Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Solve forming problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing cellulose microsphere by taking ionic liquid as solvent

InactiveCN101612540ASolve forming problemsSolve the problem of sphericityOther chemical processesAlkali metal oxides/hydroxidesCelluloseLow speed

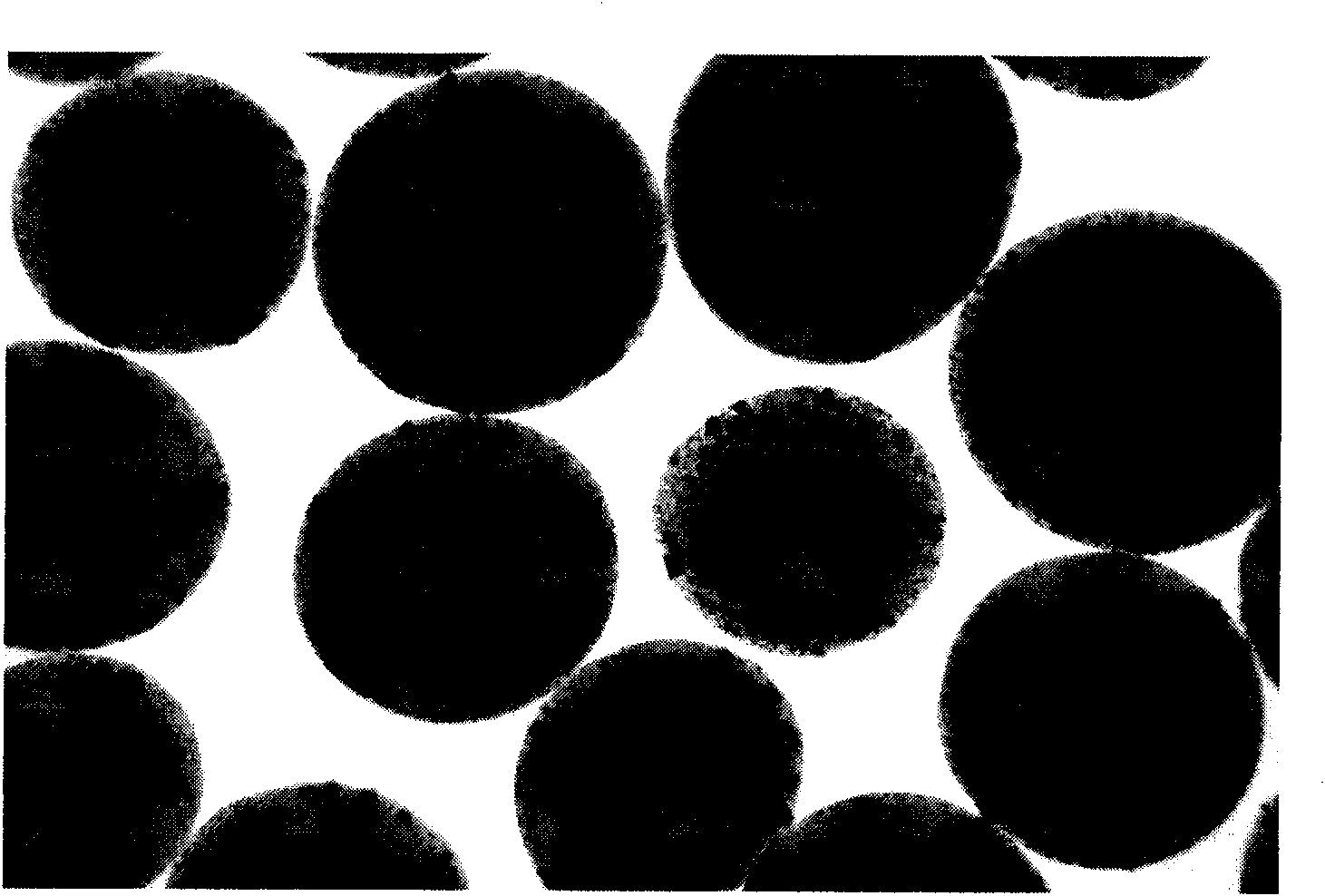

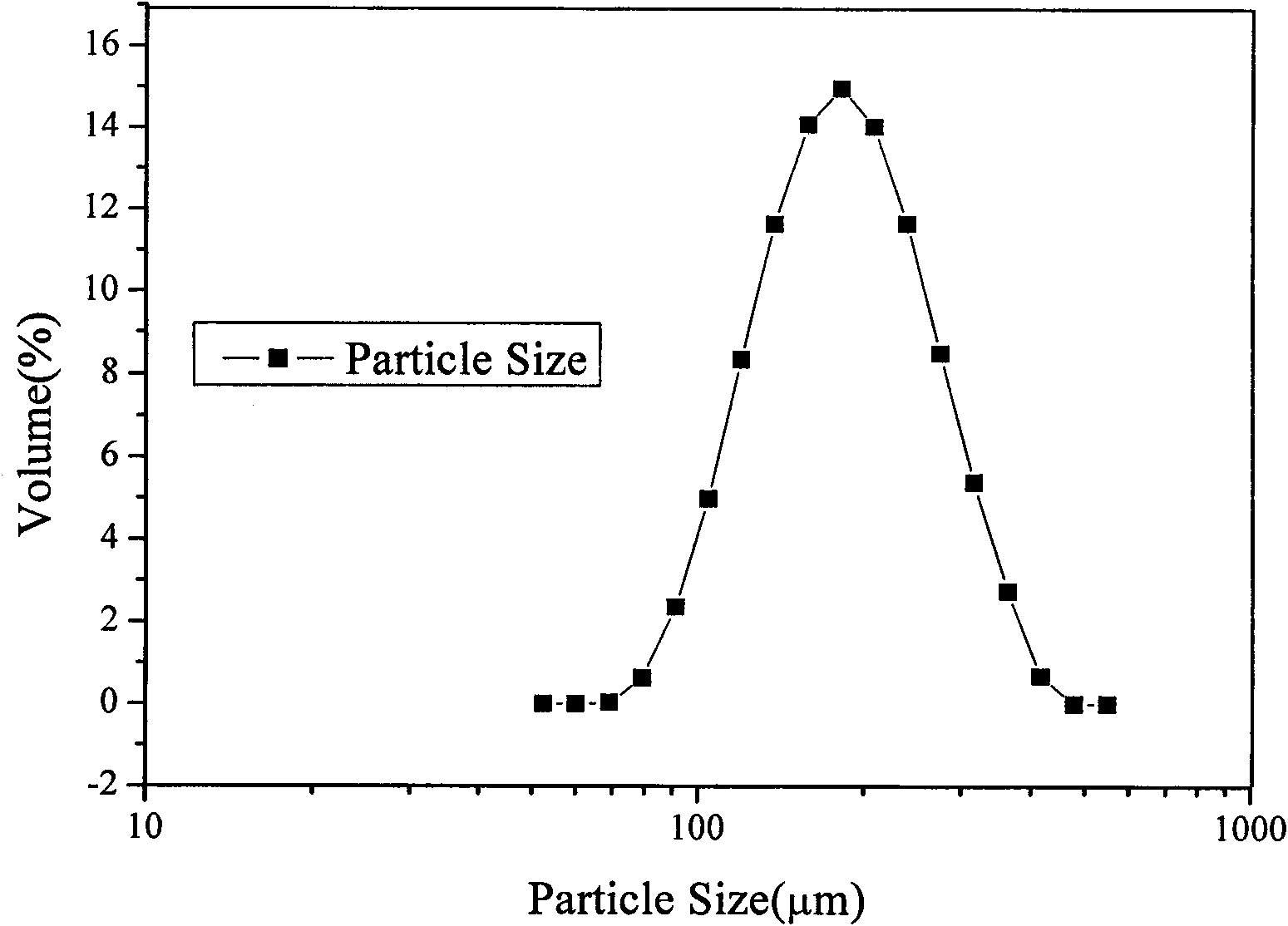

The invention discloses a method for preparing cellulose microspheres by taking ionic liquid as a solvent. The method comprises the steps of: 1) preparing cellulose solution as follows: dissolving the cellulose into the ionic liquid under low-speed stirring and proper temperature; 2) adding inert particles: adding proper amount of inert particles, and stirring evenly; 3) forming spheres by reversed phase suspension: adding oil phase and a surface active agent, leading the cellulose solution to be condensed into spheres by reversed phase suspension and program temperature reduction; 4) curving microspheres: adding a curving agent and curving to form the cellulose microspheres; 5) washing: using deionized water to wash and soak so as to obtain the cellulose microspheres; and 6) screening: screening in a wet state and obtaining the cellulose microspheres with a certain particle size range. The developed preparation process is simple and convenient, the used solvent is safe and non-toxic, the prepared cellulose micrsphere has porous structure and proper particle size, high sphericity and good hydropathy, can adjust density, can be used as substrate of an absorbent and has good biocompatibility.

Owner:ZHEJIANG UNIV

Hydroxyalkyl cationic guar gum and its preparation method and application

InactiveCN1757827ASolve forming problemsImprove adsorption capacityPaper/cardboardRetention agents additionAlcoholGraft reaction

A process for preparing the cationic hydroxyalkyl guar gum includes such steps as dispersing the raw powder of guar gum in the aqueous solution of low-carbon alcohol, adding high-alkaline catalyst, immersing, adding cationic etherifying agent, cationic graft reaction, adding phase-transfer catalyst and alkoxy etherifying agent, hydro-xyalkylating reaction, neutralizing and filtering. It can be used as the retention aid or filter aid of paper pulp.

