Synthetic method of methyl 2-fluoro-3-hydroxypropionate

A kind of technology of methyl hydroxypropionate and synthesis method, which is applied in the synthesis field of methyl 2-fluoro-3-chloropropionate, and can solve the problem that there is no good method for preparing methyl 2-fluoro-3-hydroxypropionate and other problems, to achieve the effect of low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

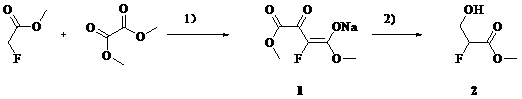

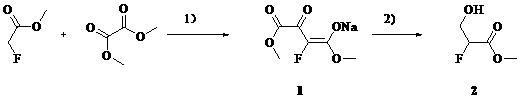

[0018] Embodiment one: the synthesis of sodium enolate intermediate, methyl tert-butyl ether is used as solvent

[0019] Add methyl tert-butyl ether (1L), methyl fluoroacetate (460 g), and dimethyl oxalate (620 g) into a 5 L three-necked flask at 20 – 30 o C and stirred for 10 min. NaOMe / MeOH (27% by weight) solution (1050mL) was added dropwise, and the temperature was controlled at 20-30 o c. The color of the solution changed from colorless to yellow immediately. The dropwise addition is complete. Warm 20 – 30 o C reacted for 4 h. After filtration, the filter cake was slurried with methyl tert-butyl ether (500 mL), and suction filtered. Obtained 1 (840 g, 84 %) as a pale yellow solid.

[0020] Its reaction formula is:

[0021]

Embodiment 2

[0022] Embodiment two: the synthesis of sodium enolate intermediate, tetrahydrofuran is made solvent

[0023] Add tetrahydrofuran (1L), methyl fluoroacetate (460 g), and dimethyl oxalate (620 g) into a 5 L three-neck flask at 20 – 30 o C and stirred for 10 min. NaOMe / MeOH (27% by weight) solution (1050 mL) was added dropwise, and the temperature was controlled at 20-30 o c. The color of the solution changed from colorless to yellow immediately. The dropwise addition is complete. Warm 20 – 30 o C reacted for 4h. After filtration, the filter cake was slurried with tetrahydrofuran (500 mL), and suction filtered. Obtained 1 (870 g, 87 %) as a pale yellow solid.

Embodiment 3

[0024] Example Three: Methyl 2-fluoro-3-hydroxypropionate, N,N-dimethylformamide as solvent

[0025] Throw in 5.6L of N,N-dimethylformamide, and cool down to 0 in an ice-water bath o C, throw 700 g enol sodium salt and Na 2 CO 3 360 g of the mixture, at the same time start rapid (within 1 hour) dropwise addition of 37% HCHO aq 263 mL, the addition is complete, 0 - 10 o C, heat preservation reaction for 2 h, add 5L×3EA to extract three times, combine the organic phase, Na 2 SO 4 Dried, filtered, and the filtrate was evaporated to dryness to give 423.4 g, distilled, collected in 100 - 110 o Fraction between C. Yield 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com