Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Reduce aldehyde content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

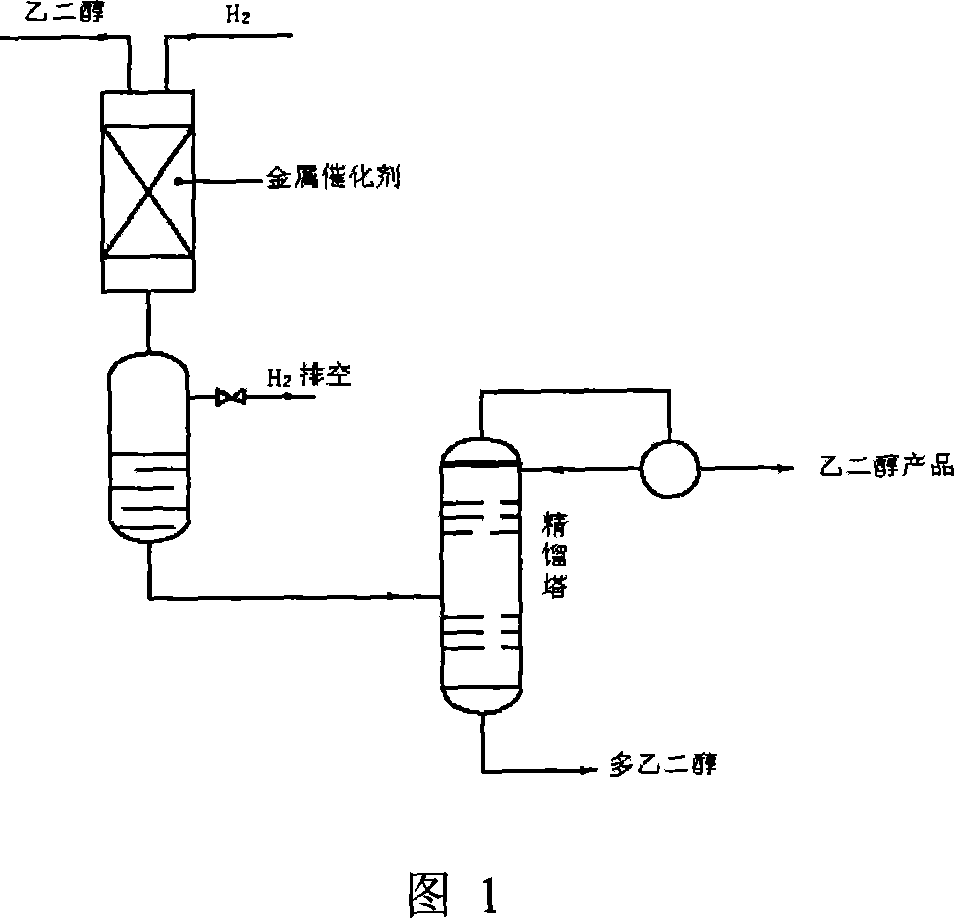

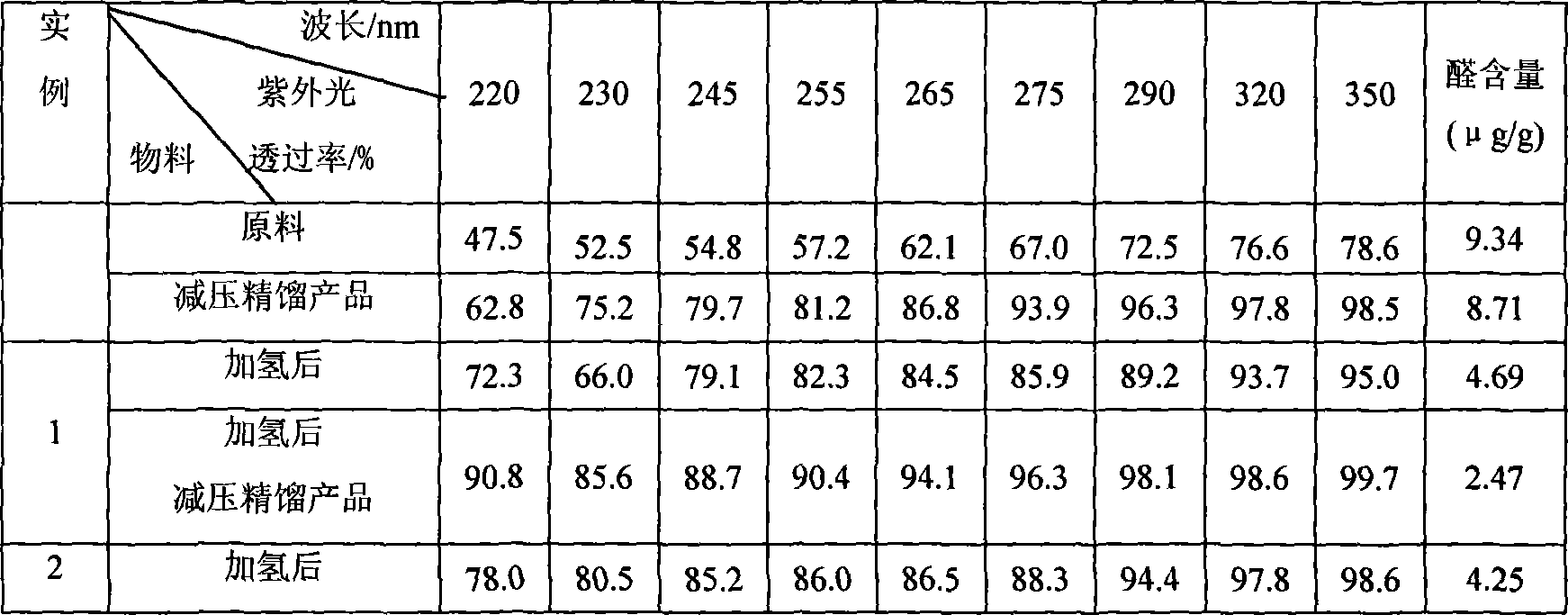

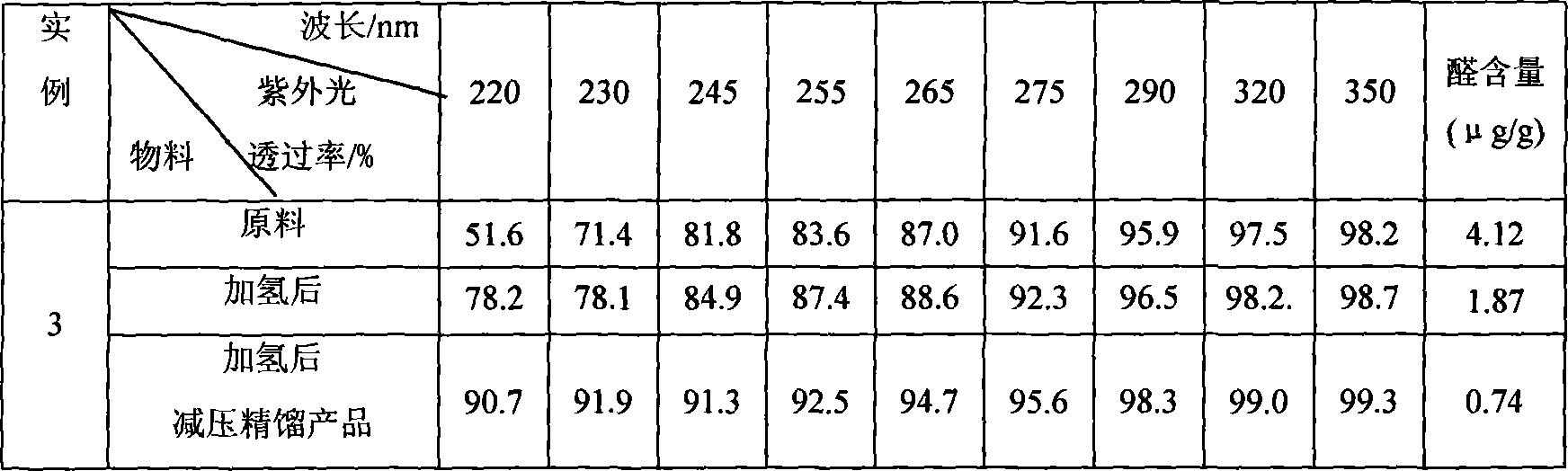

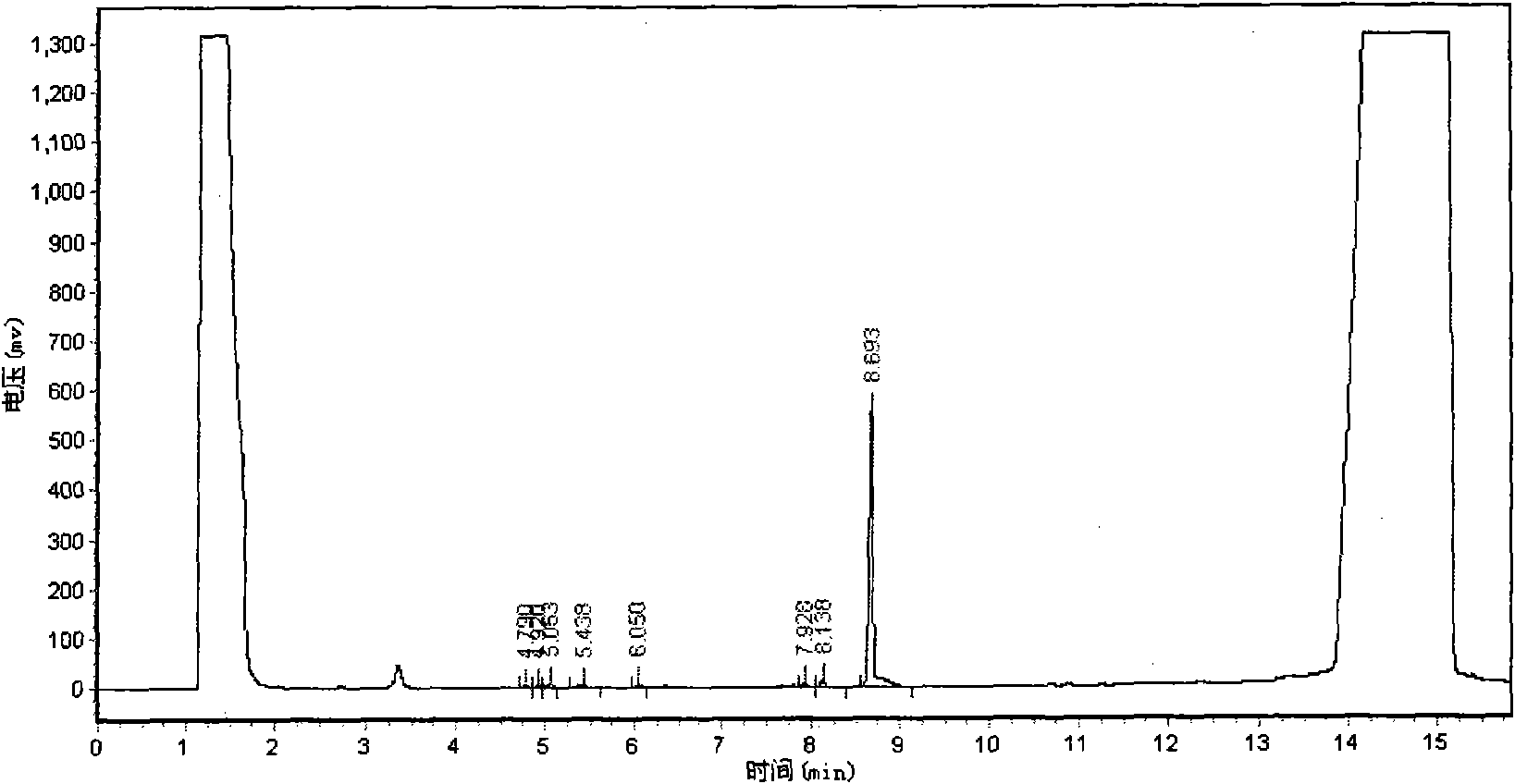

Method of increasing quality of glycol

InactiveCN101058526AQuality improvementThe implementation process is simpleOrganic compound preparationHydroxy compound preparationPalladium on carbonVolumetric Mass Density

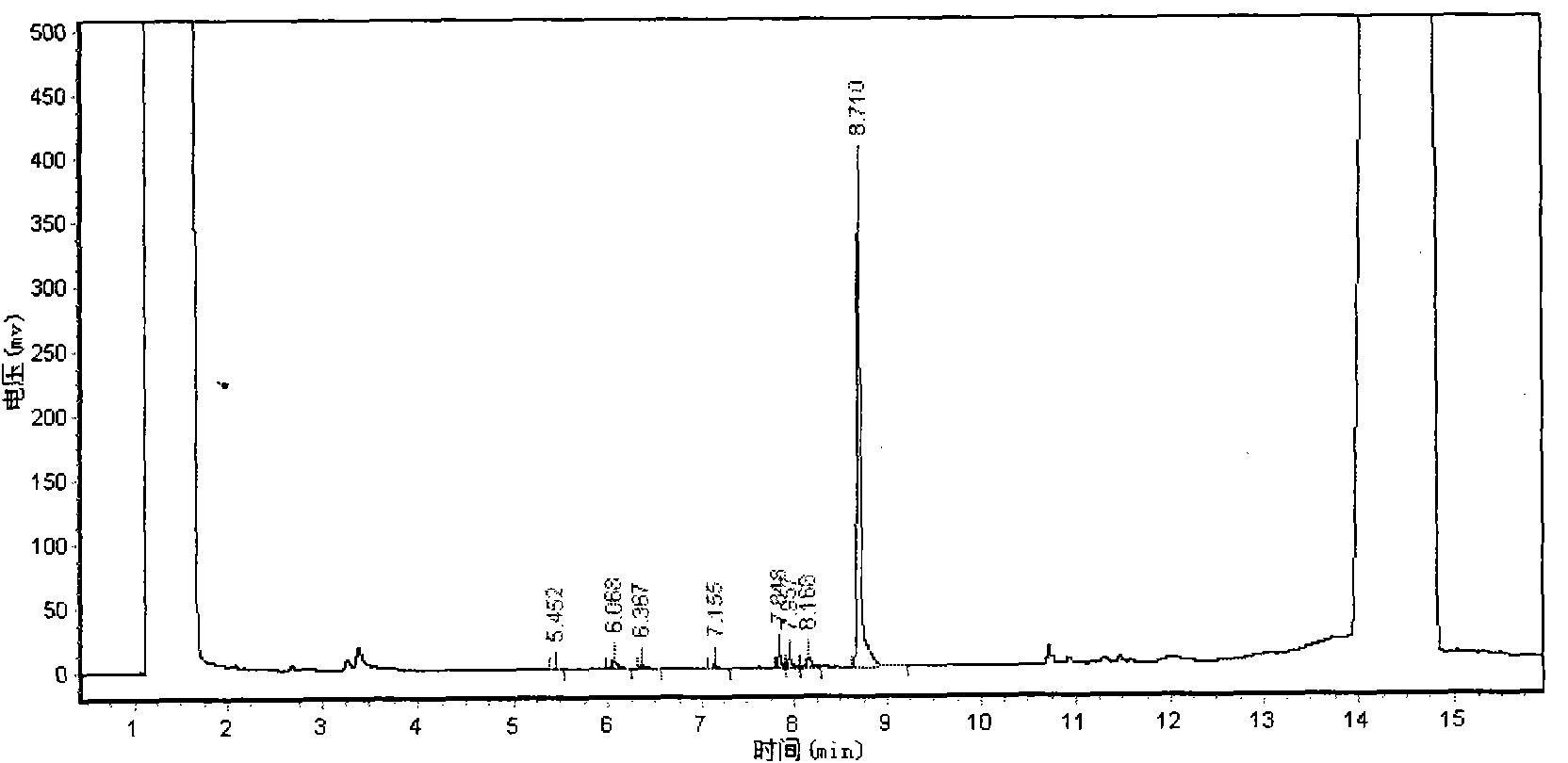

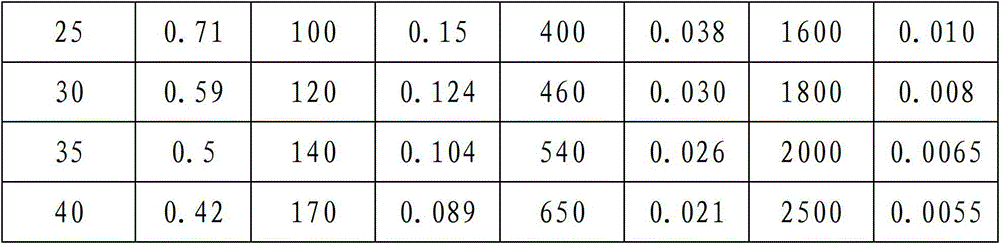

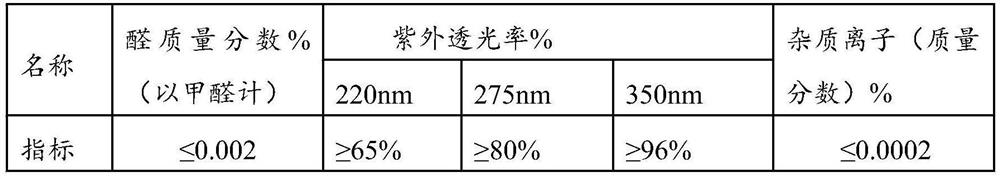

The invention discloses an interval or continuous catalytic hydrogenating for ethandiol (weight density at 10-100%), which is characterized by the following: adopting aggregate nickel or palladium carbon as catalyst; transmitting C=C and C-O into saturated material not to adsorbed by ultraviolet in the ethandiol; reducing the content of aldehyde; improving ultraviolet transmission rate; controlling the reacting temperature between 45 deg. c and 95 deg. c; setting the reacting pressure between 0. 05 and 0. 5Mpa and air speed not less than 60h-1; obtaining the product with ultraviolet transmitting rate more than 90% at 220nm, more than 95% at 275nm, more than 99% at 350nm.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Method for preparing TCPP (Tris(Chloroisopropyl)Phosphate) flame retardant

ActiveCN101775031AReduce aldehyde contentRealize low tastePhosphorus organic compoundsPhosphateAcid value

The invention relates to a preparation method which can effectively eliminate odor ingredients (mainly aldehydes compounds) in TCPP (Tris(Chloroisopropyl)Phosphate). The method is characterized by comprising the following steps of: adding excessive oxidant solution relative to the aldehydes compound for reaction after a TCPP crude product is obtained through reaction, standing, separating liquid, then alkaline washing, water washing and distilling. The aldehyde compound which has favorable compatibility with the TCPP and is not separated easily can be removed, the aldehyde content in the TCPP is reduced to below 10 ppm from the previous 100 ppm or more and can be reduced to 0.7 ppm in the maximum degree, the odor of the TCPP and the prepared product is less, and the mild odor of the TCPP flame retardant is realized; and oxidant aqueous solution converting aldehyde into acid is added to react, wash and remove the odor, the method has convenient operation as well as simple, convenient and easy implementation, is beneficial to operation in production and does not affect the TCPP yield (the yield can increase by 0.5-1%) and an acid value compared with the previous patents; the aldehyde content can be reduced to a lower degree, and the obtained TCPP product is more stable.

