Stabilizing treatment method for polyformaldehyde

A technology for stabilizing polyoxymethylene, which is applied in the field of stabilizing polyoxymethylene with a screw extruder, can solve the problems of unstable end groups, uneven distribution of additives, appearance performance, heat resistance and environmental protection performance. Improvement and other issues to achieve the effect of improving uniformity and appearance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

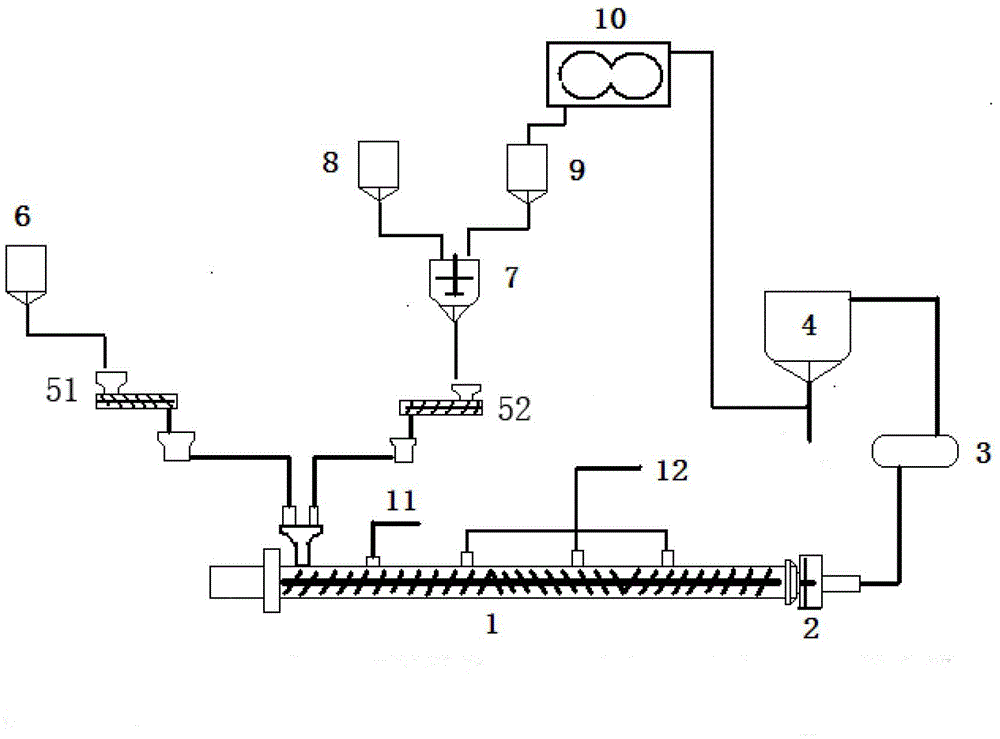

Method used

Image

Examples

Embodiment 1

[0059] Preparation of compound additives:

[0060] ①With 186g aldehyde absorbent melamine, 546g antioxidant triethylene glycol bis[3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate], 268g lubricant ethylene bisstearate Add the amide into a 3L high-speed mixer, and mix evenly at a speed of 3000 rpm;

[0061] ②Put the uniformly mixed additives into the extrusion molding machine, extrude and pelletize to obtain long compound additives;

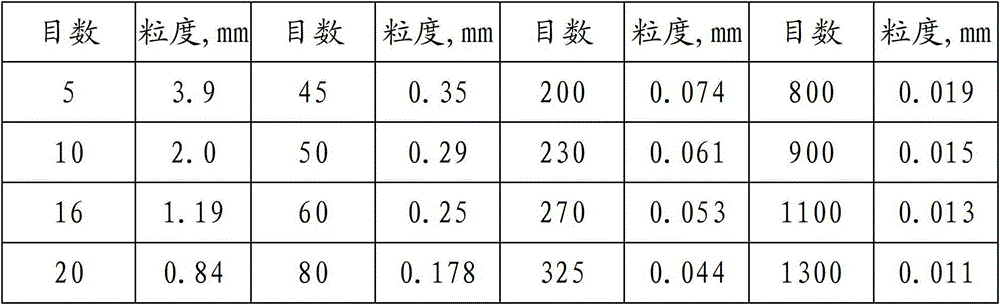

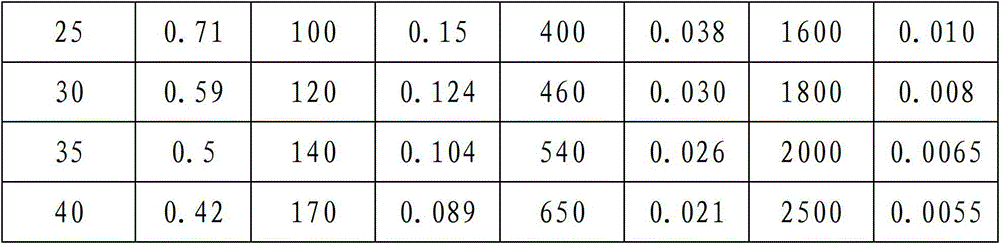

[0062] ③Put the granulated composite additives into the crusher for crushing, and finally obtain granular composite additives with a particle size of 0.65-0.85 mm.

[0063] POM stabilization treatment:

[0064] Grind 2.95kg of polyoxymethylene pellets with stable end groups into a powder with a particle size of 0.58-0.94mm through a mill, then mix the powder with 213g of compound additives in a mixer, and mix with 27.04 kg polyoxymethylene powder with unstable end groups from the polymerization reactor (the molecular chain is not terminated...

Embodiment 2

[0067] Preparation of compound additives:

[0068] ①With 175g aldehyde absorbent melamine, 563g antioxidant triethylene glycol bis[3-(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate], 218g lubricant ethylene bisstearate Add the amide into a 3L high-speed mixer, and mix evenly at a speed of 3000 rpm;

[0069] ② Add 284g of ethanol to the compounding additive and mix evenly, then add the compounding additive into the extrusion molding machine, extrude and pelletize to obtain a strip-shaped compounding additive;

[0070] ③Dry the granulated compound auxiliary agent and put it into a crusher for crushing, finally obtain a granular compound auxiliary agent with a particle size of 0.58-0.85 mm.

[0071] POM stabilization treatment:

[0072] Mix 3.05kg of polyoxymethylene powder with stable end groups (particle size: 0.54-0.89mm) and 215g of composite additives in the mixer after being pulverized by a mill, and then mix them with 26.95kg of polyoxymethylene powder from the polyme...

Embodiment 3

[0075] Preparation of compound additives:

[0076] ① Mix 182g aldehyde absorbent melamine formal, 538g antioxidant N,N'-hexamethylenebis(3,5-di-tert-butyl-4-hydroxyphenylpropanamide), 271g lubricant ethylene bisoleic acid Add the amide into a 3L high-speed mixer, and mix evenly at a speed of 3000 rpm;

[0077] ②Put the uniformly mixed additives into the extrusion molding machine, extrude and pelletize to obtain long compound additives;

[0078] ③Put the granulated composite additives into the crusher for crushing, and finally obtain granular composite additives with a particle size of 0.59-0.83 mm.

[0079] POM stabilization treatment:

[0080]Mix 2.98kg of polyoxymethylene powder (particle size: 0.53-0.91mm) and 211g of composite additives in a mixer with stable end groups after being pulverized by a pulverizer, and then mix them with 26.98kg of polyoxymethylene powder from a polymerization reactor. The polyoxymethylene powder with unstable end groups (molecular chain is n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com