Owner:SOUTH CHINA UNIV OF TECH

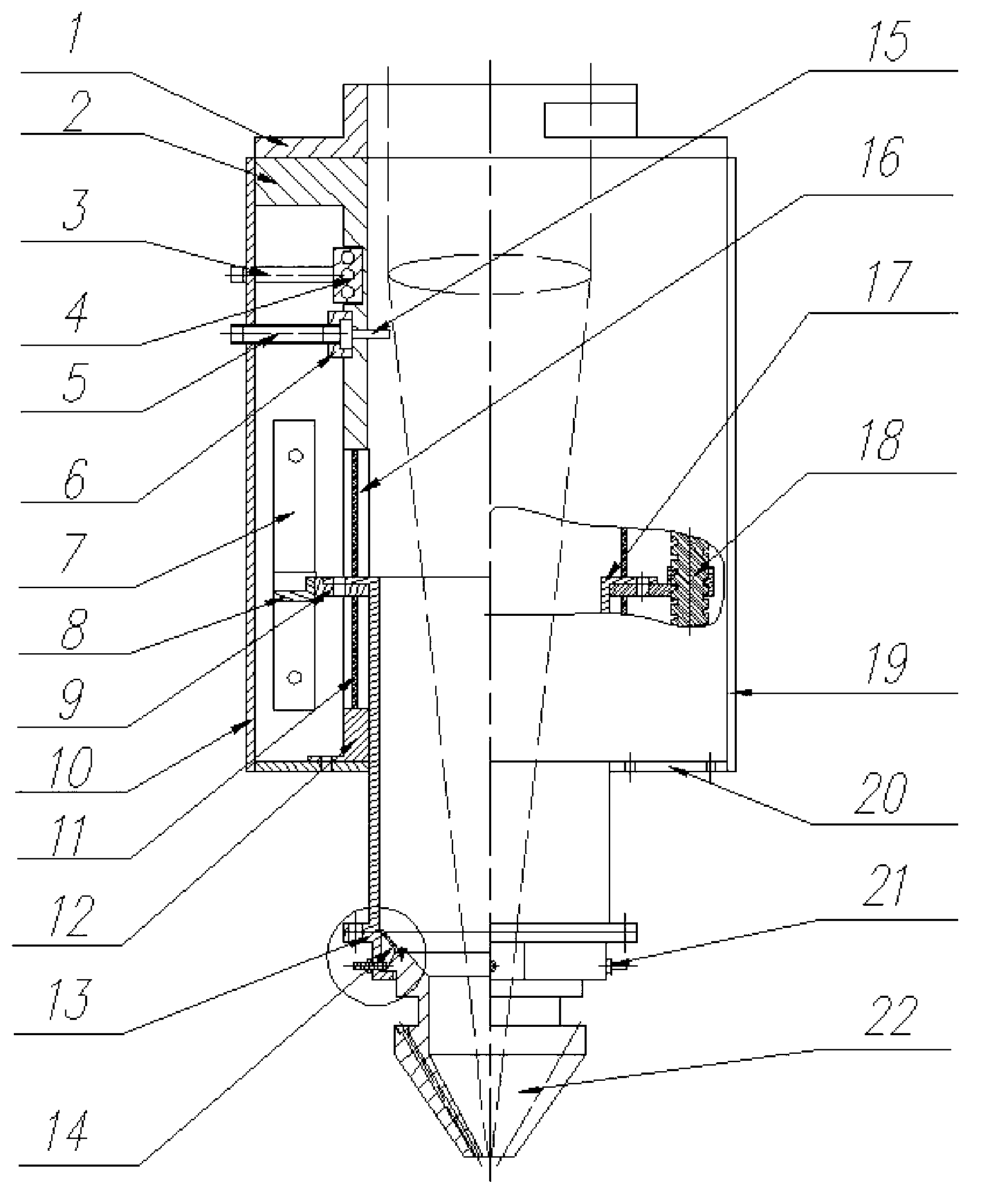

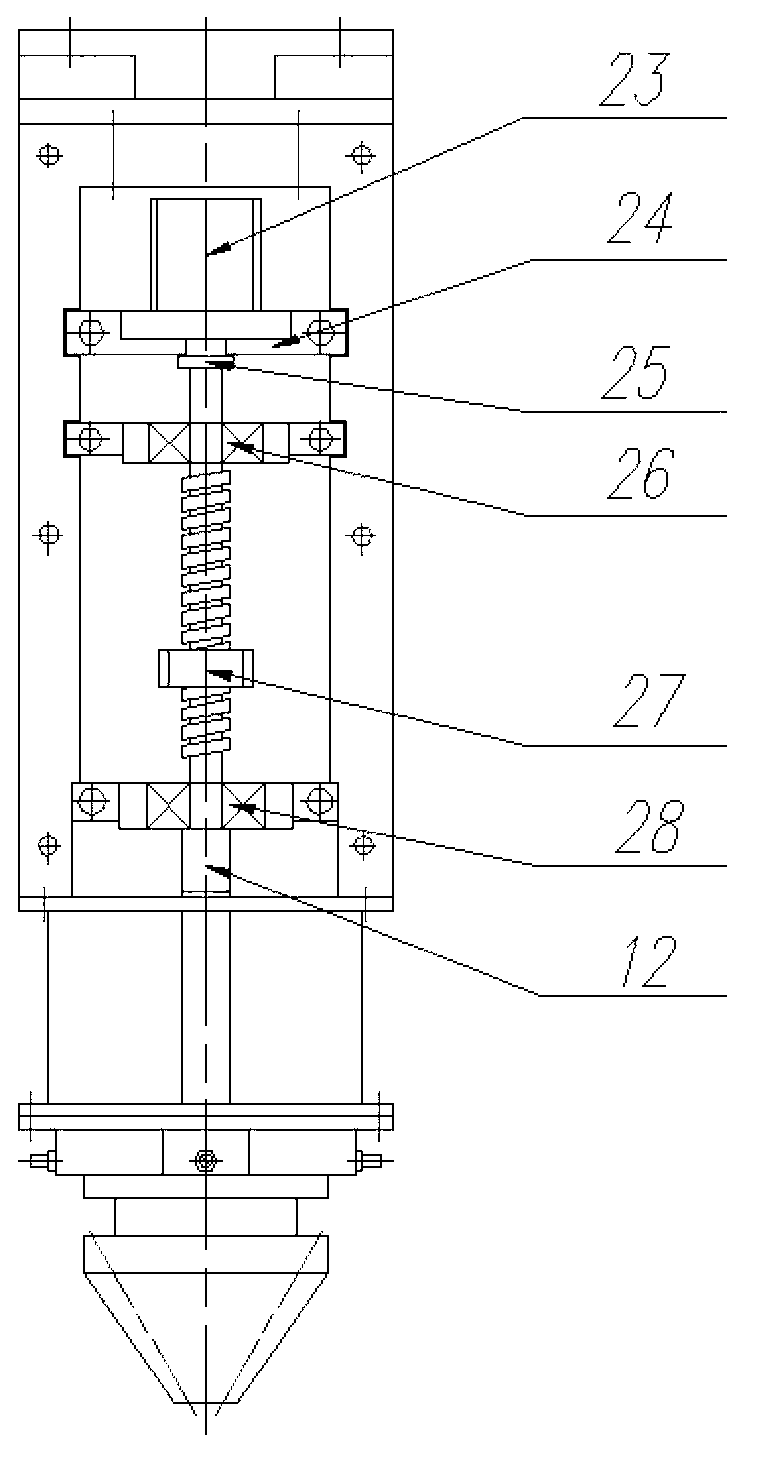

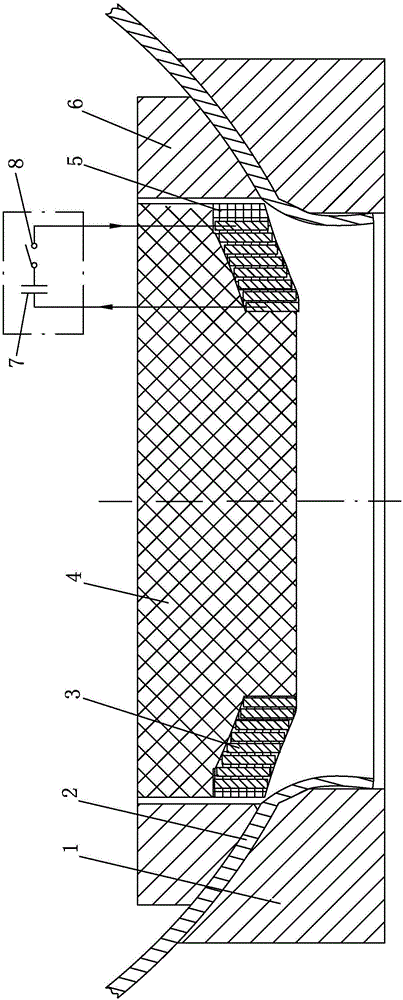

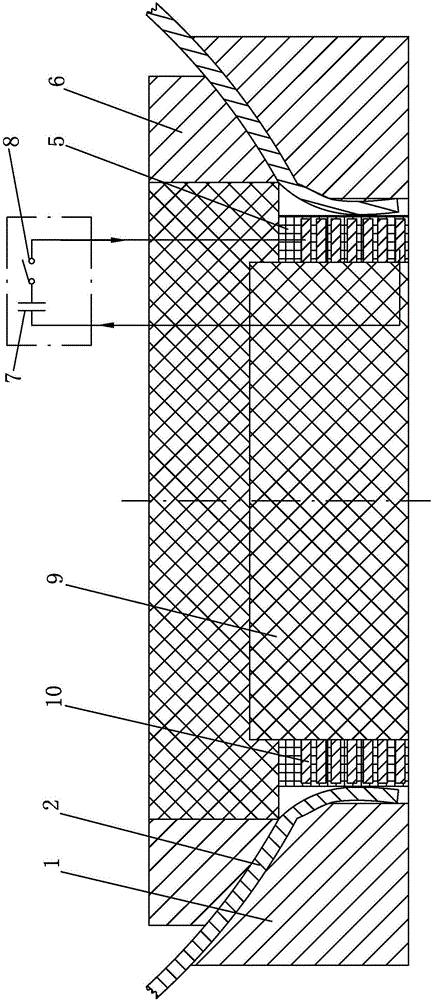

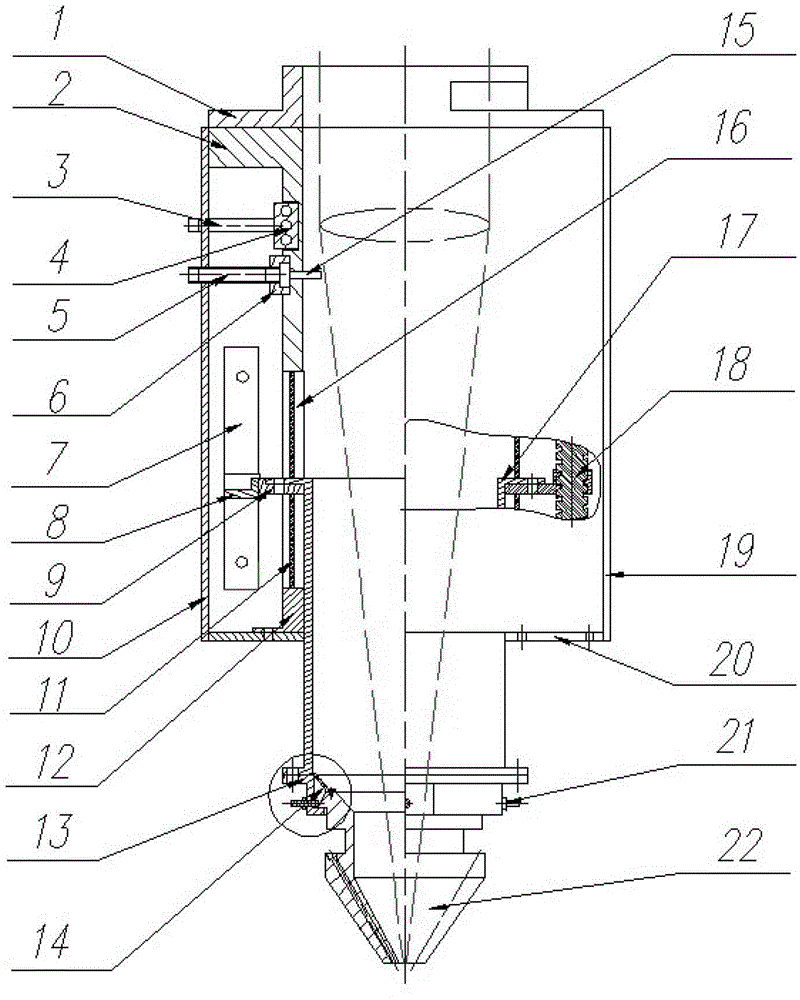

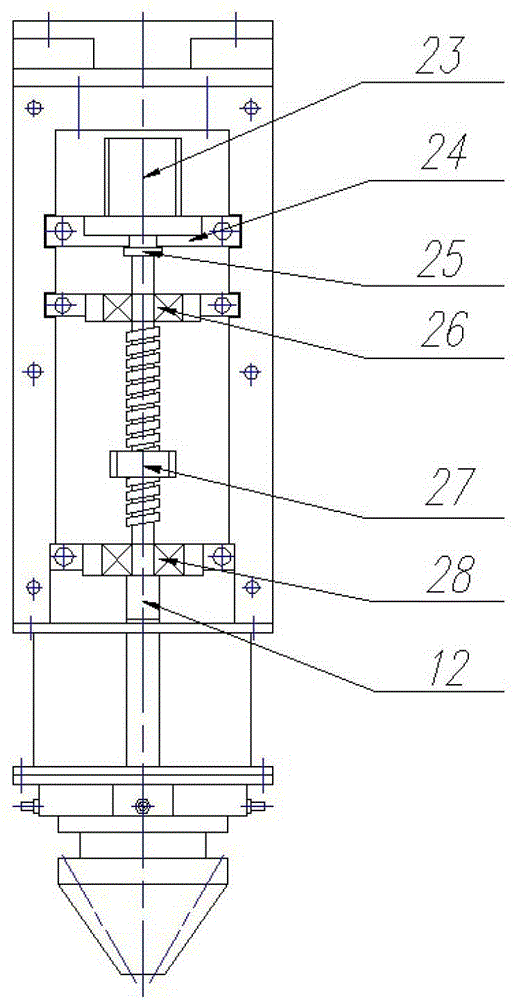

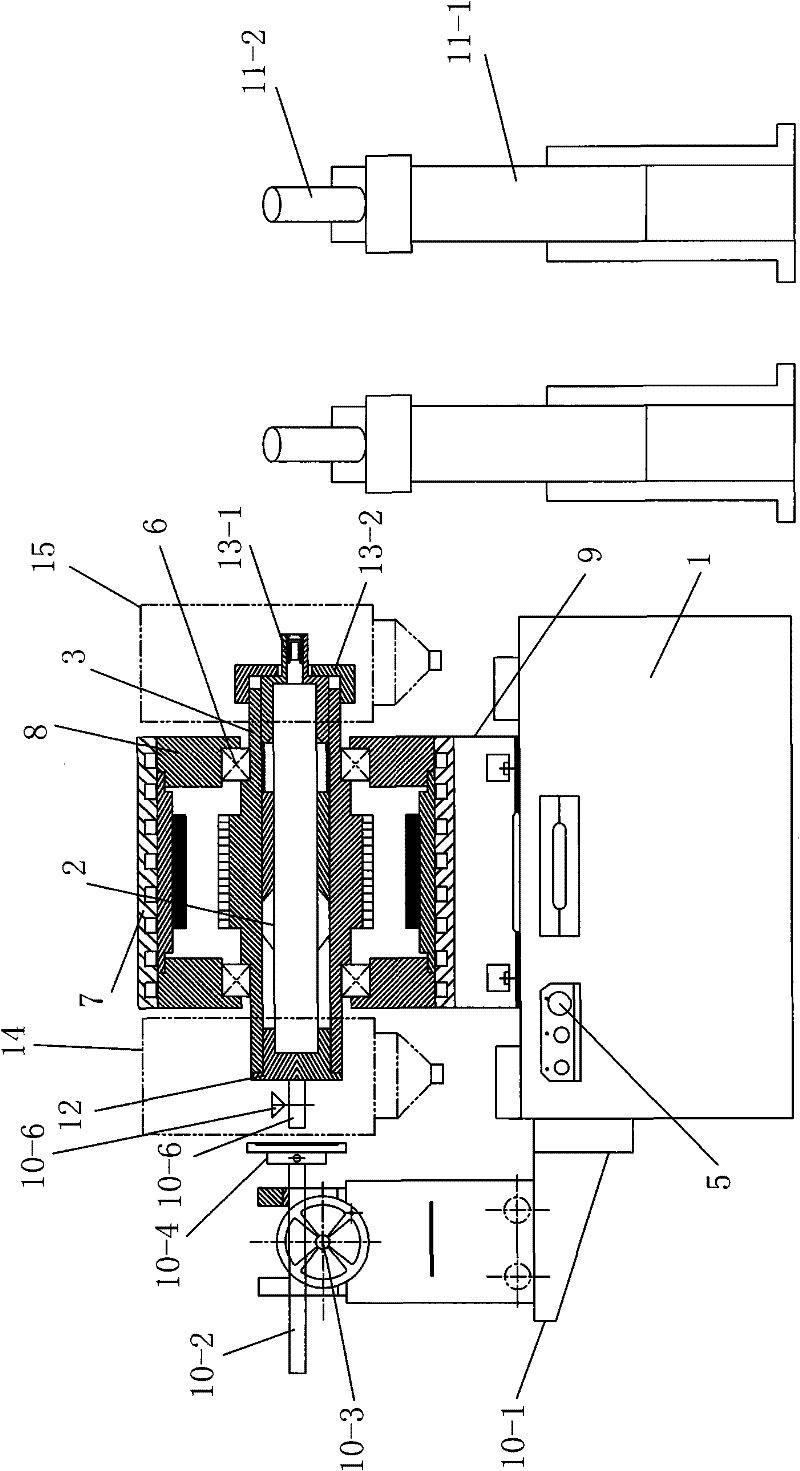

Coaxial powder delivery nozzle applied to variable spot technique

InactiveCN103060801APrecise automatic control of up and down moving distancePrecise guarantee of verticalityMetallic material coating processesLaser beam welding apparatusTemporary variableSpray nozzle

The invention relates to a coaxial powder delivery nozzle applied to a variable spot technique. The nozzle consists of three parts, wherein a first part is a structure for automatically regulating the collection position of powder in the nozzle in the vertical direction, and the part further comprises a cooling water loop and a gas protecting device; a second part is a structure for manually regulating the collection position of the powder in the horizontal diameter direction; and a third part is a powder delivery sprayer structure. The coaxial powder delivery nozzle disclosed by the invention is applicable to the field of material increase manufacturing, and especially applicable to an application place adopting a defocusing manner to realize temporary variable spot formation of laser for realizing both formation efficiency and precision. The coaxial powder delivery nozzle disclosed by the invention can also be applied to the field of laser welding.

Owner:XI AN JIAOTONG UNIV +1

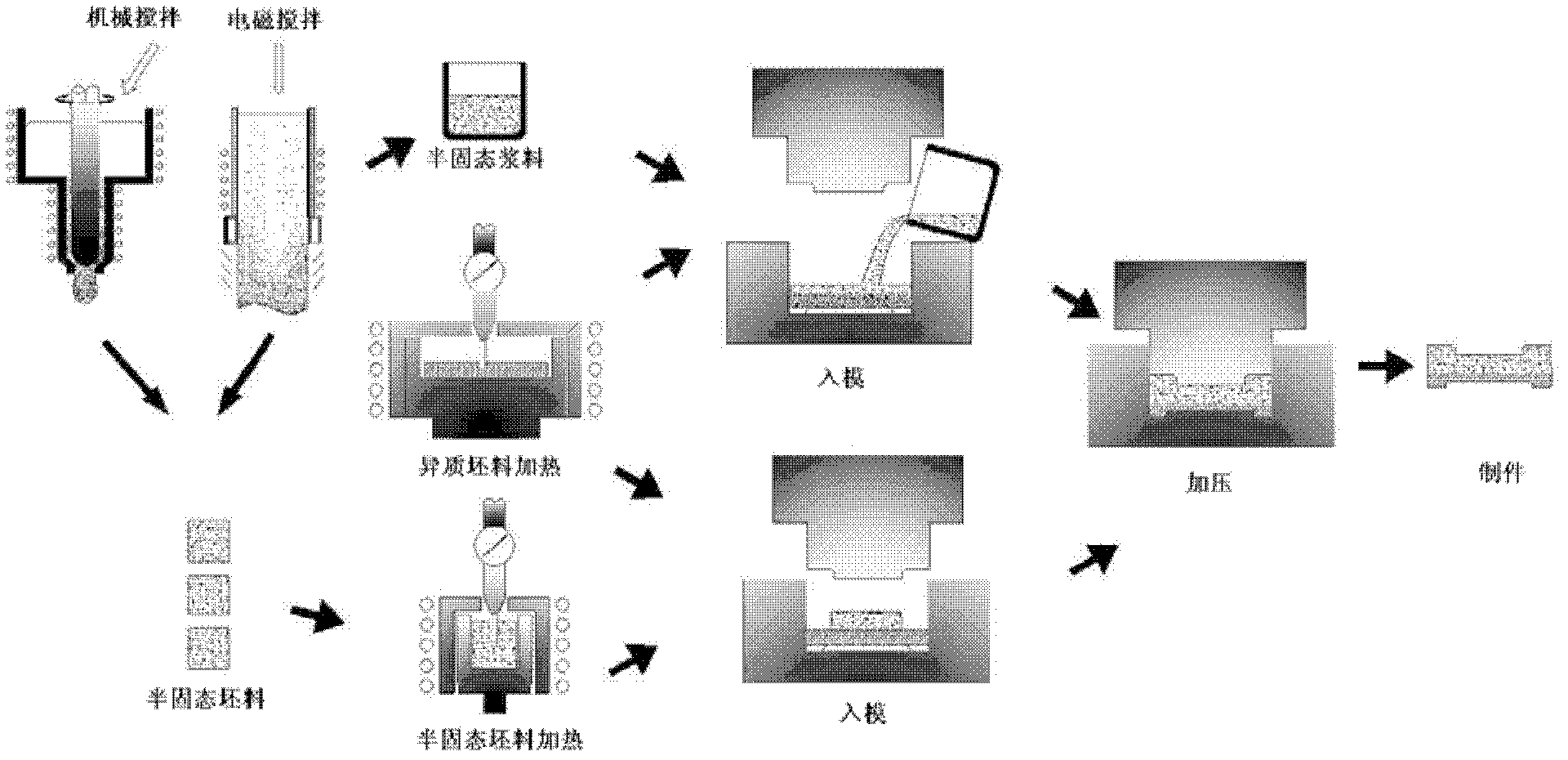

Method for connecting semi-solid materials into whole

A method for connecting semi-solid materials into a whole relates to the technical field of material connection and formation and solves the problem that an existing mechanical connection, glue joint and conventional fusion welding method is difficult to obtain good joint comprehensive performance. The method for connecting the semi-solid materials into the whole includes that 1 two kinds or more than two kinds of pre-connection materials are prepared into semi-solid blank or semi-solid slurry respectively; and 2 the semi-solid blank or the semi-solid slurry prepared in step one is put in a die cavity or below a roller to perform one-time composite formation under pressure. A material interface prepared by the method is good in combination, high in performance, small in product residual stress and high in production efficiency. Semi-solid formation is low in temperature, requirements on die materials are not high, and production environment is good. The semi-solid formation is high in mechanical property, requirements for the mechanical property can be satisfied, and the method for connecting the semi-solid materials into the whole is used in the field of material connection and formation.

