtained by using the recombinant bacteria organism to synthesize polyhydroxyalkanoate. The obtained hydroxyalkanoate homopolymer has high purity and high yield. The method of the invention can synthesize the medium and long-chain hydroxyalkanoate homopolymer with random length, and overcomes the defect that only one 3-hydroxybutyrate (HB) homopolymer can be obtained by biosynthesis in the prior art. Therefore, the method of the invention has broad application prospect in the biosynthesis field of the hydroxyalkanoate homopolymer.

Owner:TSINGHUA UNIV

Elastomer composition, method for producing the same, and eraser using the same

An elastomer composition is provided which contains a matrix of poly-(3-hydroxybutyrate-co-3-hydroxyhexanoate) produced from microorganisms and crosslinked natural rubber particles dispersed like islands in the matrix. An eraser using the elastomer composition is also provided. The present invention is capable of providing an elastomer composition and eraser using the same, which can be recycled, are friendly to the environment, and corresponds to the recycling society, without relying on fossil resources.

Owner:SEED CO LTD

Recyclate Blends

ActiveUS20160108233A1Improve material performanceIncrease loadProductsReagentsPolyesterPolymer science

Compositions comprising recyclate blends of polymer recyclate and polyester additives are described. In certain embodiments, the polyester additive is a PHA such as a poly-3-hydroxybutyrate-co-4-hydroxybutyrate copolymer having a weight percent 4-hydroxybutyrate of 8.5-45%. In other embodiments the PHA is mixed with the recyclate polymer at concentrations of 10-50% by weight of the recyclate blend. Methods of making the compositions of the invention are also described. The invention also includes articles made from the recyclate blends.

