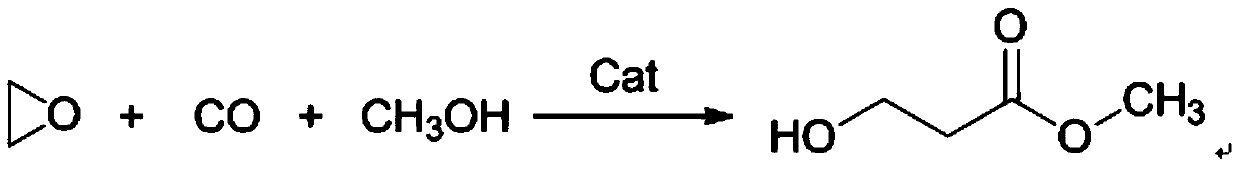

The method of synthesizing 3-hydroxy propionate

A technology for hydroxypropionate and cobalt carbonyl, applied in the field of synthesizing 3-hydroxypropionate, can solve the problem of difficult separation of catalysts, and achieve the effects of mild catalytic reaction conditions, high activity, and solving difficult separations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Catalyst preparation

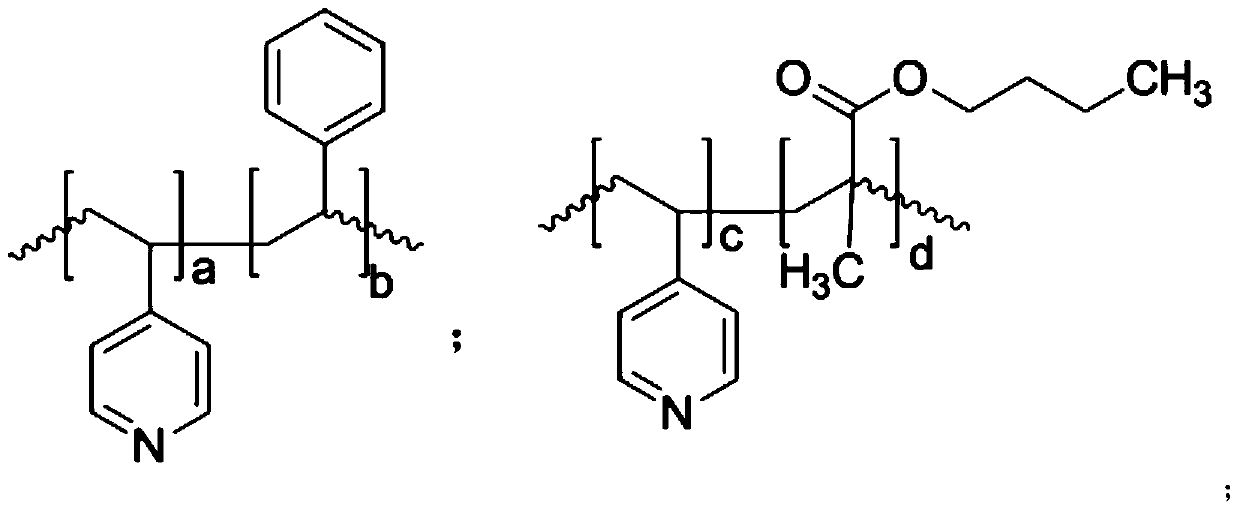

[0040] 1.0 mmol of Co 2 (CO) 8 Dissolve in 740mmol of methanol, add poly(4-vinylpyridine) powder with a number average molecular weight of 100,000, make the molar ratio of nitrogen to cobalt carbonyl 2:1, stir at room temperature for 2 hours to obtain a catalyst mixture.

[0041] 2. Synthesis of methyl 3-hydroxypropionate

[0042] The obtained catalyst mixture was transferred to a 100 mL reactor; the reactor was purged three times with nitrogen, and carbon monoxide and 50 mmol ethylene oxide were added to make the system pressure 5 MPa; reacted at 60° C. for 6 hours. After the reaction was completed, the reactor body was cooled to 0° C., the pressure was slowly released to normal pressure, and the reactor was purged three times with nitrogen. Sampling analysis showed that the conversion rate of ethylene oxide was 31%, and the selectivity of methyl 3-hydroxypropionate was 79%.

