Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "3-Hydroxypropionate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyhydroxyalkanoate biopolymer compositions

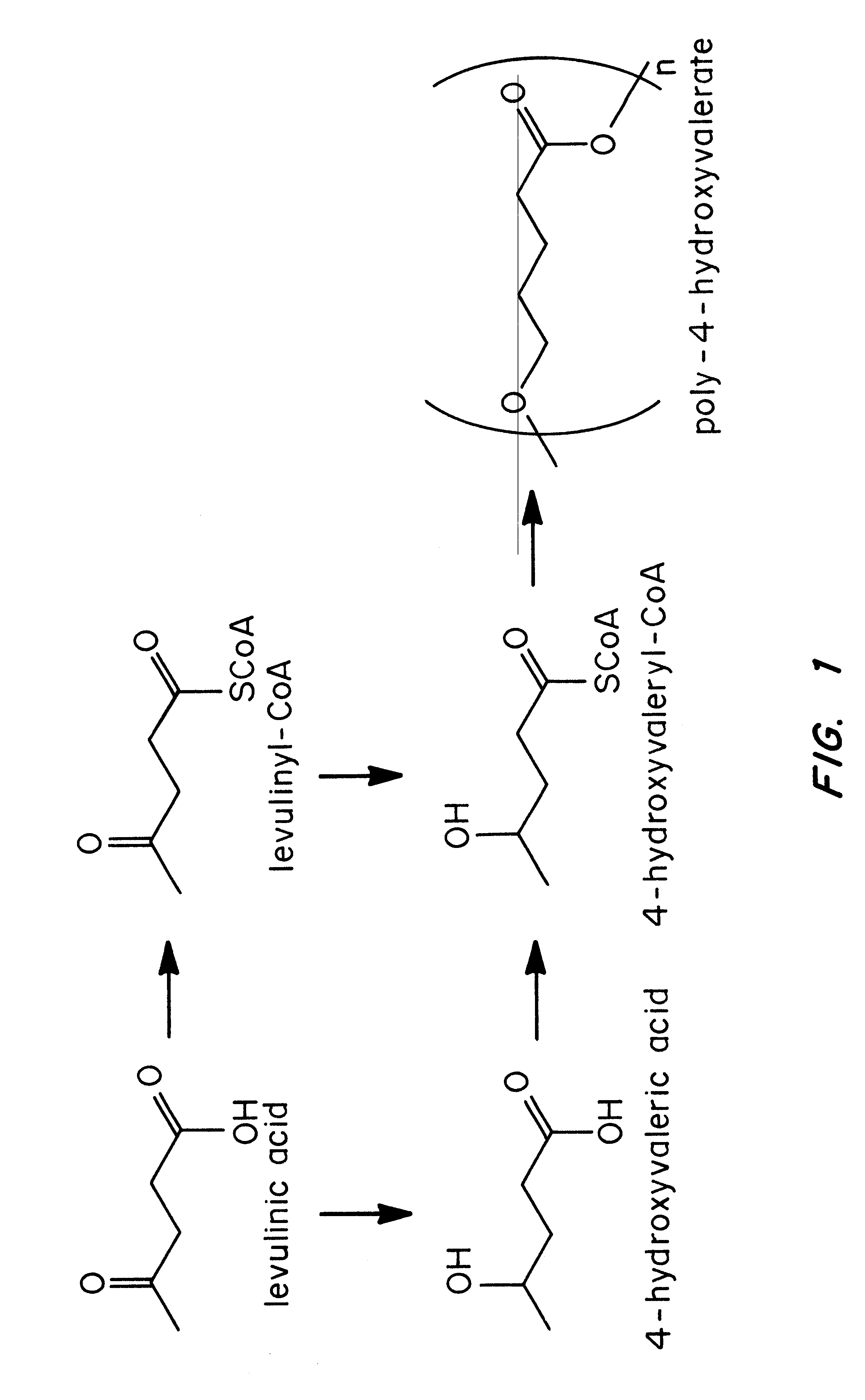

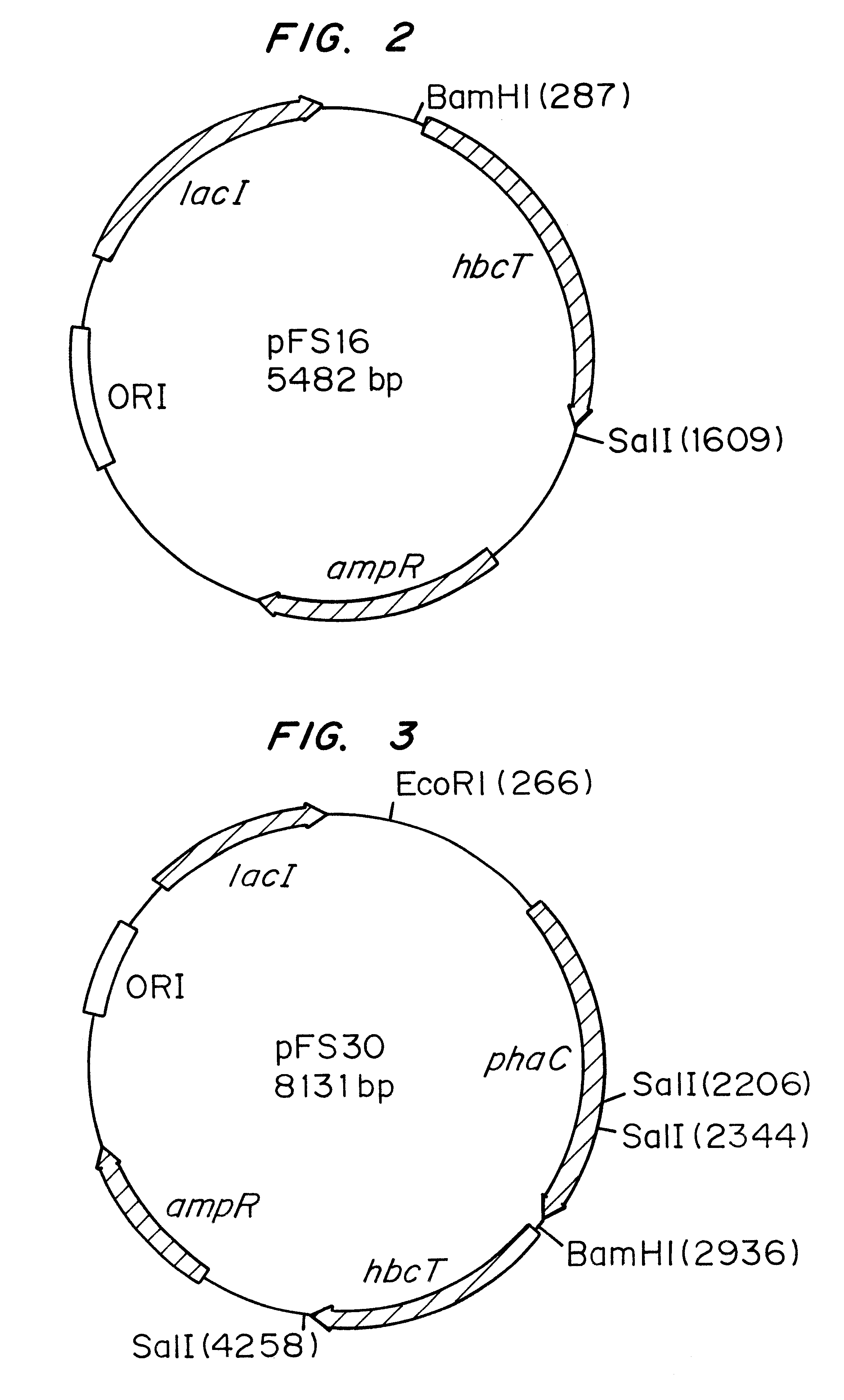

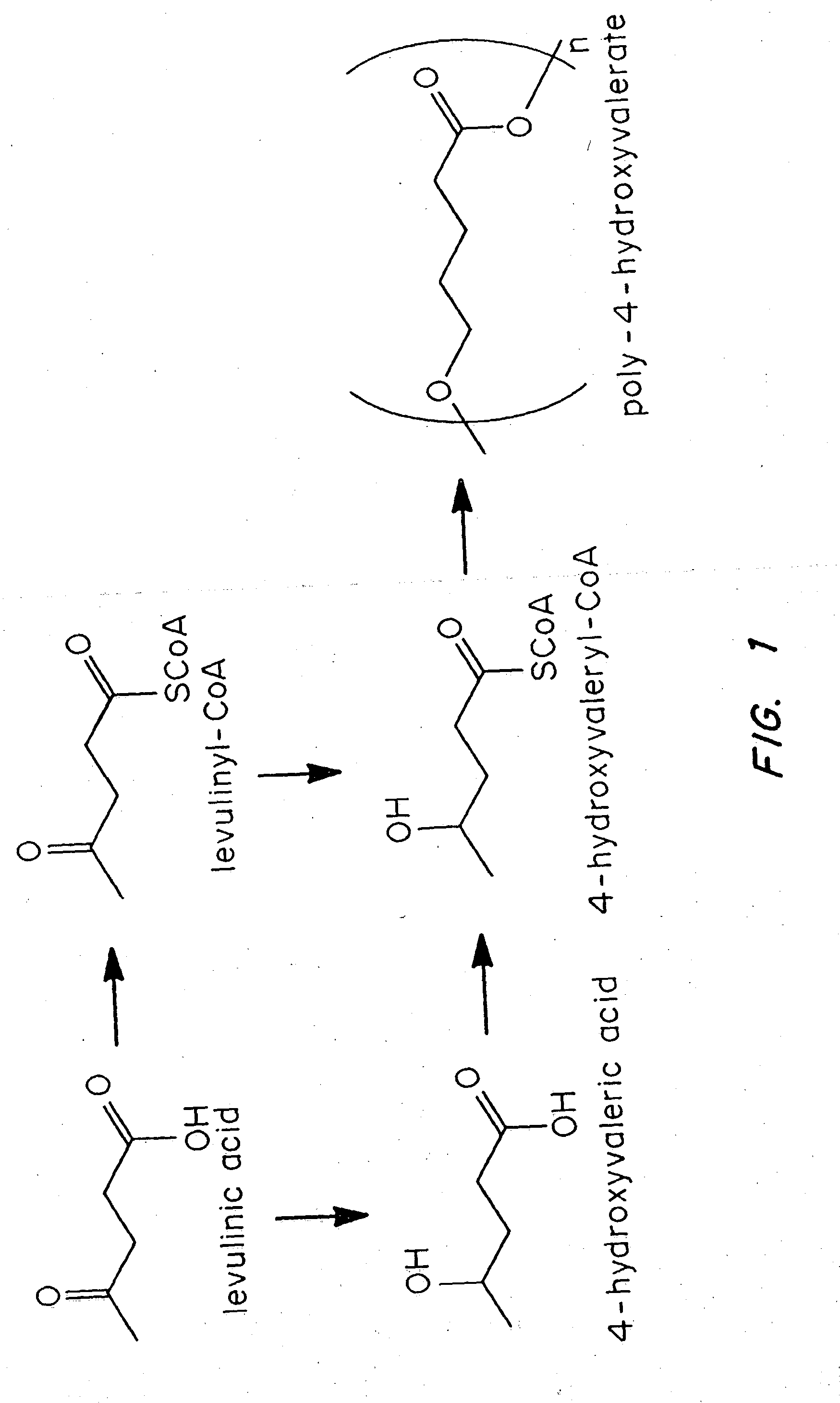

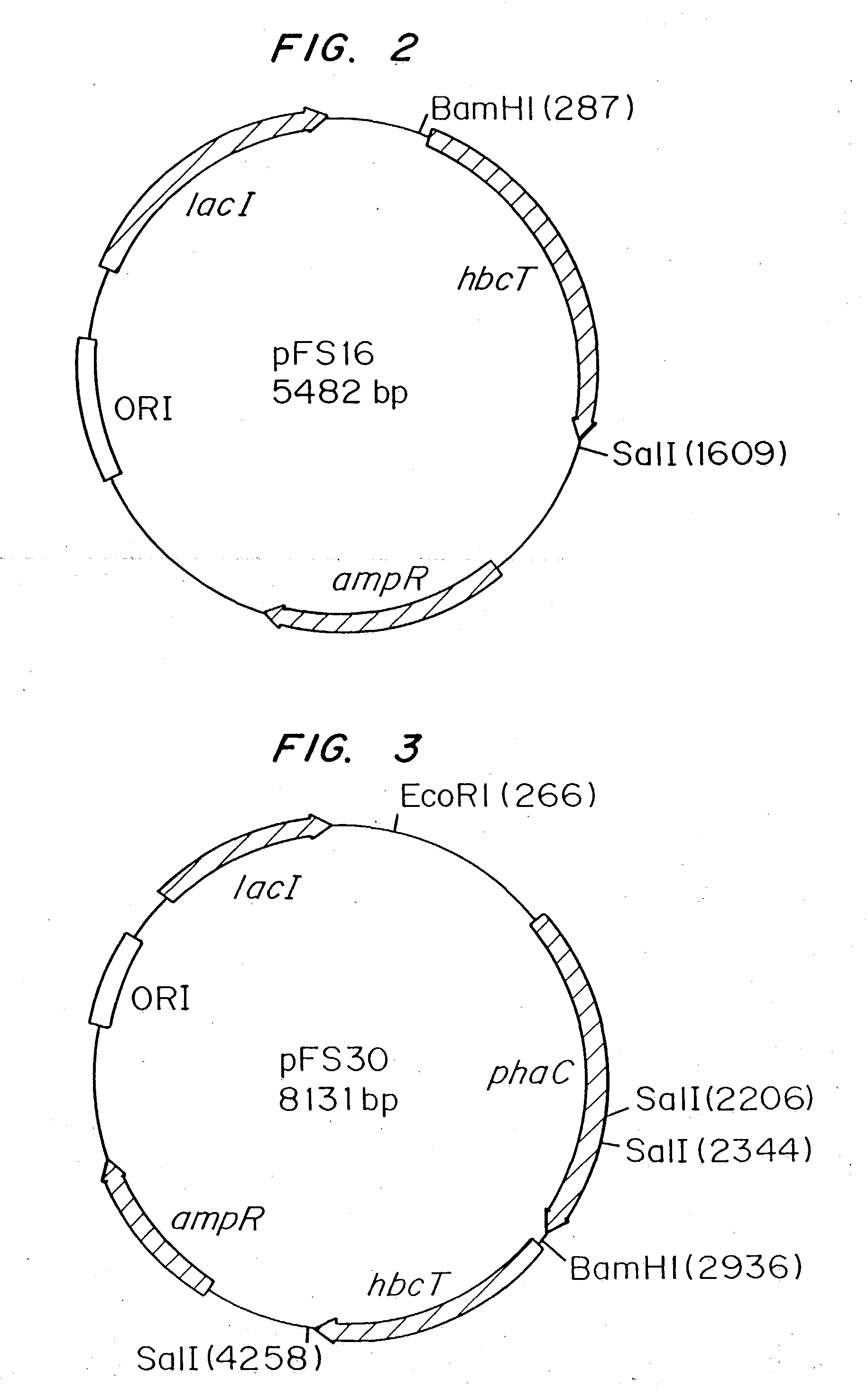

Several novel PHA polymer compositions produced using biological systems include monomers such as 3-hydroxybutyrate, 3-hydroxypropionate, 2-hydroxybutyrate, 3-hydroxyvalerate, 4-hydroxybutyrate, 4-hydroxyvalerate and 5-hydroxyvalerate. These PHA compositions can readily be extended to incorporate additional monomers including, for example, 3-hydroxyhexanoate, 4-hydroxyhexanoate, 6-hydroxyhexanoate or other longer chain 3-hydroxyacids containing seven or more carbons. This can be accomplished by taking natural PHA producers and mutating through chemical or transposon mutagenesis to delete or inactivate genes encoding undesirable activities. Alternatively, the strains can be genetically engineered to express only those enzymes required for the production of the desired polymer composition. Methods for genetically engineering PHA producing microbes are widely known in the art (Huisman and Madison, 1998, Microbiology and Molecular Biology Reviews, 63: 21-53). These polymers have a variety of uses in medical, industrial and other commercial areas.