Owner:CJ CHEILJEDANG CORP

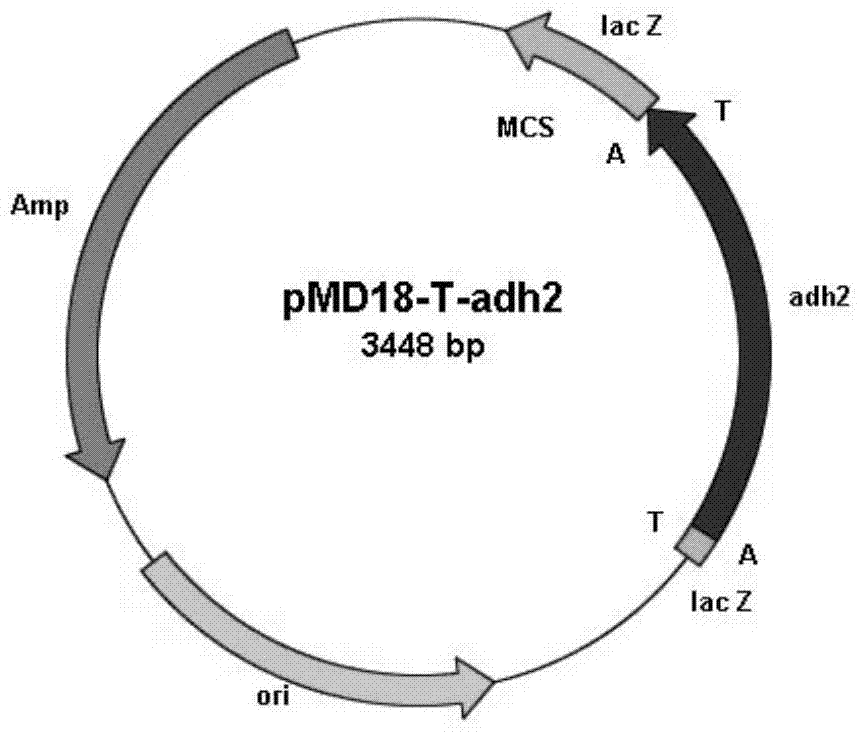

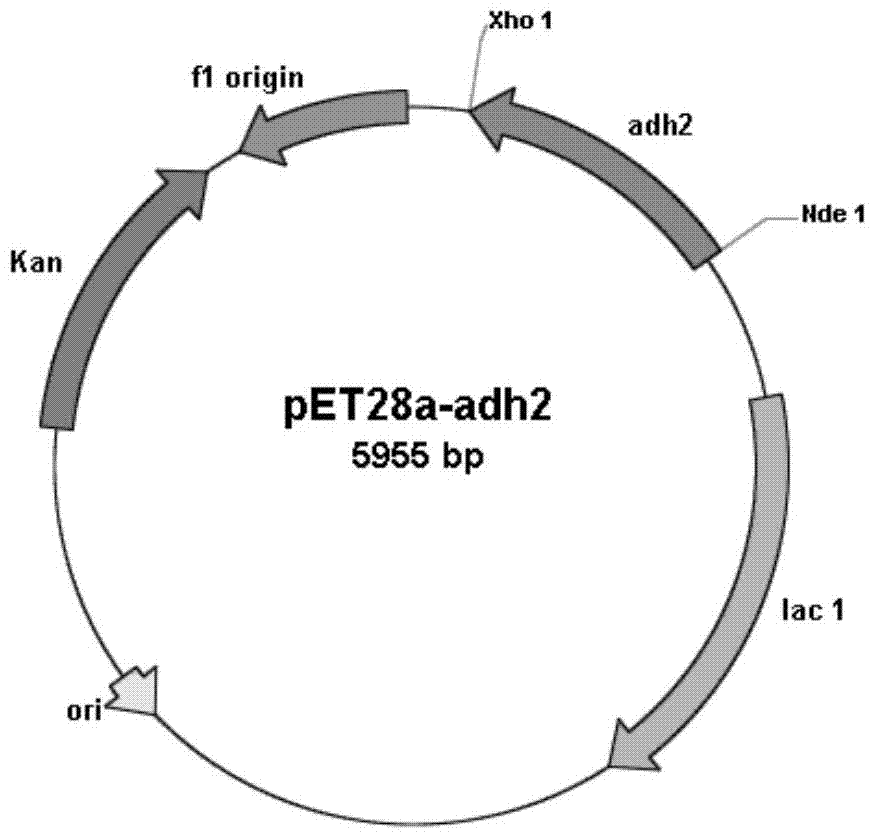

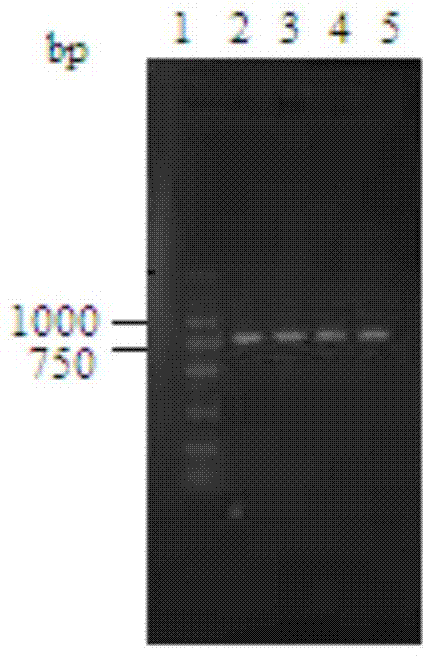

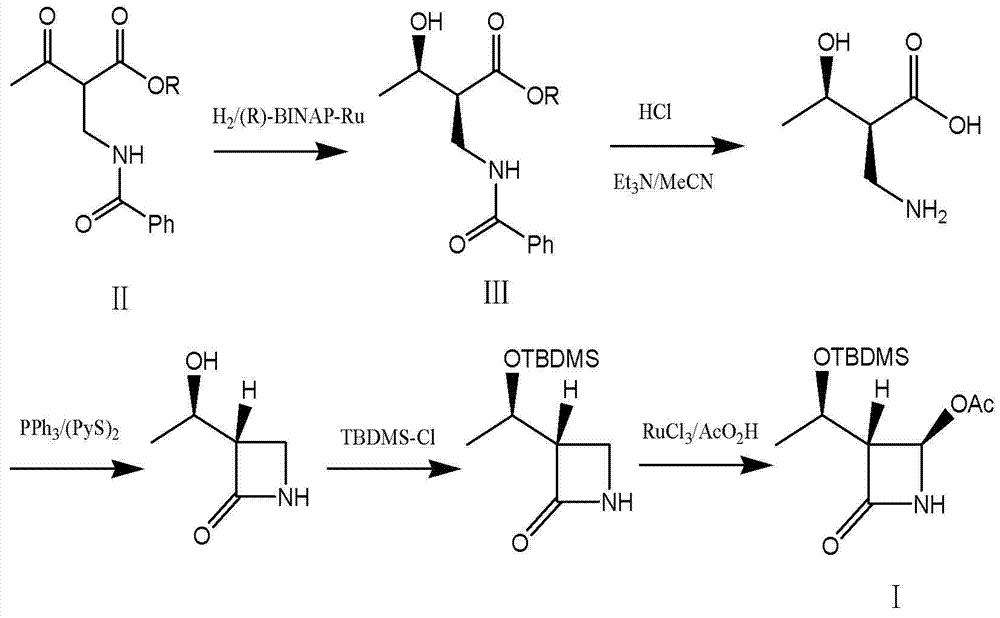

Carbonyl reductase gene, codase, vector, engineering bacterium and application thereof

InactiveCN104263742AHigh enantioselectivityImprove conversion rateBacteriaMicroorganism based processesKetoneEthyl acetate

The invention discloses a recombinant carbonyl reductase derived from Burkholderia gladioli ZJB-12126 and a coding gene thereof, a recombinant vector containing the gene, a recombinant gene engineering bacterium converted from the recombinant vector and application in preparing the recombinant carbonyl reductase.2-benzoylaminomethyl-3-one butyrate, N,N-bis-methyl-3-one-3-(2-thienyl)propanamide, ethyl 4-chloroacetoacetate (COBE) and tert-butyl (R)-6-cyano-5-hydroxy-3-carbonylhexanoate used as substrates are subjected to biological catalytic reaction to prepare high-optical-purity (2S,3R)-2-benzamidomethyl-3-hydroxybutyrate, (S)-N,N-bis-methyl-3-hydroxy-3-(2-thienyl)propanamide, ethyl (S)-4-chloro-3-hydroxybutyrate and tert-butyl 6-cyano-(3R,5R)-dihydroxyhexanoate.

Owner:ZHEJIANG UNIV OF TECH

Microorganism catalysis prepared (2S,3R)-2-benzoyl aminomethyl-3-hydroxybutyric acid ester and bacterial strain

ActiveCN103045504ASynthetic reaction conditions are mildEasy to operateBacteriaMicroorganism based processesMicroorganismMicrobial transformation

The invention provides Burkholderia gladioli ZIB-12126, which is a new bacterial strain capable of catalyzing asymmetrical reduction of carbonyl, and application of the bacterial strain in preparation of (2S,3R)-2-benzoyl aminomethyl-3-hydroxybutyric acid ester by racemizing 2-benzoyl