[0043] For the convenience of comparison, the results of the sy...

Embodiment 2

[0045] 1. Catalyst preparation

[0046] 1.0 mmol of Co 2 (CO) 8 Dissolve in 740mmol of methanol, add poly(4-vinylpyridine-co-styrene) powder with a number average molecular weight of 100,000 (wherein the molar ratio of 4-vinylpyridine monomer units to styrene monomer units is 1:1), The molar ratio of nitrogen to cobalt carbonyl was 2:1, and stirred at room temperature for 2 hours to obtain a catalyst mixture.

[0047] 2. Synthesis of methyl 3-hydroxypropionate

[0048]The obtained catalyst mixture was transferred to a 100 mL reactor; the reactor was purged three times with nitrogen, and carbon monoxide and 50 mmol ethylene oxide were added to make the system pressure 5 MPa; reacted at 60° C. for 6 hours. After the reaction was completed, the reactor body was cooled to 0° C., the pressure was slowly released to normal pressure, and the reactor was purged three times with nitrogen. Sampling analysis showed that the conversion rate of ethylene oxide was 34%, and the selectivi...

Embodiment 3

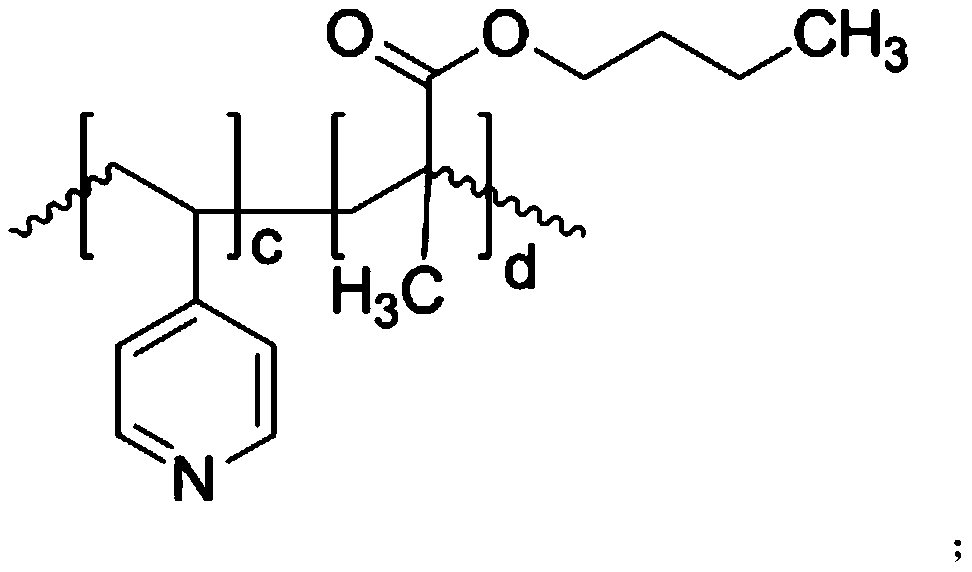

[0051] 1. Catalyst preparation

[0052] 1.0 mmol of Co 2 (CO) 8 Dissolve in 740mmol of methanol, add poly(4-vinylpyridine-co-ethylvinylbenzene) powder with a number average molecular weight of 100,000 (wherein the molar ratio of 4-vinylpyridine monomer unit to ethylvinylbenzene monomer unit 1:1), the molar ratio of nitrogen to cobalt carbonyl was 2:1, and stirred at room temperature for 2 hours to obtain a catalyst mixture.

[0053] 2. Synthesis of methyl 3-hydroxypropionate

[0054] The obtained catalyst mixture was transferred to a 100 mL reactor; the reactor was purged three times with nitrogen, and carbon monoxide and 50 mmol ethylene oxide were added to make the system pressure 5 MPa; reacted at 60° C. for 6 hours. After the reaction was completed, the reactor body was cooled to 0° C., the pressure was slowly released to normal pressure, and the reactor was purged three times with nitrogen. Sampling analysis showed that the conversion rate of oxirane was 40%, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com