Owner:METABOLIX

Polyhydroxyalkanoate production from polyols

InactiveUS20050239179A1Promote recoveryProduct can be usedBacteriaMicroorganism based processes3-Hydroxypropionic acidPropanoic acid

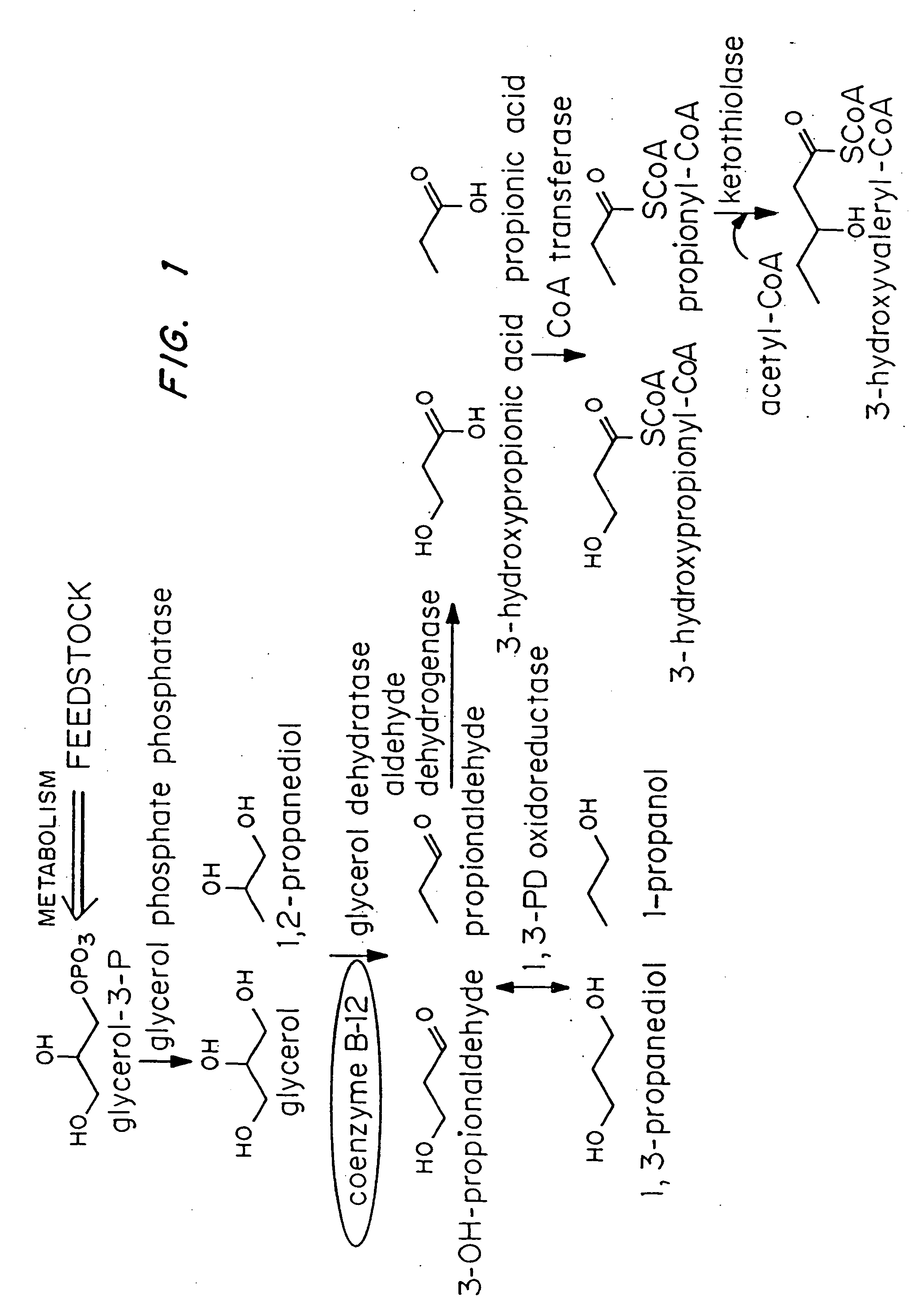

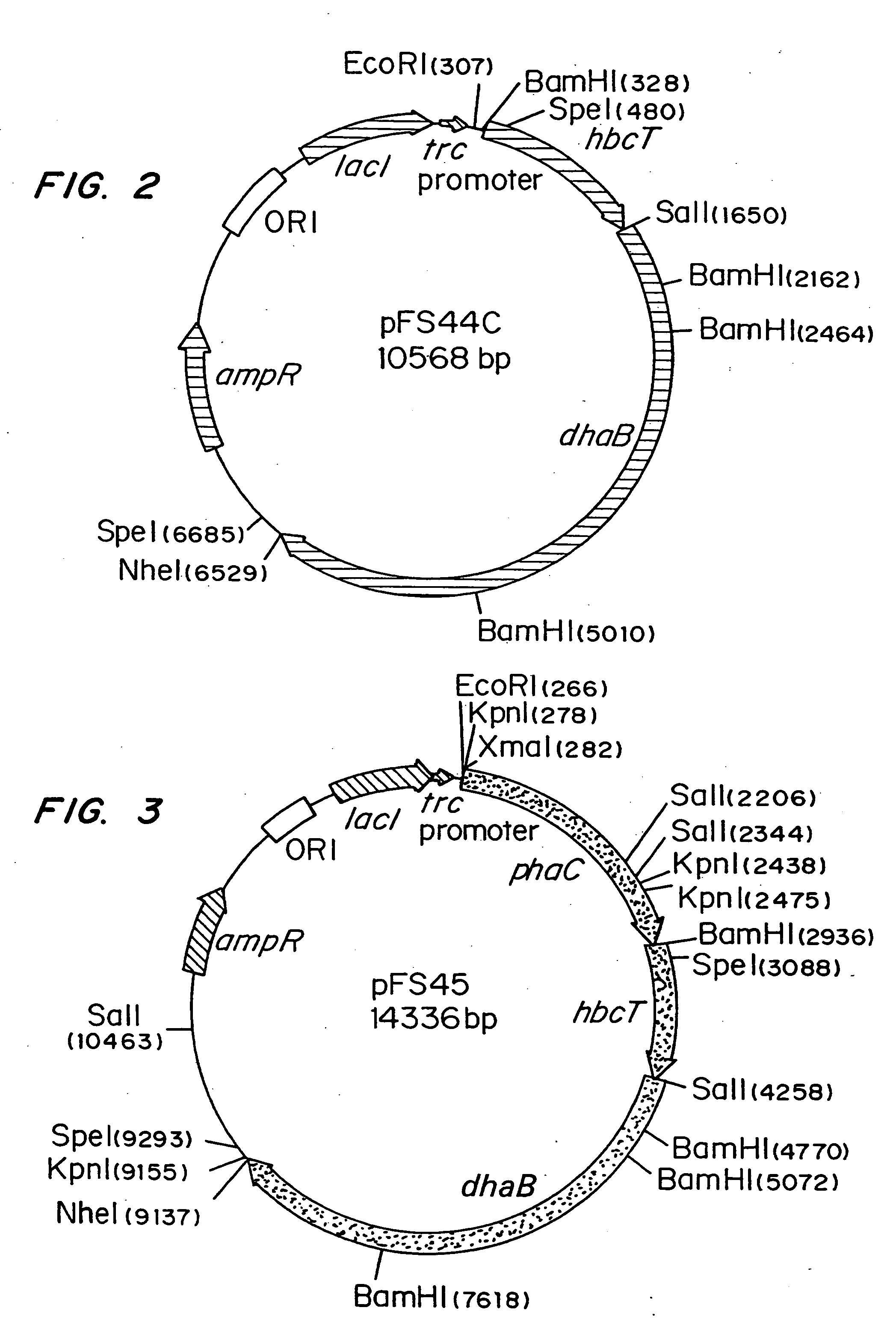

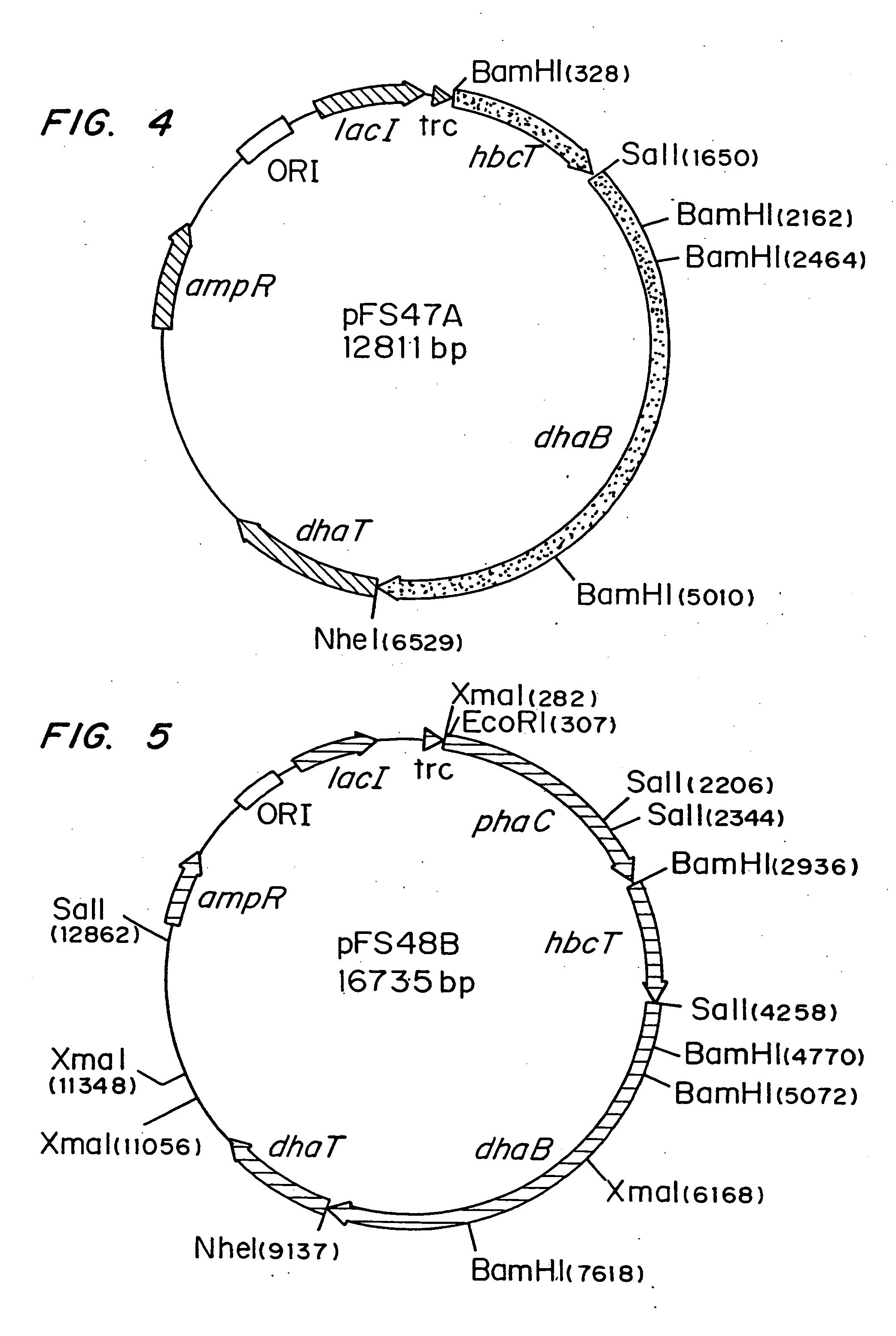

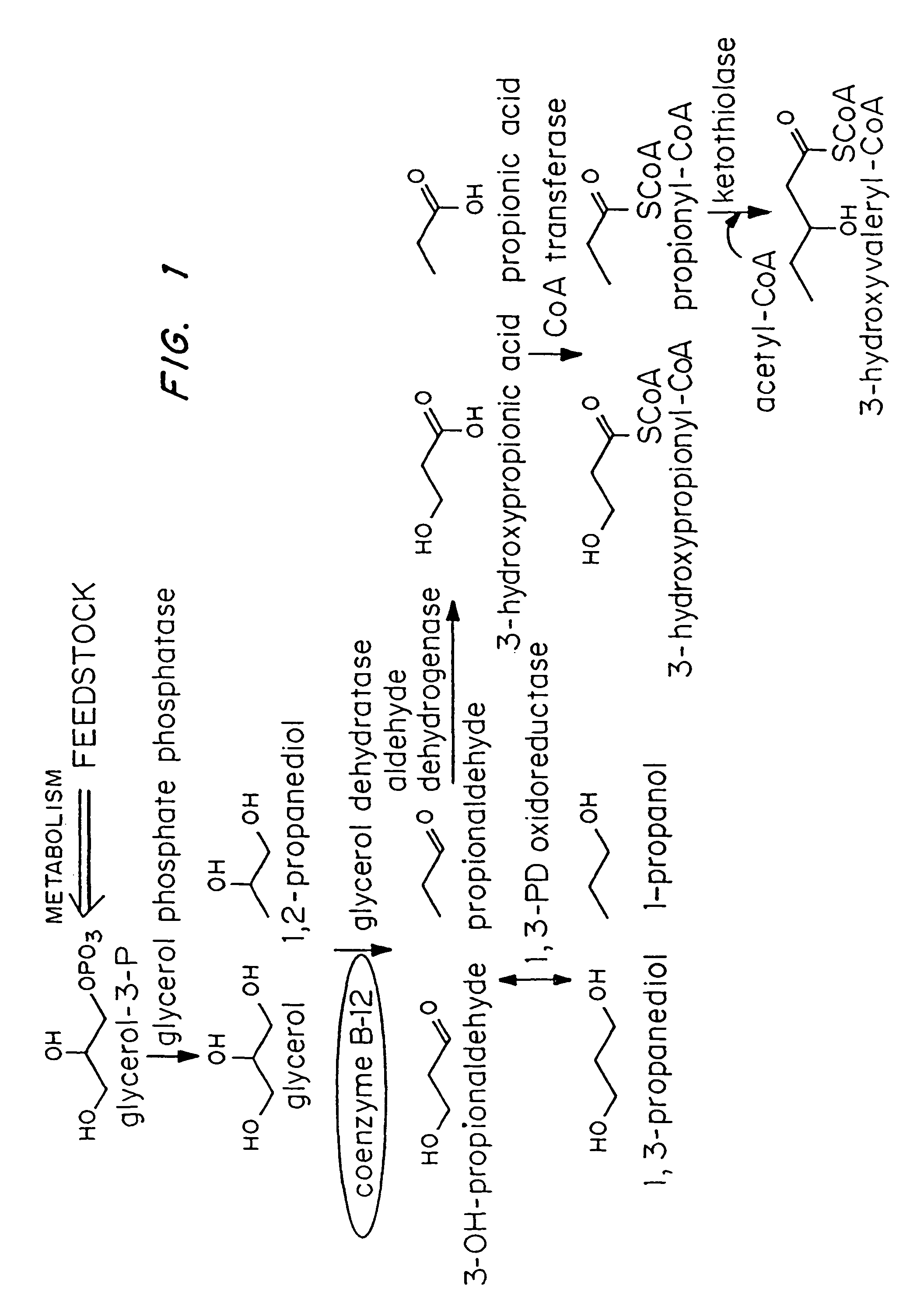

Organisms are provided which express enzymes such as glycerol dehydratase, diol dehydratase, acyl-CoA transferase, acyl-CoA synthetase β-ketothiolase, acetoacetyl-CoA reductase, PHA synthase, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase, which are useful for the production of PHAs. In some cases one or more of these genes are native to the host organism and the remainder are provided from transgenes. These organisms produce poly (3-hydroxyalkanoate) homopolymers or co-polymers incorporating 3-hydroxypropionate or 3-hydroxyvalerate monomers wherein the 3-hydroxypropionate and 3-hydroxyvalreate units are derived from the enzyme catalysed conversion of diols. Suitable diols that can be used include 1,2-propanediol, 1,3 propanediol and glycerol. Biochemical pathways for obtaining the glycerol from normal cellular metabolites are also described. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates including 1,3-propanediol, 3-hydroxypropionaldehyde, acrylics, malonic acid, esters and amines.