Owner:HARBIN INST OF TECH

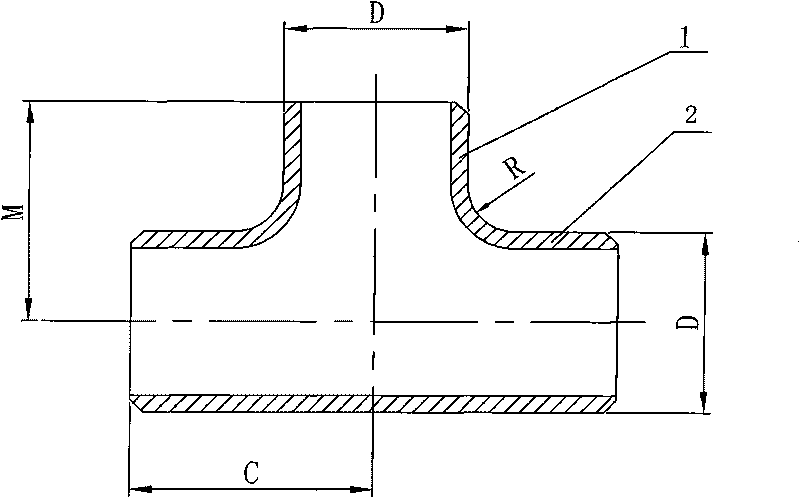

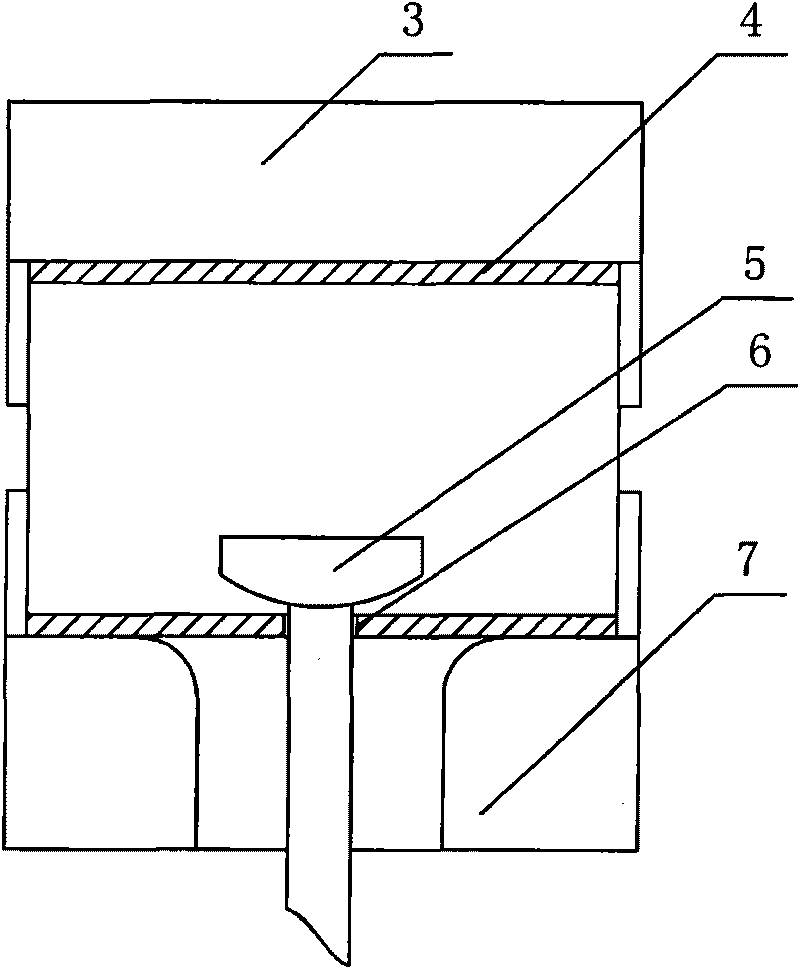

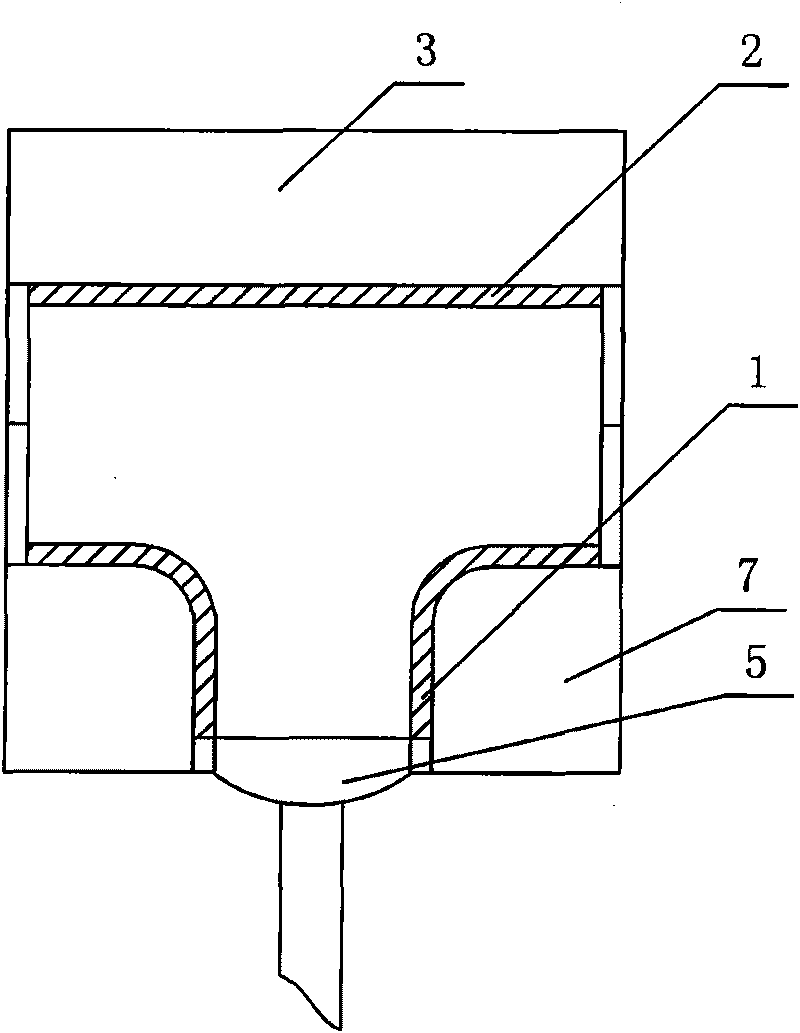

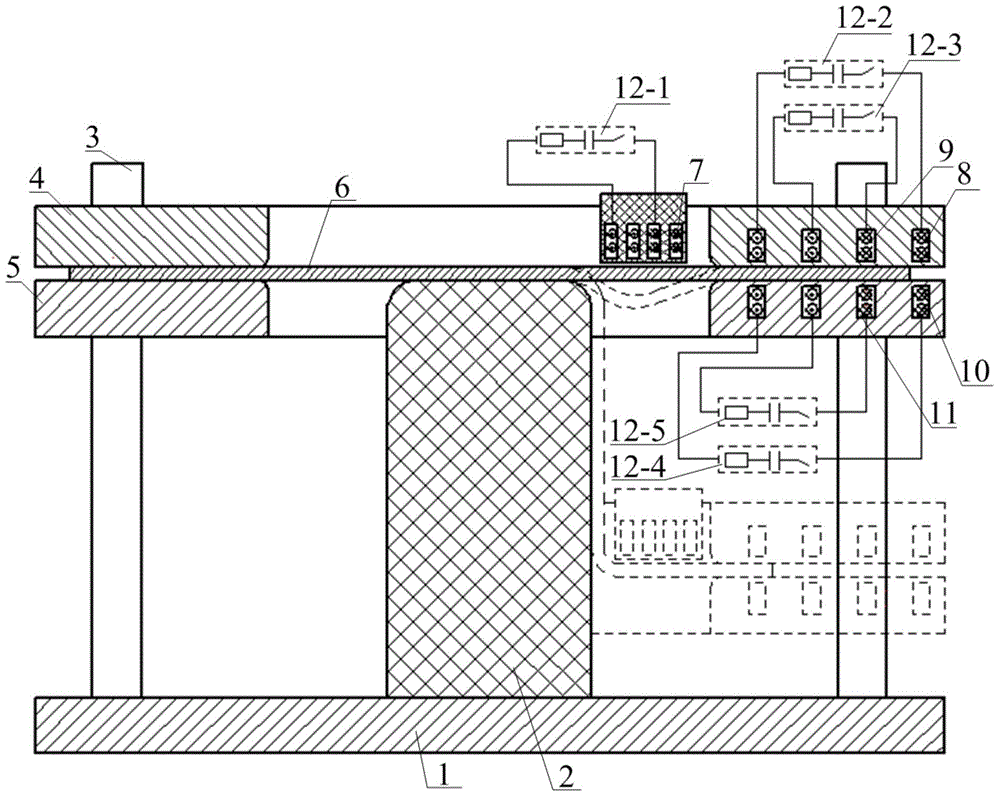

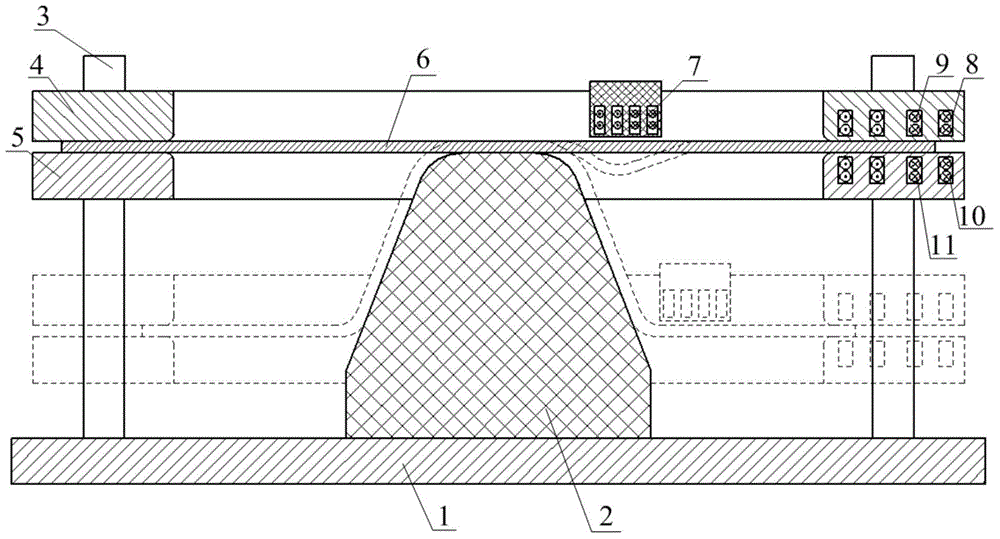

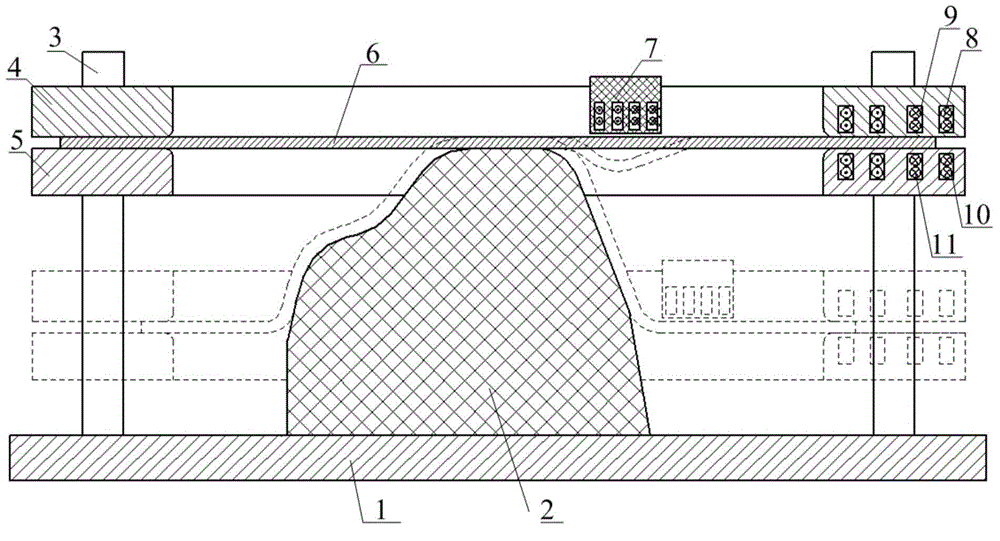

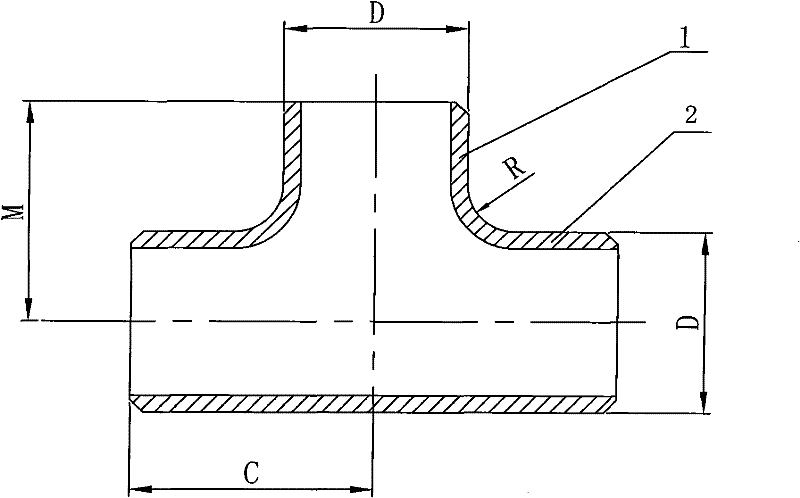

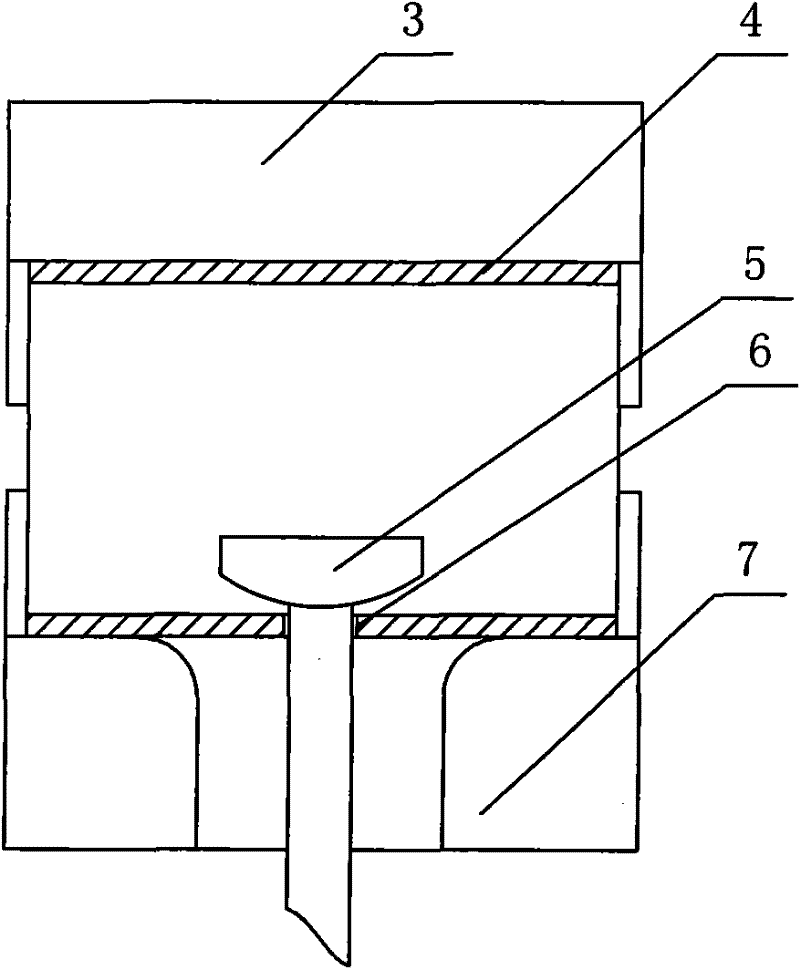

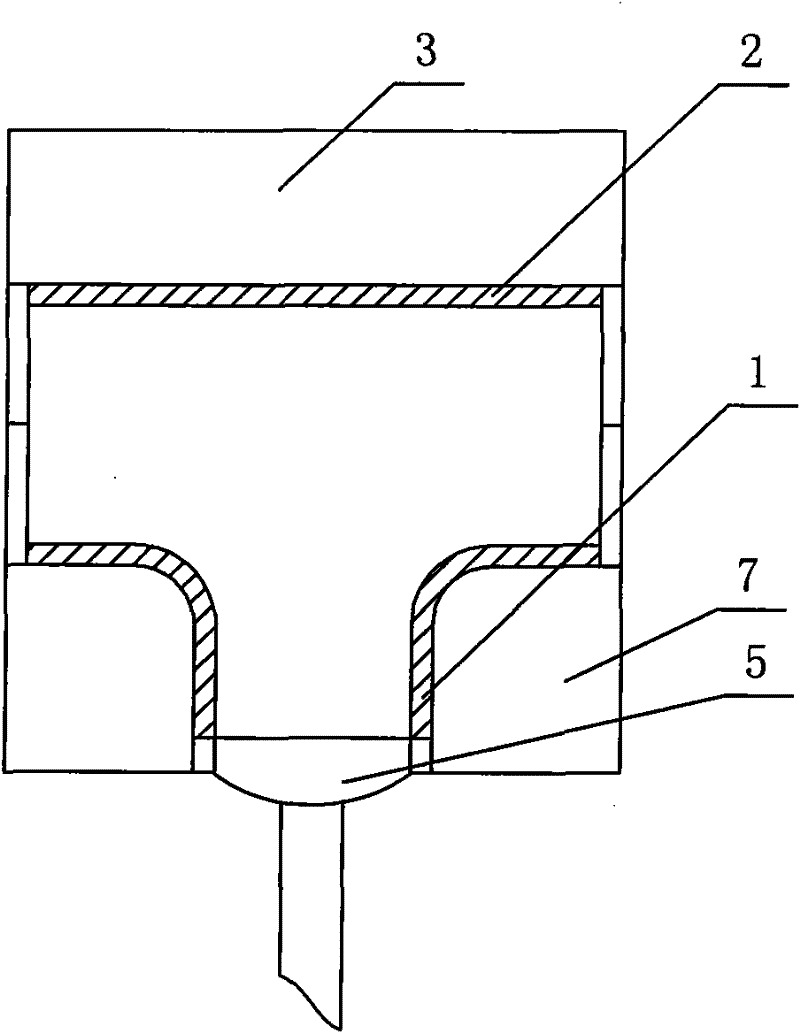

Hot pressing forming mould and hot pressing forming method of super long branch pipe three-way pipe fitting