Owner:雅克(上海)化工新材料有限公司

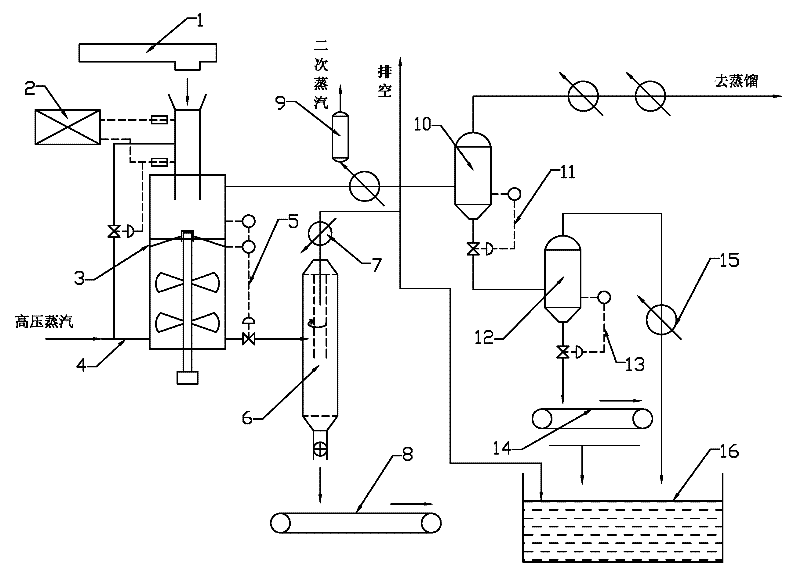

Automatic acidless continuous furfural hydrolysis system

The invention discloses an automatic acidless continuous furfural hydrolysis system. The system comprises a feeding system, a hydrolysis unit and a residue treating unit, wherein the residue treating unit consists of a solid-liquid separation unit and a stock solution storage tank, and a secondary steam generator is arranged between the hydrolysis unit and the solid-liquid separation unit; and the solid-liquid separation unit consists of a furfural residue separator, a self evaporator, a hydrocyclone separator, a conveyor belt and a rotary slag tapping device. Compared with the prior art, the automatic acidless continuous furfural hydrolysis system has the advantages of having no added acid and continuous hydrolysis, being higher in automation level, and having higher steam utilization ratio due to addition of the secondary steam generator; and the use of a stirring device additionally arranged improves the raw material utilization ratio, thus leading the reaction of the raw materials to be more full, reducing and properly treating the acid content of residue, improving the yield of the hydrolyzed furfural, lowering the production cost and being more environment-friendly.

Owner:SHANDONG WANSHENG ENVIRONMENTAL TECH DEV

Preparation method of automobile urea solution

InactiveCN104258730ALow impurity contentAvoid generatingDispersed particle separationIon-exchange resinImpurity

The invention relates to a preparation method of an automobile urea solution. The method comprises the following steps: (1) selecting agricultural grade urea and pure water serving as raw materials, and preparing the raw materials into a urea solution; (2) purifying the urea solution prepared in the step (1) through a filter; (3) adding an aldehyde treatment agent into the urea solution obtained in the step (2) to lower the aldehyde content of the urea solution; and (4) loading the urea solution obtained in the step (3) through an ion exchange resin column, and removing metal ions and other impurities from the urea solution to obtain the urea solution which meets automobile use requirements. The preparation method disclosed by the invention is simple and easy to implement, and has high technical adaptability and high raw material yield. The obtained urea solution has low impurity content and good development and application values.

Owner:HENAN JUNHUA DEV

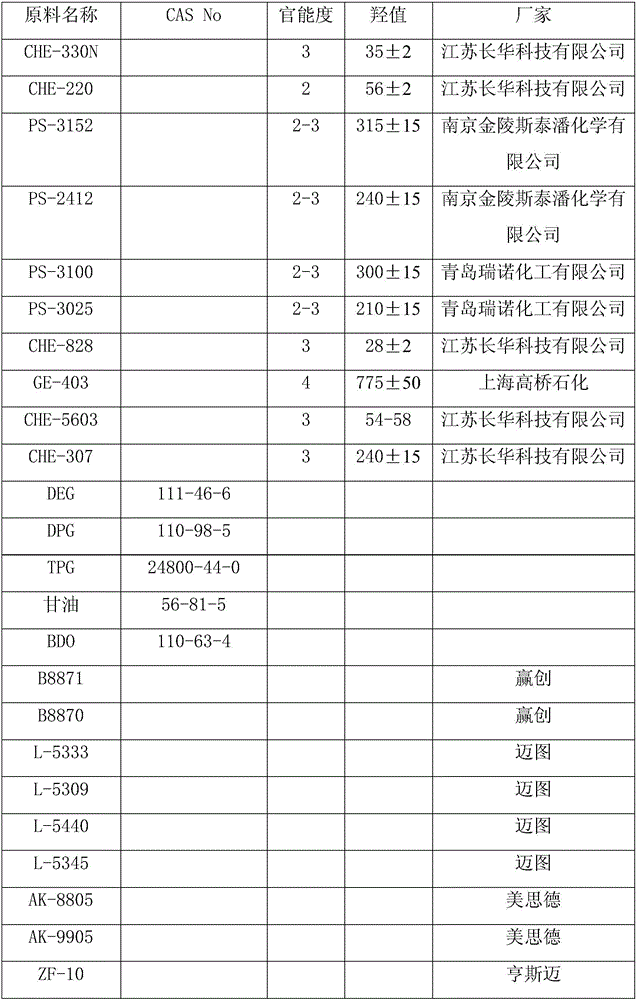

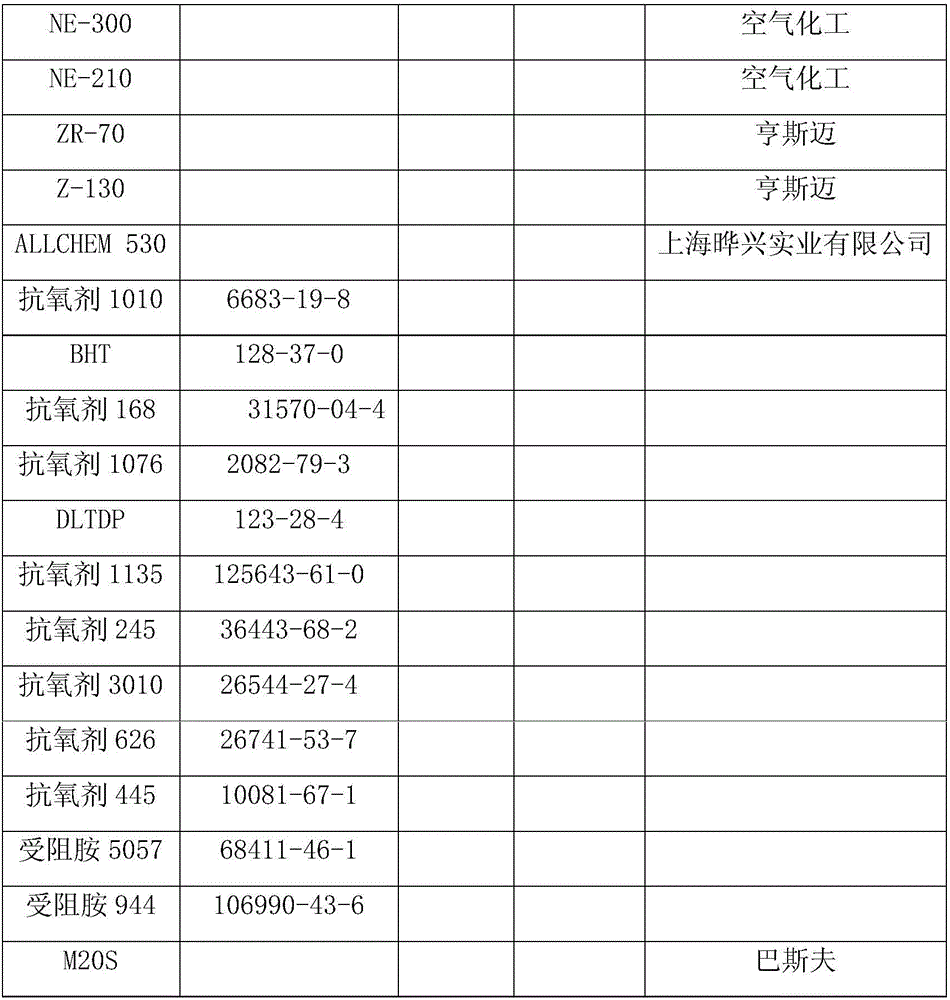

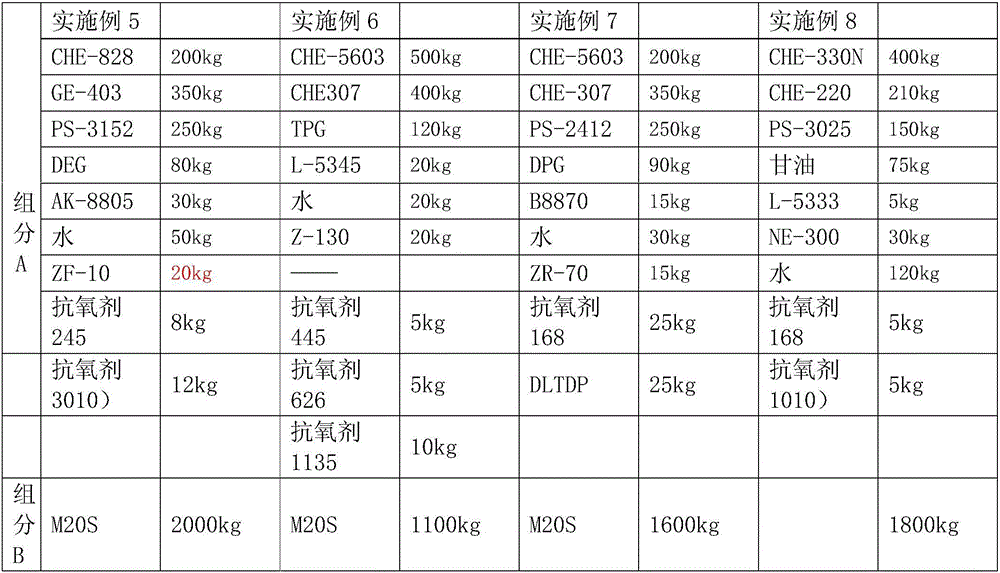

Automobile roof polyurethane composition

The invention relates to an automobile roof polyurethane composition which mainly solves the problems existing in the prior art such as high VOC value and great odor due to relatively high aldehyde content. With the adoption of the technical scheme of the invention, the low-VOC low-odor automobile roof composition is composed of a component A and a component B, wherein a ratio of the weight percentage of the component A to the component B is 1:(1.1-2.0); the component A comprises polyether polyol, polyester polyol, polypolyols, a chain extender, a foam stabilizer, a catalyst, water and at least one aid of colorants, antioxidants and dispersing agents; and the component B refers to polymethylene polyphenyl isocyanate or modified polymethylene polyphenyl isocyanate. The problems are well solved, and the composition can be used in industrialized production of the low-VOC low-odor automobile roof composition.