Owner:CJ CHEILJEDANG CORP

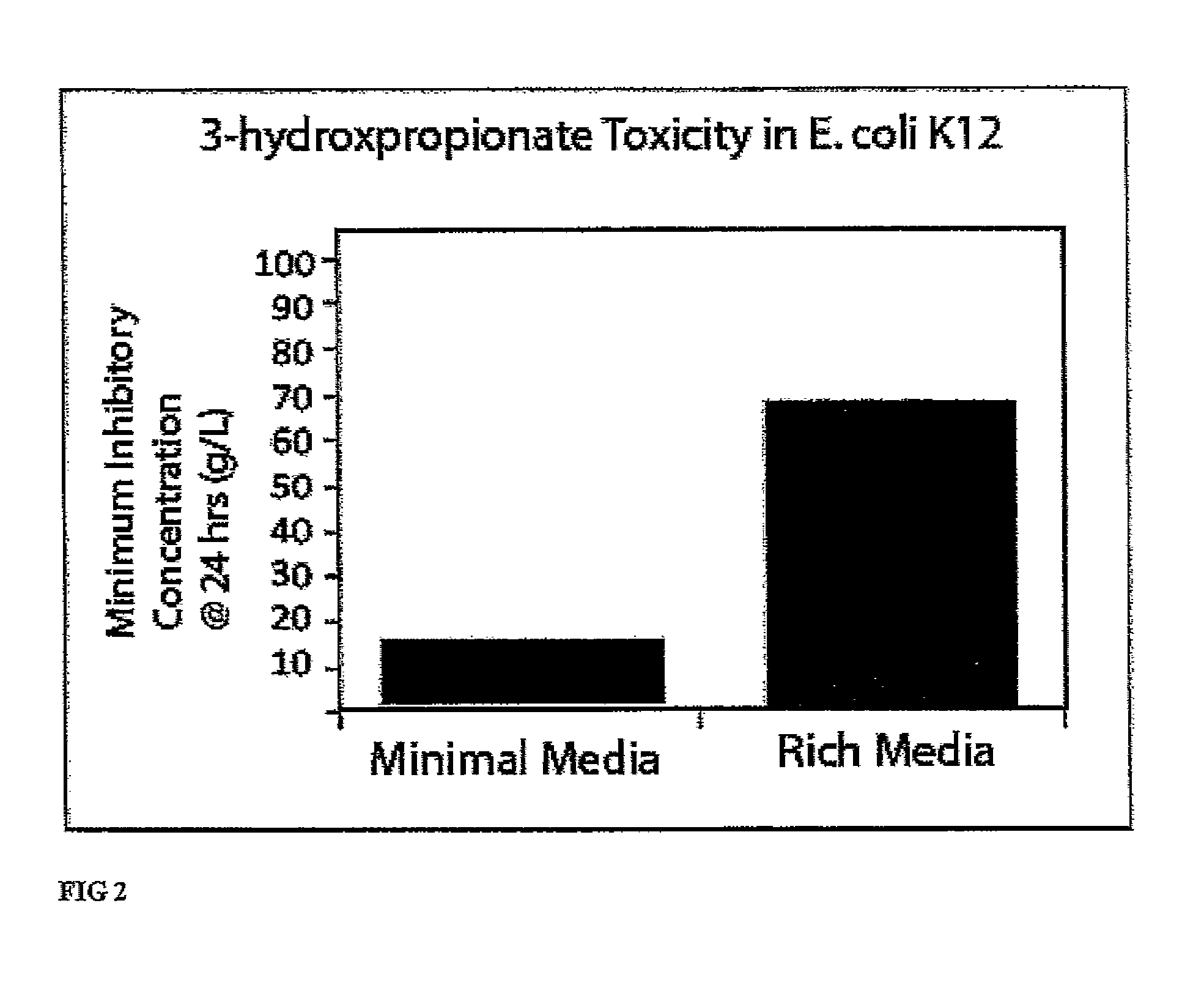

Compositions and methods for 3-hydroxypropionate bio-production from biomass

ActiveUS8048624B1BacteriaMicrobiological testing/measurement3-Hydroxypropionic acidDecarboxylase activity

Methods of obtaining mutant nucleic acid sequences that demonstrate elevated oxaloacetate α-decarboxylase activity are provided. Compositions, such as genetically modified microorganisms that comprise such mutant nucleic acid sequences, are described, as are methods to obtain the same.

Owner:OPX BIOTECH

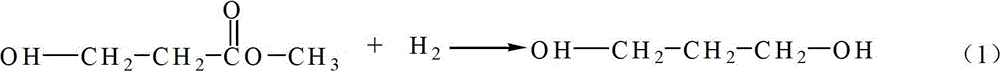

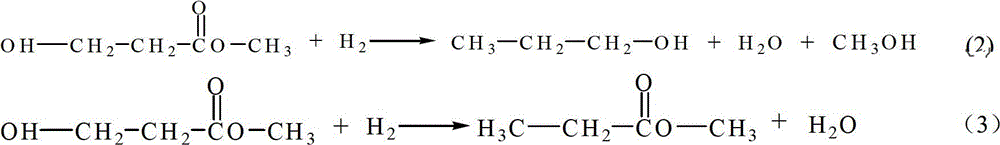

Catalyst for hydrogenation preparation of 1,3-propanediol from methyl 3-hydroxypropionate and preparation method of catalyst

InactiveCN106111155APrevent sinteringHelps stabilize the active centerOrganic compound preparationHeterogenous catalyst chemical elementsDispersityActive component

The invention relates to the field of hydrogenation catalysts, in particular to a catalyst for hydrogenation preparation of 1,3-propanediol from methyl 3-hydroxypropionate and a preparation method of the catalyst. The catalyst for hydrogenation preparation of 1,3-propanediol from methyl 3-hydroxypropionate is characterized in that SiO2 serves as a carrier, a Cu-based catalyst is adopted, one or more of the elements of Zn, Zr, Mn, La, P, Mo and Ni are added to serve as auxiliaries, and the catalyst comprises, by mass, 45%-75% of CuO, 15%-45% of SiO2 and 0.1%-25% of auxiliaries. The obtained catalyst is small in particle size, high in dispersity of active components and large in specific surface area; when the catalyst is used for hydrogenation preparation of 1,3-propanediol from methyl 3-hydroxypropionate, the activity and selectivity are high, and the repeatability is good.

Owner:山东玉皇盛世化工股份有限公司

Polyhydroxyalkanoate production from polyols

Organisms are provided which express enzymes such as glycerol dehydratase, diol dehydratase, acyl-CoA transferase, acyl-CoA synthetase β-ketothiolase, acetoacetyl-CoA reductase, PHA synthase, glycerol-3-phosphate dehydrogenase and glycerol-3-phosphatase, which are useful for the production of PHAs. In some cases one or more of these genes are native to the host organism and the remainder are provided from transgenes. These organisms produce poly (3-hydroxyalkanoate) homopolymers or co-polymers incorporating 3-hydroxypropionate or 3-hydroxyvalerate monomers wherein the 3-hydroxypropionate and 3-hydroxyvalerate units are derived from the enzyme catalysed conversion of diols. Suitable diols that can be used include 1,2-propanediol, 1,3 propanediol and glycerol. Biochemical pathways for obtaining the glycerol from normal cellular metabolites are also described. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates including 1,3-propanediol, 3-hydroxypropionaldehyde, acrylics, malonic acid, esters and amines.

Owner:CJ CHEILJEDANG CORP

Catalyzer for preparing 1, 3-trimethylene glycol from 3-hydracrylic acid ester through hydrogenation and preparation method thereof

ActiveCN101176848AEasy to prepareRaw materials are cheap and easy to getOrganic chemistryPhysical/chemical process catalystsFour componentSalt solution

The invention relates to the technical field of catalysts, in particular to a catalyst for hydrogenating 3-hydroxypropionate to prepare 1,3-propanediol and a preparation method thereof. The catalyst of the present invention is composed of CuO, ZnO, P and SiO2 four components, and the weight percentage of each component is CuO 25%~60%, ZnO 1%~30%, P 0.01%~10%, SiO2 30%~60% %, the total amount of the four components satisfies 100%. The preparation method of the catalyst is to first complex the copper salt and the ammonium salt and then blend them with a salt solution containing a certain amount of Cu and Zn, then add ammonium hypophosphite and silica sol in turn, and undergo aging, filtration, drying, molding, and high-temperature roasting. The obtained catalyst can be used to hydrogenate 3-hydroxy propionate to prepare 1,3-propanediol after being reduced in a reactor. The catalyst preparation method of the invention is simple and convenient, has long service life, good stability and high selectivity of 1,3-propanediol.

Owner:SHANGHAI HUAYI ENERGY CHEM

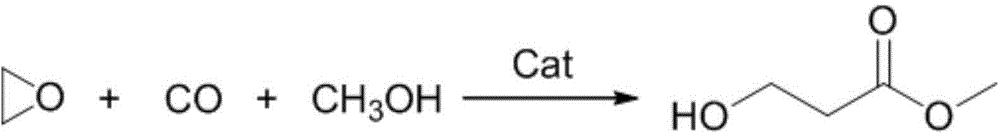

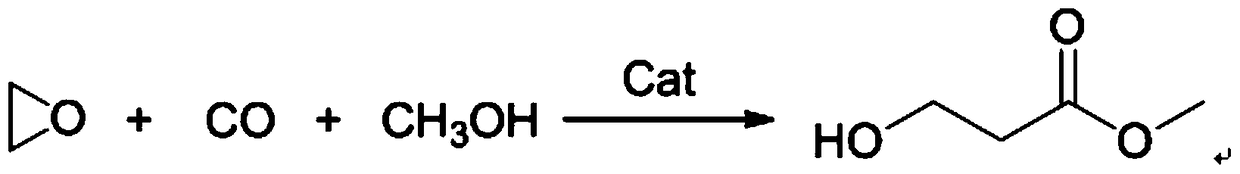

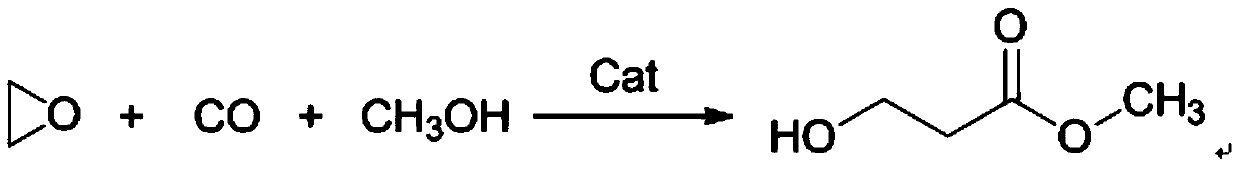

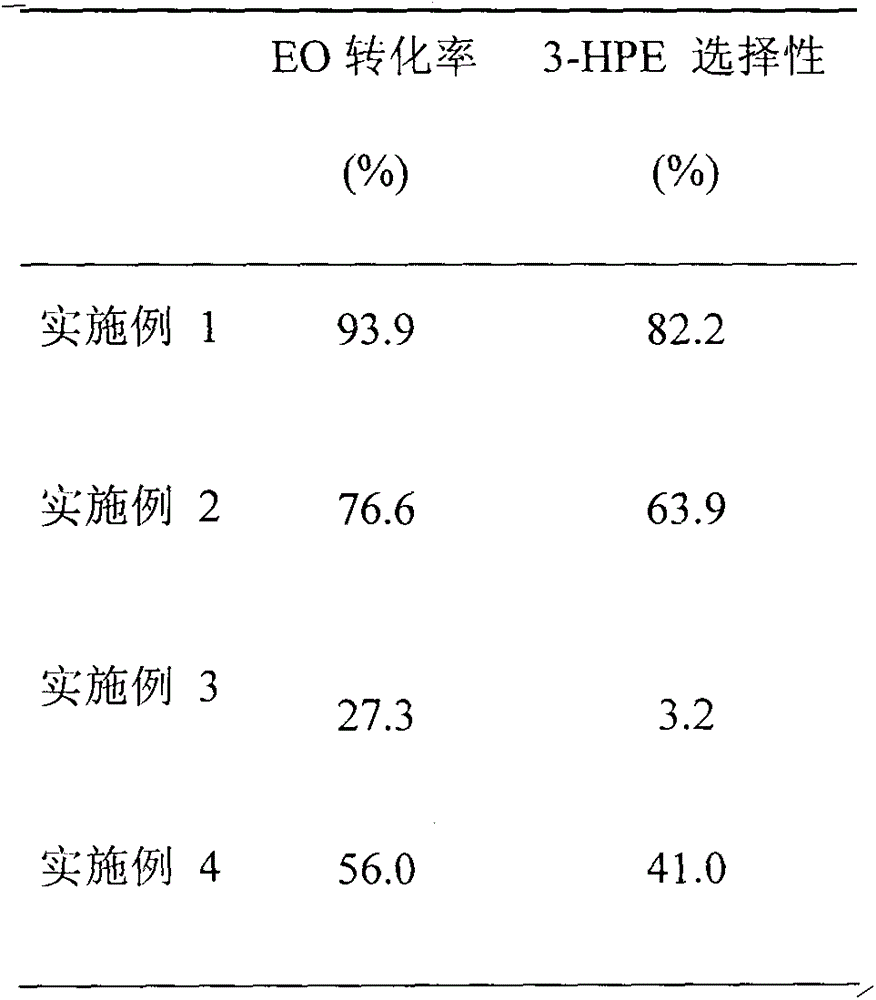

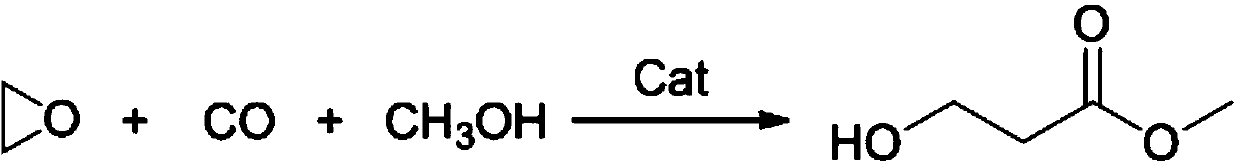

Method for preparing methyl 3-hydroxypropionate from ethylene oxide

InactiveCN107417527AImprove conversion rateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reactionNitrogenous heterocyclic compoundTetrazole

The invention relates to a method for preparing methyl 3-hydroxypropionate from ethylene oxide. According to the method, Co2(CO)8 is used as a catalyst, and one selected from nitrogen-containing heterocyclic compounds such as pyridine, pyrimidine, imidazole, triazole, tetrazole and purine is used as an auxiliary agent. The method provided by the invention has the advantages of cheap raw materials, mild reaction and short reaction time; and the nitrogen-containing heterocyclic compounds substantially improve the conversion of ethane and the selectivity of 3-HPE in alkoxycarbonylation of ethylene oxide catalyzed by Co2(CO)8.

Owner:南京大学扬州化学化工研究院

Polyhydroxyalkanoate biopolymer compositions

Several novel PHA polymer compositions produced using biological systems include monomers such as 3-hydroxybutyrate, 3-hydroxypropionate, 2-hydroxybutyrate, 3-hydroxyvalerate, 4-hydroxybutyrate, 4-hydroxyvalerate and 5-hydroxyvalerate. These PHA compositions can readily be extended to incorporate additional monomers including, for example, 3-hydroxyhexanoate, 4-hydroxyhexanoate, 6-hydroxyhexanoate or other longer chain 3-hydroxyacids containing seven or more carbons. This can be accomplished by taking natural PHA producers and mutating through chemical or transposon mutagenesis to delete or inactivate genes encoding undesirable activities. Alternatively, the strains can be genetically engineered to express only those enzymes required for the production of the desired polymer composition. Methods for genetically engineering PHA producing microbes are widely known in the art (Huisman and Madison, 1998, Microbiology and Molecular Biology Reviews, 63: 21-53). These polymers have a variety of uses in medical, industrial and other commercial areas.

Owner:CJ CHEILJEDANG CORP

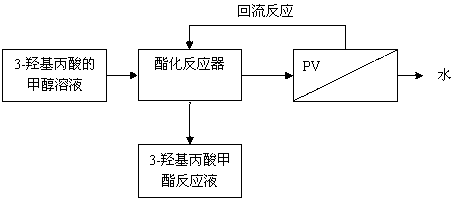

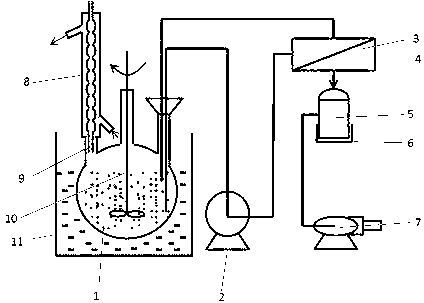

Esterification reaction-pervaporation membrane separation integrated method for producing methyl 3-hydroxypropionate

InactiveCN103012149ASimple production processImprove conversion rateOrganic compound preparationCarboxylic acid esters separation/purification3-Hydroxypropionic acidReaction temperature

The invention relates to an esterification reaction-pervaporation membrane separation integrated method for producing methyl 3-hydroxypropionate. The method comprises a process of performing esterification reaction between methanol and 3-hydroxypropionic acid to generate methyl 3-hydroxypropionate, wherein the process comprises the following steps: (1) mixing 3-hydroxypropionic acid and methanol in an esterification reactor, heating, then adding a catalyst, and reacting; and (2) pumping the obtained reaction solution into a pervaporation membrane separation device, dewatering the reaction liquid through the membrane, circularly returning the reaction solution into the esterification reactor, and further performing esterification reaction, thus obtaining the high-purity methyl 3-hydroxypropionate product after the esterification reaction is completed. According to the method provided by the invention, the area of the used membrane is small, the raw material solution / catalyst mass ratio and the reaction temperature are low, the purity and yield of methyl 3-hydroxypropionate can be greatly increased, the process is simple, and the course is stable. Thus, the invention can be easily used in the large-scale production of methyl 3-hydroxypropionate.