aminomethyl-3-hydroxybutyric acid ester in a microbial conversion mode. The bacterial strain is preserved in the Chinese Typical Culture Collection Center with an address of Wuhan College, Wuhan, China and the zip code of 430072, the preservation serial number of CCTCC No. M 2012379 on September 255th, 2012. The bacterial strain provided by the invention is used for synthesizing the (2S,3R)-2-benzoyl aminomethyl-3-hydroxybutyric acid ester through biologic conversion, with gentle reaction condition and environmental-friendliness; and more importantly, the product configuration is mainly (2S,3R) configuration, and step of turning the product configuration by using a chemical method is not needed, so that the operation process is simple and has good industrial application prospects.

Owner:ZHEJIANG UNIV OF TECH

Biobased Rubber Modifiers for Polymer Blends

ActiveUS20150203674A1Improve performanceEasy to processPlastic/resin/waxes insulatorsOrganic dyesPolyvinyl chlorideMechanical property

Compositions of polymer blends of polyvinylchloride (PVC) or polymethylmethacrylate (PMMA) or polyoxymethylene (POM) and polyhydroxyalkanoate (PHA) are described. In certain embodiments, the PHA is a poly-3-hydroxybutyrate-co-4-hydroxybutyrate copolymer having a weight percent 4-hydroxybutyrate of 30-45%. In other embodiments the PHA is a multiphase P3HB-4HB copolymer blend having one phase fully amorphous. The PHA is mixed with the PVC or PMMA or POM to optimize its optical, thermal and mechanical properties. In certain embodiments, the polymer is branched with optionally additives that improve properties. Methods of making the compositions of the invention are also described. The invention also includes articles, films and laminates comprising the compositions.

