Rare-earth composite wall heat-insulating layer preparation method

A technology of rare earth compounding and manufacturing methods, which is applied in the direction of heat preservation, building structure, building components, etc., can solve the problems of poor bonding treatment, poor thermal performance, and low strength, so as to enhance reliability and safety, improve Insulation performance, strong bearing capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

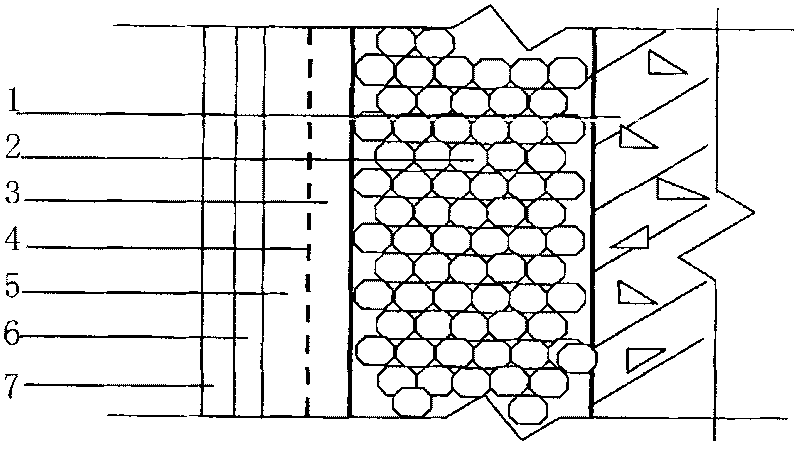

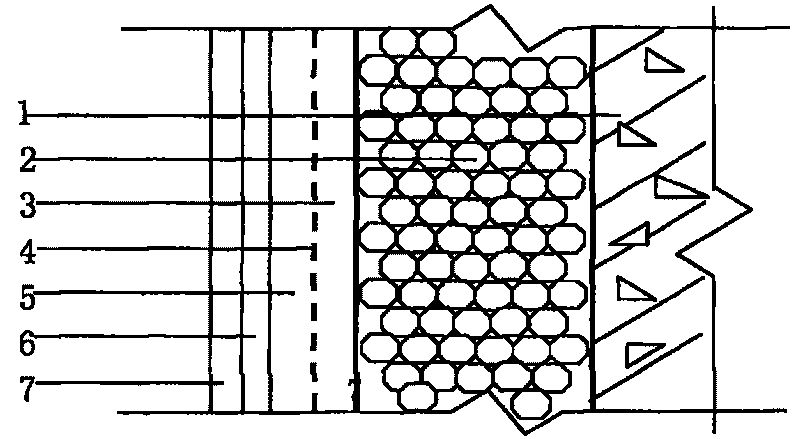

Method used

Image

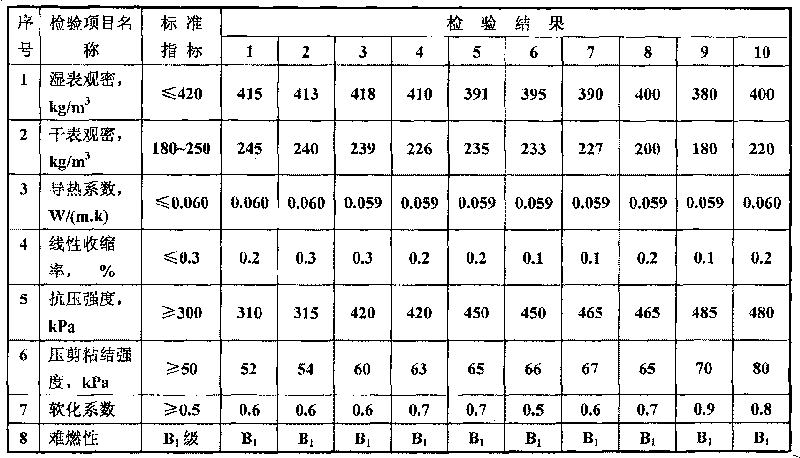

Examples

Embodiment 1

[0043] ① The rare earth rubber powder of the present invention is composed of the weight ratio of the following materials, light rare earth oxide 5, ordinary Portland cement 60, methyl cellulose 10, ethyl cellulose 10, defoamer 0.3, soluble rubber powder, microfoam Agent and N series water reducer mixture 1.5, PP fiber 5, wollastonite powder 15.

[0044] ② Rare earth plastering sand is composed of the following materials in weight ratio, light rare earth oxide 8, ordinary silicon 42.5 cement 30, heavy calcium carbonate 15, quartz sand 50 (60-140 mesh), methyl cellulose 5, polypropylene rubber powder 9. Defoamer 0.4, microfoam agent and N-series water reducer mixture 5, PP fiber 6.

[0045] The process steps are as follows:

[0046] 1) Stir the materials in ① in the agitator according to the above proportions to make rare earth rubber powder;

[0047] 2) Stir the rare earth rubber powder in step 1) for 5 minutes by weight ratio, rubber powder: water=1:1~1.5, and then add poly...

Embodiment 2

[0057] ① The rare earth rubber powder of the present invention is composed of the weight ratio of the following materials, light rare earth oxide 5, ordinary Portland cement 65, methyl cellulose 10, ethyl cellulose 10, defoamer 0.3, soluble rubber powder, microfoam Agent and N series superplasticizer mixture 1.5, PP fiber 5, wollastonite powder 12.

[0058] ② Rare earth plastering sand: composed of the following materials in weight ratio, light rare earth oxide 8, ordinary silicon 42.5 cement 35, heavy calcium carbonate 10, quartz sand 50 (60-140 mesh), methyl cellulose 5, polypropylene glue Powder 9, defoamer 0.4, microfoam agent and N-series water reducer mixture 5, PP fiber 6.

[0059] The process steps are as follows:

[0060] 1) Stir the materials in ① in the agitator according to the above proportions to make rare earth rubber powder;

[0061] 2) Stir the rare earth rubber powder in step 1) for 5 minutes according to the weight ratio, rubber powder: water = 1:1-1.5, an...

Embodiment 3

[0071] The rare earth rubber powder of the present invention is made up of the weight ratio of following material, light rare earth oxide 6, ordinary portland cement (42.5) 70, methyl cellulose 10, ethyl cellulose 10, defoamer 0.3, soluble rubber powder, Mixture of microfoam agent and N series water reducing agent 1.5, PP fiber 5, wollastonite powder 10.

[0072] ② Rare earth plastering sand is composed of the following materials in weight ratio, light rare earth oxide 8, ordinary Portland cement 30 (42.5), heavy calcium carbonate 20, quartz sand 60 (60-140 mesh), methyl cellulose 5, Polypropylene rubber powder 9, defoamer 0.4, microfoam agent and N-series water reducing agent mixture 5, PP fiber 6.

[0073] The process steps are as follows:

[0074] 1) Stir the materials in ① in the agitator according to the above proportions to make rare earth rubber powder;

[0075] 2) Stir the rare earth rubber powder in step 1) for 5 minutes according to the weight ratio, rubber powder:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com