Owner:NANCHANG UNIV

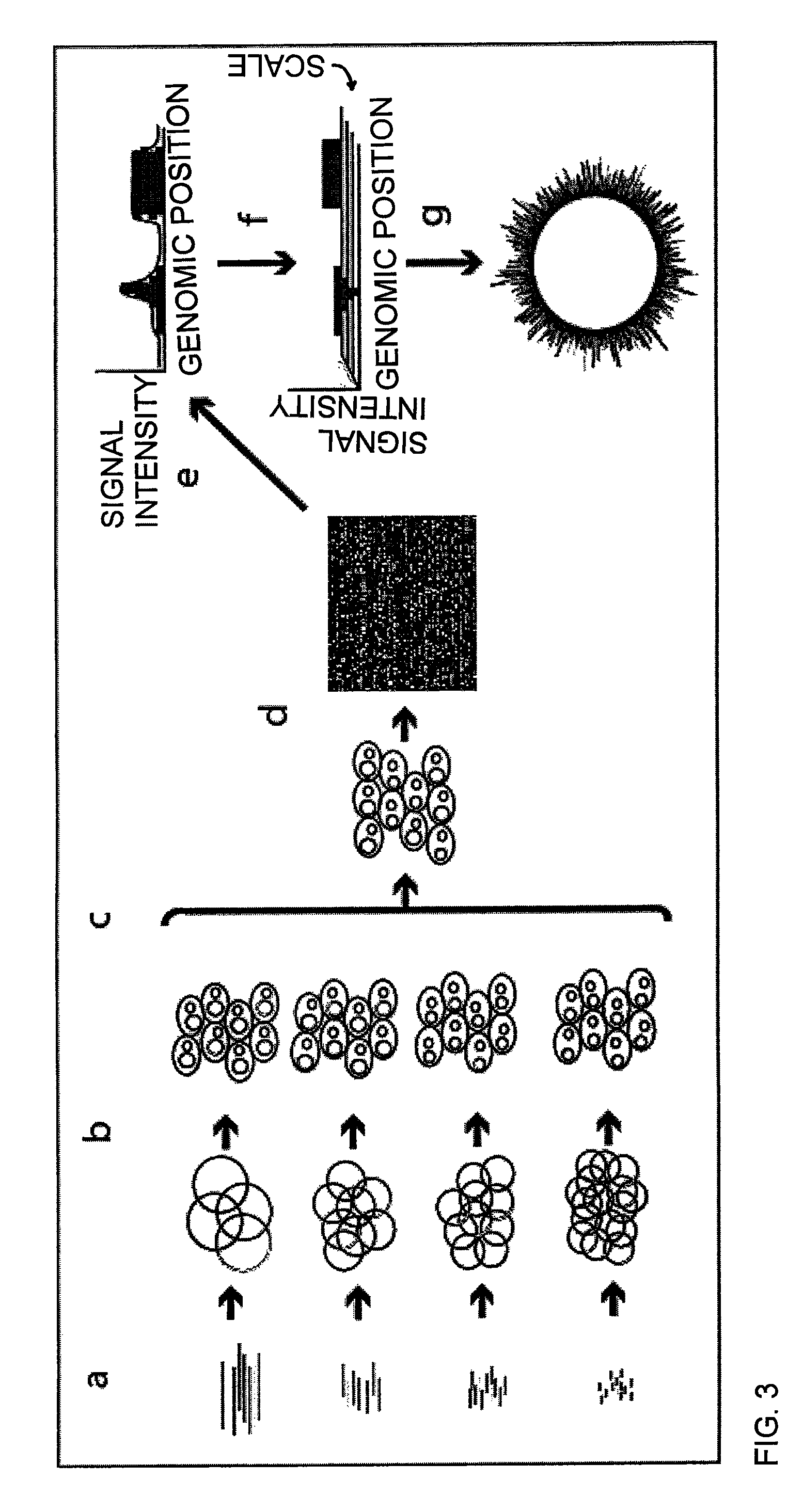

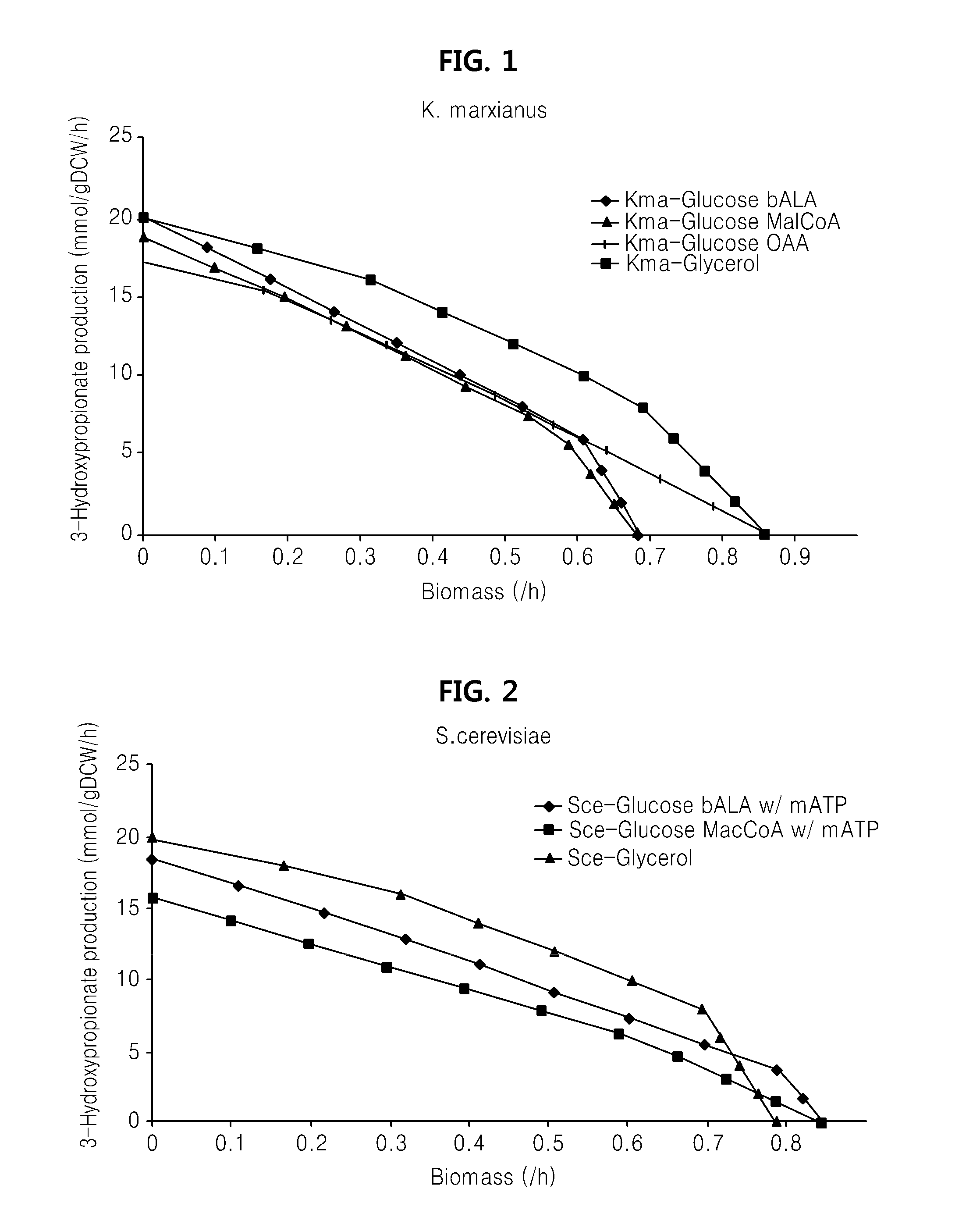

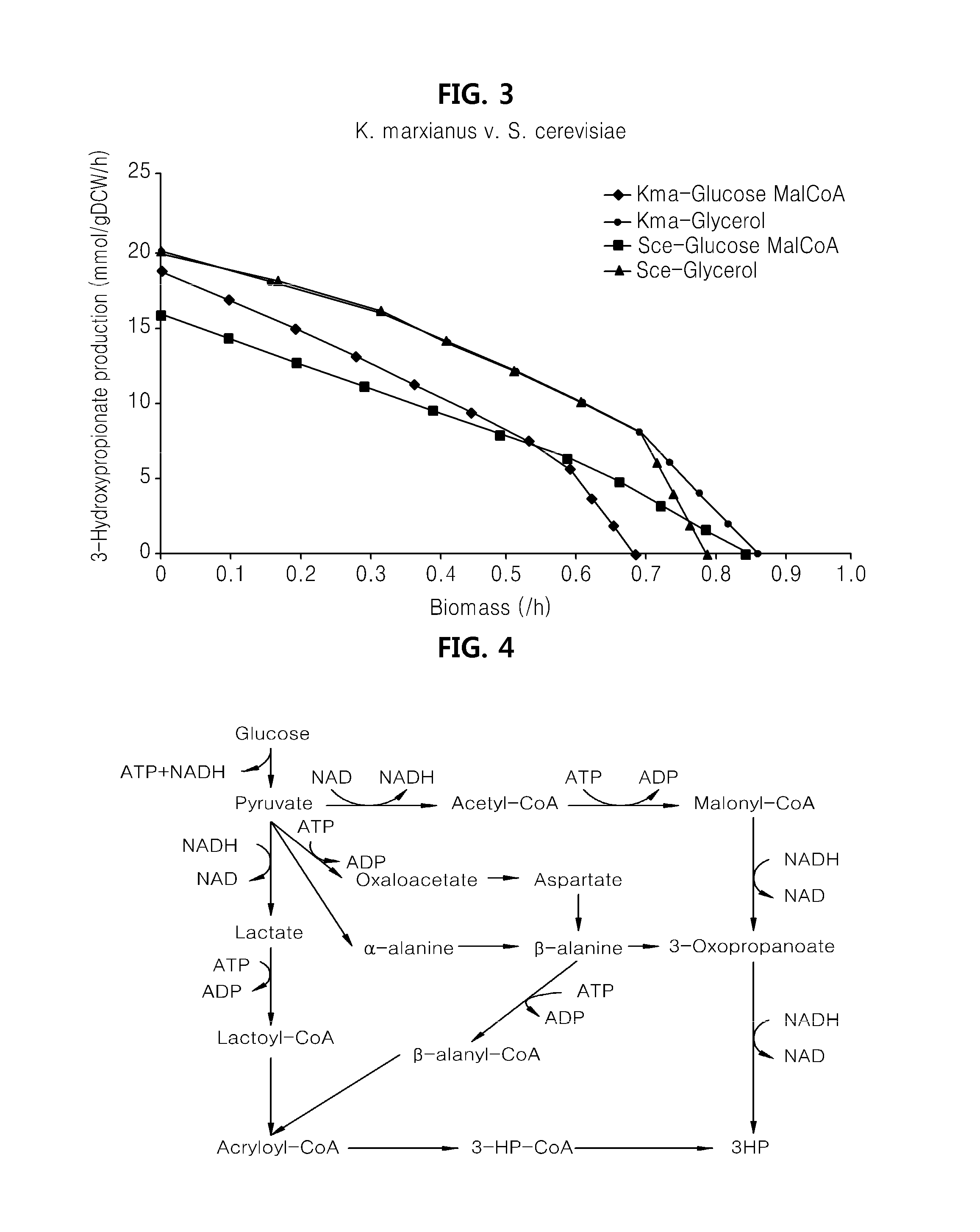

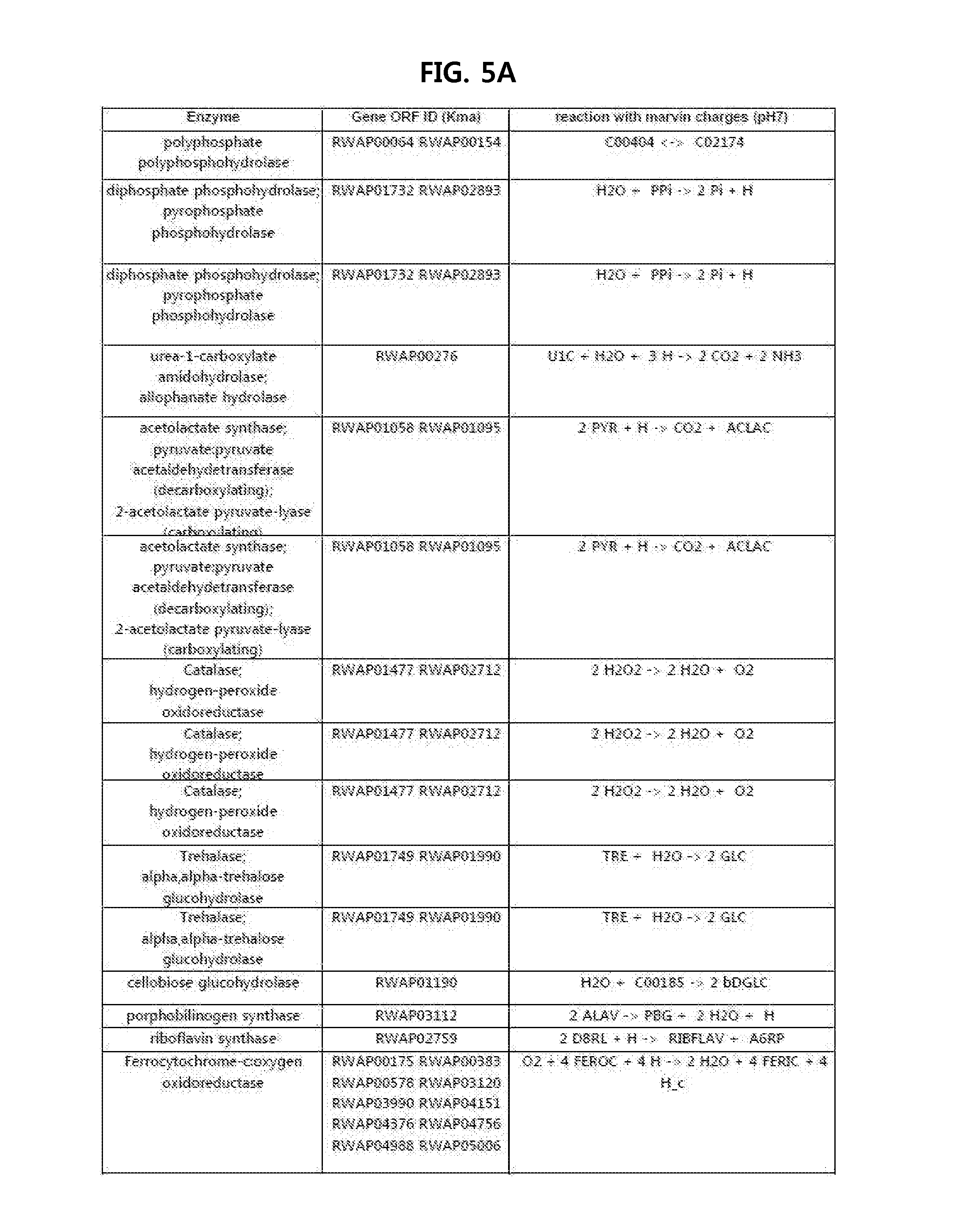

Genome-scale metabolic network model reconstruction of kluyveromyces marxianus and strategies for engineering non-native pathways for 3-hydroxypropionate production in kluyveromyces marxianus

InactiveUS20140093901A1Maximizing growth rateEfficient productionMicroorganismsMicrobiological testing/measurementBiotechnology3-Hydroxypropionic acid

Use of a metabolic network model for analyzing metabolic characteristics of microorganisms for producing a metabolic product, such as 3HP enabling estimation of productivity and cell growth speed of microorganisms, optimizing new metabolic pathway, and providing transformed microorganisms that may produce a specific metabolic product with high efficiency.

Owner:SAMSUNG ELECTRONICS CO LTD

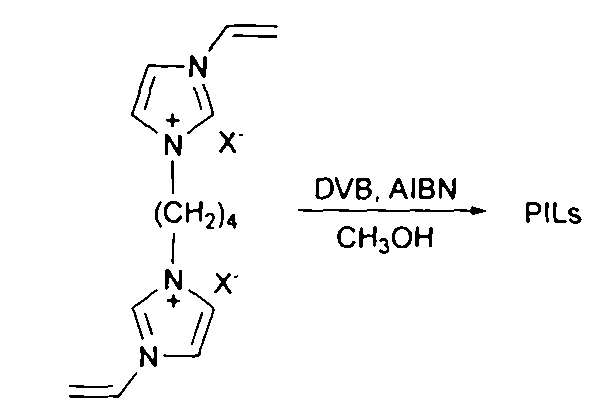

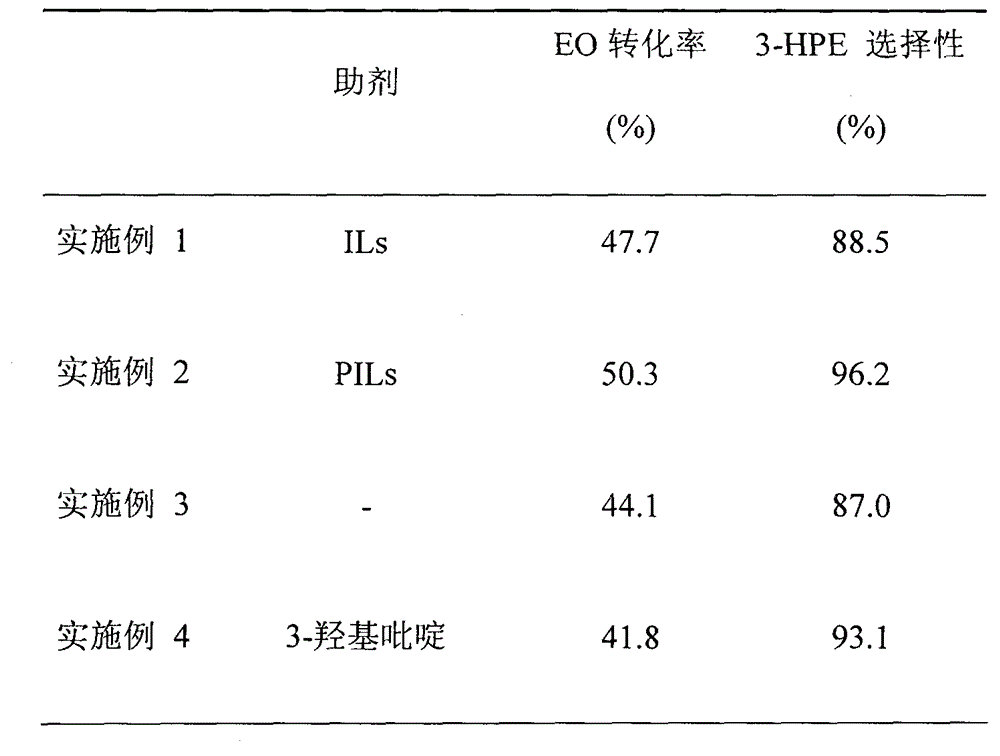

Application of recyclable efficient ionic liquid auxiliary in carbonyl-methyl esterification reaction of ethylene oxide

InactiveCN105272855AEasy to makeImprove performanceOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reaction3-Hydroxypropionic acidEthylene oxide

The invention provides an application of a poly(ionic liquid) as an auxiliary agent in a carbonyl-methyl esterification reaction of ethylene oxide to prepare methyl 3-hydroxypropionate. The poly(ionic liquid) can not only be used for improving the conversion ratio of ethylene oxide and the selectivity of methyl 3-hydroxypropionate, but also can be recovered through simple centrifugalization and separation after a catalytic reaction. The method improves the purity of a product, shortens the product purification flow and lowers the cost.

