Preparation for KCo(CO)4, and application of KCo(CO4) in catalyzing carbonyl-methyl esterification reaction of ethylene oxide

A technology for oxirane carbonyl methyl esterification reaction, applied in physical/chemical process catalysts, carbon monoxide or formate reaction preparation, organic compound/hydride/coordination complex catalysts, etc. Removal, difficult separation, complex operation and other problems, to achieve the effect of low cost, short reaction time and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

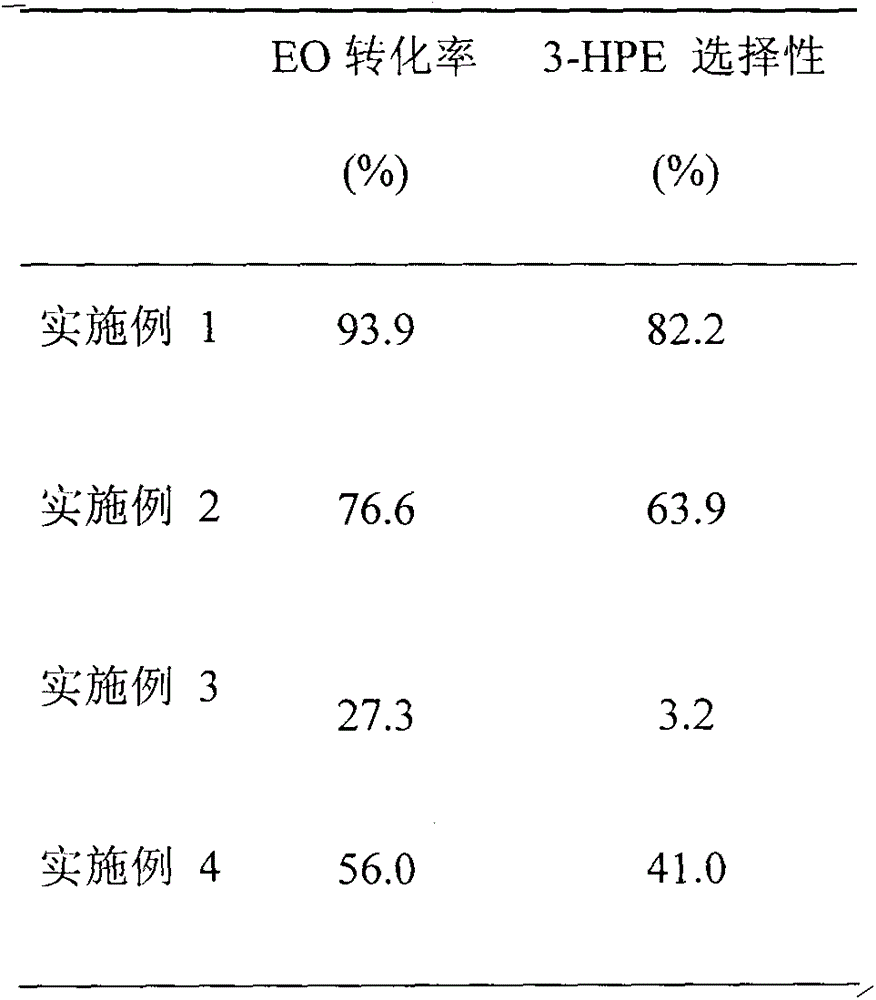

Examples

Embodiment 1

[0014] 1.0g anhydrous CoCl 2 , 1.4gKBH 4 , 0.2gKOH was placed in a reaction kettle containing 20mL tetrahydrofuran (THF), carbon monoxide (CO) was replaced 3 times, P co =2MPa, react at room temperature for 2h. After the reaction, filter to obtain KCo(CO) 4 of THF solution. Will get KCo(CO) 4 THF solution, 3.4g ethylene oxide, 20mL methanol, added to the reactor, filled with carbon monoxide (CO) and replaced 3 times, P co =2MPa, reacted at 75°C for 5h. After the reaction, it was directly filtered, and the filtrate was analyzed by GC to obtain the conversion rate of ethylene oxide and the selectivity of 3-HPE.

Embodiment 2

[0016] 1.0g anhydrous CoCl 2 , 1.4gKBH 4 , 0.2gKOH was placed in a reaction kettle containing 20mL tetrahydrofuran (THF), carbon monoxide (CO) was replaced 3 times, P co =2MPa, reacted under ice bath for 2h. After the reaction, filter to obtain KCo(CO) 4 of THF solution. Will get KCo(CO) 4 THF solution, 3.4g ethylene oxide, 20mL methanol, added to the reactor, filled with carbon monoxide (CO) and replaced 3 times, P co =2MPa, reacted at 75°C for 5h. After the reaction, it was directly filtered, and the filtrate was analyzed by GC to obtain the conversion rate of ethylene oxide and the selectivity of 3-HPE.

Embodiment 3

[0018] 1.0g anhydrous CoCl 2 , 1.4gKBH 4 , 0.2gKOH was placed in a reaction kettle containing 20mL of methanol, carbon monoxide (CO) was replaced 3 times, P co =2MPa, reacted under ice bath for 2h. After the reaction, filter to obtain KCo(CO) 4 methanol solution. Will get KCo(CO) 4 methanol solution, 3.4g ethylene oxide, 20mL methanol, added to the reactor, filled with carbon monoxide (CO) and replaced 3 times, P co =2MPa, reacted at 75°C for 5h. After the reaction, it was directly filtered, and the filtrate was analyzed by GC to obtain the conversion rate of ethylene oxide and the selectivity of 3-HPE.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com