Owner:江苏长顺高分子材料研究院有限公司

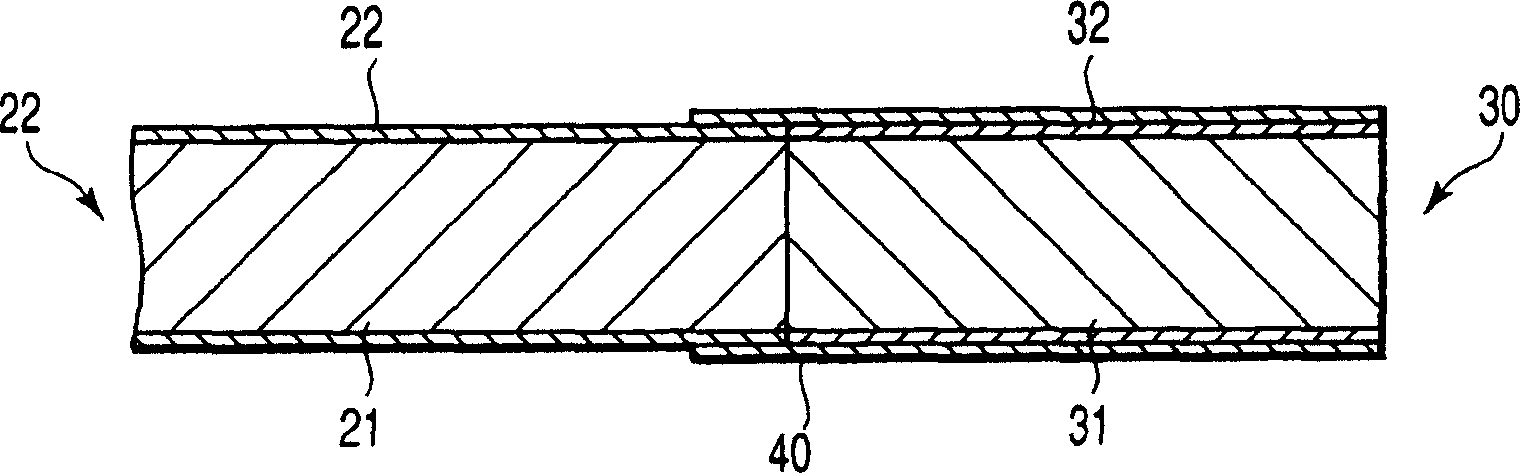

Cigarette and cigarette filter

InactiveCN1612699AReduce aldehyde contentTobacco treatmentTobacco smoke filtersSURFACTANT BLENDCigarette filter

The invention provides a cigarette and a cigarette filter tip added with basic amino acid or basic amino acid salt. The content of the basic amino acid or basic amino acid salt is preferably 1 ng or more per cigarette, and the basic amino acid or basic amino acid salt is preferably added in the form of an aqueous solution. In addition, a basic amino acid or a basic amino acid salt may be added together with a surfactant.

Owner:JAPAN TOBACCO INC

Method for preparing propylene oxide by utilizing micro-channel reactor

ActiveCN106632147AImprove mixing efficiencyImprove conversion rateOrganic chemistryChemical/physical/physico-chemical microreactorsRoom temperatureSide reaction

The invention discloses a method for preparing propylene oxide by utilizing a micro-channel reactor. The method comprises the following steps: uniformly stirring a cumyl hydroperoxide material and a catalyst at room temperature to obtain a mixed solution; conveying the mixed solution and a propylene material into the micro-channel reactor and reacting to obtain a crude product; separating and purifying the crude product to obtain a target product. According to the method disclosed by the invention, the mixing efficiency of the raw materials can be greatly improved and the occurrence of side reactions is reduced; the conversion ratio of the cumyl hydroperoxide and the selectivity of the propylene oxide are improved; meanwhile, the propylene utilization rate is effectively improved and the feeding amount of the propylene is reduced; the reaction is safe, rapid and effective and the method is suitable for industrial production.

Owner:HONGBAOLI GRP CO LTD +1

Method for producing composition using alcohol as starting material

ActiveUS8187347B2Improve Oxidation StabilityReduce compositionOxygen-containing compound preparationOrganic compound preparationChemical industryGas phase

Owner:SANGI CO LTD

Ecological bating method

This invention provides an ecological tanning method. The method comprises: pre-tanning with aldehyde tanning agent, tanning with tetrahydroxymethyl phosphonium salt, and then adding collagen to enhance the bonding of the tanning agents. The method utilizes the reaction among aldehyde tanning agent, tetrahydroxymethyl phosphonium salt and collagen to enhance the bonding of the tanning agents as well as increase the shinkage temperature. Besides, the addition of collagen can improve the comprehensive properties of leather and reduce the aldehyde content in leather. The method can be used to replace chrome tannage, thus can avoid the harm of chrome salt to human body and environment.

Owner:XUZHOU XINGNING LEATHER CO LTD

Preparation method of low formaldehyde urea solution used for urea

InactiveCN105061265ALow priceSimple processUrea derivatives preparationOrganic compound preparationFiltrationAldehyde

The invention discloses a preparation method of a low formaldehyde urea solution used for urea, which belongs to the technical field of chemical technology, and especially relates to a preparation method of a low formaldehyde urea solution used for urea. The preparation method comprises the following steps: 1)dissolving industrial grade urea in deionized water to obtain an urea solution A; 2)employing a filtration system 1, filtering an insoluble substance in the urea solution A to obtain an urea solution B; 3)removing aldehyde on the urea solution B through a photocatalysis system to obtain an urea solution C; 4)decolouring the urea solution C through active carbon to obtain an urea solution D; and 5)passing through the urea solution D through a two-grade filtration system 2, and purifying to obtain the low formaldehyde urea solution used for vehicle. The low formaldehyde urea solution has the advantages of low cost and simple technology, formaldehyde content in the urea solution is reduced, and formaldehyde content can reach a GB2951-2013 requirement.

Owner:JIANGMEN CITY GUANGYAO CHEM CO LTD

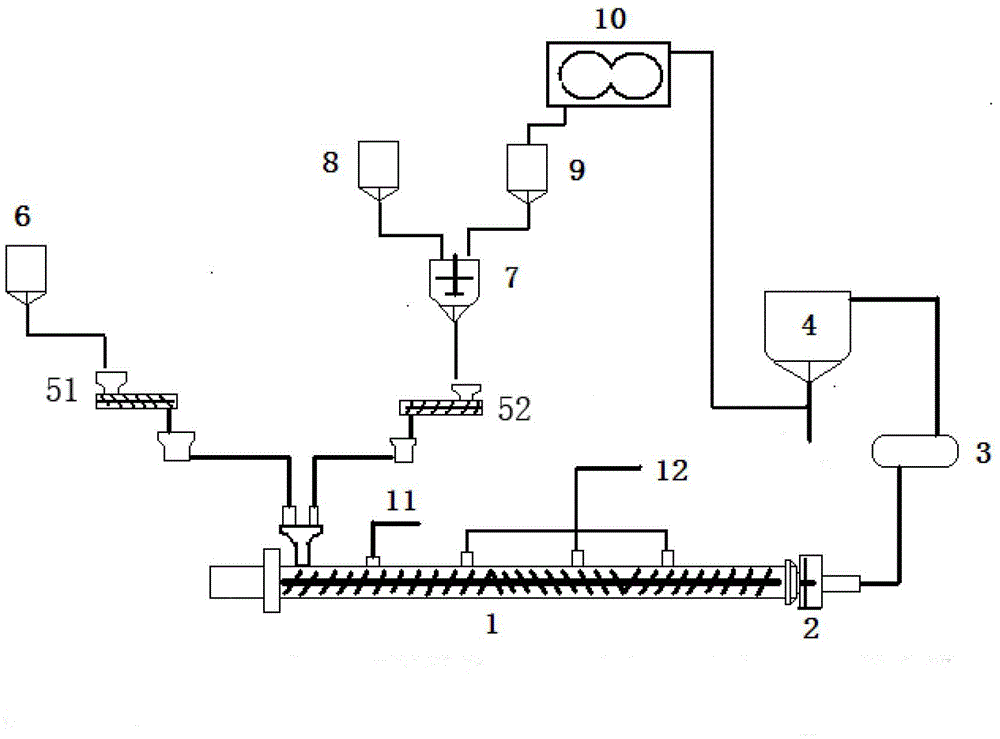

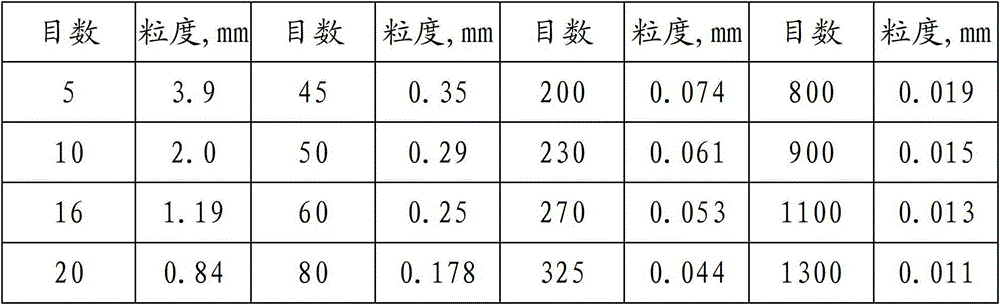

Stabilizing treatment method for polyformaldehyde

The invention discloses a stabilizing treatment method for polyformaldehyde. The method comprises the following steps: (1) uniformly mixing polyformaldehyde having a stable end group with a composite auxiliary agent to form a premix; and (2) uniformly mixing the premix with polyformaldehyde having an instable end group in a screw extruder and converting polyformaldehyde having the instable end group into polyformaldehyde having the stable end group through fused termination in the screw extruder; wherein the composite auxiliary agent comprises an aldehyde absorbing agent, an anti-oxidant and a lubricant. With the method provided by the invention, uniformity of dispersion of the auxiliary agent in polyformaldehyde can be improved; furthermore, appearance performance, heat resistance and environmental protection performance (e.g., aldehyde content on the surface of polyformaldehyde is reduced) of a product can be improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Formaldehyde-free plywood preparation process

ActiveCN108381688AReduce aldehyde contentGood aldehyde contentPolyureas/polyurethane adhesivesWood veneer joiningSingle plateBond strength

The invention discloses a formaldehyde-free plywood preparation process. The formaldehyde-free plywood preparation process comprises single-plate manufacturing, glue preparation, sizing, assembling, cold pressing and aftertreatment. After the cold pressing procedure is carried out, the step of a hot pressing procedure is further needed, and a waterborne polyurethane mixing agent is adopted as an adhesive composition in the sizing procedure. The formaldehyde-free plywood preparation process is suitable for adopting waterborne polyurethane, and plywood is good in bonding strength, even in plateblank thickness, not likely to deform and good in stability.