Owner:南京大学扬州化学化工研究院

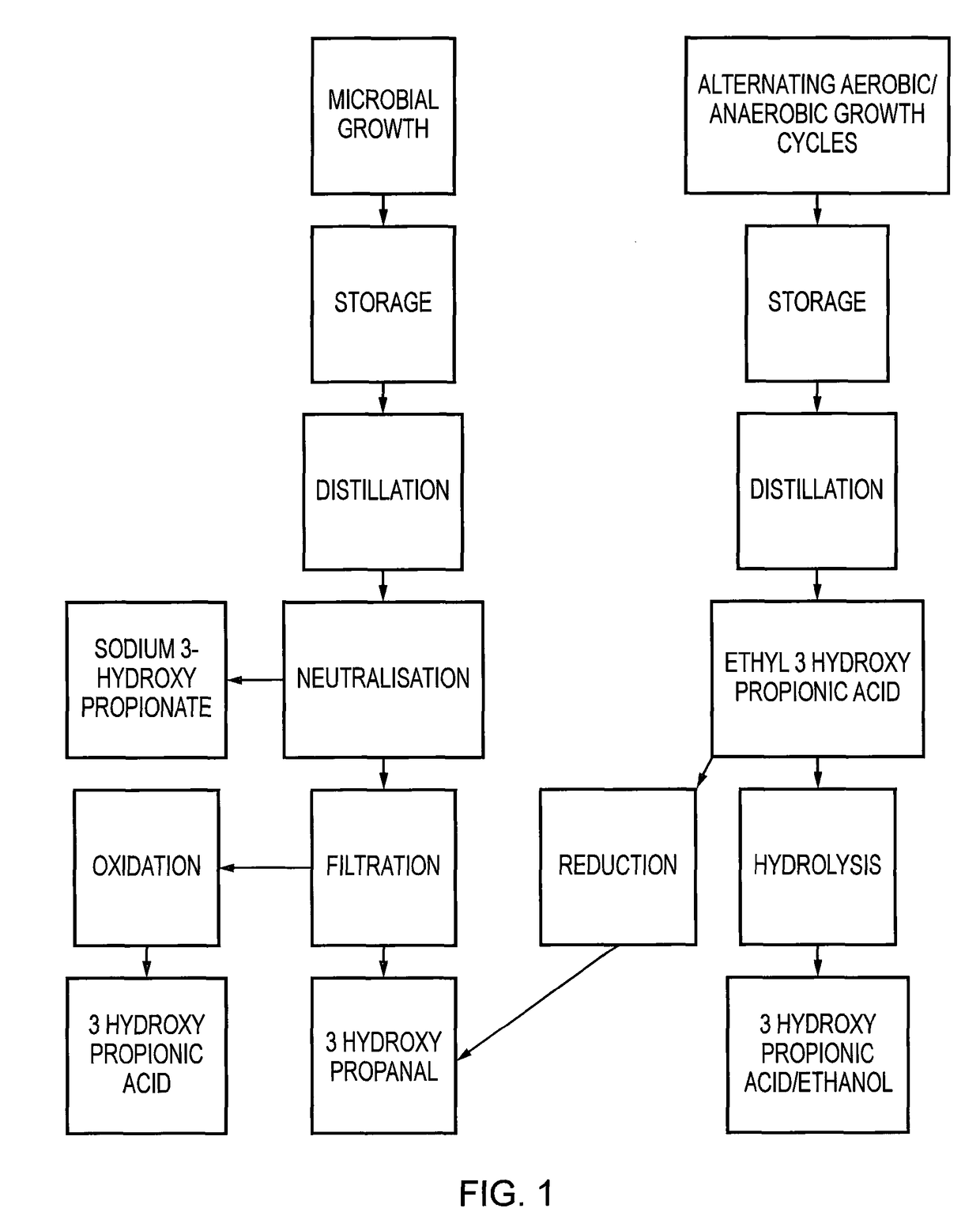

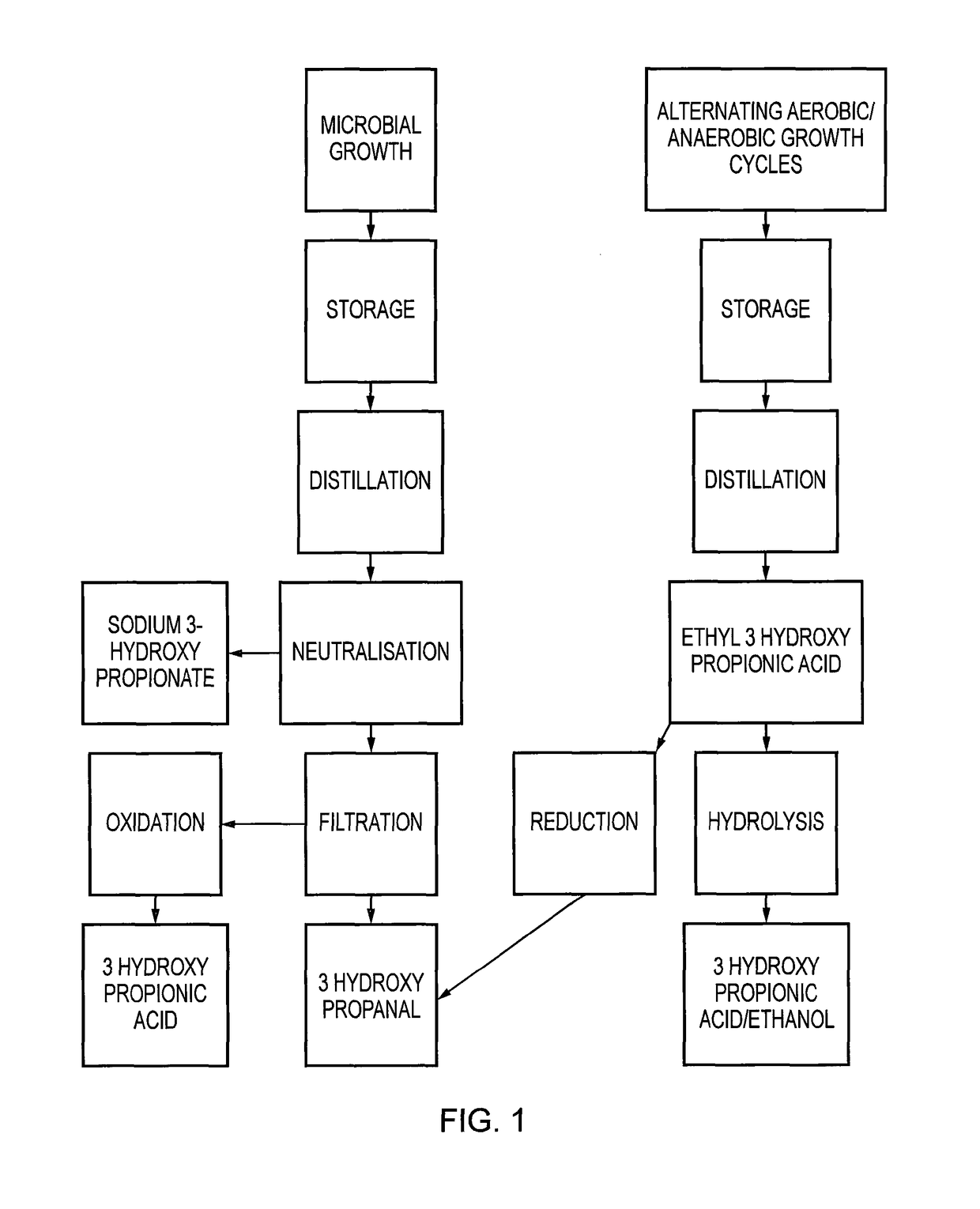

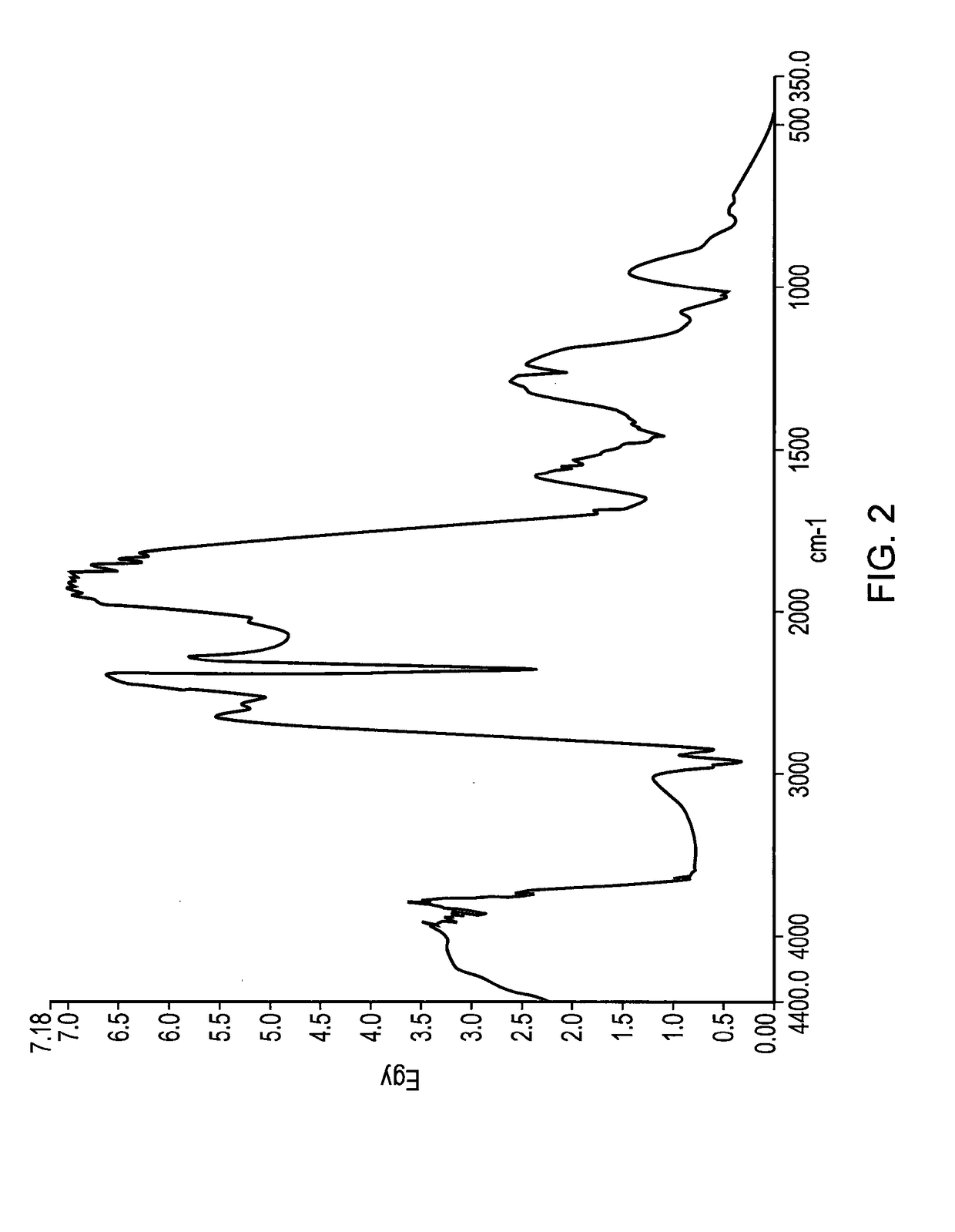

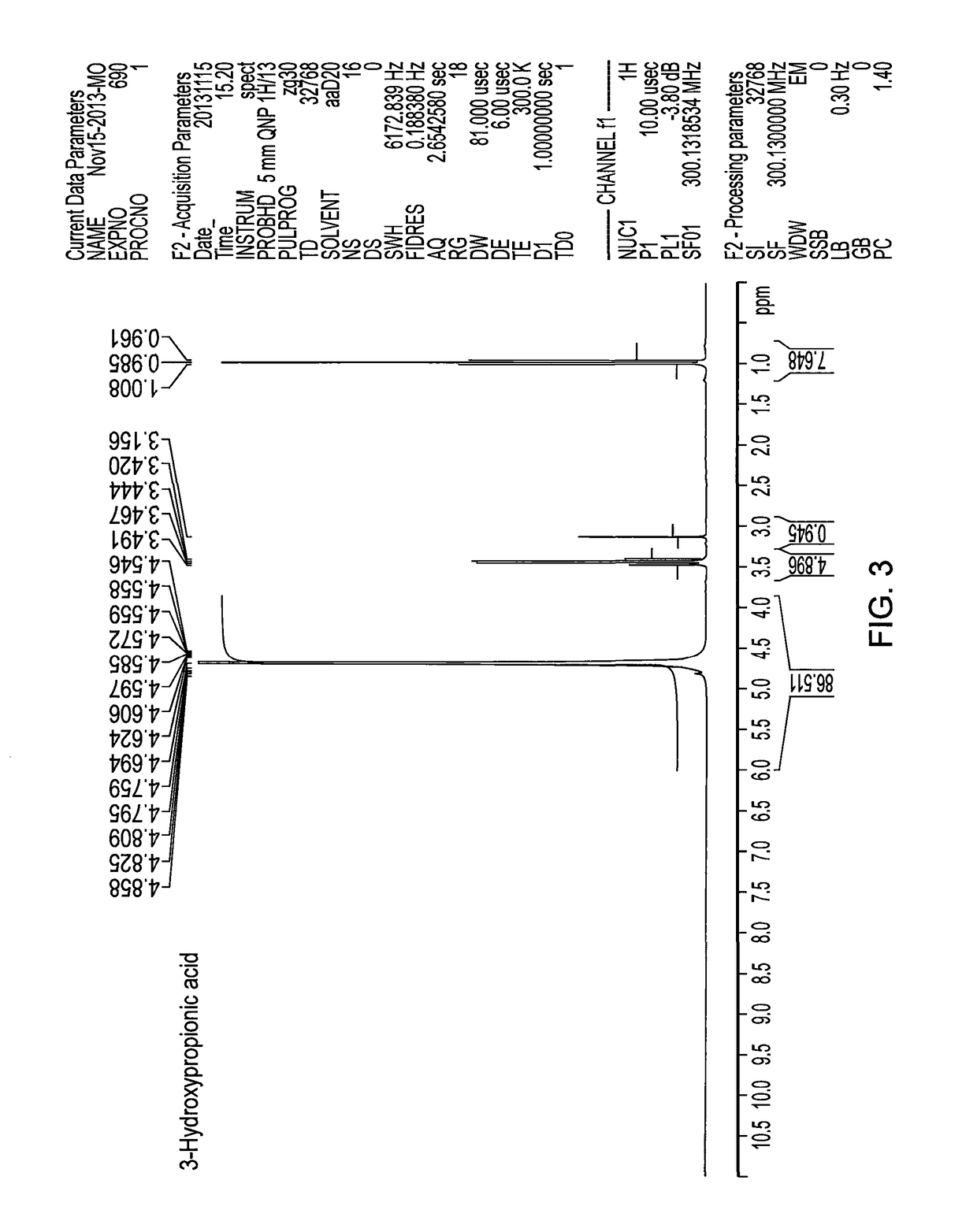

Method for producing 3-hydroxypropanal

InactiveUS20170233773A1Increase volumeReduce moistureMembranesBacteria3-Hydroxypropionic acidPhosphate

There is described a method for producing 3-hydroxypropanal, the method comprising: culturing an Acetobacter lovaniensis bacterium in a growth medium containing phosphate at a level which is more than 1 g / litre and nitrate at a level which is more than 0.1 g / litre, wherein culturing of the bacterium produces the 3-hydroxypropanal. The 3-hydroxypropanal can be separated from the growth medium or, when the microorganism has converted some or all of the 3-hydroxypropanal to 3-hydroxypropionic acid and / or a 3-hydroxypropionate ester, it may be separated as 3-hydroxypropionic acid or a 3-hydroxypropionate ester. The separated product can be converted into other chemicals such as an ester of 3-hydroxypropionic acid, 3-hydroxypropionic acid, 3-hydroxypropionate salts (including ammonium, sodium and calcium 3-hydroxypropionate), acrylic acid, acrylates, acrylamide, acrylonitrile, acrolein and 1,3 propanediol.