ActiveCN101704055AGuaranteed tensile deformationSolve forming problemsShaping toolsPipe fittingEngineering

The invention relates to a hot pressing forming mould of a super long branch pipe three-way pipe fitting, comprising a first upper die, a second upper die, a first lower die, a second lower die, a third lower die, a fourth lower die and a draw bar. A primary forming mould consists of the first upper die and the first lower die; a secondary forming mould consists of the first upper die and the second lower die; a third forming mould consists of the first upper die and the third lower die; and a final forming mould consists of the second upper die, the fourth lower die and the draw bar. The invention also relates to a hot pressing forming method which adopts the mould to manufacture the super long branch pipe three-way pipe fitting. Two upper dies and four lower dies are adopted by the invention to be drawn and extruded step by step into a super long branch pipe; in each hot pressing forming process, the tensile deformation of the materials is ensured to be within the tensile rate limit by controlling the root R and the outer diameter D of the branch pipe to be decreased successively, thereby solving the forming problem of super long branch pipe tee (M>1.5C).

Owner:WUXI XINFENG TUBE IND

Magnetic pulse flanged hole method for shells

The invention relates to shell flanged hole part forming methods, in particular to a magnetic pulse flanged hole forming method for shells. The method aims at solving the problems that in the flanged hole manufacturing process of an existing steel die hole flanging method, the technology is complex, the production efficiency is low, and the production cycle is long. The method comprises the steps that firstly, the shape of a flanged hole coil bobbin is designed according to a curved surface shell with pre-manufactured holes; secondly, the curved surface shell with the pre-manufactured holes is arranged on a flanged hole forming female die, an edge pressing ring is arranged on the inner surface of the curved surface shell in the periphery direction, a hole flanging coil matched with the hole flanging deforming area is wound on the flanged hole coil bobbin, covers the hole flanging deforming area and is attached to the hole flanging deforming area, one end of a capacitor set is connected with one terminal of the hole flanging coil, the other end of the capacitor set is connected with one end of a gap switch, the other end of the gap switch is connected with the other terminal of the hole flanging coil, and the capacitor set is charged to reach the preset voltage value; thirdly, magnetic pulse flanged hole forming is carried out; fourthly, flanged holes are corrected. The method is used for forming flanged hole parts of shells.

Owner:HARBIN INST OF TECH +1

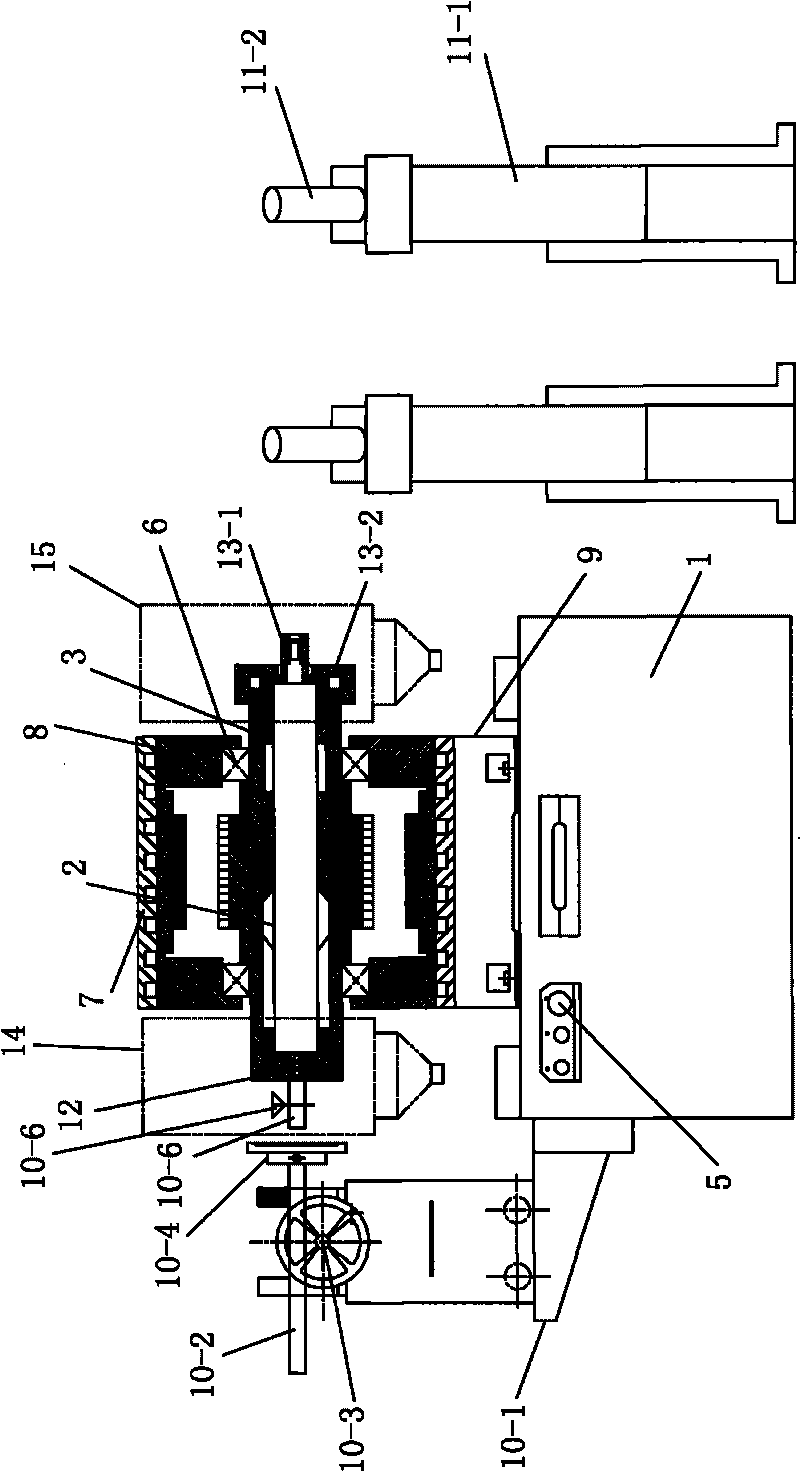

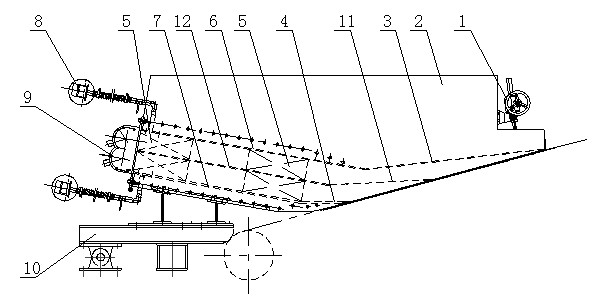

Metal plate electromagnetic pulse local flow incremental forming device and method

InactiveCN104475531AOvercome the flaw of crackingImprove plastic fluidityShaping toolsMetal-working feeding devicesElectromagnetic pulseEngineering

The invention discloses a metal plate electromagnetic pulse local flow incremental forming device which comprises a base, a mould forming mechanism, a pressing plate and an electromagnetic forming coil, wherein the mould forming mechanism is arranged on the base, the pressing plate is matched with the mould forming mechanism and used for pressing a plate, and the electromagnetic forming coil is driven to move by a power device. A radial side push coil for applying thrust to the outside edge of the plate is mounted on the pressing plate and / or the mould forming mechanism, and a power system supplies power for the electromagnetic forming coil and the radial side push coil. The local area of the plate has small deformation by the aid of the electromagnetic forming coil and the radial side push coil in each discharging process, so that the requirement for the sizes of the coils and equipment energy is reduced, and the device solves the problem that traditional large plate forming needs a high-cost forming device.

Owner:HUAZHONG UNIV OF SCI & TECH

Rapid shaping method for manufacturing metal laminated solid mass

InactiveCN101480753ASolve forming problemsShorten forming timeResistance welding apparatusElectrical resistance and conductanceSolid mass

A fast forming method for the manufacture of a metal laminated entity comprises the following steps of establishing a CAD geometrical model for metal parts, finishing the inner hole cutting of a metal sheet layer in a first work station through a laser cutting system, rejecting the wastes in the inner hole, welding the metal sheet with a metal sheet thereunder in a second work station through a welder, finishing the cutting of peripheral outline of the metal sheet layer in the second work station through the laser cutting system, and repeating the process between the steps 2 and 6 by moving a lifting working platform downwards (negative direction of Z) with a pace, until the metal sheets in the work piece are completely bonded or welded so as to obtain a formed work piece of metal laminated entity. Compared with the prior art, the invention thoroughly solves the forming problem of the parts with spatially totally-enclosed holes so as to greatly save time, can weld the metal sheet in each layer by smoothly using an electrical welding method, and remarkably improves the mechanical performance of the parts.