Owner:CJ CHEILJEDANG CORP

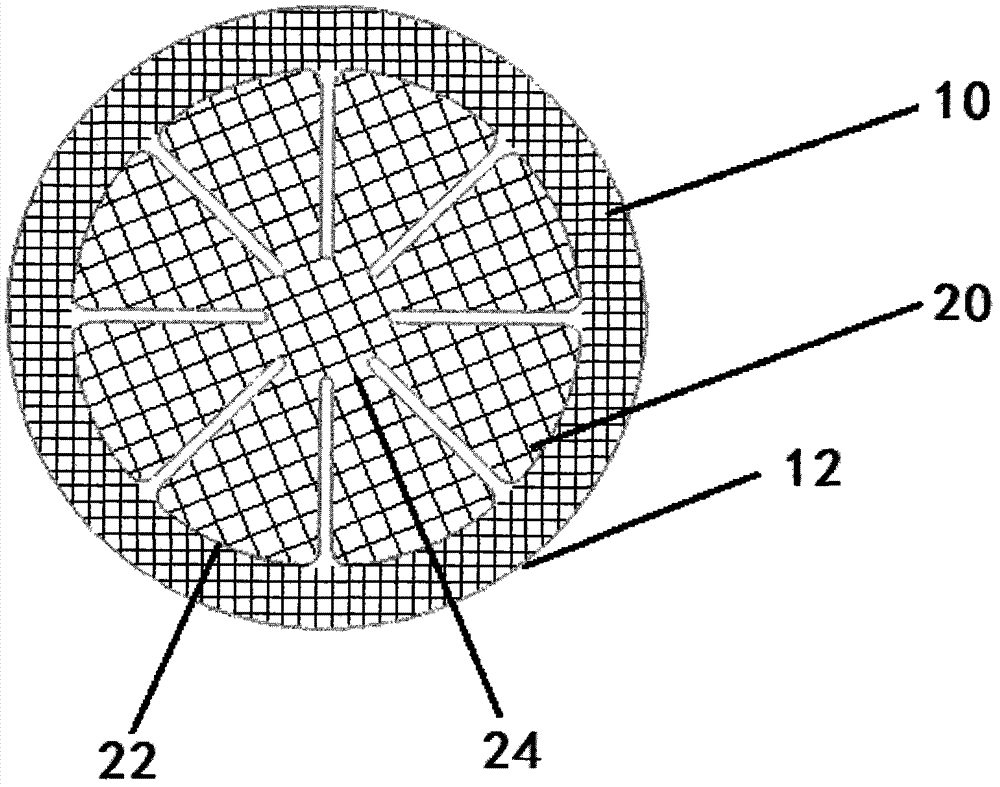

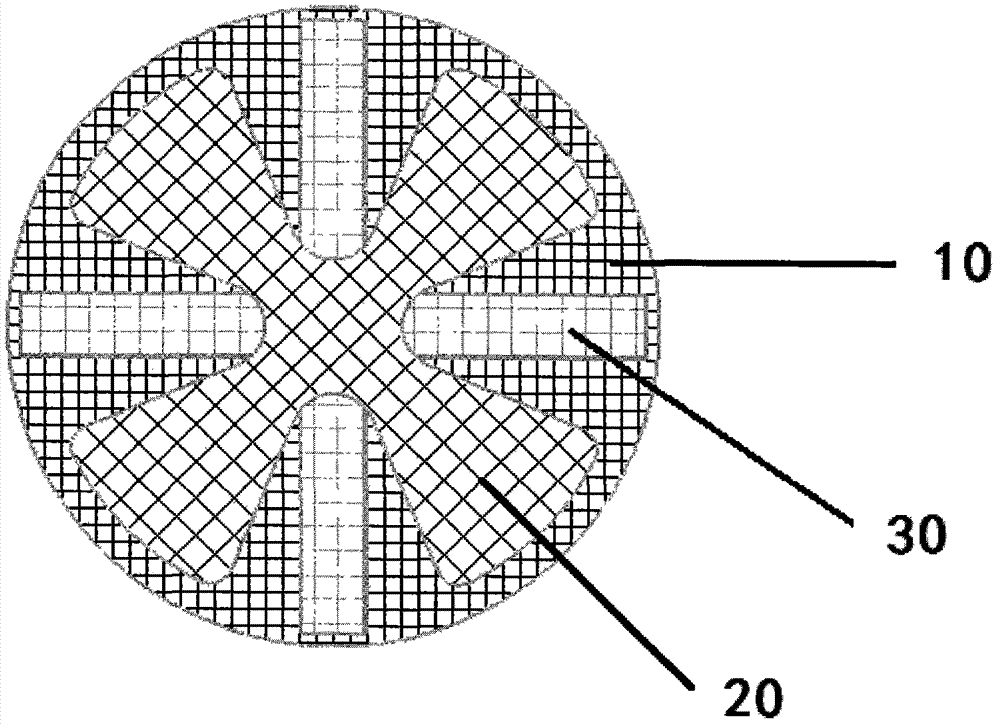

Partially absorbed herniorrhaphy patch

InactiveCN102772829AGood flexibilityStrong resistance to deformationSurgeryProsthesisForeign matterAbsorbent material

The invention relates to a partially absorbed herniorrhaphy patch, which comprises a meshed bottom patch and a plurality of petals, wherein the meshed bottom patch is made of an absorbable material; the petals are located on the meshed bottom patch; and the absorbable material is a blend of poly(3-polyhydroxybutyrate and poly-4-polyhydroxybutyrate) and polylactic acid. According to the partially absorbed herniorrhaphy patch, through compound knitting, implantation quantity of foreign matter is reduced. The partially absorbed herniorrhaphy patch is good in tissue compliance and can be used for effectively repairing defected parts.