Owner:VERDANT BIOPRODS

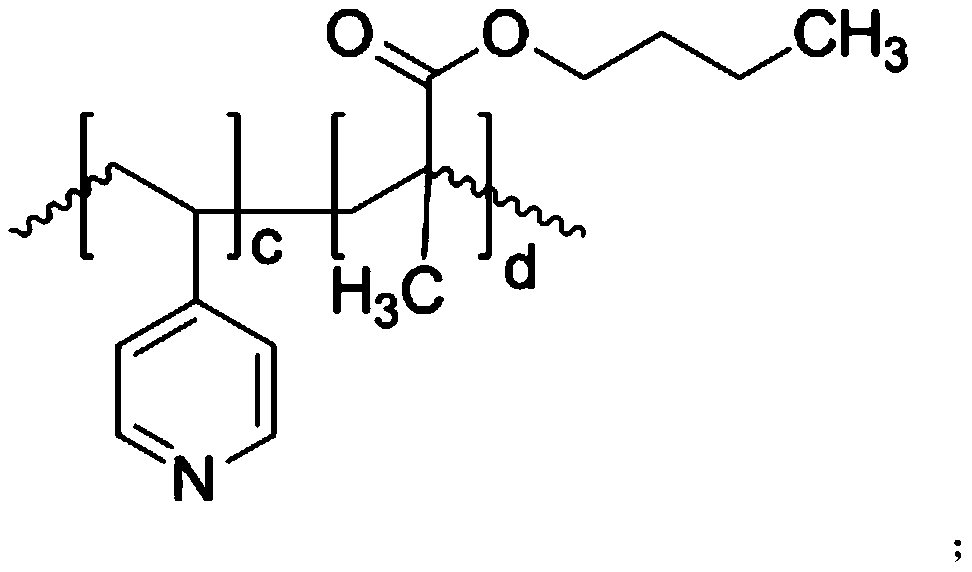

Method for preparing 3-hydroxypropionate

ActiveCN106431922ACatalytic reaction conditions are mildHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reaction3-Hydroxypropionic acidAlcohol

The invention relates to a method for preparing 3-hydroxypropionate and mainly aims to solve the problem that in the prior art, a catalyst in a homogeneous system is hard to separate. The method for preparing 3-hydroxypropionate comprises the steps that first, a ligand and cobalt carbonyl are subjected to a coordination reaction in an alcoholic solvent to obtain turbid liquid of a catalyst; second, ethylene oxide and carbon monoxide are added, and a reaction is carried out to obtain 3-hydroxypropionate. According to the technical scheme that the ligand is an acrylonitrile homopolymer or a copolymer which contains acrylonitrile monomer units, the technical problem is well solved, and the method can be applied to industrial production of 3-hydroxypropionate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for producing 1,3-propanediol through hydrogenation of methyl 3-hydroxypropionate, and preparation method of catalyst

InactiveCN106179361AMild reaction conditionsEasy to makeOrganic compound preparationHeterogenous catalyst chemical elementsRepeatabilityPropanediol

The invention relates to the technical field of plastic preparation, and particularly relates to a catalyst for producing 1,3-propanediol through hydrogenation of methyl 3-hydroxypropionate, and preparation method of the catalyst. The catalyst is prepared from the following components in percentage by weight: 40-70% of CuO, 1-20% of ZrO2, 0.5-5% of ZnO, and 18-40% of SiO2. The preparation method comprises the following steps: firstly, according to proportion, dissolving precursors of Cu, Zr and Zn elements into deionized water and evenly mixing, separately dissolving Si precursor into deionized water, then coprecipitating alkaline precipitator under stirring condition at special rate, aging, washing and drying, then baking, tableting and forming and crushing, sieving with certain meshes to obtain the catalyst. The reaction conditions of the catalyst are mild, the preparation process is simple, the conversion rate and yield for preparing 1,3-propanediol through hydrogenation of methyl 3-hydroxypropionate are high, and the repeatability is good.

Owner:山东玉皇盛世化工股份有限公司

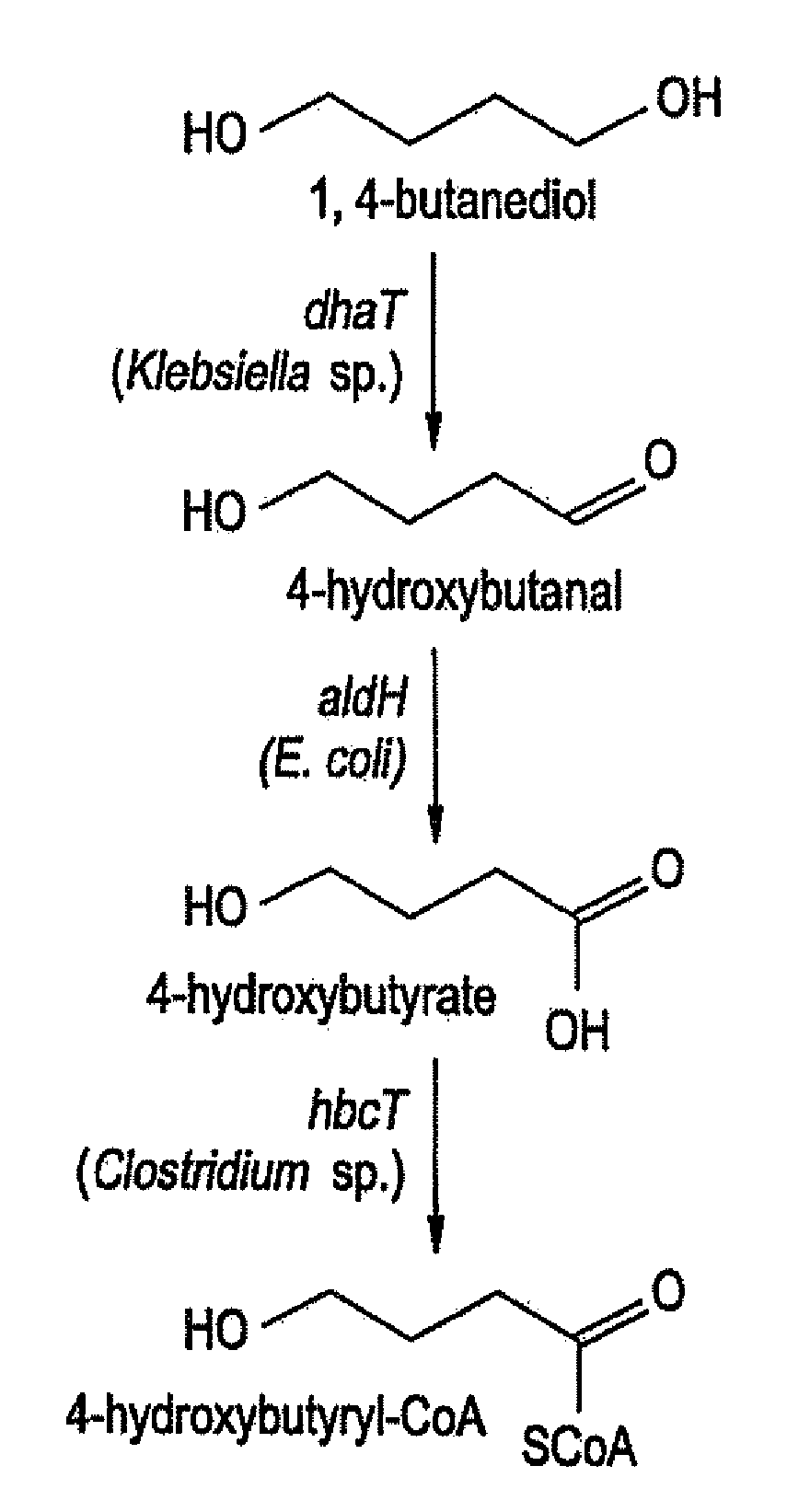

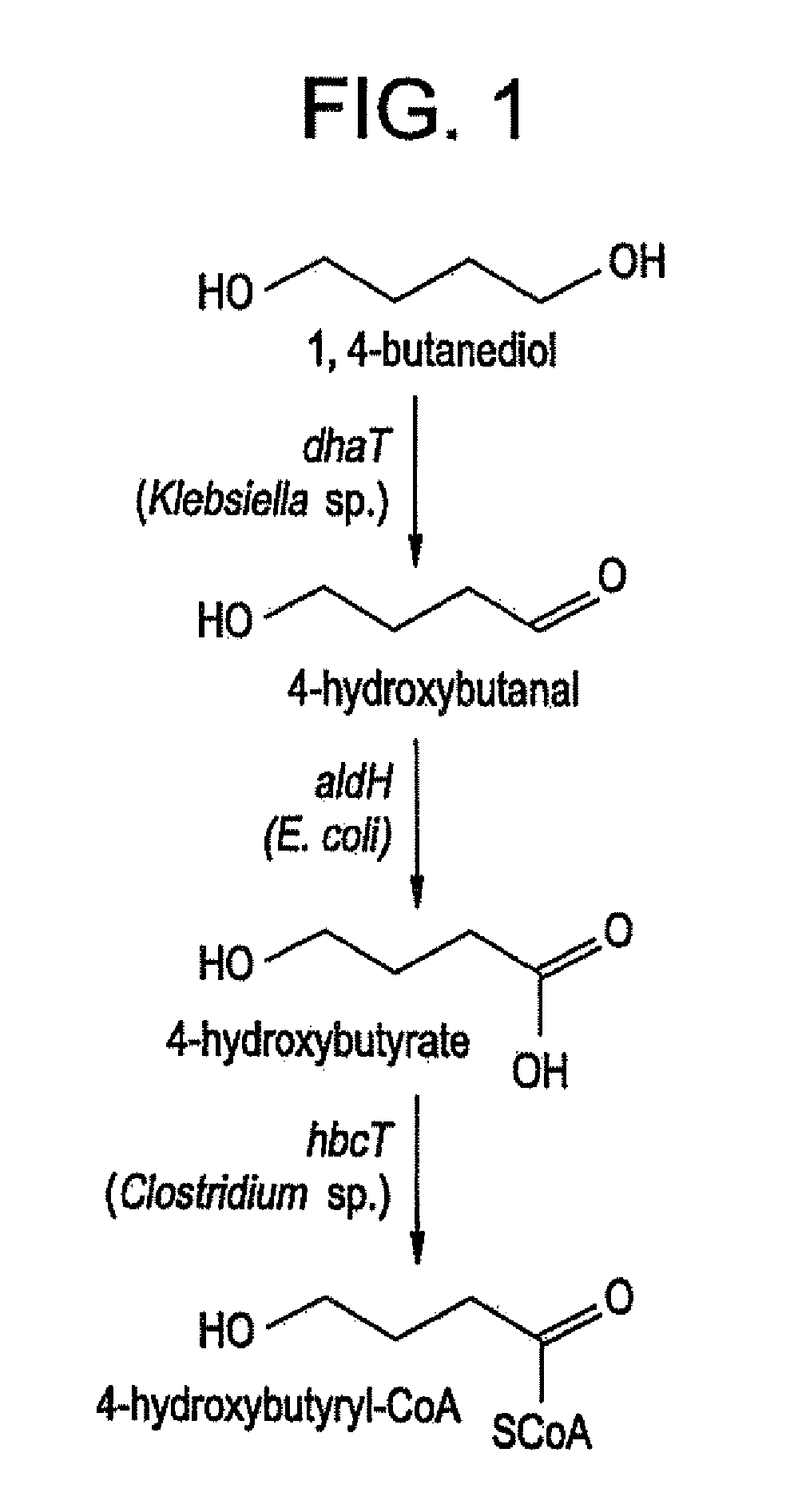

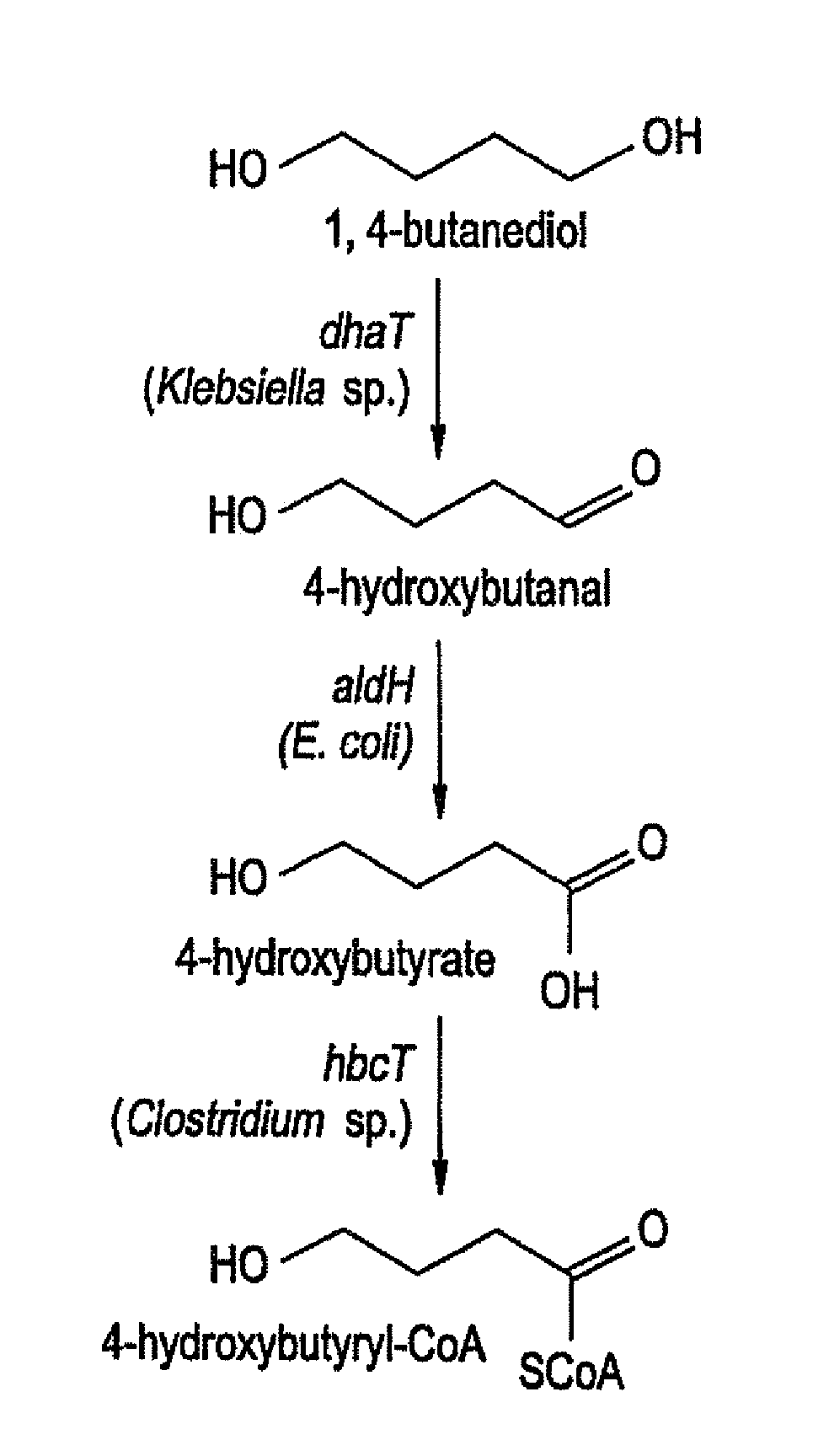

Production of Polyhydroxyalkanoates From Polyols

InactiveUS20100021919A1Increase productionPromote recoveryBacteriaSugar derivativesEscherichia coli3-Hydroxypropionic acid

Recombinant processes are provided whereby additional genes are introduced into E. coli which have been genetically engineered to produce PHA so that the improved strains produce PHA homopolymers and copolymers directly from diols. In preferred embodiments, PHAs containing 4-hydroxybutyrate monomers are produced directly from 1,4-butanediol; PHAs containing 5-hydroxyvalerate are produced from 1,5-pentanediol; PHAs containing 6-hydroxyhexanoate (6HH) are produced from 1,6-hexanediol; PHAs containing 3-hydroxypropionate are produced from 1,3-propanediol; PHAs containing 2-hydroxypropionate (lactate) are produced from 1,2-propanediol (propylene glycol); PHAs containing 2-hydroxyethanoate (glycolate) are produced from 1,2-ethanediol (ethylene glycol). Genes encoding these same enzyme activities can be introduced or their expression amplified in wild type PHA producers to improve the production of PHA homopolymers and copolymers directly from diol and other alcohol feedstocks. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates.

Owner:CJ CHEILJEDANG CORP

Microorganisms And Methods For Producing Acrylate And Other Products From Propionyl-CoA

InactiveUS20140107377A1Increase gene expressionCarbon-nitrogen lyasesFungi3-Hydroxypropionic acidMicroorganism

This invention relates to microorganisms that convert a carbon source to acrylate or other desirable products using propionyl-CoA as an intermediate. The invention provides genetically engineered microorganisms that carry out the conversion, as well as methods for producing acrylate by culturing the microorganisms. Also provided are microorganisms and methods for converting propionyl-CoA and propionate to 3-hydroxypropionyl-CoA, 3-hydroxypropionate (3-HP) and poly-3-hydroxypropionate.

