Process for preparing 1,3-propanediol by hydrogenation of high-concentration methyl 3-hydroxypropionate

A high-concentration technology of methyl hydroxypropionate, applied in the field of ester hydrogenation to alcohol, can solve the problems of no separation, separation and purification difficulties, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Prepare the hydrogenation catalyst used in the first hydrogenation reactor and the second hydrogenation reactor of this process: CuO: 55%, NiO: 0.5%, MnO 2 : 6.5%, ZnO: 3%, SiO 2 : 35%

[0056] (1) Copper nitrate, manganese nitrate, zinc nitrate, SiO 2 Silica sol with a content of 25% is added to deionized water, stirred and mixed evenly at 30°C;

[0057] (2) Add ammonia water dropwise at 40°C for precipitation, and stop dropping when the pH value is 6.5;

[0058] (3) When the pH value was 3, the dropwise concentration was 0.5wt% potassium permanganate aqueous solution;

[0059] (4) aging at 70° C. for 6 hours;

[0060] (5) filter, wash with deionized water, and then dry in air at 100° C. for 5 hours;

[0061] (6) Roasting for 3 hours at 800° C. in an air atmosphere, crushing after tablet molding to obtain a hydrogenation catalyst with a particle size of Φ3×3 mm;

[0062] 2. Hydrogenation reaction

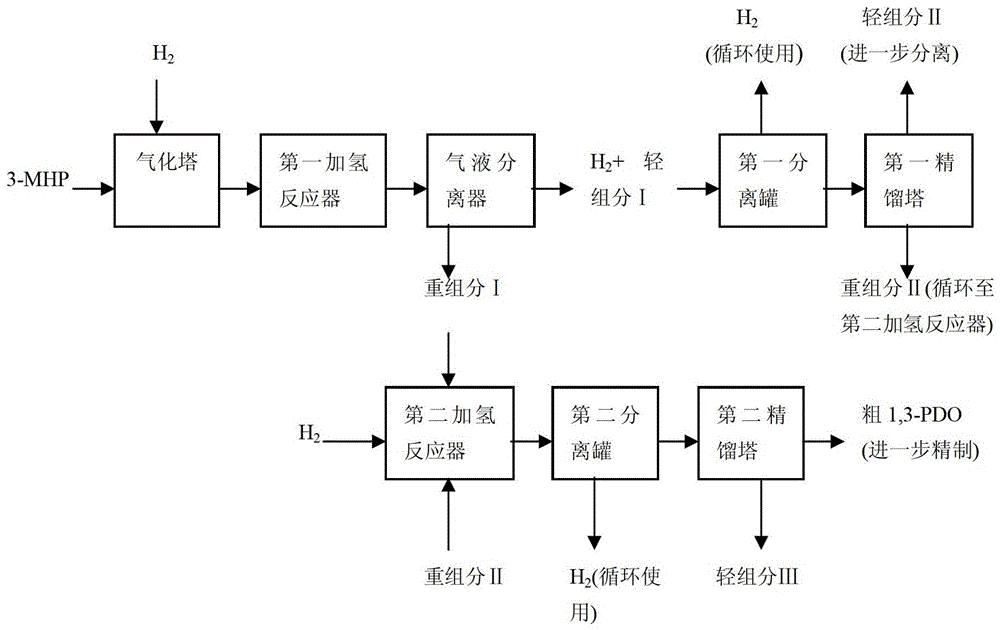

[0063] A schematic flow chart for the preparation of 1,3-prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com