Owner:SHENZHEN UNIV

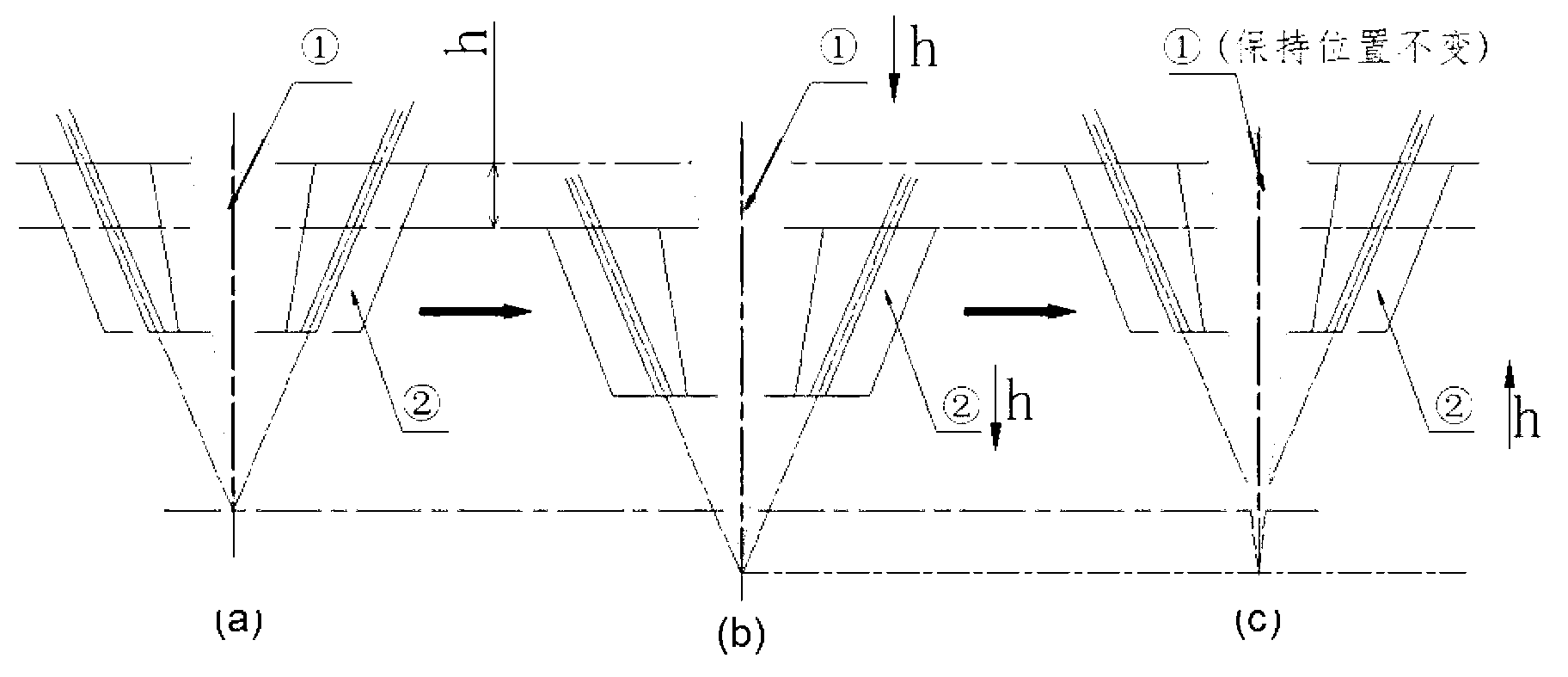

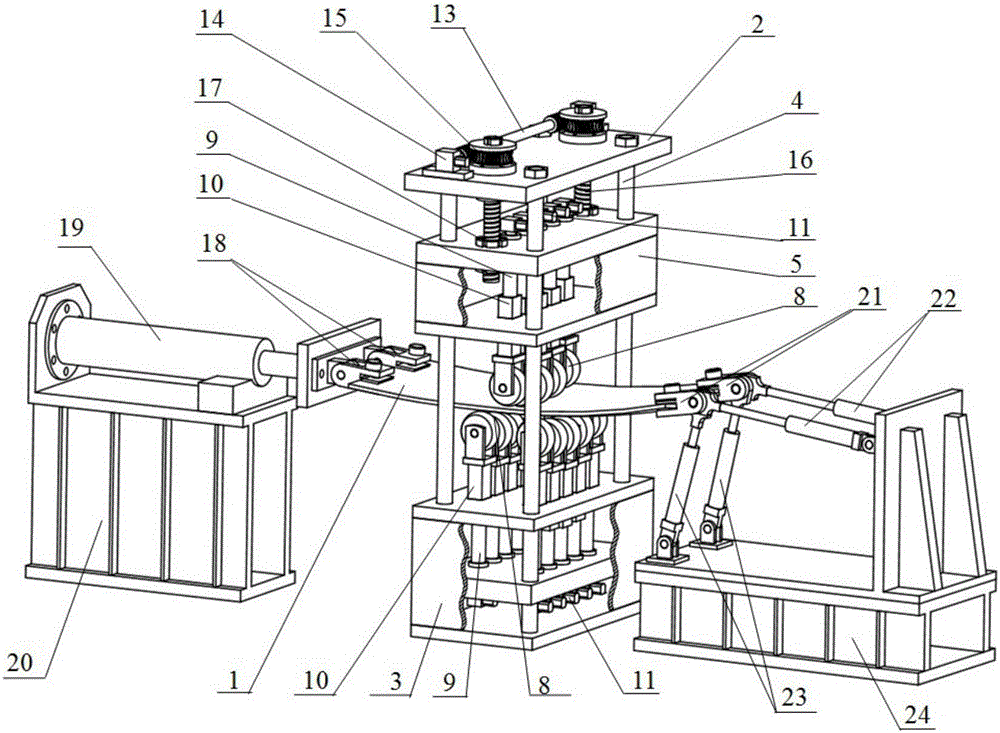

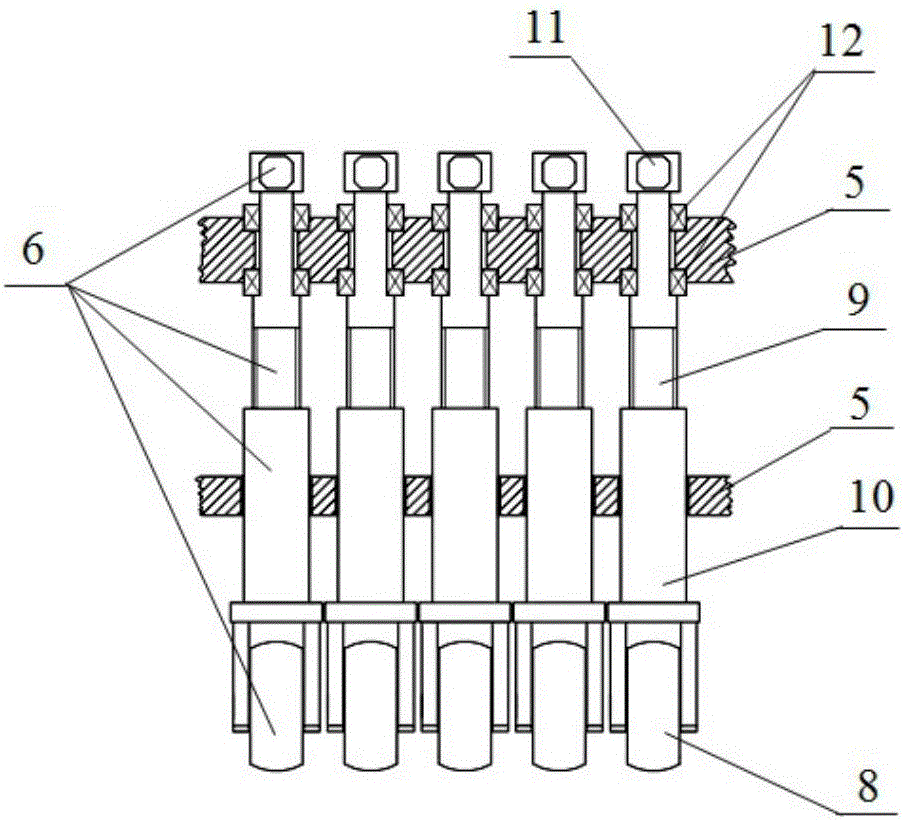

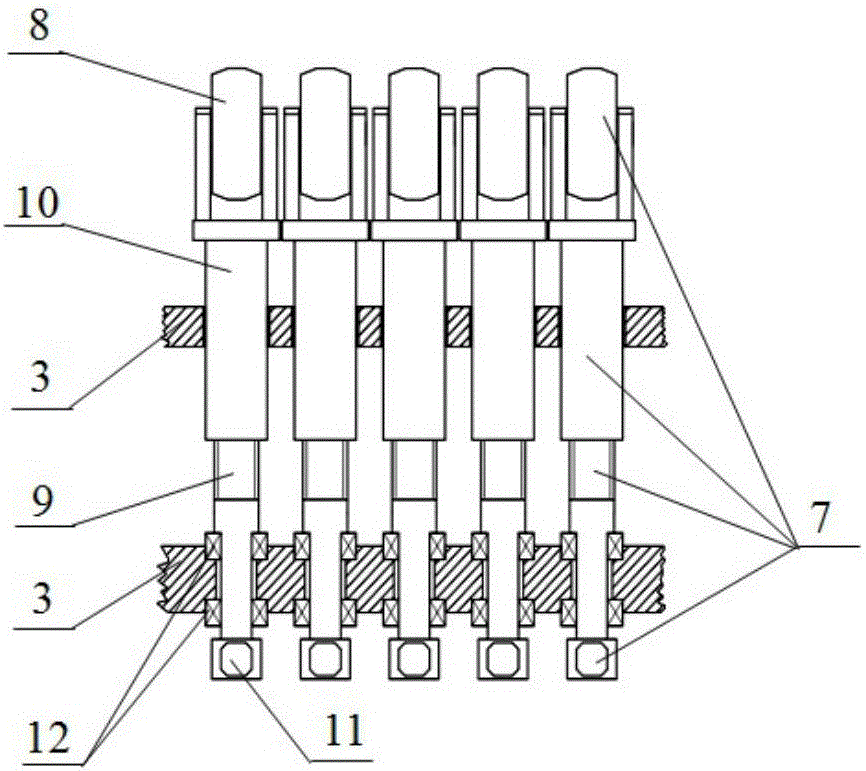

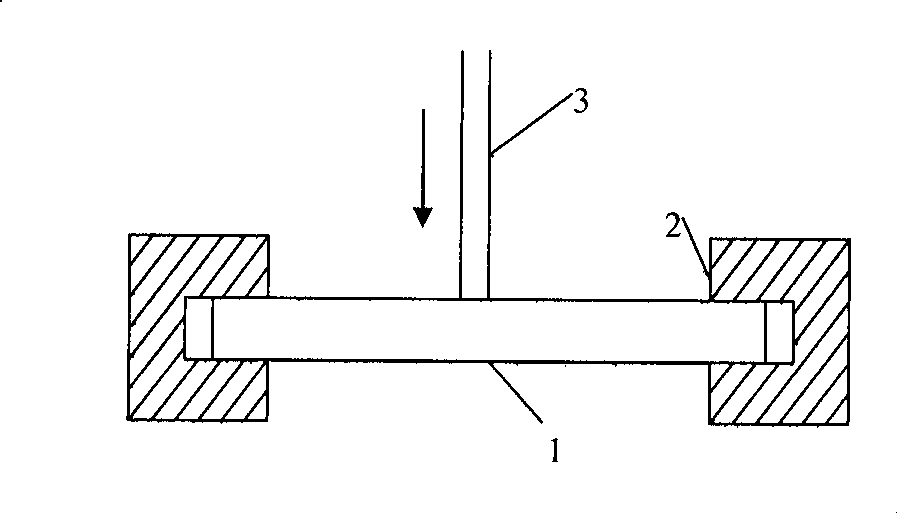

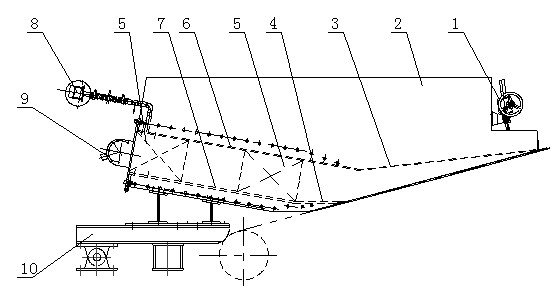

Continuous forming device for metal composite thick plate three-dimensional curved surface

ActiveCN106734415ASimple structureLow costMetal-working feeding devicesPositioning devicesEngineeringMetal

The invention provides a continuous forming device for a metal composite thick plate three-dimensional curved surface. The forming problem of the metal composite thick plate three-dimensional curved surface is solved. A plurality of rollers with the heights being adjustable which are arranged in the axial direction are adopted to form roller sets. One upper roller set and two lower roller sets serve as forming tools of a metal composite plate material. Vertically bending deformation of a contact area plate material is obtained through three-point bending of the upper roller set and the lower roller sets, and the heights of the rollers in the roller sets are changed to form a roller set curve outer contour to obtain horizontal bending deformation of the contact area plate material. By means of a pushing mechanism and a pulling mechanism, continuous feeding of the plate material is achieved, and therefore, the double-curvature metal composite thick plate three-dimensional curved surface is continuously formed. The continuous forming device is simple in structure, low in construction cost and good in flexibility. A curved surface is formed through two-way bending, a mould is not needed, and no-mould forming of different shapes of curved parts can be conducted on one piece of equipment. Due to the adoption of the mode of continuous forming, the continuous forming device is applicable to curved surface machining of a large-scale composite plate.

Owner:JILIN UNIV

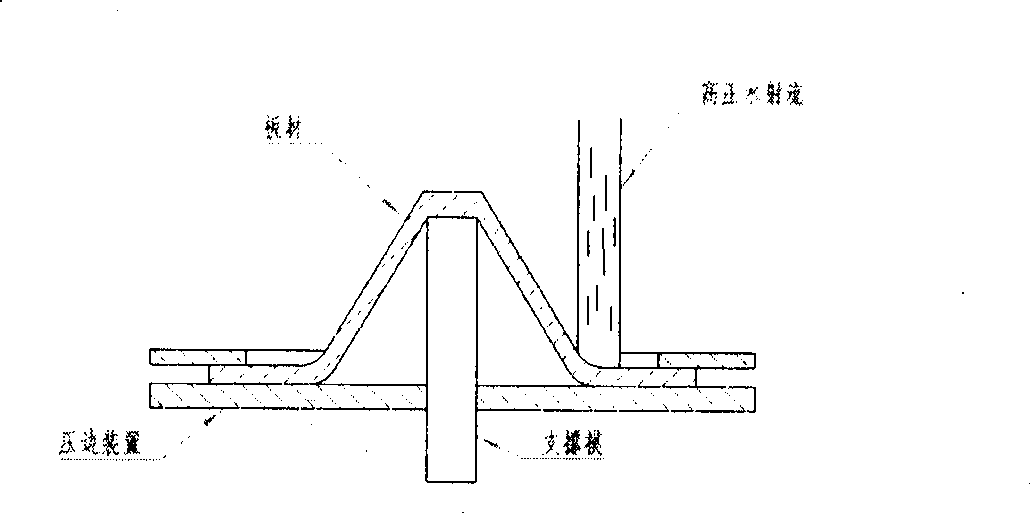

Water-jet asymptotic shaping method of sheet

The invention relates to a water-jet asymptotic forming method of plates, which is the method for processing and forming the plates by utilizing high-pressure water jet and belongs to the mechanical engineering field. The invention can solve the forming problem of plates with small batch and multiple varieties and is characterized in that the high-pressure water jet with large flow is adopted and the high-pressure water jet, the pressure and the flow rate as well as the flow of which can be controlled is jetted to the surfaces of the plates through a nozzle of an injection device to form the plates; the plates are fixed on a working table and move along a preset deformation path under the control of a digital control device; the injection device moves up and down along the vertical direction so as to adjust the working range of the high-pressure water jet. Plates of arbitrary shapes can be formed by adopting the method.

Owner:程晓民

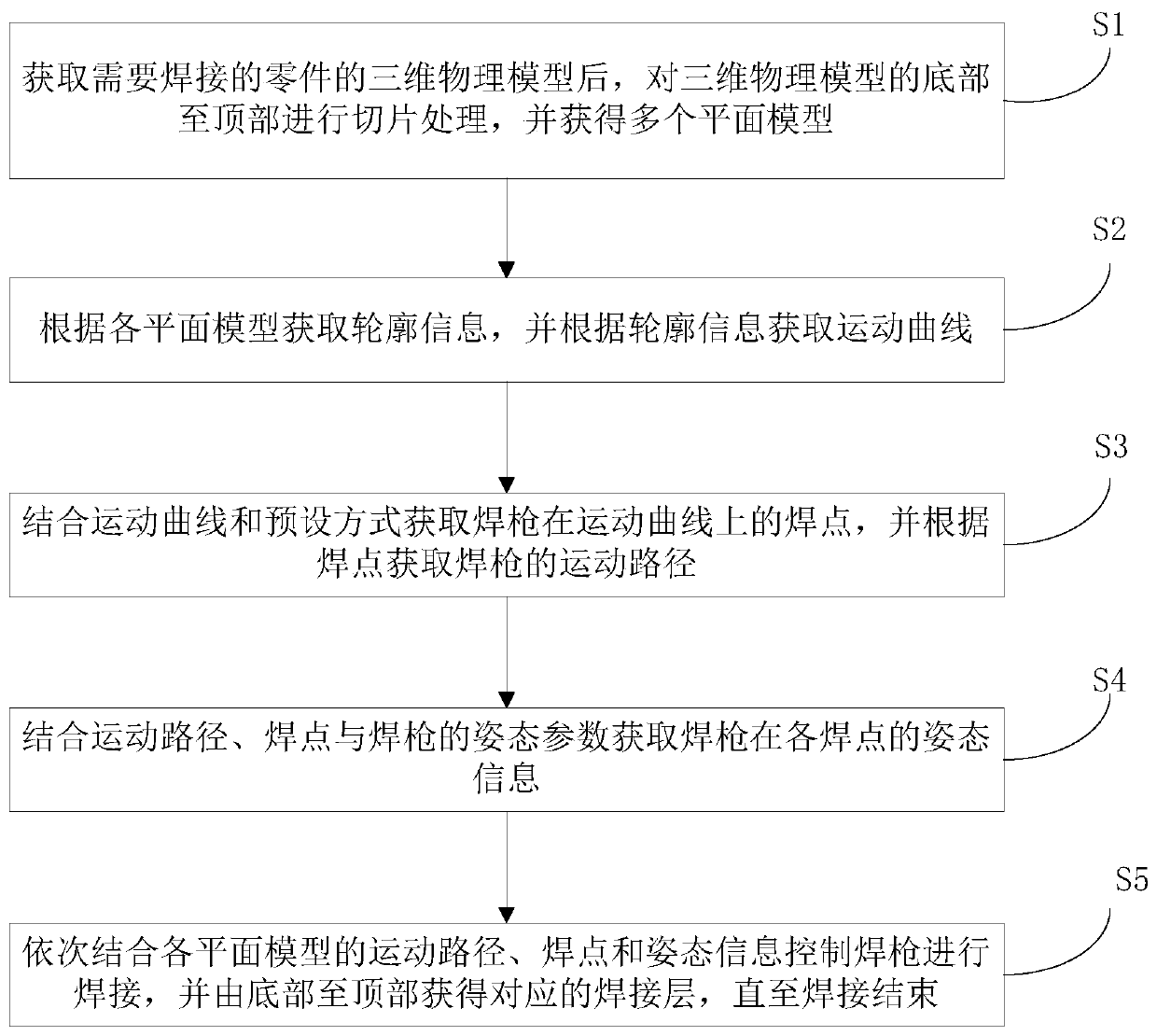

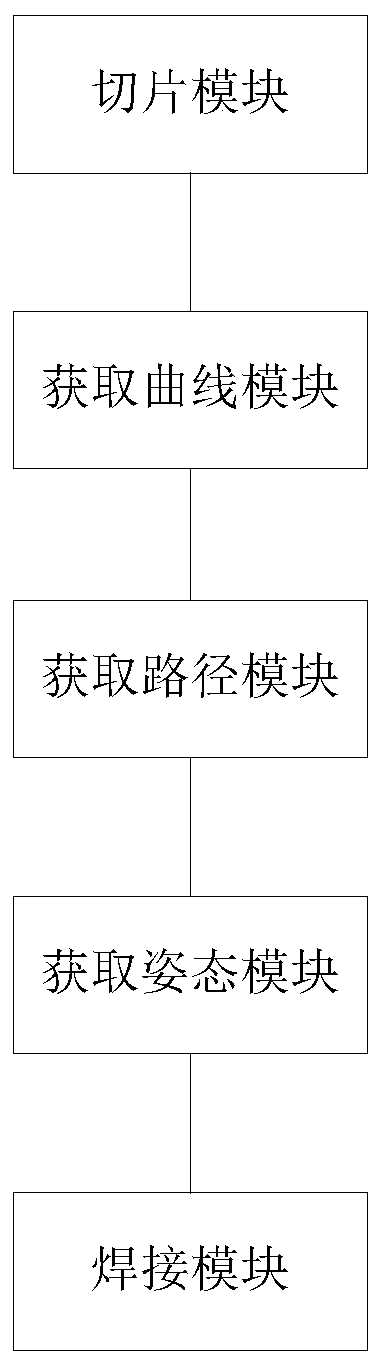

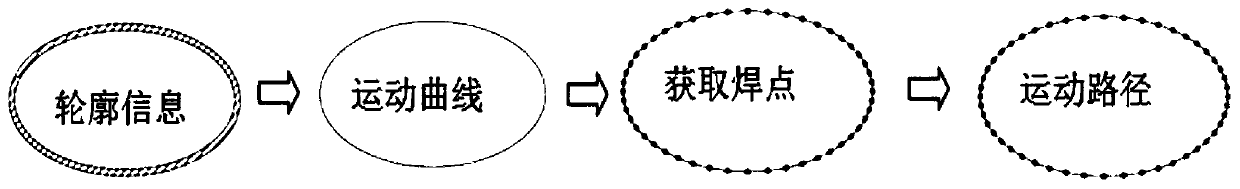

Control method, system and device for electric arc additive manufacturing

InactiveCN109702294AMeet the requirements of welding complex partsQuality improvementWelding accessoriesPhysical modelEngineering

The invention discloses a control method, a system and a device for electric arc additive manufacturing. The method comprises the following steps that after a three-dimensional physical model of partsneeding to be welded is obtained, slicing processing is carried out on the three-dimensional physical model from the bottom to the top, and a plurality of plane models are obtained; the contour information is obtained according to the plane models, and a motion curve is obtained according to the contour information; welding points of a welding gun on the motion curve are obtained in combination with a motion curve and a preset mode, and a movement path of the welding gun is acquired according to the welding points; the movement path, and the posture parameters of the welding points and the welding gun are combined to acquire the posture information of the welding gun at each welding point; and the welding gun is controlled to be welded through combining the movement path, the welding points and the posture information of all the plane models in sequence, and corresponding welding layers are obtained from the bottom to the top until the welding is finished. According to the control method, the system and the device, the welding gun can automatically weld some complex curved parts, so that the welding quality is improved, and the method can be widely applied to the field of additivemanufacturing.