Owner:THE PROCTER & GAMBLE COMPANY

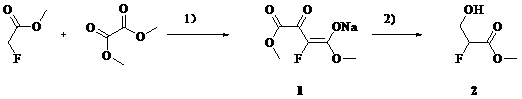

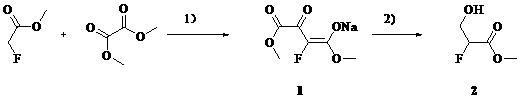

Synthetic method of methyl 2-fluoro-3-hydroxypropionate

ActiveCN105646216BLow costHigh yieldOrganic compound preparationCarboxylic acid esters preparationPropanoic acidSynthesis methods

The invention relates to a synthesis method of 2-fluoro-methyl 3-hydroxypropionate. The method comprises the following two steps: step one: a sodium enol intermediate is generated under an alkaline condition with methyl fluoroacetate and dimethyl oxalate as raw materials; step two: the sodium enol intermediate has a reaction with a paraformaldehyde or formaldehyde aqueous solution in a solvent to generate 2-fluoro-methyl 3-hydroxypropionate. Cheap methyl fluoroacetate and dimethyl oxalate are taken as raw materials, and the solvent with a low cost is used, so that 2-fluoro-methyl 3-hydroxypropionate is low in cost, high in yield and suitable for large-scale production. In particular, generation of 2-fluoro-methyl 3-hydroxypropionate in a reaction of sodium enol and the paraformaldehyde or formaldehyde aqueous solution under an alkaline condition is a breakthrough in the field.

Owner:HUBEI ENG UNIV

A catalyst for preparing 1,3 propanediol by hydrogenation of methyl 3-hydroxypropionate and its preparation and application

ActiveCN103721734BHigh selectivityLow selectivityPhysical/chemical process catalystsOrganic compound preparationOrganic acidHigh concentration

The invention relates to a catalytic agent for preparing 1,3-PDO by performing hydrogenization on 3-hydracrylic acid methyl ester. The catalytic agent consists of the following components in percentage by weight: 55 to 80 wt% of CuO, 2 to 5 wt% of MnO2, 0.1 to 2 wt% of MoO3, 0.1 to 2 wt% of P2O5 and 15 to 40 wt% of SiO2. The catalytic agent prepared by the invention is used for the technology of preparing the 1,3-PDO by performing hydrogenization on the 3-hydracrylic acid methyl ester, the reaction condition is mild, the requirement on the content of organic acid and moisture in the raw material of the 3-hydracrylic acid methyl ester is low (less than 0.5 wt%), the selectivity of the 1,3-PDO is improved, the selectivity of the 1,3-PDO and ester exchange products is reduced, and meanwhile the catalytic agent is suitable for preparing the 1,3-PDO by performing hydrogenization on the 3-hydracrylic acid methyl ester in high concentration; the conversion rate of the 3-hydracrylic acid methyl ester is larger than 99%, and the yield coefficient of the 1,3-PDO is larger than 85%.

Owner:SHANGHAI HUAYI ENERGY CHEM

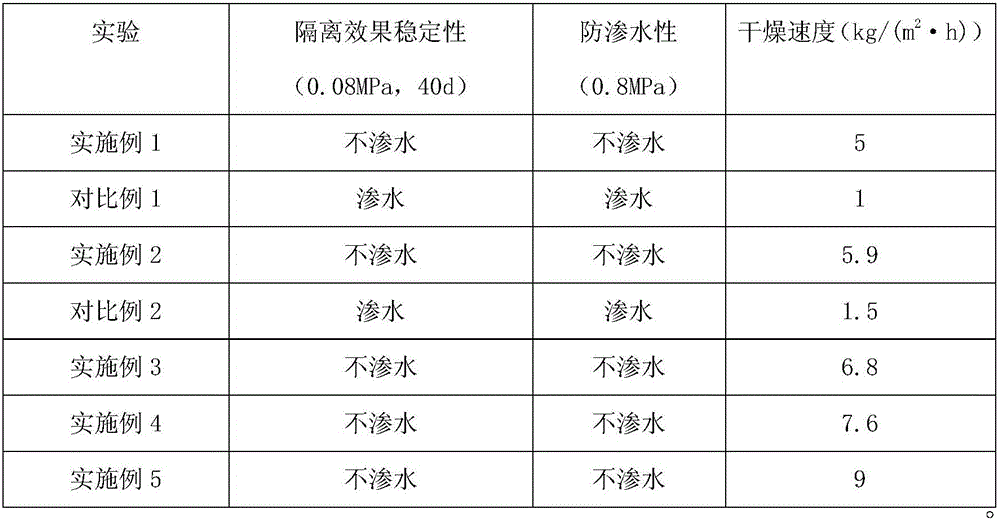

Quick-dry waterproof material and preparation method thereof

The invention discloses a quick-dry waterproof material. The quick-dry waterproof material is prepared from, by weight, 80-100 parts of deionized water, 12-16 parts of ethyl acrylate, 8-12 parts of hydroxymethyl cellulose, 3-6 parts of ammonium persulfate, 1-4 parts of aluminum sulfate, 2-5 parts of vinyl trimethoxy silane, 6-10 parts of propylene carbonate, 10-16 parts of octyl 4-hydroxybenzoate, 7-11 parts of tetrahydromyrcenol, 12-15 parts of 3-methyl-5-phenyl-1-pentanol, 7-11 parts of 5-tert-butylpyrogallol, 11-15 parts of 2-sulfydryl ethyl sulfide, 9-12 parts of methyl 2-chloro-3-hydroxypropionate and 2-6 parts of 2-hydroxylepidine. The waterproof material is high in initial setting speed, short in drying time, high in binding force and good in waterproof effect.

Owner:安徽五星凯虹防水建材科技有限公司

Synthetic method of acrylate

ActiveCN106588653BHigh selectivityBeneficial technical effectMolecular sieve catalystsOrganic compound preparationMolecular sieveSynthesis methods

The present invention relates to an acrylic acid ester synthesis method. A purpose of the present invention is mainly to solve the problem of low selectivity of acrylic acid ester in the prior art. According to the present invention, by using the acrylic acid ester synthesis method, in the presence of a molecular sieve catalyst, 3-hydroxypropionate is subjected to dehydrating to obtain the acrylic acid ester; and with the technical scheme, the problem in the prior art is well solved, and the method can be used in the industrial production of the acrylic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

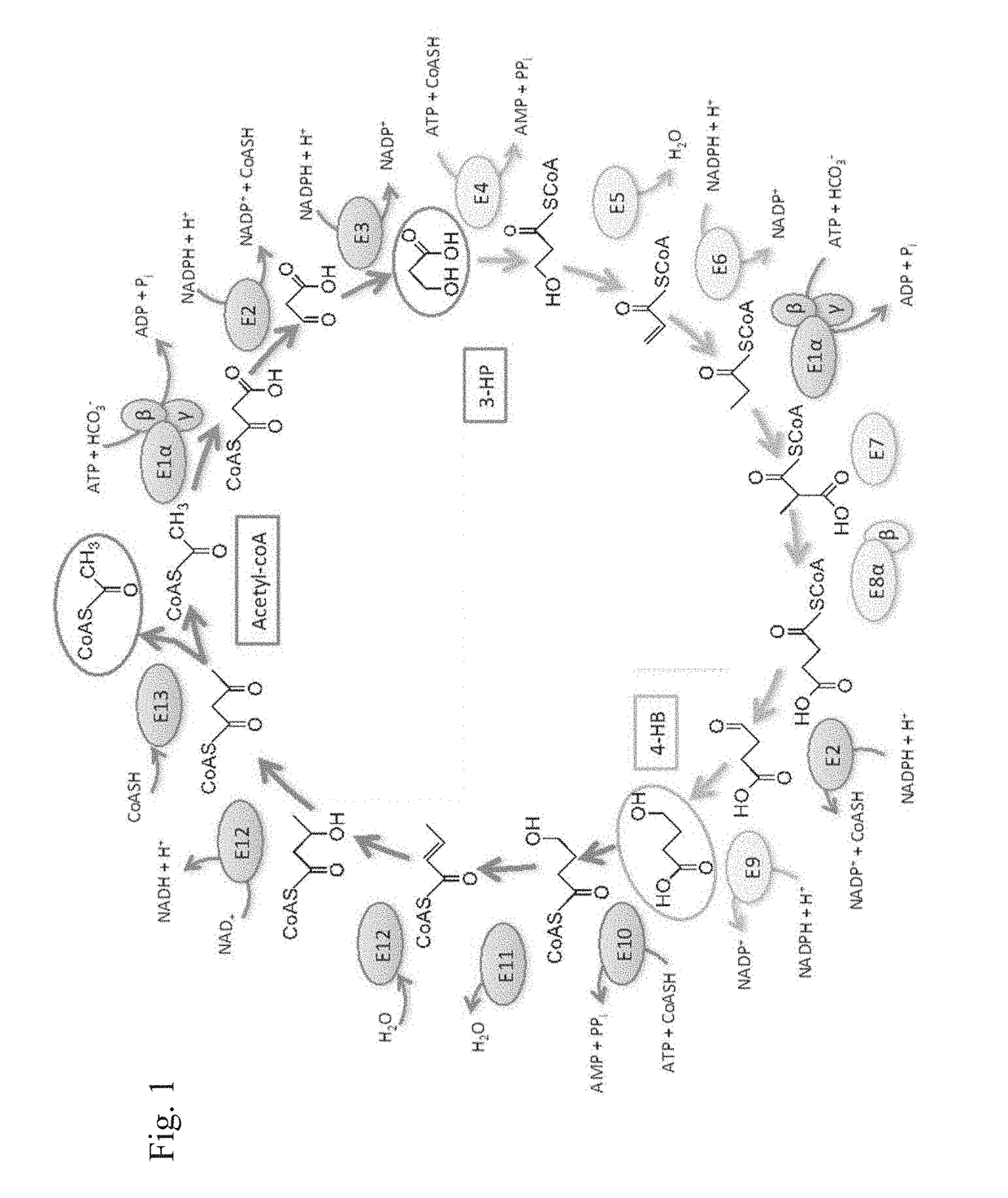

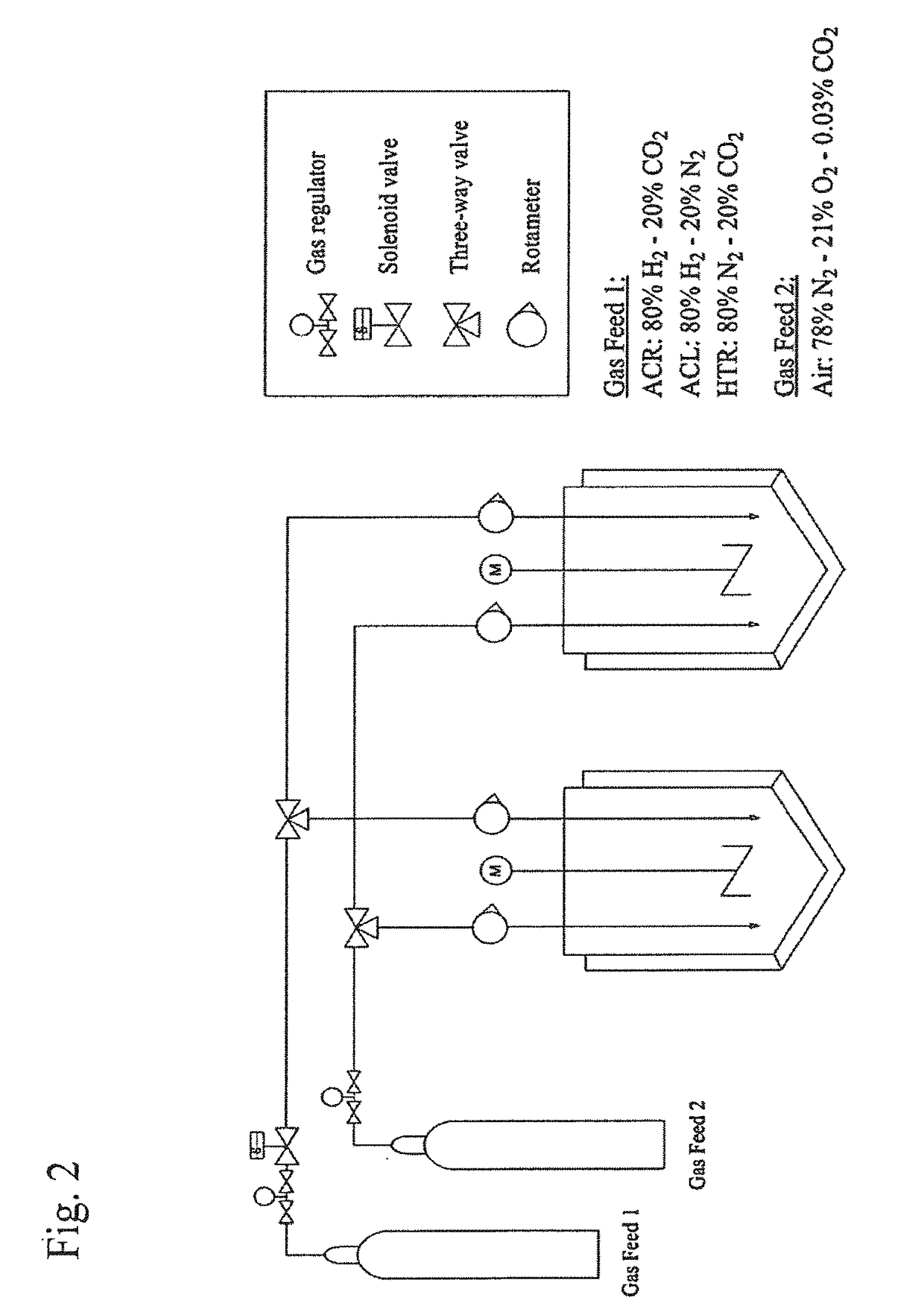

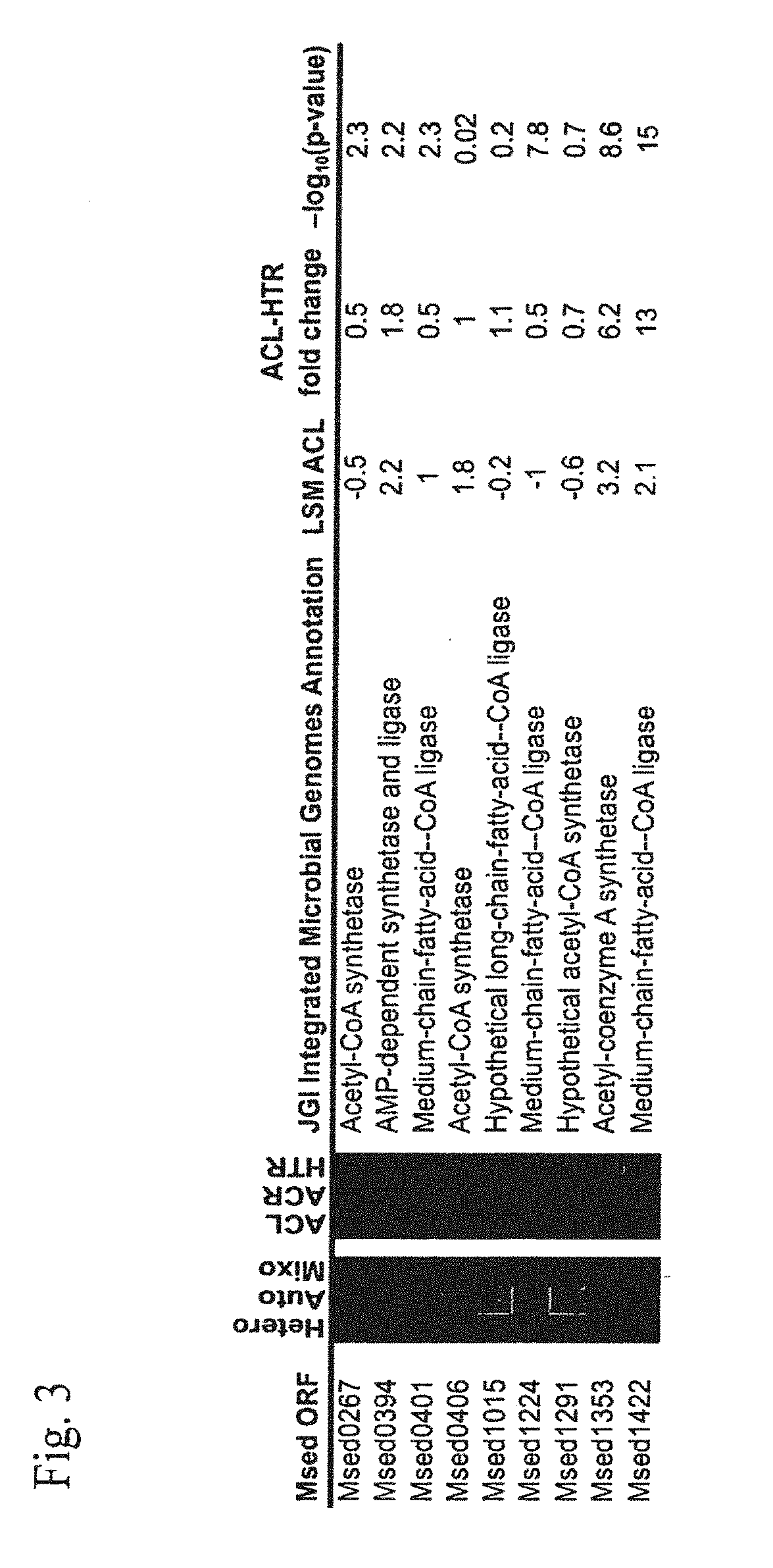

Sequestration of carbon dioxide with hydrogen to useful products

Provided herein are genetically engineered microbes that include at least a portion of a carbon fixation pathway, and in one embodiment, use molecular hydrogen to drive carbon dioxide fixation. In one embodiment, the genetically engineered microbe is modified to convert acetyl CoA, molecular hydrogen, and carbon dioxide to 3-hydroxypropionate, 4-hydroxybutyrate, acetyl CoA, or the combination thereof at levels greater than a control microbe. Other products may also be produced. Also provided herein are cell free compositions that convert acetyl CoA, molecular hydrogen, and carbon dioxide to 3-hydroxypropionate, 4-hydroxybutyrate, acetyl CoA, or the combination thereof. Also provided herein are methods of using the genetically engineered microbes and the cell free compositions.