Owner:广西协力合板有限公司

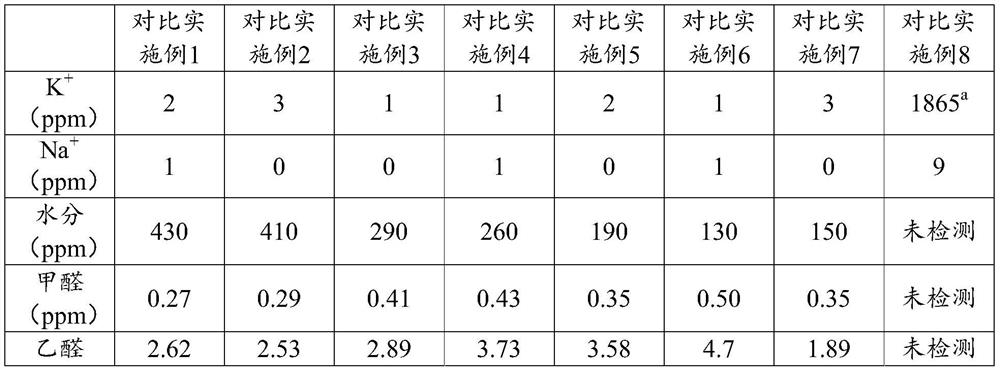

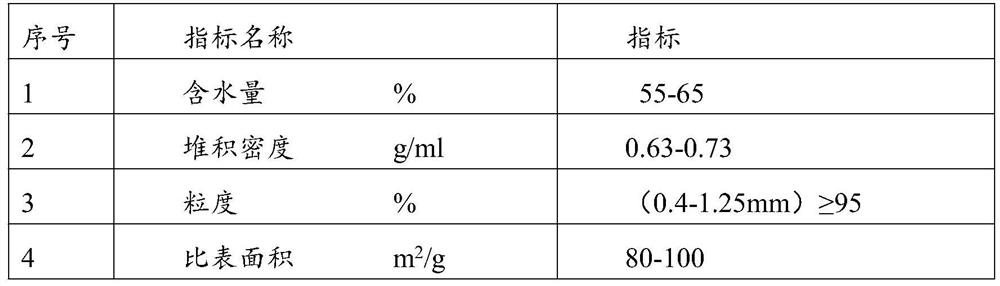

Refining method for reducing aldehyde content and odor of polyether polyol

ActiveCN111763309AImprove adsorption capacityEfficient removalSeparation with moving sorbentsPolymer sciencePolyol

The invention relates to a refining method for reducing aldehyde content and odor of polyether polyol. The refining method comprises the following steps: 1) adding water accounting for 0.1-10.0% of the total mass of crude polyether polyol into the crude polyether polyol at 25-100 DEG C, and carrying out uniform mixing; 2) adding an adsorbent accounting for 0.1-3% of the total mass of the crude polyether polyol into the polyether polyol obtained in the step 1), controlling an adsorption temperature to be 80-130 DEG C, carrying out filter pressing circulation after adsorption equilibrium, and testing the contents of potassium and sodium ions in the polyether polyol having undergone filter pressing; 3) repeating the step 2 until the contents of potassium and sodium ions in the polyether polyol are less than required contents; 4) adding a desired amount of an antioxidant into the polyether polyol obtained in the step 3); and 5), carrying out heating and vacuum dehydration to obtain refinedpolyether polyol. The method can reduce both aldehyde content and odor.

Owner:WANHUA CHEMYANTAI RONGWEI POLYURETHANE CO LTD

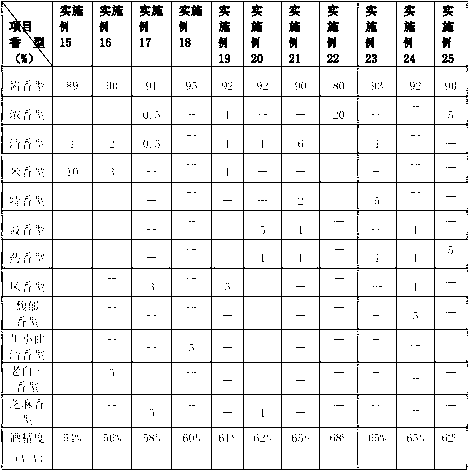

Encapsulated composition for binding aldehydes in the stomach

InactiveUS20160022620A1Reduce aldehyde contentMask their tasteBiocideOrganic active ingredientsMedicineLarge intestine

The present invention relates to non-toxic composition containing, as active compounds, one or more aldehyde-binding compounds, such as L- or D-cysteine, N-acetyl cysteine, and the pharmaceutically acceptable salts thereof, and optionally one or more further active compounds selected from sulphites and xylitol, the composition being used for decreasing the risk of a subject contracting cancer of the stomach, and indirectly of the small intestine and the large intestine. The composition is formulated into a controlled-release formulation consisting of granules contained in a capsule.

Owner:BIOHIT OYJ

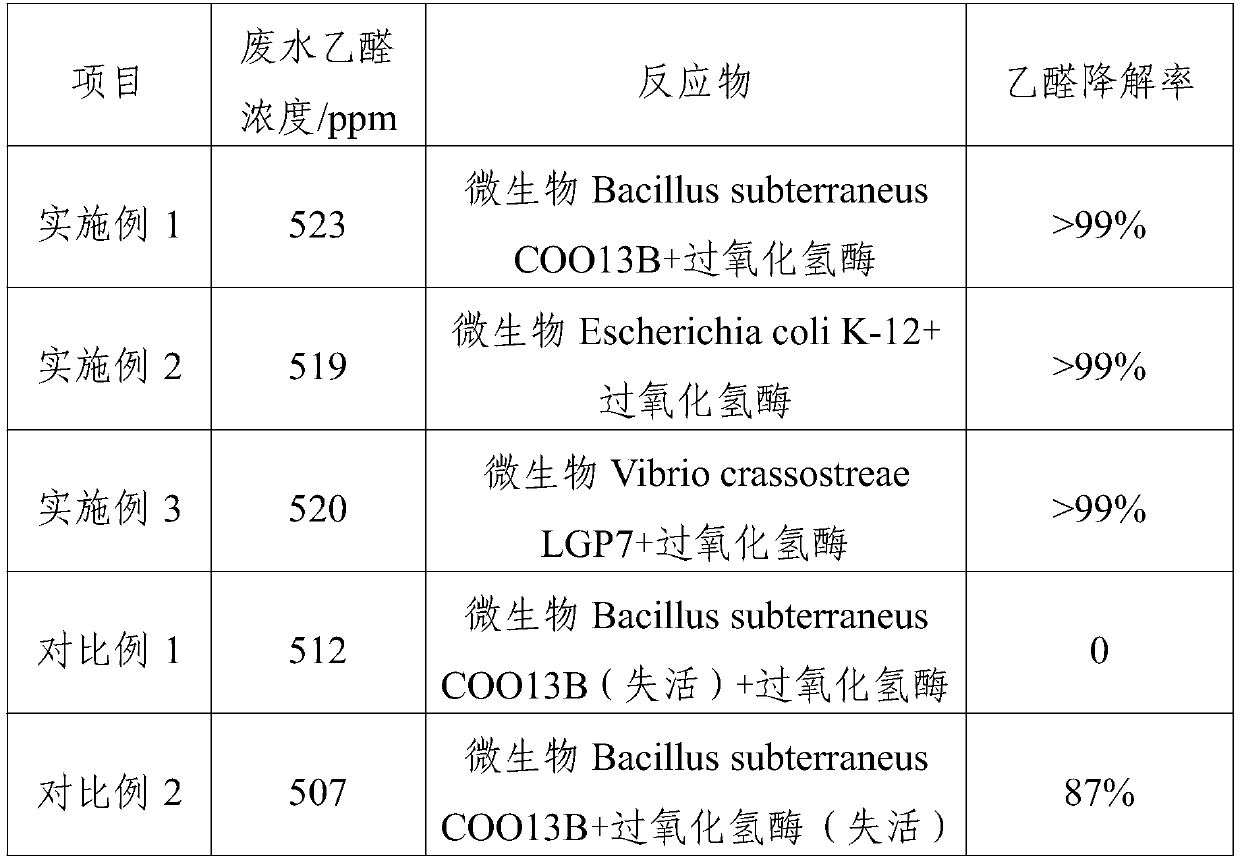

Method for treating acetaldehyde wastewater through cooperation of microorganisms and enzymes

InactiveCN111018253AThe principle is simpleEasy to operateWater contaminantsMultistage water/sewage treatmentNutritionSodium hydroxide

The invention provides a method for treating acetaldehyde wastewater through cooperation of microorganisms and enzymes. The method specifically comprises the following steps: (1) proportionally mixingmicroorganisms and enzymes to obtain a composite biological preparation; (2) adding a certain amount of a nutrition regulator and sodium hydroxide into industrial acetaldehyde wastewater, and regulating carbon, nitrogen and phosphorus in and the pH value of the wastewater; and (3) adding the composite biological agent into the adjusted acetaldehyde wastewater, carrying out stirring and mixing, maintaining a temperature at 30 DEG C, carrying out treating for 48 hours to remove aldehyde organic matters in the wastewater, and introducing the wastewater into a biochemical pool for subsequent treatment. According to the method, organic matters such as acetaldehyde in the wastewater are degraded by utilizing the synergistic effect of the microorganisms and the enzymes, so the biotoxicity of theacetaldehyde wastewater is reduced, and subsequent biochemical treatment efficiency is improved.