Owner:深圳市智能机器人研究院

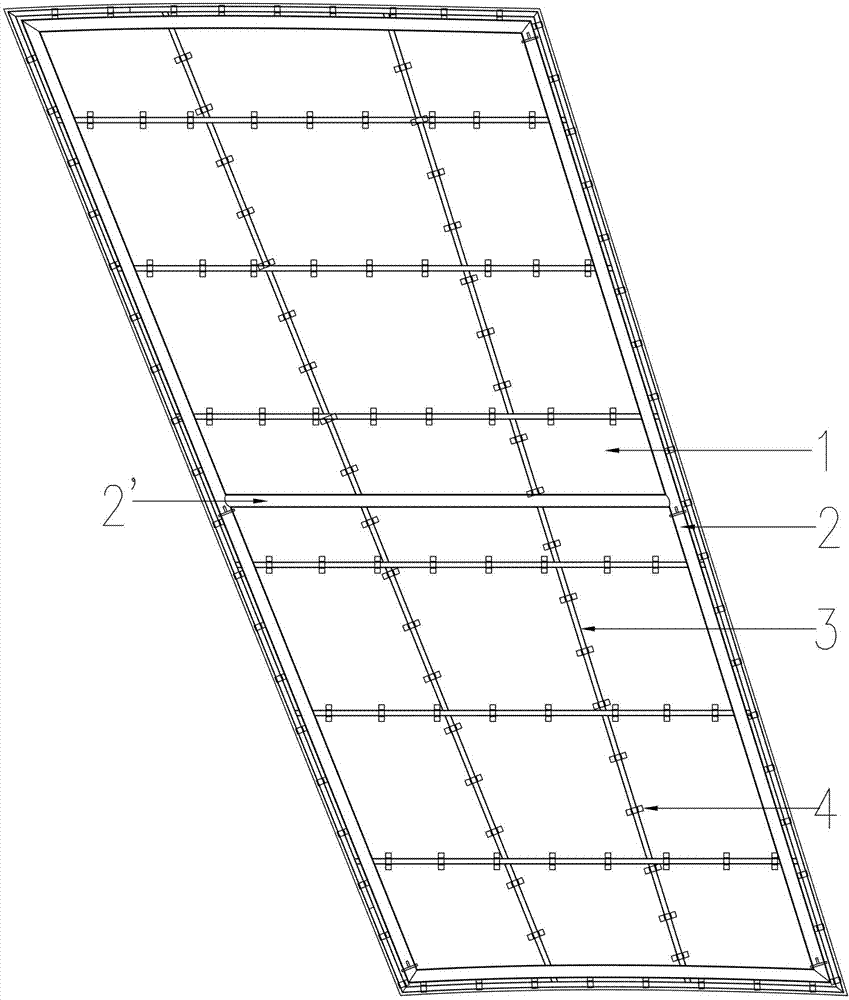

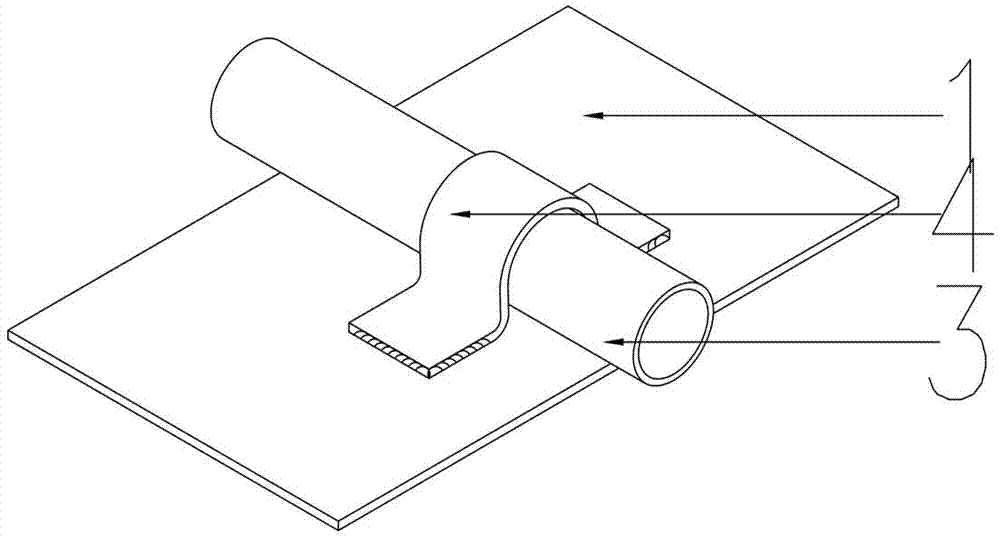

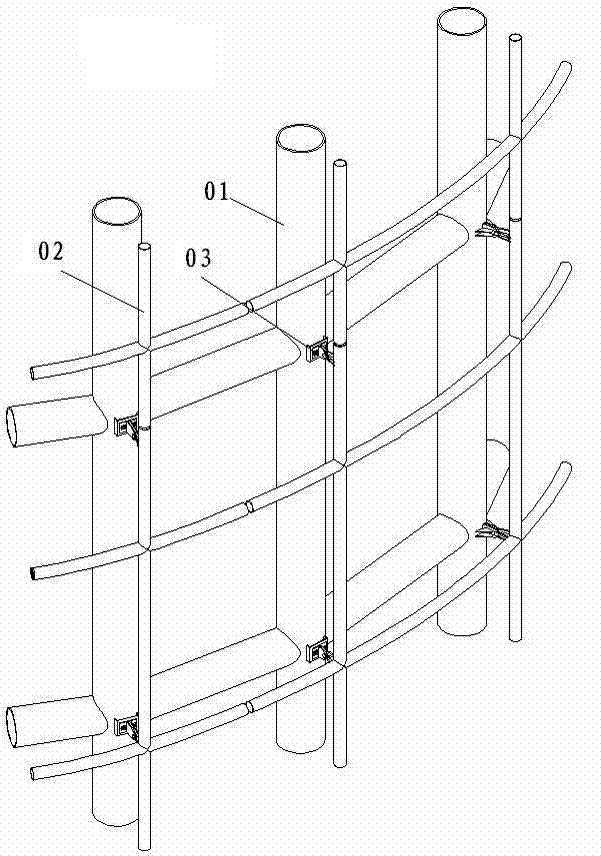

Large-grid non-mold molded welding metal curtain wall and forming process thereof

The invention provides a large-grid non-mold molded welding metal curtain wall comprising a stiffening rib which is a metal frame, wherein a metal plate covers the stiffening rib; the metal plate is closely attached with the stiffening rib; and the metal plate is welded on the metal frame or fixed on the metal frame through a fastener. The invention also provides a forming process of the metal curtain wall, comprising the steps of fabricating the stiffening rib system, processing the metal plate with the predetermined shape and shaping the metal plate with any shape on the stiffening rib through a non-mold molding forging process, so that the stiffening rib is connected with the metal plate, and the metal plates in at least one part or all of the metal plate units on the metal curtain wall can be welded into a whole. According to the large-grid non-mold molded welding metal curtain wall, the metal curtain wall in any shape can be fabricated without fabricating a special die, so that a large-grid or ultra-large-grid or seamless metal curtain wall is formed.