Owner:UNIV OF GEORGIA RES FOUND INC +1

Method for producing 3-hydroxypropanal

There is described a method for producing 3-hydroxypropanal, the method comprising: culturing an Acetobacter lovaniensis bacterium in a growth medium containing phosphate at a level which is more than 1 g / liter and nitrate at a level which is more than 0.1 g / liter, wherein culturing of the bacterium produces the 3-hydroxypropanal. The 3-hydroxypropanal can be separated from the growth medium or, when the microorganism has converted some or all of the 3-hydroxypropanal to 3-hydroxypropionic acid and / or a 3-hydroxypropionate ester, it may be separated as 3-hydroxypropionic acid or a 3-hydroxypropionate ester. The separated product can be converted into other chemicals such as an ester of 3-hydroxypropionic acid, 3-hydroxypropionic acid, 3 -hydroxypropionate salts (including ammonium, sodium and calcium 3-hydroxypropionate), acrylic acid, acrylates, acrylamide, acrylonitrile, acrolein and 1,3 propanediol.

Owner:VERDANT BIOPRODS

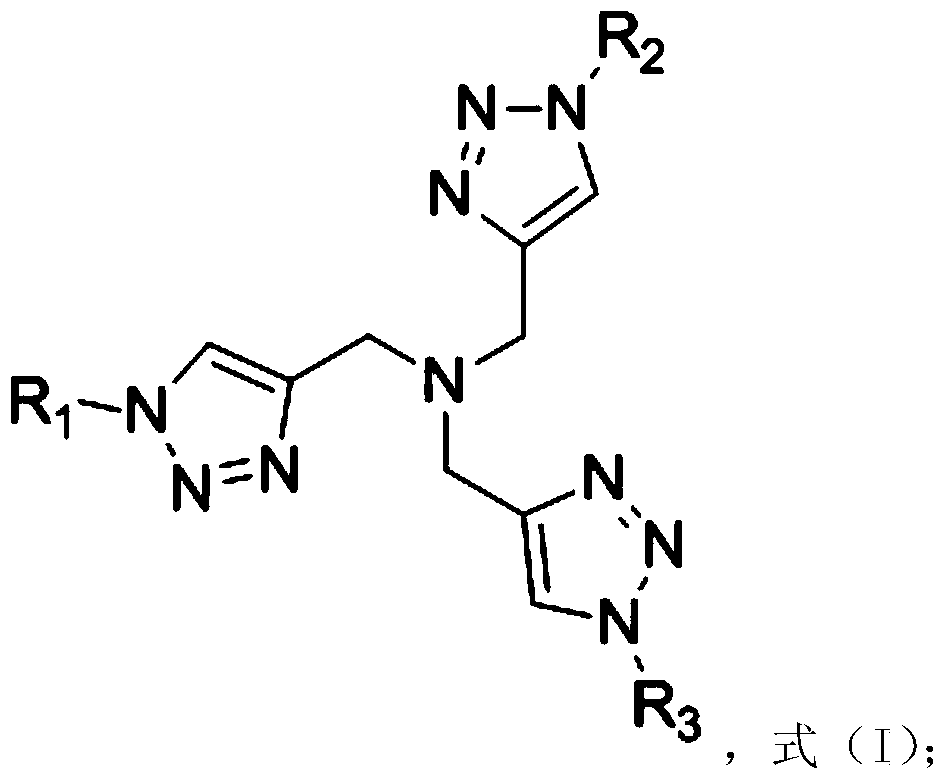

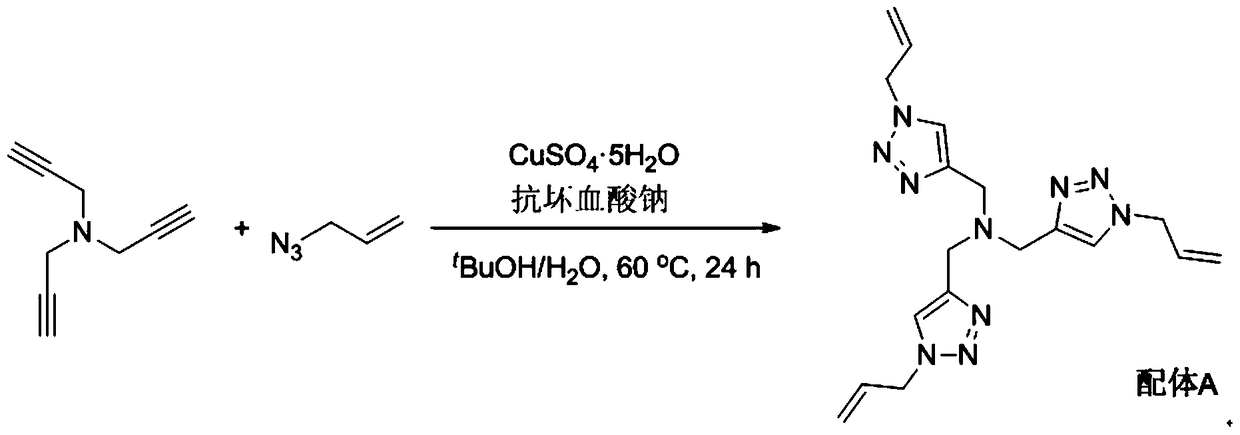

The synthetic method of 3-hydroxypropionate

ActiveCN106431921BHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reaction3-Hydroxypropionic acidAryl

The invention relates to a synthesis method of 3-hydroxy propionate. The method mainly solves the problem that the selectivity of the 3-hydroxy propionate in the prior art is low. The synthesis method of the 3-hydroxy propionate comprises the following steps: i, enabling the ligand as shown in the formula (I) to perform the complexing reaction with cobalt carbonyl in a solvent to obtain a catalyst solution, wherein the solvent is the alcohol or the solvent containing the alcohol; R1 to R3 are independently selected from one of alkyl or alkenyl, aryl or substituted aryl, and heterocyclo, and R1 to R3 independently contain 1 to 6 carbon atoms; ii, adding ethylene oxide and carbon monoxide in the catalyst solution, reacting to obtain the 3-hydroxy propionate. The technical scheme well solves the technical problem, and can be used for the industrial production of the 3-hydroxy propionate. The the formula (I) is shown in the description.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of polyhydroxyalkanoates from polyols

InactiveUS8741624B2Increase productionPromote recoverySugar derivativesBacteriaEscherichia coli3-Hydroxypropionic acid

Recombinant processes are provided whereby additional genes are introduced into E. coli which have been genetically engineered to produce PHA so that the improved strains produce PHA homopolymers and copolymers directly from diols. In preferred embodiments, PHAs containing 4-hydroxybutyrate monomers are produced directly from 1,4-butanediol; PHAs containing 5-hydroxyvalerate are produced from 1,5-pentanediol; PHAs containing 6-hydroxyhexanoate (6HH) are produced from 1,6-hexanediol; PHAs containing 3-hydroxypropionate are produced from 1,3-propanediol; PHAs containing 2-hydroxypropionate (lactate) are produced from 1,2-propanediol (propylene glycol); PHAs containing 2-hydroxyethanoate (glycolate) are produced from 1,2-ethanediol (ethylene glycol). Genes encoding these same enzyme activities can be introduced or their expression amplified in wild type PHA producers to improve the production of PHA homopolymers and copolymers directly from diol and other alcohol feedstocks. The PHA polymers are readily recovered and industrially useful as polymers or as starting materials for a range of chemical intermediates.

Owner:CJ CHEILJEDANG CORP

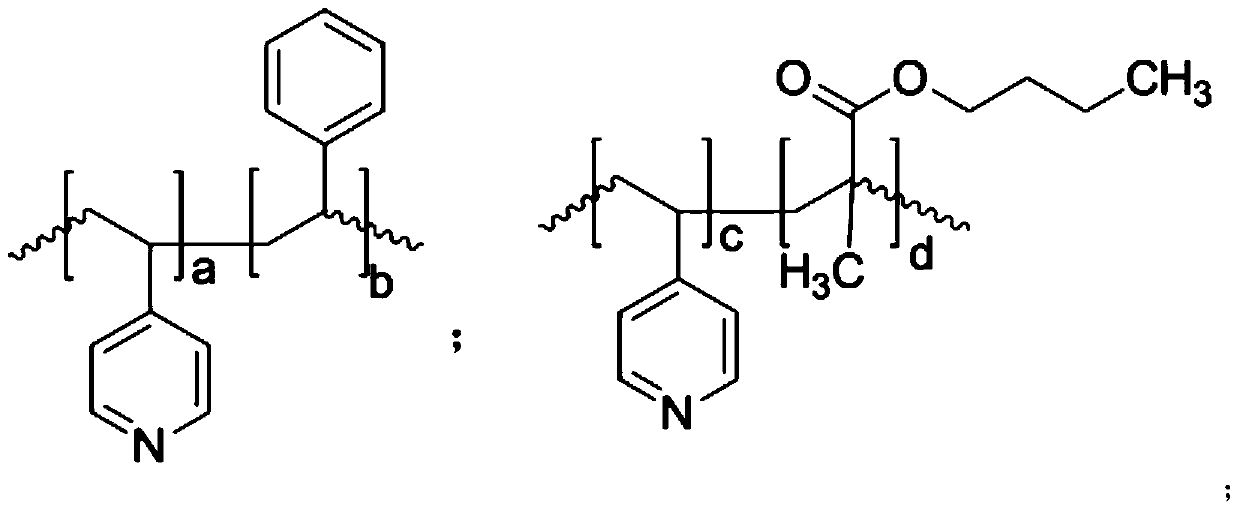

The method of synthesizing 3-hydroxy propionate

ActiveCN106431926BAvoid easy separationEasy to separateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reaction3-Hydroxypropionic acidAlcohol

The invention relates to a method for synthesizing 3-hydracrylic acid ester. The method mainly solves the problem that in the prior art, catalysts in a homogeneous system are difficult to separate. The method for synthesizing 3-hydracrylic acid ester includes the following steps that firstly, a ligand and cobalt carbonyl are subjected to a coordination reaction in an alcohol solvent to obtain turbid liquid of a catalyst; secondly, ethylene oxide and carbon monoxide are added, and a reaction is conducted to obtain 3-hydracrylic acid ester. According to the technical scheme, the ligand is selected from 4-vinylpyddine homopolymers or copolymers containing 4-vinylpyddine monomeric units, the technical problem is well solved, and the method can be used in industrial production of 3-hydracrylic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation for KCo(CO)4, and application of KCo(CO4) in catalyzing carbonyl-methyl esterification reaction of ethylene oxide

InactiveCN105271439ALow priceHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reaction3-Hydroxypropionic acidEthylene oxide

The invention provides a novel method for efficiently preparing a KCo(CO)4 catalyst and applying the KCo(CO)4 catalyst in catalyzing a carbonyl-methyl esterification reaction of ethylene oxide to prepare methyl 3-hydroxypropionate with a low cost. The method is mild in reaction condition and short in reaction time in a process for preparing KCo(CO)4. The obtained KCo(CO)4 can be used for efficiently catalyzing the carbonyl methyl esterification reaction of ethylene oxide. The whole process is short in reaction time and low in cost.

Owner:南京大学扬州化学化工研究院

Process for preparing 3-hydroxypropionate

ActiveCN106431922BAvoid easy separationEasy to separateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide or formate reaction3-Hydroxypropionic acidAlcohol

The invention relates to a method for preparing 3-hydroxypropionate and mainly aims to solve the problem that in the prior art, a catalyst in a homogeneous system is hard to separate. The method for preparing 3-hydroxypropionate comprises the steps that first, a ligand and cobalt carbonyl are subjected to a coordination reaction in an alcoholic solvent to obtain turbid liquid of a catalyst; second, ethylene oxide and carbon monoxide are added, and a reaction is carried out to obtain 3-hydroxypropionate. According to the technical scheme that the ligand is an acrylonitrile homopolymer or a copolymer which contains acrylonitrile monomer units, the technical problem is well solved, and the method can be applied to industrial production of 3-hydroxypropionate.

Owner:CHINA PETROLEUM & CHEM CORP +1

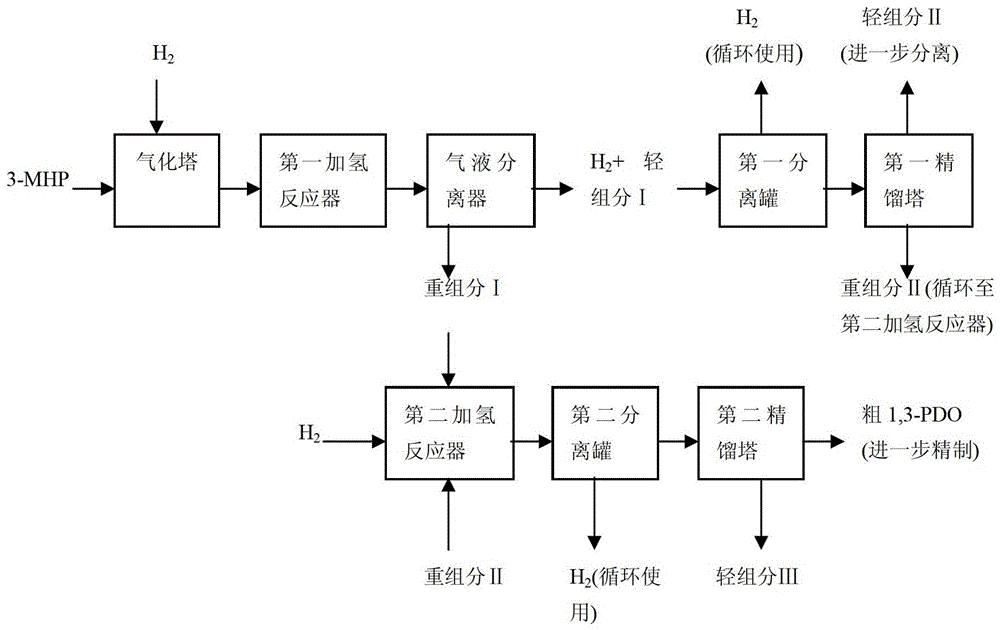

Process for preparing 1,3-propanediol by hydrogenation of high-concentration methyl 3-hydroxypropionate

ActiveCN103804143BHigh yieldReduce energy consumptionOrganic compound preparationHydroxy compound preparationHigh concentrationN-Propyl alcohol

The invention relates to a process for preparing 1,3-propylene glycol (1,3-PDO) by means of hydrogenating high-concentration 3-methyl lactate (3-MHP). The process comprises the following flow: gasifying 3-MHP and H2 in a mixed manner, feeding the mixed gas into a first hydrogenation reactor, feeding a hydrogenation product into a gas-liquid separator to separate mixed gas of a heavy component I, hydrogen and a light component I; feeding the mixed gas into a first separating tank to separate H2 out for recycling, and feeding a retaining liquid phase into a first rectification tower for separating into a light component II and a heavy component II; feeding the heavy component II and the heavy component I into a second hydrogenation reactor for further hydrogenating, feeding a hydrogenation product into a second separating tank for separating H2 out for recycling, feeding remaining components into a second rectification tower into a light component III and crude 1,3-PDO, and refining the crude 1,3-PDO to obtain a 1,3-PDO product; separating the light component II from the light component III to obtain methyl alcohol and n-propyl alcohol. In the entire process, the high-concentration 3-MHP is used for hydrogenating, so that the energy consumption of solvent separation is lowered. Meanwhile, by two-segment hydrogenation is performed, the yield of the 1,3-PDO is increased.

Owner:SHANGHAI HUAYI ENERGY CHEM

Acrylic acid ester synthesis method

ActiveCN106588653AHigh selectivityBeneficial technical effectMolecular sieve catalystsOrganic compound preparationMolecular sieve3-Hydroxypropionic acid

The present invention relates to an acrylic acid ester synthesis method. A purpose of the present invention is mainly to solve the problem of low selectivity of acrylic acid ester in the prior art. According to the present invention, by using the acrylic acid ester synthesis method, in the presence of a molecular sieve catalyst, 3-hydroxypropionate is subjected to dehydrating to obtain the acrylic acid ester; and with the technical scheme, the problem in the prior art is well solved, and the method can be used in the industrial production of the acrylic acid ester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com