A kind of extraction method of litsea cubeba oil

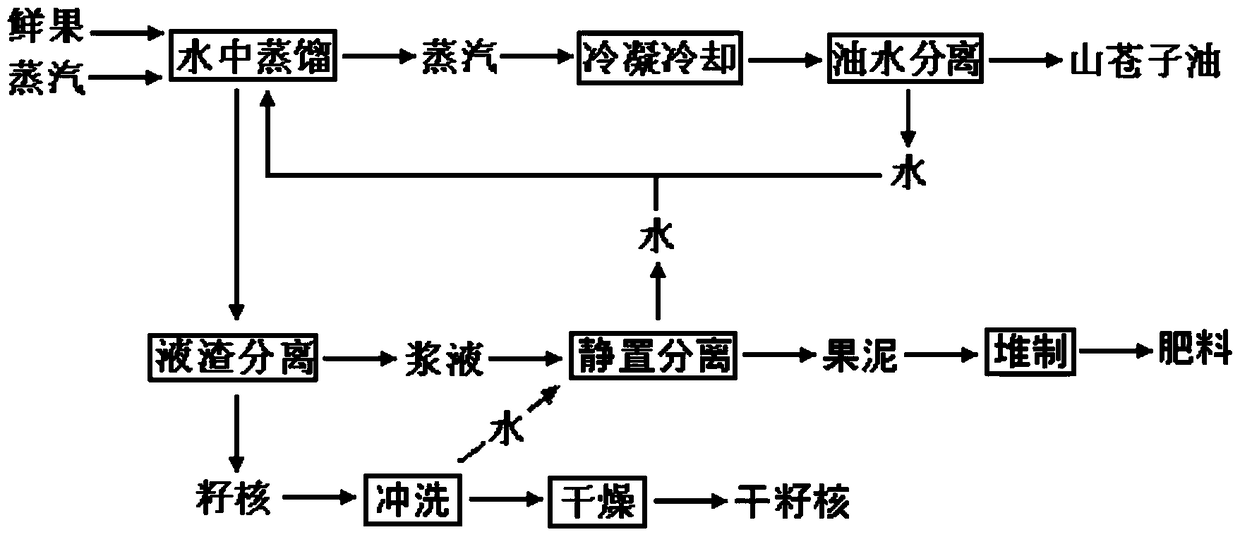

A technology of Radix vulgaris oil and an extraction method, which is applied in the production of fat oil/fat, the preparation of organic fertilizers, and the fertilizers made from biological wastes, etc., can solve the problems of large loss of components of Radix radix, long process flow and high production cost. , to achieve the effect of convenient recycling of seed cores, improved product quality, and short distillation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for extracting Litsea Cubeba Oil, the specific process steps are:

[0031] (1) Fruit cleaning: wash the fresh fruit of litsea cubeba in a sink to remove impurities;

[0032] (2) Boiling water: Add clean water into the still pot, pass in steam with a pressure of 0.25Mpa, boil the water in the still pot, and discharge the air in the still pot;

[0033] (3) Feeding: Add the washed Litsea cubeba fresh fruit into the water in the still pot, and close the feeding valve;

[0034] (4) Distillation: Turn on the cooling water of the condenser, increase the steam flow rate, and control the steam pressure to 0.25Mpa. After the boiling gas is evaporated, cool the evaporated gas into a liquid, and control the steam volume and constant pressure to carry out water distillation. The distillation time is 1.2h;

[0035] (5) Oil-water separation: Send the condensed liquid into two series-connected oil-water separators, let it sit for precipitation to separate oil and water to ob...

Embodiment 2

[0042] A method for extracting Litsea Cubeba Oil, the specific process steps are:

[0043] (1) Fruit cleaning: wash the fresh fruit of litsea cubeba in a sink to remove impurities;

[0044] (2) Boiling water: Add distilled recovered water, distilled slurry standing water and clean water into the still, and introduce steam with a pressure of 0.2Mpa to boil the water in the still and discharge the air in the still;

[0045] (3) Feeding: Add the washed Litsea cubeba fresh fruit into the water in the still pot, and cover the feeding lid;

[0046] (4) Distillation: Turn on the cooling water of the condenser, increase the steam flow rate, and control the steam pressure to 0.2Mpa. After the boiling gas is evaporated, cool the evaporated gas into a liquid, and control the steam volume and constant pressure to carry out water distillation. The distillation time is 1.5h;

[0047] (5) Oil-water separation: Send the condensed liquid into two series-connected oil-water separators, let it...

Embodiment 3

[0054] A method for extracting Litsea Cubeba Oil, the specific process steps are:

[0055] (1) Fruit cleaning: wash the fresh fruit of litsea cubeba in a sink to remove impurities;

[0056] (2) Boiling water: Add distilled recovery water and or distilled slurry static water into the still, and introduce steam with a pressure of 0.3Mpa, boil the water in the still, and discharge the air in the still;

[0057] (3) Feeding: Add the washed Litsea cubeba fresh fruit into the water in the still pot, and close the feeding valve;

[0058] (4) Distillation: Turn on the cooling water of the condenser, increase the steam flow, and control the steam pressure to 0.3Mpa. After the boiling gas is evaporated, the evaporated gas is cooled to liquid, and the steam volume is controlled to carry out water distillation at a constant pressure. The distillation time for 1h;

[0059] (5) Oil-water separation: Send the condensed liquid into two series-connected oil-water separators, let it sit for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com