Owner:ANHUI COSTAR BIOCHEM CO LTD

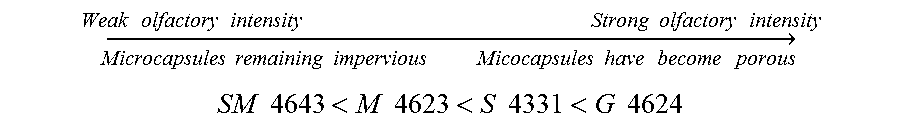

Process for manufacturing double-walled microcapsules, microcapsules prepared by this process and the use thereof

Process for manufacturing reservoir microcapsules containing an active principle in a polymer shell comprising the steps of: (iii) dispersion of a lipophilic active principle in an aqueous continuous phase, forming an oil-in-water emulsion, (iv) introduction into the lipophilic phase of one or more compounds A bearing alkoxysilane groups, (v) introduction into the aqueous phase of amine-containing organic monomers B comprising at least one group selected from melamine, urea, glycoluril, benzoguanamine or dicyandiamide groups and one or more aldehydes, or pre-polymers thereof and (vi) hydrolysis and polymerization, in situ, of the compounds A and B in an acid medium to give a silicone polymer and an amine-containing polymer, bonded together by polar, hydrogen or covalent bonds, forming the wall of the shell of the microcapsules, containing the active principle. Microcapsules containing a lipophilic active agent, the double-walled shell of which is formed from two polymers, one being a silicone copolymer, the other an amine-containing organic polymer, and use of these microcapsules in formulations comprising surfactants.

Owner:MICROCAPSULES TECH

Stable phenolic resin polymer dispersions having low free aldehyde content

ActiveUS20060270809A1Reduce aldehyde contentAffect chemical reactivityOther chemical processesMixing methodsDispersion stabilityCooking & baking

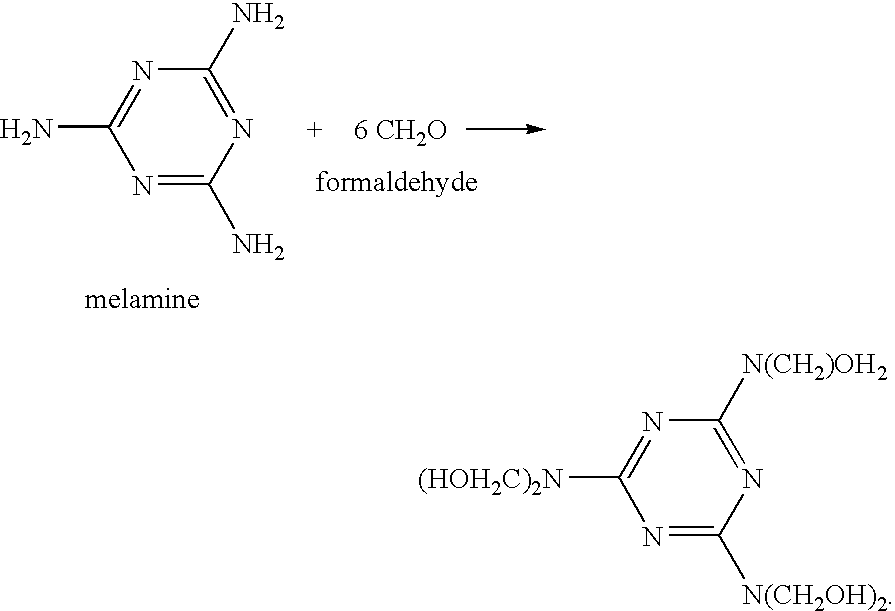

Stable dispersions of phenolic resins, particularly bisphenol-A / formaldehyde resins, for use in e.g., baking enamels, coatings, adhesives, binders, etc., are disclosed. The dispersions have low levels (e.g., <0.1% by weight) of free aldehyde, thereby reducing environmental harms associated with aldehyde emissions. Low free aldehyde levels are achieved using melamine as an aldehyde scavenger during preparation. It has now been discovered that melamine, in contrast to other scavengers of aldehydes, does not adversely affect dispersion stability, interfere with later processing operations, or negatively impact the final resin product quality (e.g., after curing).

Owner:GEORGIA PACIFIC CHEM LLC

Brewing technology of healthy selenium-enriched Baijiu

InactiveCN108753524AEasy post-processingQuick clearAlcoholic beverage preparationArteriolar VasoconstrictionFood flavor

The invention discloses a brewing technology of healthy selenium-enriched Baijiu, and relates to the technical field of selenium-enriched liquor. The technology comprises the following steps of (1) preparation of selenium-enriched brewed liquor, (2) preparation of distilled Baijiu and (3) preparation of the selenium-enriched Baijiu. The brewed liquor has low ester and aldehyde contents and higheralcohol and lactic acid contents; the ester and aldehyde contents of the first-cut distilled liquor are high, and the higher alcohol and lactic acid contents are lower; by combining the brewed liquorand the first-cut distilled liquor, component complementing and quantity relative ratio coordination are achieved, and not only can the traditional flavor of a liquor body be guaranteed, but also whenthe combined Baijiu is drunk, balance of human body vasoconstriction and angiectasis can be achieved to make blood circulation of the human body always in the normal state; the healthy selenium-enriched Baijiu is tasty and delicious, and a person feels comfortable after drinking and is not prone to be drunk.

Owner:安徽省金裕皖酒业有限公司

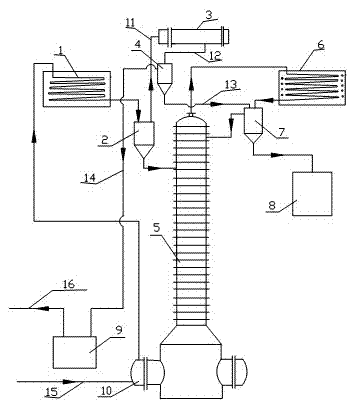

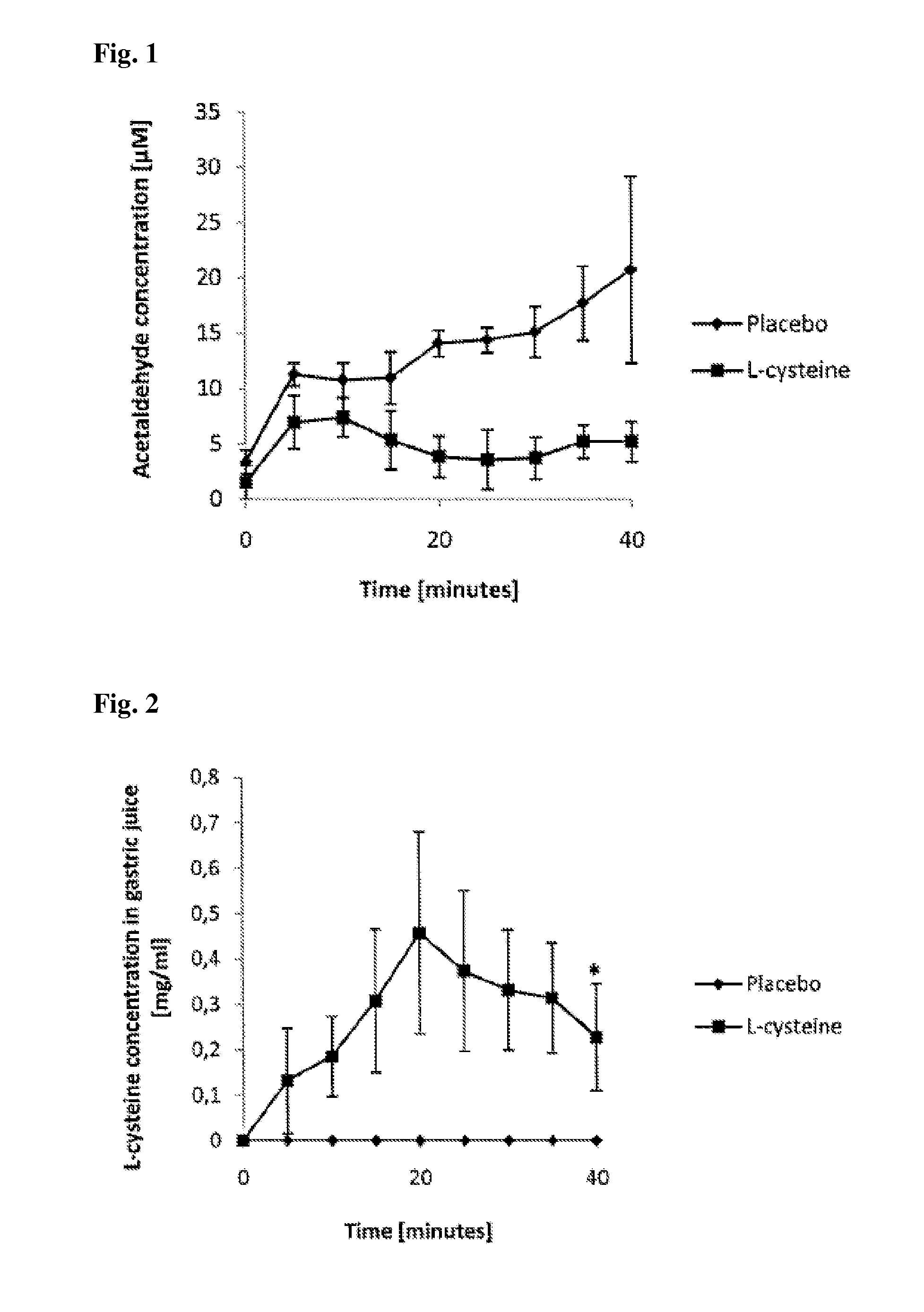

Recycling system for low-boiling point substance in furfural production

The invention discloses a recycling system for a low-boiling-point substance in furfural production. The recycling system comprises a stock solution condenser, a stock solution tank, a primary tower, an overhead condenser, an aldehyde separation device, a crude aldehyde measuring tank, a waste gas mixing box, a tower bottom heater, a tail gas semi-condenser and a gas-liquid separator. In the invention, the low-boiling point substance is separated from aldehyde gas before the aldehyde gas enters into a fractionator to be used as combustion-supporting gas of a boiler, thereby avoiding the pollution of the low-boiling point substance on the environment and the influence on separative efficiency of the fractionator, improving the distillation efficiency and simultaneously improving the yield of furfural.

