Recycling system for low-boiling point substance in furfural production

A technology of low boiling matter and furfural, which is applied in the field of low boiling matter recovery and utilization system, can solve the problems of heavy influence of the initial distillation tower, environmental pollution, operator injury, etc., and achieve enhanced combustion effect, increased distillation efficiency, furfural yield rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

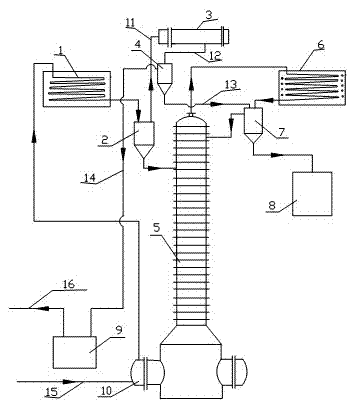

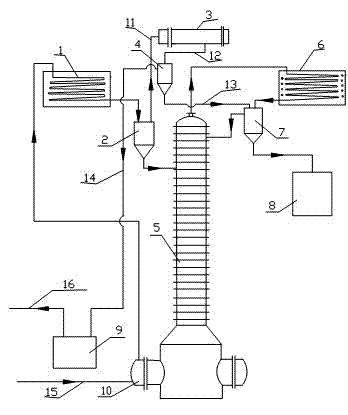

[0018] The recovery and utilization system of low boilers in furfural production of the present invention comprises: raw liquid condenser 1, raw liquid tank 2, primary distillation tower 5, tower top condenser 6, aldehyde separator 7, crude aldehyde metering tank 8, waste gas mixing box 9 , tower bottom heater 10, also comprise tail gas semi-condenser 3, vapor-liquid separator 4;

[0019] Wherein, the tail gas outlet at the top of the stock solution tank 2 is communicated with the feed port of the tail gas semi-condenser 3 through the first pipeline 11;

[0020] The feed port of the vapor-liquid separator 4 is communicated with the discharge port of the tail gas semi-condenser 3 through the second pipeline 12, and the vapor phase outlet of the vapor-liquid separator 4 is connected with the inlet of the waste gas mixing box 9 through the fourth pipeline 14 The liquid phase outlet of the vapor-liquid separator 4 communicates with the feed port of the aldehyde separator 7 through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com