Owner:JANGHO GRP

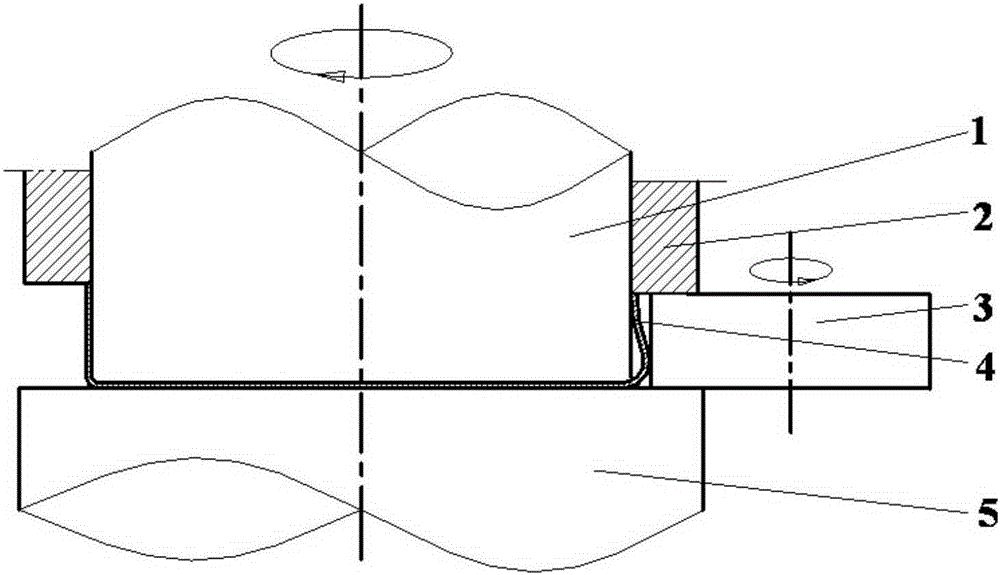

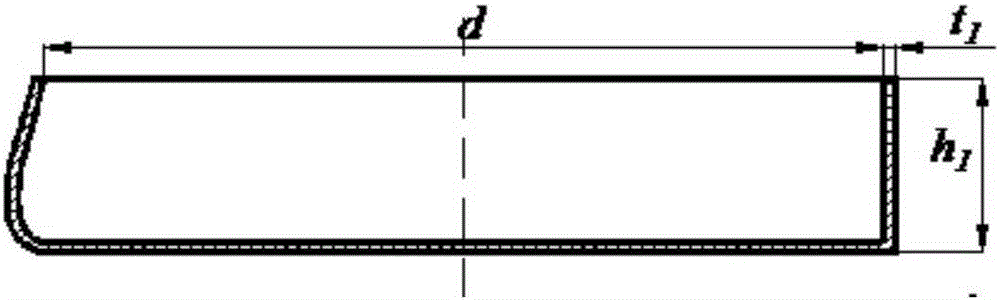

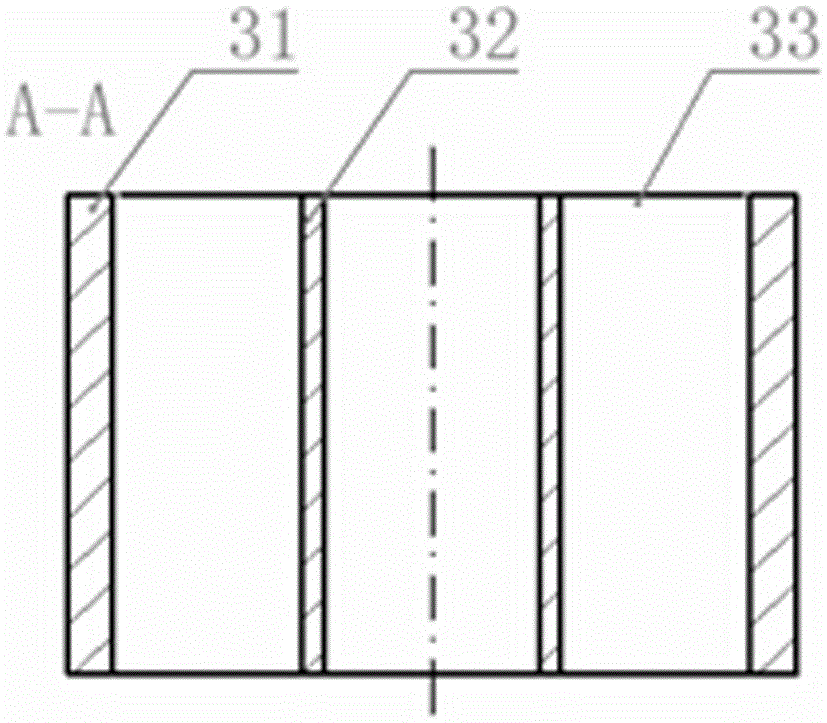

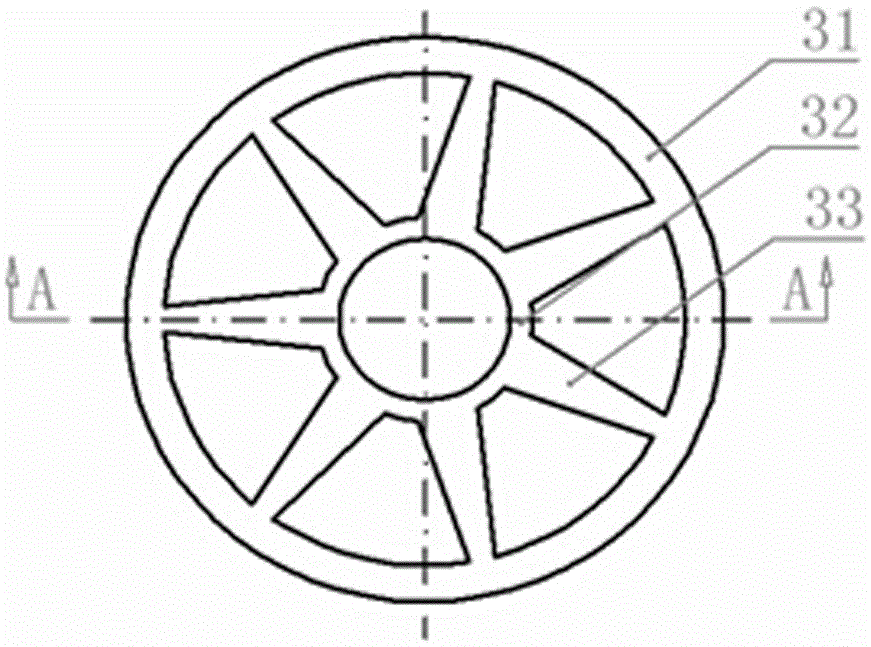

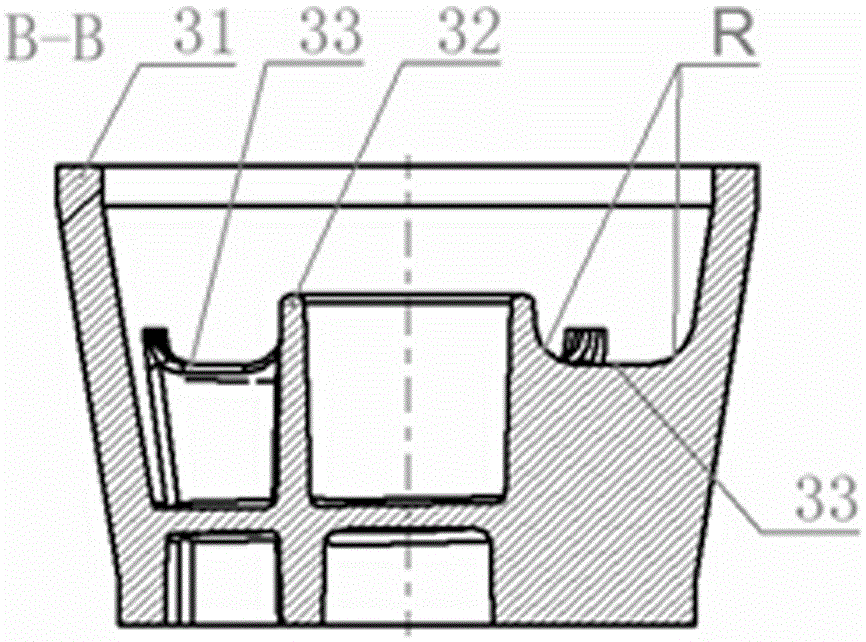

Centrifugal film coating apparatus

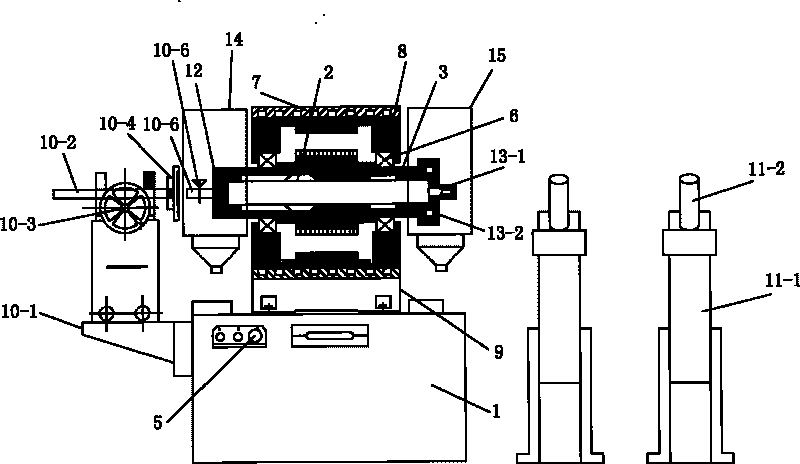

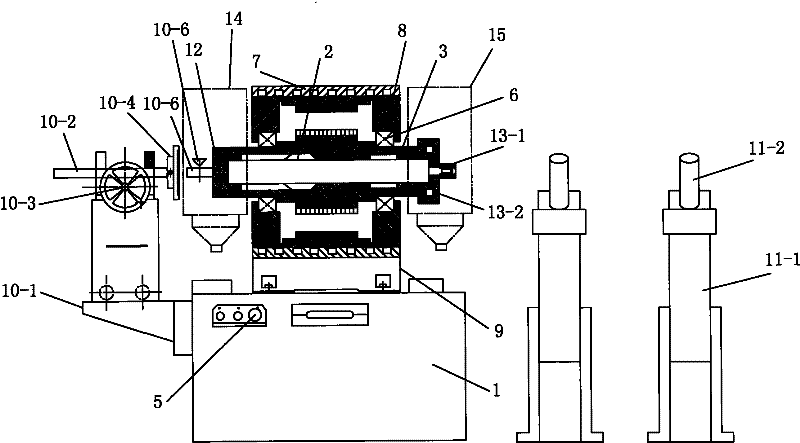

ActiveCN101722137ASimple structureEasy to operateLiquid surface applicatorsCoatingsLow noiseGranularity

The invention discloses a centrifugal film coating apparatus, which comprises a base and a centrifugal film coating device arranged on the base. The centrifugal film coating device comprises a film coating tool, a transmission sleeve shaft, a drive motor and a drive control system, wherein the film coating tool is arranged in the horizontal direction, continuously rotates and simultaneously drives internal materials to carry out centrifugal motion; the transmission sleeve shaft is coaxially sleeved outside the film coating tool and drives the film coating tool to continuously rotate; the drive motor is connected with the transmission sleeve shaft; the drive control system controls and adjusts the rotating direction and the rotation of the drive motor; and the left end part and the right end part of the transmission sleeve shaft have openings and the right ends of the left end part and the right end part are assembled with a U-shaped compressing member through a plugging member, and the left end is assembled through a Pi-shaped compressing member. The invention has the advantages of simple structure, simple and convenient using operation, low noise, safe and reliable operation, recyclable slurry, high rotation speed and high efficiency, can completely meet the technical requirement on molding centrifugal classification deposition, and solves the actual problem that the powder with different granularities is deposited in turn.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Double-heat-source collaborative welding method and device for large thermal conductivity mismatched metal materials

ActiveCN108436234AImprove welding qualityControl soldering temperatureArc welding apparatusWelding/soldering/cutting articlesThree-dimensional spaceHeat losses

The invention discloses a double-heat-source collaborative welding method and device for large thermal conductivity mismatched metal materials, and belongs to the field of metal material welding. Whenwelding the large thermal conductivity mismatched metal materials, the method adopts two heat sources to simultaneously heat the front and back sides of joints and optimizes energy distribution of the joints by controlling energy parameters and positional parameters of the two heat sources, side heat input of high thermal conductivity metal is increased, the heat loss caused by the higher thermalconductivity is compensated, the low thermal conductivity metal side welding temperature is controlled, and the problem of large thermal conductivity mismatched metal material welding forming is solved and the joint welding quality is improved. The preheating effect of the joints is obtained by tilting the two heat sources on the front and back sides at a certain angle in the welding direction, and the single-pass welding double-sided forming of the joints is realized under auxiliary measures such as no chamfering and pre-weld preheating. The welding device can effectively adjust and controlthe heat distribution of the joints by precisely controlling the position of the welding heat sources in the three-dimensional space, and efficient and reliable connection of the large thermal conductivity mismatched metal materials is realized.

Owner:UNIV OF SCI & TECH BEIJING

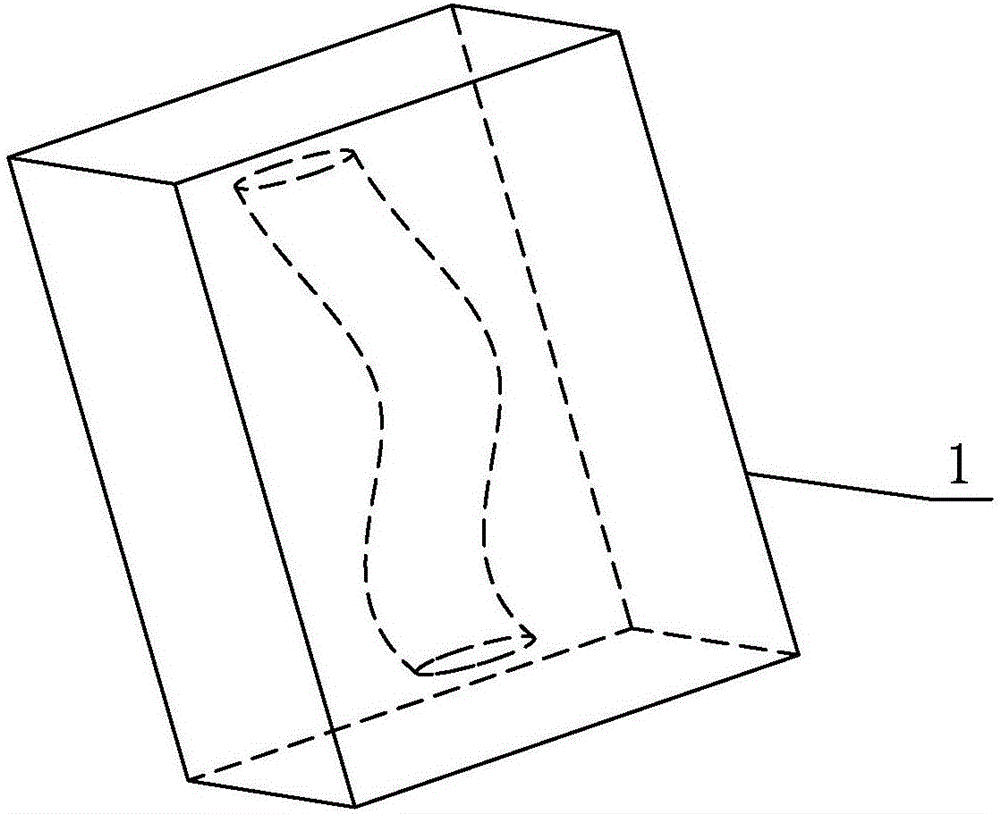

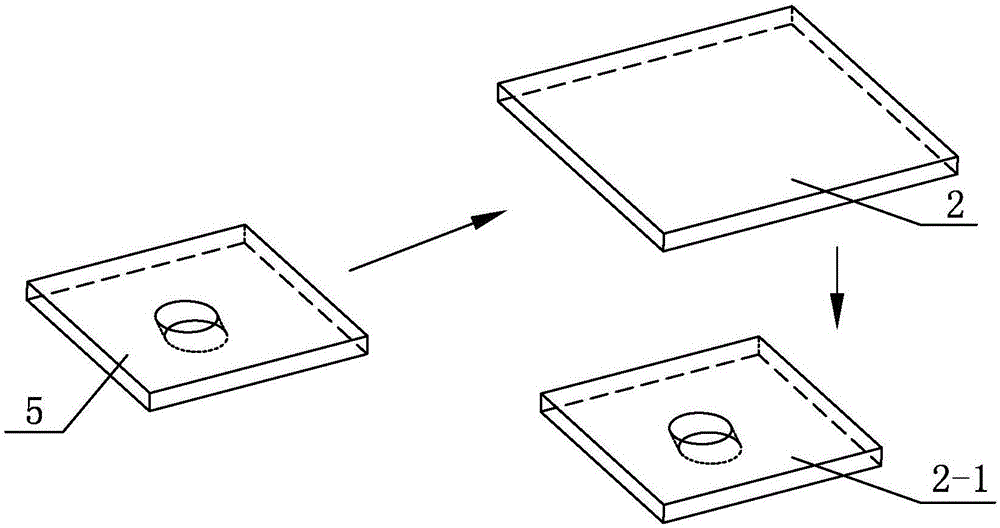

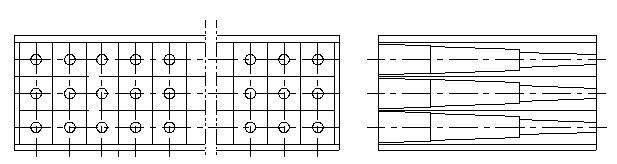

Lamination manufacturing method for large-size and complex-structure metal component

ActiveCN106670736ASolve forming problemsEfficient processingLamination ancillary operationsLaminationLarge sizeAdditive layer manufacturing

The invention discloses a lamination manufacturing method for a large-size and complex-structure metal component and relates to a part manufacturing method in order to solve the problem that large-size metal components which have complex special-shaped structures and high performance requirement are difficult to manufacture through traditional machining, overall plastic shaping and existing additive manufacturing methods. The manufacturing method includes the steps that firstly, a three-dimensional digital model of the large-size and complex-structure metal component is acquired, and is divided into a plurality of sheet layers; secondly, actually-usable metal plates corresponding to the thickness of the sheet layers divided in the first step are selected, and are machined so that formed plates consistent with the model of the sheet layers in the first step can be obtained; thirdly, the pieces of formed plates obtained through machining in the second step are stacked according to the sequence of the sheet layers corresponding to the first step; and fourthly, after all the formed plates are connected into a whole, and the required large-size and complex-structure metal component is obtained. The lamination manufacturing method is used for forming the large-size deep cavity inner hole complex structure component.