Owner:任丘市恒达农产品科技开发有限公司

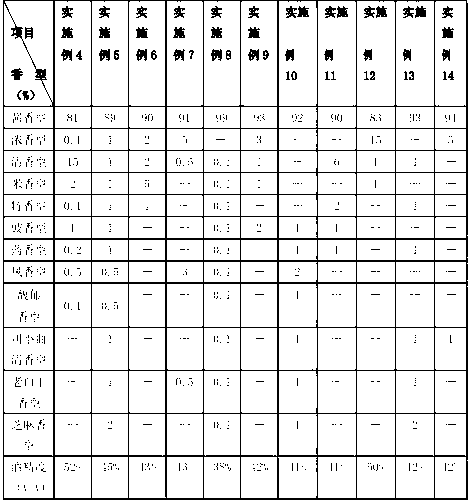

Preparation method of multi-taste Maotai-flavor white spirit

ActiveCN102453651BLong aftertastePerfect display of personality styleAlcoholic beverage preparationBiotechnologyWhite spirit

The invention discloses a preparation method of multi-taste Maotai-flavor white spirit. Eleven flavor types of white spirits are taken as seasoning liquors, the preparation method is characterized by comprising the following steps of: finishing and soaking grains; cooking, gelatinizing and mixing with Luzhou-flavor white spirit fermented grains and Maotai-flavor white spirit fermented grains; spreading out and airing, stirring distiller's yeast, adding Maotai-flavor ending liquor, Luzhou-flavor yellow wine, Maotai-flavor fermented grains and Maotai-flavor yeast, and accumulating and fermenting; fermenting in a cellar, and spraying mixed solution of the Maotai-flavor ending liquor and the Luzhou-flavor yellow wine on the surface of each distilled grain layer; making sand and adding the Luzhou-flavor white spirit fermented grains, cooking and gelatinizing, then adding the Maotai-flavor ending liquor, the Luzhou-flavor yellow wine, the Maotai-flavor fermented grains and the Maotai-flavoryeast, accumulating and fermenting, and storing in the cellar and spraying the mixed solution of the Maotai-flavor ending liquor and the Luzhou-flavor yellow wine on each distilled grain layer; steaming by using a rice steamer to obtain unblended wine in rounds of 1, 2, 3, 4, 5, 6 and 7, and the wine in the seven rounds are combined according to taste and-flavor characteristics, so as to obtain combined Maotai-flavor unblended wine; and then blending the combined unblended wine with flavoring liquor, thus obtaining the multi-taste Maotai-flavor white spirit. The preparation method disclosed by the invention has the advantages of enriching-flavor of Maotai-flavor white spirit, meeting market demand and promoting development of the Maotai-flavor white spirit.

Owner:SICHUAN TUOPAI SHEDE WINE

Novel pollution-free drying treatment process for waste vinasse generated by brewing

InactiveCN102039302AReduce consumptionReduce processing energy consumptionSolid waste disposalEnvironmental engineeringVinasse

The invention discloses a novel pollution-free drying treatment process for waste vinasse generated by brewing, relating to a treatment process for waste vinasse generated by brewing. The process comprises the following process steps of: material deacidification treatment, acid-base detection, strain inoculating and stirring, inoculating, temperature raising treatment before a material pile, material pile mixed culture fermentation and precipitation treatment, treatment indication detection, turn / blowing treatment, fermentation process requirement detection, property stability treatment, property requirement detection and packaging and storing. A production mode more suitable for a wine production enterprise is developed in the invention; the novel pollution-free drying treatment process for waste vinasse generated by brewing has larger production elasticity and adopts a brand new treatment flow with low energy consumption and low pollution to finish the drying treatment flow on waste vinasse; and process parameters can be regulated according to the purpose of the following dried vinasse, thereby high-quality raw material is provided.

Owner:范宏筠

Composition for oral administration for binding aldehydes in the gastrointestinal tract

InactiveUS20160022621A1Reduce aldehyde contentMask their tasteBiocideOrganic active ingredientsCvd riskIntrathecal

The present invention relates to a non-toxic composition containing one or more cysteine compounds selected from L- or D-cysteine, N-acetyl cysteine, and the pharmaceutically acceptable salts thereof, for decreasing the risk of a subject contracting cancer of the stomach, the small intestine and the colon, by locally binding aldehydes present in the stomach, and optionally also separately the aldehydes carried to the small intestine or the colon, or both, whereby the composition is formulated with the help of two or more additives into controlled-release tablets containing at least one additive selected from cationic and gel-forming polymers, which tablets are formed from two or more separate layers with different release profiles, whereby the cysteine compounds are added both into the inner layer(s) and into the tablet material surrounding these.

Owner:BIOHIT OYJ

Preparation method of acetyl-terminated allyl alcohol polyether

The invention provides a preparation method of acetyl-terminated allyl alcohol polyether, which comprises the following steps: (1) adding reactants allyl alcohol polyether and acetic anhydride into a reaction kettle at room temperature, conducting replacing with inert gas, conducting heating to 125-135 DEG C, and conducting reacting for 3-5 hours; (2) heating the mixture in the reaction kettle to 135-145 DEG C, and then carrying out vacuum nitrogen charging and degassing for 3-5 hours; (3) stopping nitrogen charging and degassing, cooling the mixture in the reaction kettle to 70-80 DEG C, adding an aldehyde adsorbent, and conducting stirring; (4) vacuumizing the reaction kettle for one hour, and cooling the mixture to 40-50 DEG C; and (5) discharging the mixture in the reaction kettle, and conducting packaging and bagging under the protection of inert gas. The method has the beneficial effects that the peroxide value of acetyl-terminated allyl alcohol polyether can be effectively reduced, and meanwhile, the taste and the aldehyde content of polyether polyol can be remarkably reduced.

Owner:NANJING WELL BIOCHEM

Method to reduce the aldehyde content of polymers

InactiveUS20080107850A1Promote yellowingMinimize aldehyde content of polymerSynthetic resin layered productsThin material handlingPolymerAlkaline catalyst

Owner:RULE MARK

Preparation process of formaldehyde-free plywood

ActiveCN108381688BGood combination stabilityImprove stabilityLayered productsPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention discloses a preparation process of formaldehyde-free plywood, including veneer manufacturing, glue mixing, sizing, billet formation, cold pressing, and post-processing. After the cold pressing process, a hot pressing process is required. In the sizing process, the water-based polyurethane mixture is used as the adhesive. The invention is suitable for using the water-based polyurethane, and realizes the preparation process of the plywood plywood with good bonding strength, uniform thickness of the slab, not easily deformed, and good stability.

Owner:广西协力合板有限公司

Treatment method of hydroxybenzene-containing wastewater

InactiveCN101037283BGuaranteed uptimeIndicators are stableTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTarget controlWastewater

The invention discloses a method of treating waste water including hydroxybenzene, including following steps: (1) synchronously adopting three segments target control method, a control method of mol ratio of hydroxybenzene to aldehyde and a timely separating method of resin and waste water, and processing a condensation polymerization of waste water in an acid condition with acid catalyst to produce resin with low molecular weight; (2) removing aldehyde of the waste water after the first treatment in an alkaline condition with alkaline catalyst and then processing an neutralization and deposition treatment; (3) adopting anaerobic and aerobic treatment to process a biochemical treatment of the waste water after the second treatment to meet emission requirements. The method meets the prescribed emission requirements of the hydroxybenzene-aldehyde resin waste water or waste water containing hydroxybenzen and has a simple art, a reliable operation, a low investment and a low operation fees and adequately utilizes the hydroxybenzene-aldehyde in the waste water.

Owner:海盐华强树脂有限公司

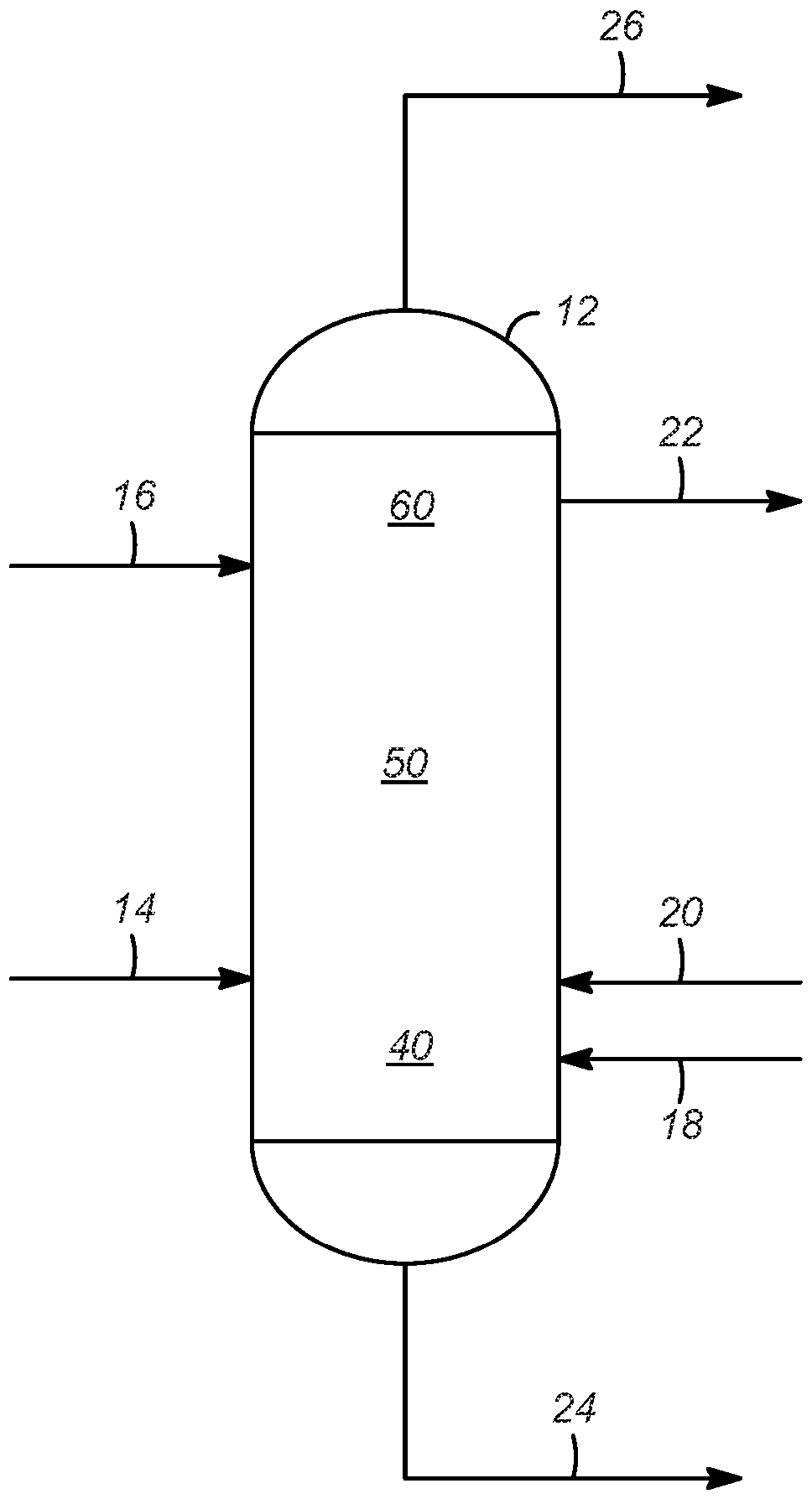

Process and apparatus for removing aldehydes from acetone

ActiveCN110785394AImprove qualityEfficient removalSolvent extractionOrganic compound preparationAldehydeAcetone

The present invention relates to process and apparatus for removing aldehydes from acetone. More specifically, the present invention relates to a process and apparatus for removing aldehydes from acetone by reacting the aldehydes with caustic in an acetone column and washing the organic phase with a plurality of water streams.

