Quick-dry waterproof material and preparation method thereof

A waterproof material, quick-drying technology, applied in the direction of coating, can solve problems such as long time, achieve the effect of fast initial setting speed, short drying time and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

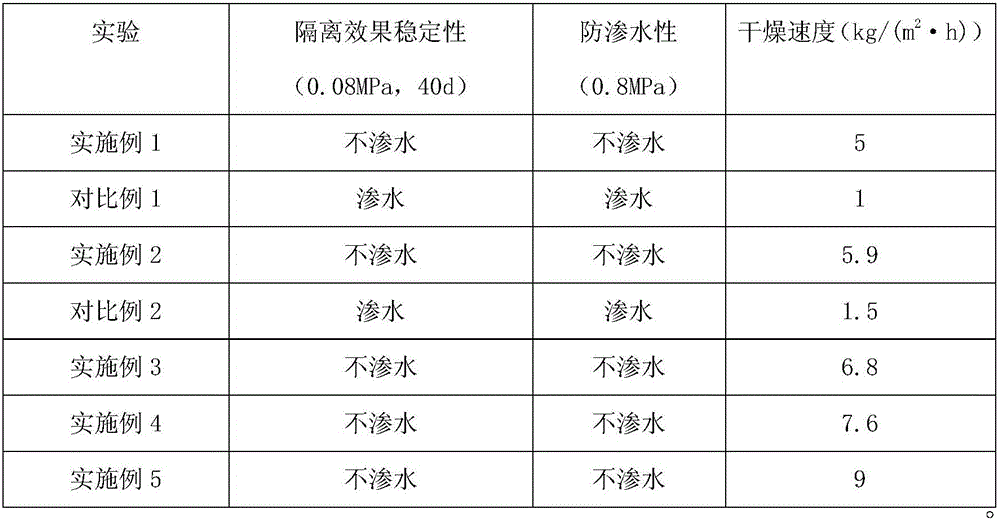

Examples

Embodiment 1

[0018] S1: Mix 80 parts of deionized water, 12 parts of ethyl acrylate, 8 parts of hydroxymethyl cellulose, 3 parts of ammonium persulfate, 1 part of aluminum sulfate, 2 parts of vinyltrimethoxysilane and 6 parts of propylene carbonate, Under the protection of nitrogen, react at a temperature of 30°C for 15 minutes to obtain a reaction solution A;

[0019] S2: 10 parts of n-octyl p-hydroxybenzoate, 7 parts of tetrahydromyrcenol, 12 parts of 3-methyl-5-phenyl-1-pentanol, 11 parts of 2-mercaptoethyl sulfide and 2- Add 9 parts of methyl chloro-3-hydroxypropionate into the ultrasonic reactor, stir and mix at room temperature for 5 minutes to a uniform state, and obtain the reaction solution B;

[0020] S3: Add 7 parts of 5-tert-butylpyrogallol dropwise to the reaction solution A described in step S1, and raise the temperature to 80°C while adding dropwise, to obtain reaction solution C; add 2 parts of 4-bromomethylquinolone Add dropwise to the reaction solution B described in ste...

Embodiment 2

[0027] S1: Mix 100 parts of deionized water, 16 parts of ethyl acrylate, 12 parts of hydroxymethyl cellulose, 6 parts of ammonium persulfate, 4 parts of aluminum sulfate, 5 parts of vinyltrimethoxysilane and 10 parts of propylene carbonate, Under the protection of nitrogen, react at a temperature of 40°C for 20 minutes to obtain a reaction solution A;

[0028] S2: 16 parts of n-octyl p-hydroxybenzoate, 11 parts of tetrahydromyrcenol, 15 parts of 3-methyl-5-phenyl-1-pentanol, 15 parts of 2-mercaptoethyl sulfide and 2- Add 12 parts of methyl chloro-3-hydroxypropionate into the ultrasonic reactor, stir and mix at room temperature for 8 minutes to a uniform state, and obtain the reaction solution B;

[0029] S3: Add 11 parts of 5-tert-butylpyrogallol dropwise to the reaction solution A described in step S1, and raise the temperature to 100°C while adding dropwise, to obtain reaction solution C; add 6 parts of 4-bromomethylquinolone Add dropwise to the reaction solution B describe...

Embodiment 3

[0036] S1: Mix 85 parts of deionized water, 13 parts of ethyl acrylate, 11 parts of hydroxymethyl cellulose, 4 parts of ammonium persulfate, 2 parts of aluminum sulfate, 3 parts of vinyltrimethoxysilane and 9 parts of propylene carbonate, Under the protection of nitrogen, react at a temperature of 40°C for 20 minutes to obtain a reaction solution A;

[0037] S2: 12 parts of n-octyl p-hydroxybenzoate, 8 parts of tetrahydromyrcenol, 13 parts of 3-methyl-5-phenyl-1-pentanol, 12 parts of 2-mercaptoethyl sulfide and 2- Add 9 parts of methyl chloro-3-hydroxypropionate into the ultrasonic reactor, stir and mix at room temperature for 5 minutes to a uniform state, and obtain the reaction solution B;

[0038] S3: Add 8 parts of 5-tert-butylpyrogallol dropwise to the reaction solution A described in step S1, and raise the temperature to 80°C while adding dropwise, to obtain reaction solution C; add 3 parts of 4-bromomethylquinolone Add dropwise to the reaction solution B described in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com