Owner:TRANSEASY MEDICAL TECH

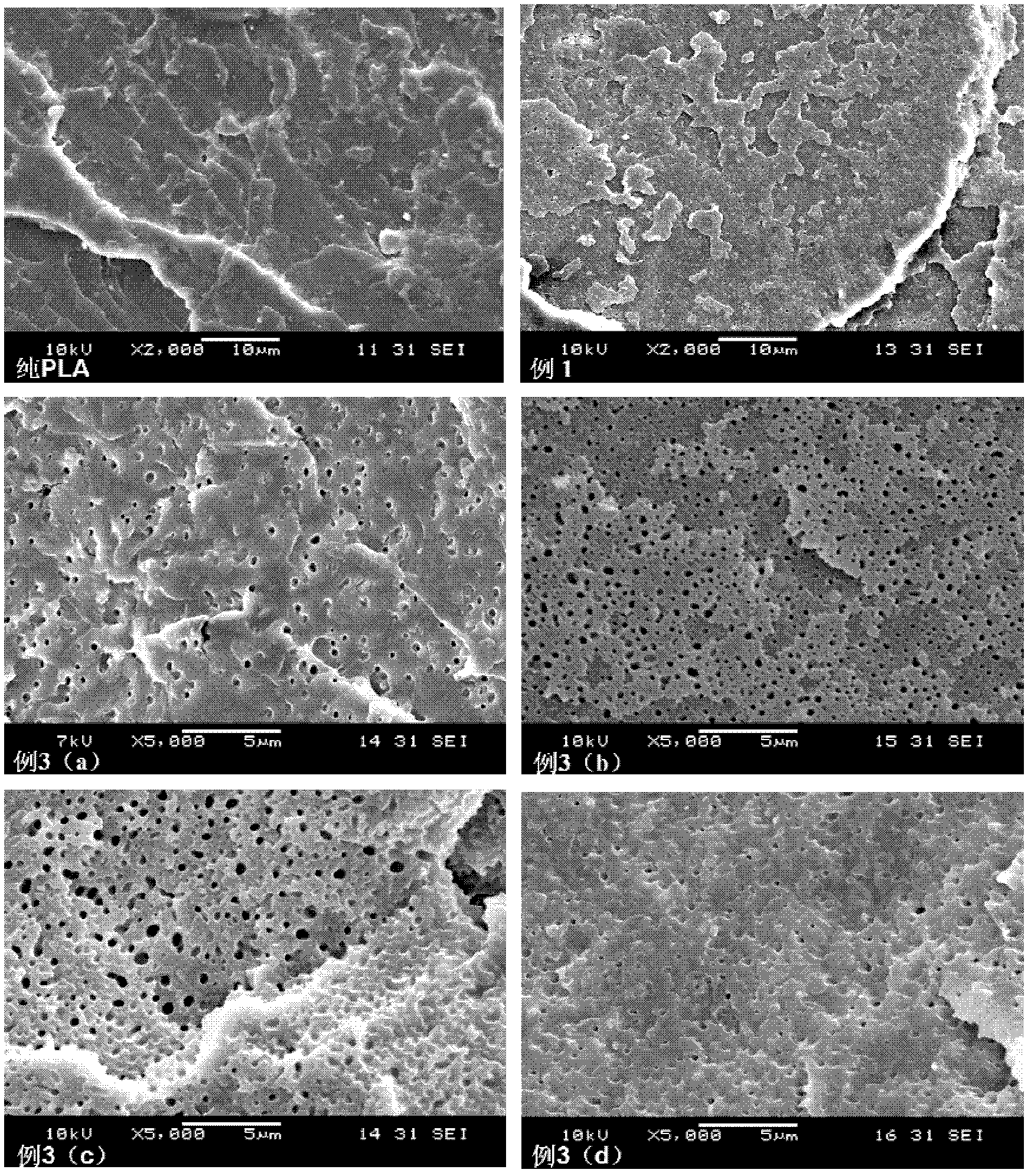

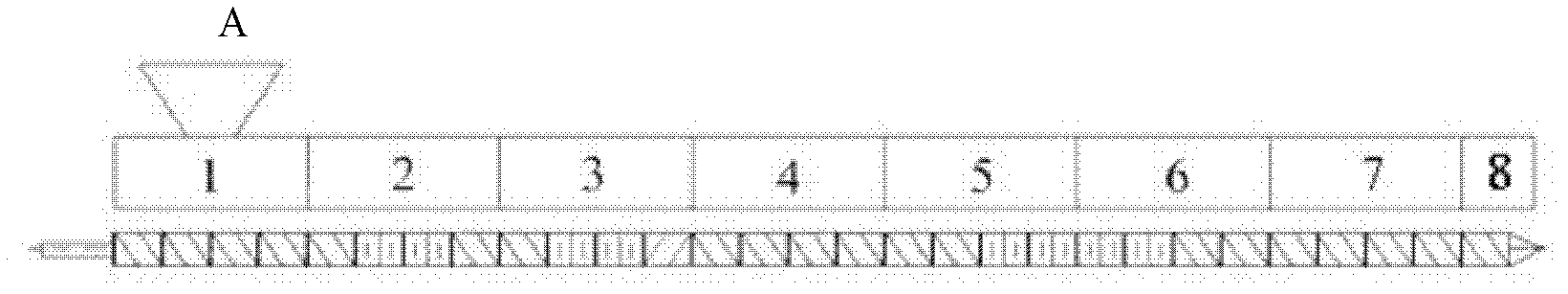

Polylactic acid and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) nano modified composite

InactiveCN102675841AMeet general use requirementsHigh impact strengthInjection molding machineNanotechnology

The invention provides a polylactic acid and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) nano modified composite. The molar content of 4-hydroxybutyrate in the poly(3-hydroxybutyrate-co-4-hydroxybutyrate) is 15%-35%. A preparation method of the composite includes: firstly, compounding polylactic acid, poly(3-hydroxybutyrate-co-4-hydroxybutyrate) and filler or auxiliaries according to a stated proportion, adding into a high-speed mixer for mixing 5-8min to obtain premixed matrix; secondly, using a double-screw extruder for mixing extrusion of the premixed matrix to obtain material strips, wherein set parameters of double screws include that the main unit frequency is 10Hz, the feeding frequency is 8Hz, eight segments are arranged from a feeding port A to a head, and temperature set values of the eight segments are 0 DEG C, 150 DEG C, 160 DEG C, 170 DEG C, 180 DEG C, 180 DEG C, 180 DEG C and 180 DEG C respectively, and temperature set parameters of a feed cylinder of an injection molding machine include that HZ, H1, H2 and H3 are 170 DEG C and H4 and H6 are 0 DEG C or heating-free; and thirdly, subjecting the material strips to cooling and granulating after extrusion to obtain the polylactic acid and poly(3-hydroxybutyrate-co-4-hydroxybutyrate) nano modified composite.

Owner:TIANJIN GREENBIO MATERIAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com