Owner:UOP LLC +1

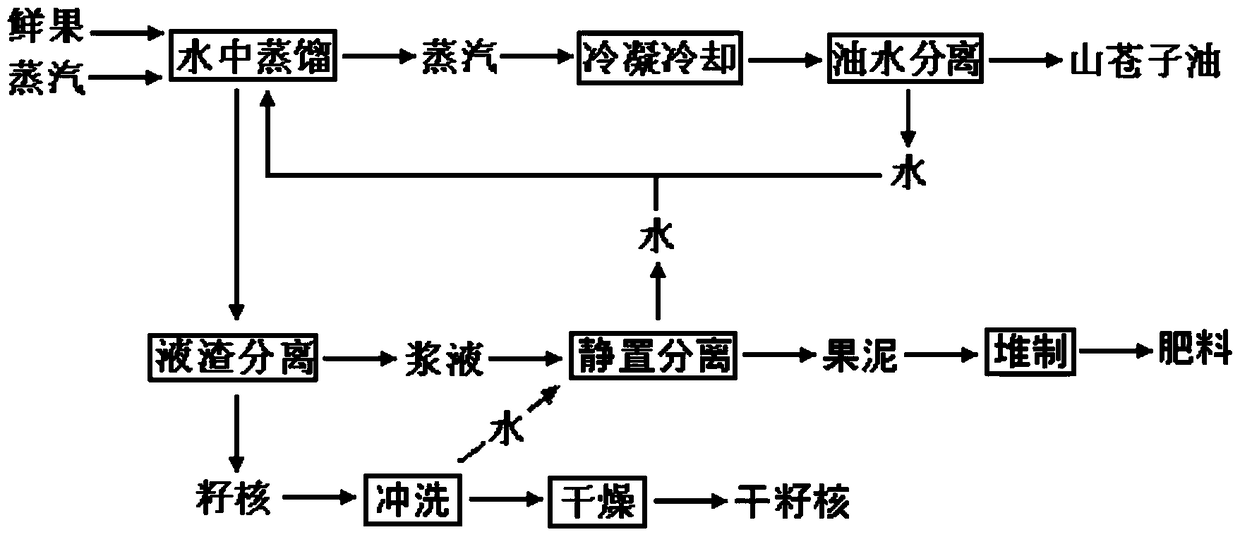

A kind of extraction method of litsea cubeba oil

ActiveCN104694248BLess investmentEasy to degradeBio-organic fraction processingBioloigcal waste fertilisersMedicinal herbsAgricultural engineering

Owner:GUANGXI FORESTRY RES INST

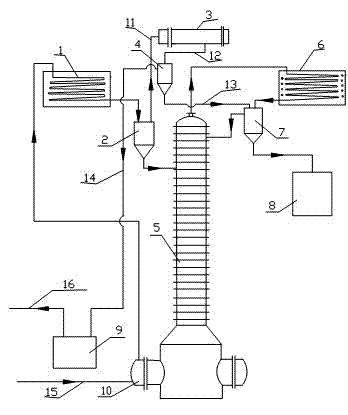

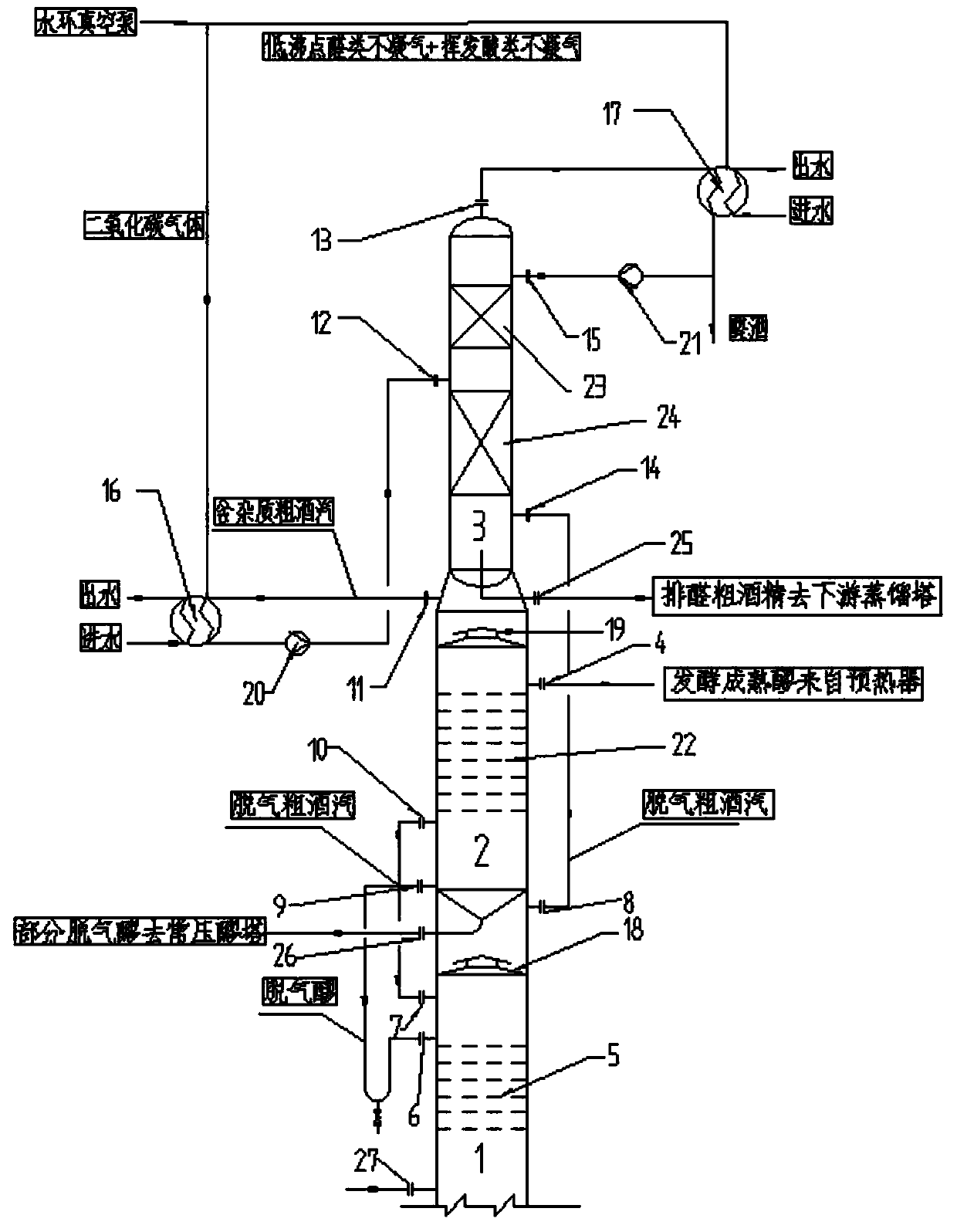

Negative pressure mash tower degassing, aldehyde-discharging and acid-discharging device for fuel ethanol and edible alcohol

PendingCN110922303AReduce aldehyde contentReduce acidityOrganic compound preparationHydroxy compound preparationAlcoholPhysics

The invention discloses a negative pressure mash tower degassing, aldehyde-discharging and acid-discharging device for fuel ethanol and edible alcohol. The device comprises a negative pressure mash tower. A first tower plate is arranged in the negative pressure mash tower; a degassing section is arranged above the negative pressure mash tower, a second tower plate is arranged in the degassing section, an aldehyde discharging section is arranged above the degassing section, and fillers are arranged in the aldehyde discharging section. The invention also discloses a production method for improving the alcohol quality by using the device. Compared with the traditional mash tower, the relatively pure crude wine steam rising from the negative pressure mash tower is used for degassing fermentedmash and discharging aldehyde from crude alcohol without increasing steam consumption, pre-impurity removal of the fermented mash and the crude alcohol is achieved, carbon dioxide in the fermented mash and most low-boiling-point aldehydes and volatile acids in the crude alcohol are removed in the degassing section and the aldehyde discharging section, the aldehyde content and the acidity of the crude alcohol are reduced, the subsequent tower impurity discharging load is effectively reduced and the comprehensive quality of the alcohol is improved.

Owner:肥城金塔酒精化工设备有限公司

Purification method for preparing ethylene glycol from coal-based synthesis gas

PendingCN113480408AAchieve purificationImprove UV transmittanceOrganic compound preparationHydroxy compound separation/purificationPolymer sciencePurification methods

The invention relates to the technical field of ethylene glycol production, and provides a purification method for preparing ethylene glycol from coal-based synthesis gas. According to the present invention, ethylene glycol is purified by using a 1# resin tower and a 2# resin tower, the resin filled in the 1# resin tower is SQYJ-2 enhanced ultraviolet resin, and the resin filled in the 2# resin tower is SQYJ-1 dealdehyding catalyst resin; and the SQYJ-2 resin can improve the ultraviolet light transmittance of ethylene glycol and has a slight dealdehyding effect, and the SQYJ-1 resin can reduce the aldehyde content of ethylene glycol. According to the specific condition of the ethylene glycol extracted from the side line of the product tower, the ethylene glycol is selectively introduced into the 1# resin tower or the 2# resin tower, or the ethylene glycol is introduced into the 1# resin tower and then into the 2# resin tower, so that the purification of the ethylene glycol is realized. The ethylene glycol purified by the method disclosed by the invention is high in ultraviolet light transmittance and low in aldehyde content, and can reach the standard of superior products in GB / T4649-2008.

Owner:JIANGSU SUQING WATER TREATMENT ENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com