Owner:HARBIN INST OF TECH

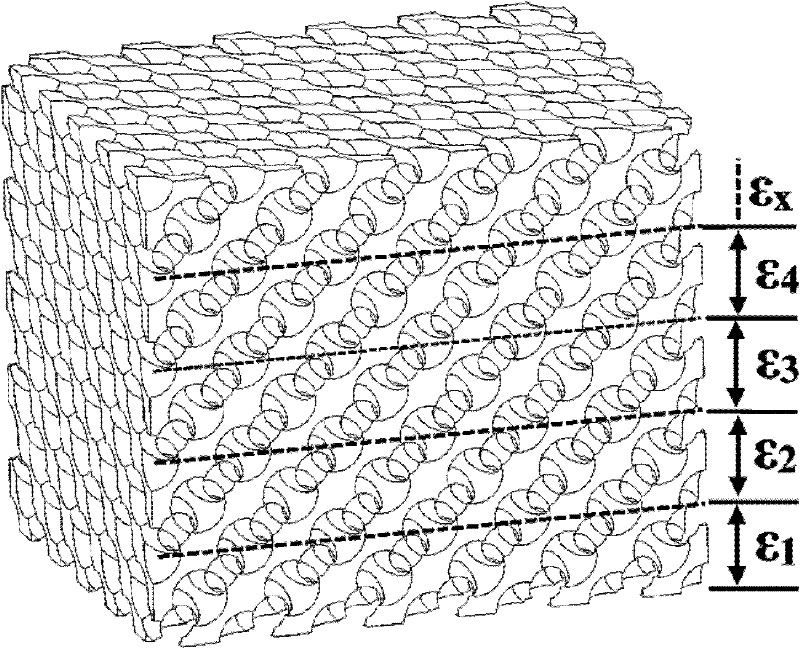

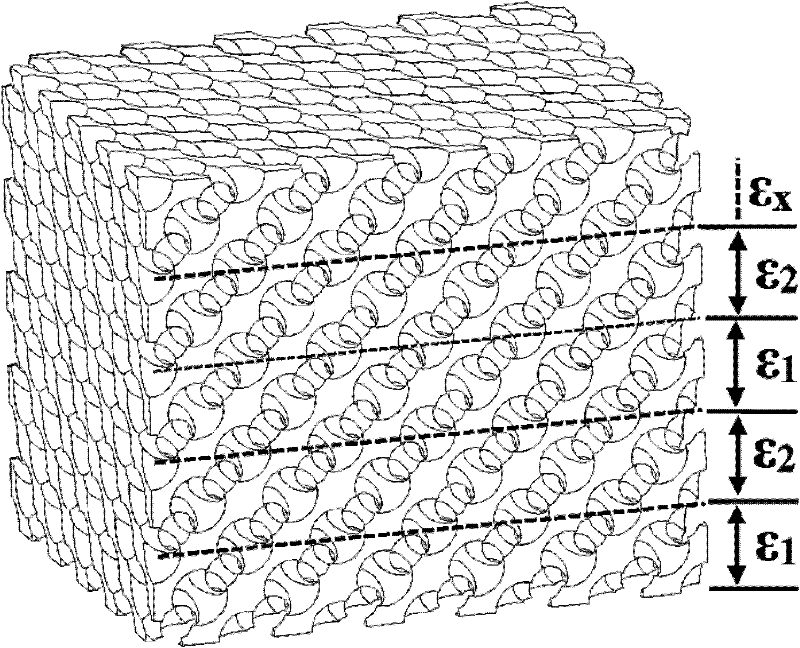

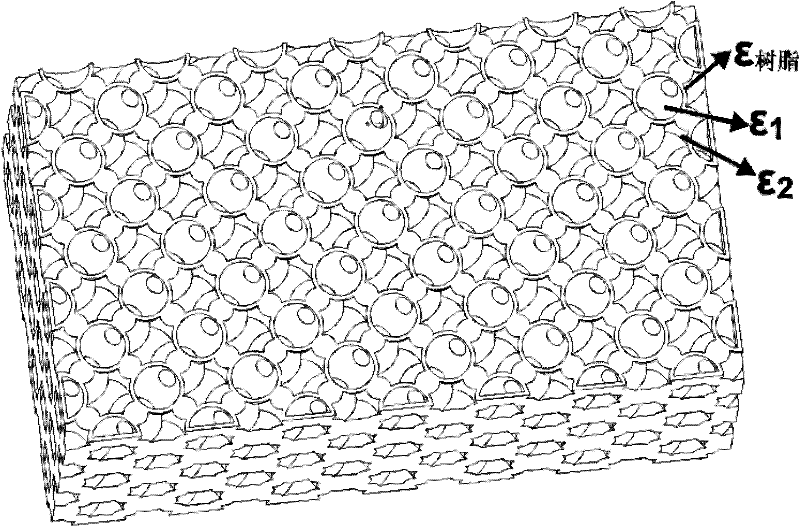

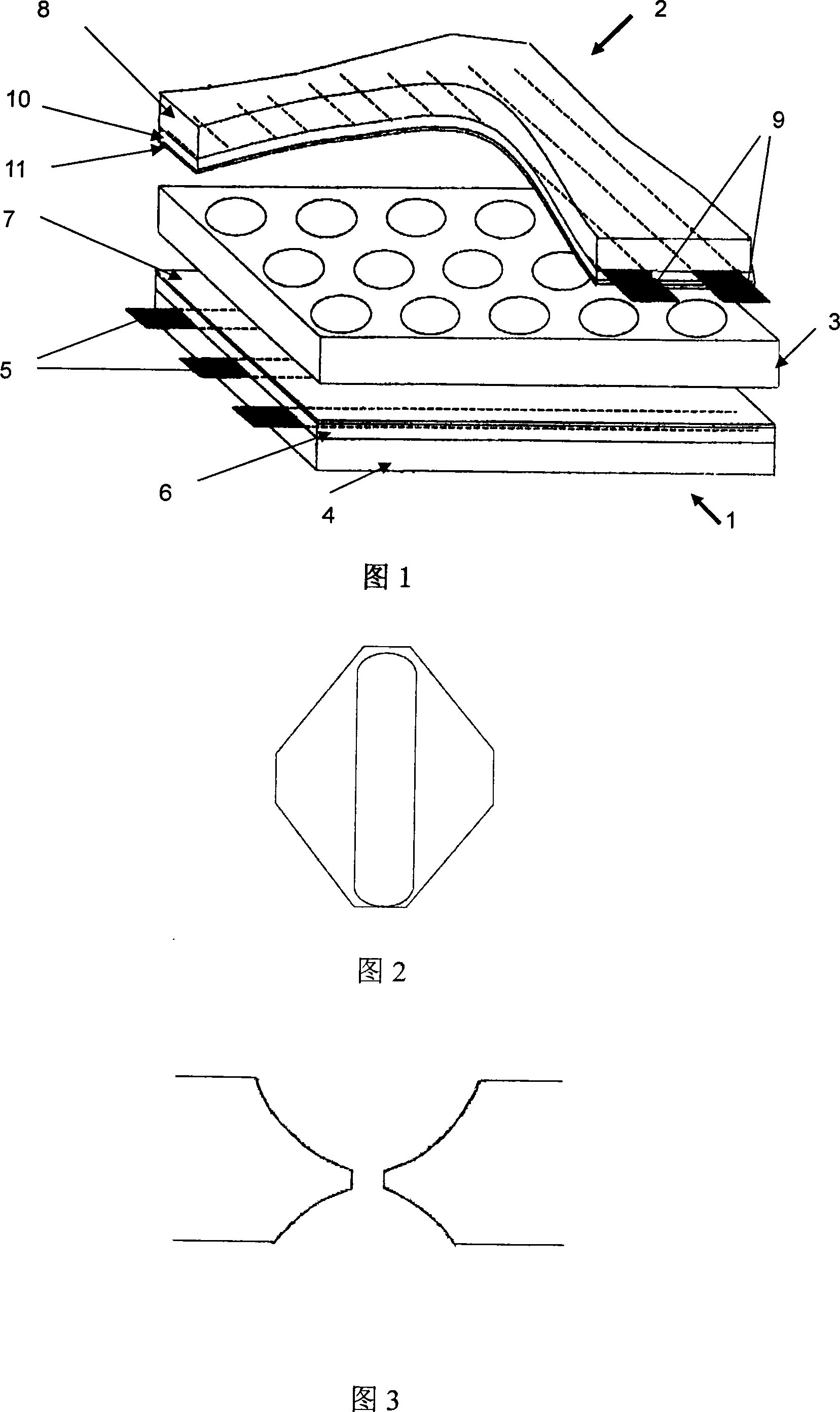

Multi-medium-coupling three-dimensional photonic crystal and method for designing and manufacturing multi-medium-coupling three-dimensional photonic crystal

InactiveCN102520480ASolve forming problemsTake full advantage of the designOptical waveguide light guidePhotonic crystalRefractive index

The invention discloses a multi-medium-coupling three-dimensional photonic crystal and a method for designing and manufacturing the multi-medium-coupling three-dimensional photonic crystal. The multi-medium-coupling three-dimensional photonic crystal has super-wide band gaps in wider frequency and is easy to manufacture. According to the invention, the multi-medium-coupling three-dimensional photonic crystal disclosed by the invention periodically contains a plurality of dielectric materials with different dielectric constants; the multi-medium-coupling three-dimensional photonic crystal comprises two forms, i.e. periodic cascading and periodic intersection, and is manufactured by adopting a rapid prototyping and a multi-step injection molding method; the multi-medium-coupling three-dimensional photonic crystal disclosed by the invention contains more than two dielectric materials, the Bragg scattering is strengthened due to the dielectric constant ratio (refractive index ratio) among the dielectric materials, therefore, band gaps wider than those of a single-dielectric-material photonic crystal are obtained.

Owner:XI AN JIAOTONG UNIV

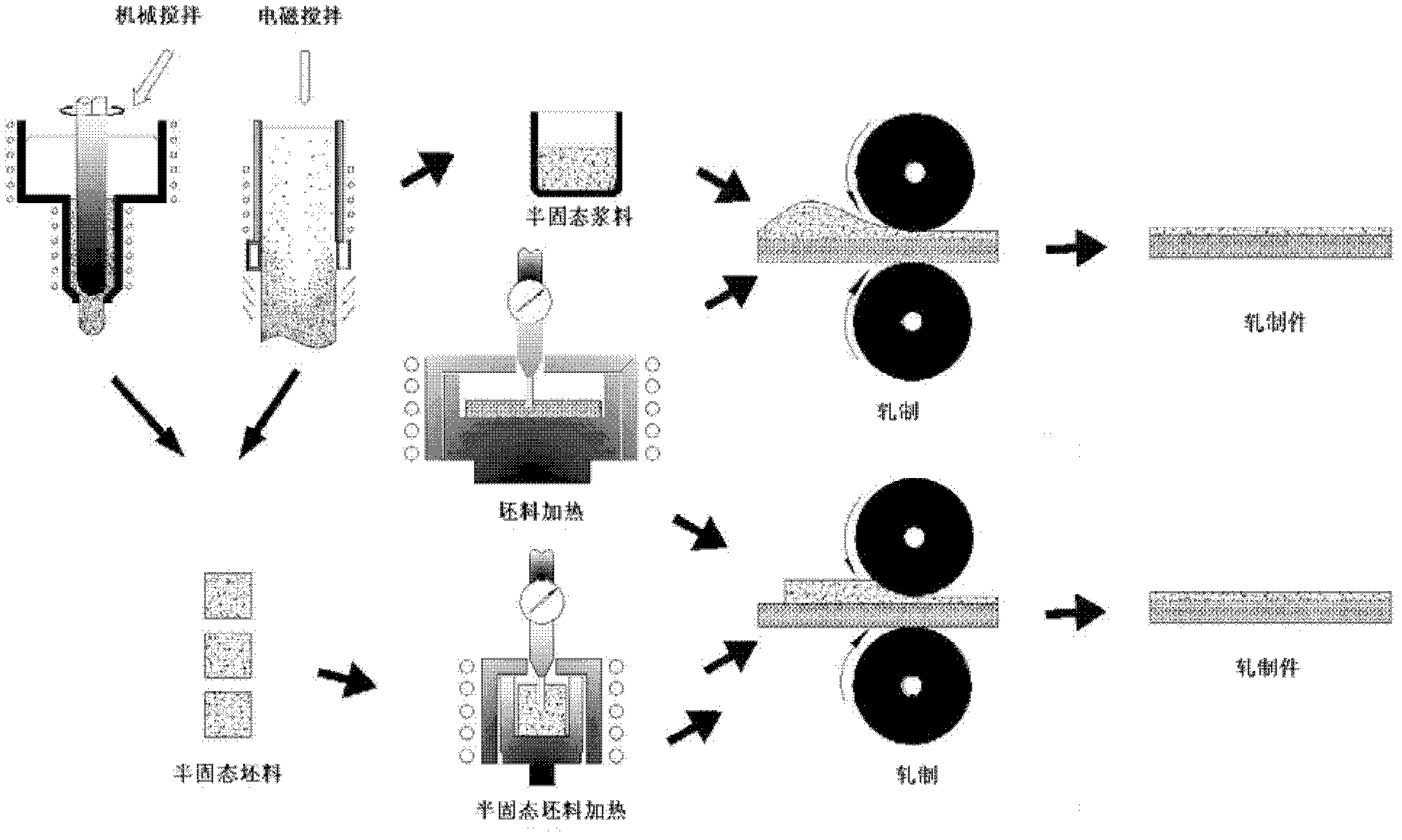

Liquid phase connected die forging integral forming method of material

ActiveCN102728945ADiffuse fullyAvoid generatingNon-electric welding apparatusPetrochemicalMelting Point Temperature

The invention discloses an aluminium alloy and an aluminium alloy composite liquid phase connected die forging integral forming method of a material, and relates to a material forming method. The technical problems of difficulty in connection and low intensity in the conventional material connection method are solved. The method comprises the following steps of: removing oil stains and impurities on the surface to be connected of the material to be connected; 2, respecting heating the materials to be connected which processed in the first step to a plastic deformation temperature under the protection of vacuum or inert gas, and keeping the temperature until the temperature of all parts of the materials are consistent; and continuously heating to ensure that the temperature of the material to be connected is quickly raised to a melting point temperature and is kept to melt the surface layer of the material; and 3, placing the material to be connected which is treated in the second step into a die cavity of a hot press for hot-pressing formation, or placing the material to be connected between rollers of a rolling machine for performing rolling formation so as to finish the liquid phase connected die forging integral formation of the material. A joint prepared by the method can be applied to the fields of aerospaces, space technology, nuclear industry, micro-electrons, automobiles and petrochemical industry.

Owner:HARBIN INST OF TECH

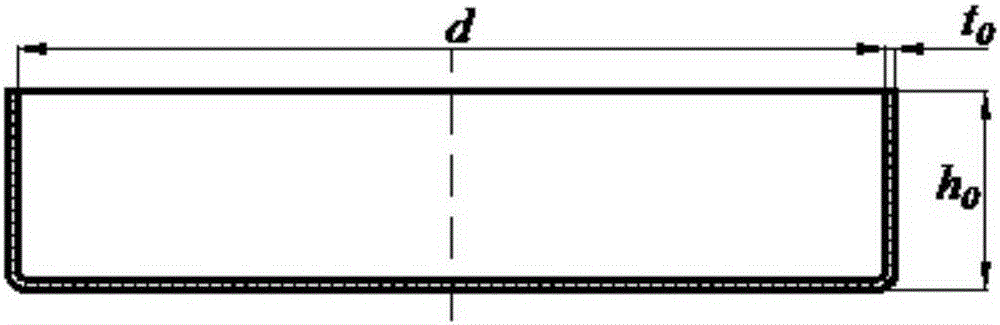

Spinning thickening method of cylinder wall of cylindrical part

ActiveCN105290188ASimple structureExtend your lifeMetal working apparatusEngineeringStructural engineering

The invention discloses a spinning thickening method of the cylinder wall of a cylindrical part. The spinning thickening method comprises the steps of firstly placing a to-be-thickened cylindrical prefabricated part on a lower main shaft of a spinning machine, and clamping the cylindrical prefabricated part through an upper inner main shaft and the lower main shaft of the spinning machine; then, lowering an upper outer main shaft mounted at the outer part of the upper inner main shaft in a sleeving manner, compressing the cylinder wall of the cylindrical prefabricated part, and fixing; then, rotating the upper inner main shaft, the upper outer main shaft, the cylindrical prefabricated part and the lower main shaft together, and feeding cylindrical rolling wheels in the radial direction of the cylindrical prefabricated part; repeating the steps, so as to achieve N-pass thickening for the cylinder wall of the cylindrical prefabricated part to prepare the cylindrical part. According to the spinning thickening method, the cylinder wall of the cylindrical part is gradually thickened through multi-pass spinning, the forming problem of the cylindrical part of which the cylinder wall is thicker than the cylinder bottom is solved, and the method is suitable for forming of the cylindrical part of which the diameter is relatively large, the cylinder wall is not high, and the cylinder wall is thicker than the cylinder bottom.

Owner:HUAZHONG UNIV OF SCI & TECH

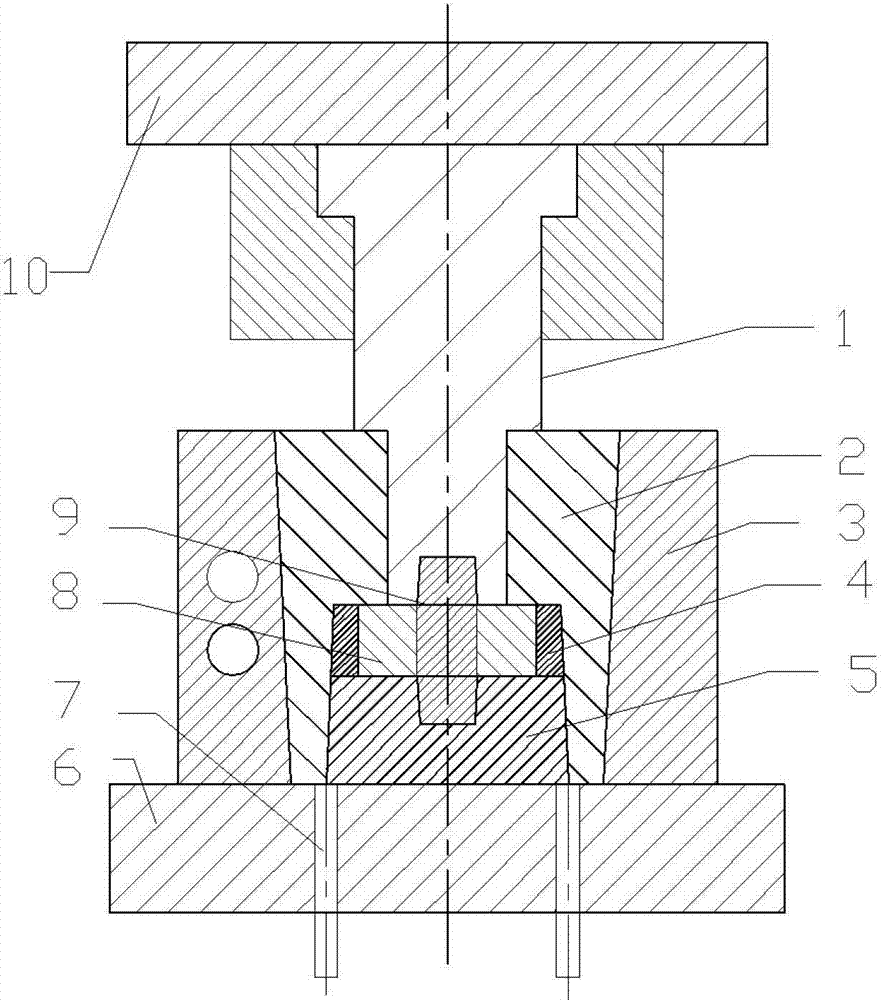

Die and method for manufacturing inner and outer pipe workpiece with separation ribs in middle through extrusion method

InactiveCN105032966AHigh strengthEasy to demouldExtrusion diesExtrusion mouldingMechanical engineering

Disclosed are a die and method for manufacturing an inner and outer pipe workpiece with separation ribs in the middle through an extrusion method. The die comprises a male die body and a female die body which are vertically and coaxially arranged. The top end of the male die body is fixed to the lower portion of an upper die plate, and the female die body is fixed to the upper portion of a lower die plate. An ejector rod is arranged in a through hole in the middle of the lower die plate in a sliding manner. The convenient extrusion method is provided under the condition that the heights of an inner pipe, an outer pipe and separation ribs are different, and the die is novel and unique in design. The surface of a product is free of weld joints, and the die can adapt to places with high requirements for strength. The die is easy to machine and low in manufacturing cost. In the extrusion process, work stress is low, the tonnage of needed equipment is low, the die is not prone to being damaged, economical benefits are high, and cross sections of extrusion parts do not need to be consistent. Along with rapid development of the industry, the application range of the inner and outer pipe workpiece with the separation ribs of this kind is wider and wider, and the extrusion moulding method and the die structure have the great application prospect in industrial production.

Owner:ZHONGBEI UNIV +1

Fluorescent powder slurry materialfor plasma display and forming method on shadow mask

InactiveCN101159214AGood dispersionGood suspensionTube/lamp screens manufactureDischarge tube luminescnet screensOrganic solventMetallurgy

The invention relates to a fluorescent powder slurry for plasma display and the formation method on shadow mask, belonging to the technical field of flat panel TV set. The inventive slurry consists of fluorescent powder, organic resin, organic solvent and nanopowder, wherein the fluorescent powder accounts for 40-50 percent of the total weight, the organic resin accounts for 3-6 percent of the total weight, the organic solvent accounts for 45-55 percent of the total weight, and the nanopowder accounts for 0.5-3 percent of the total weight. The proper amount of nanopowder (0.5-3 percent) added into the fluorescent powder slurry can effectively improve the dispersion and the suspension properties of the fluorescent powder in the slurry and can well improve the thixotropy of the fluorescent powder slurry so as to ensure that the slurry viscosity decreases during printing to obtain adequate feeding amount and also ensure that the slurry can rapidly regain the high viscosity and settle at the periphery of small holes other than flowing out when the slurry is printed to the holes of the shadow mask. Meanwhile, the slurry can be oven-dried and sintered after the printing process such that the nanopowder is filled into the gap between particles of fluorescent powder, thereby well bonding the fluorescent powder particles and preventing powder loss resulting from insufficient bonding force of the fluorescent powder.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

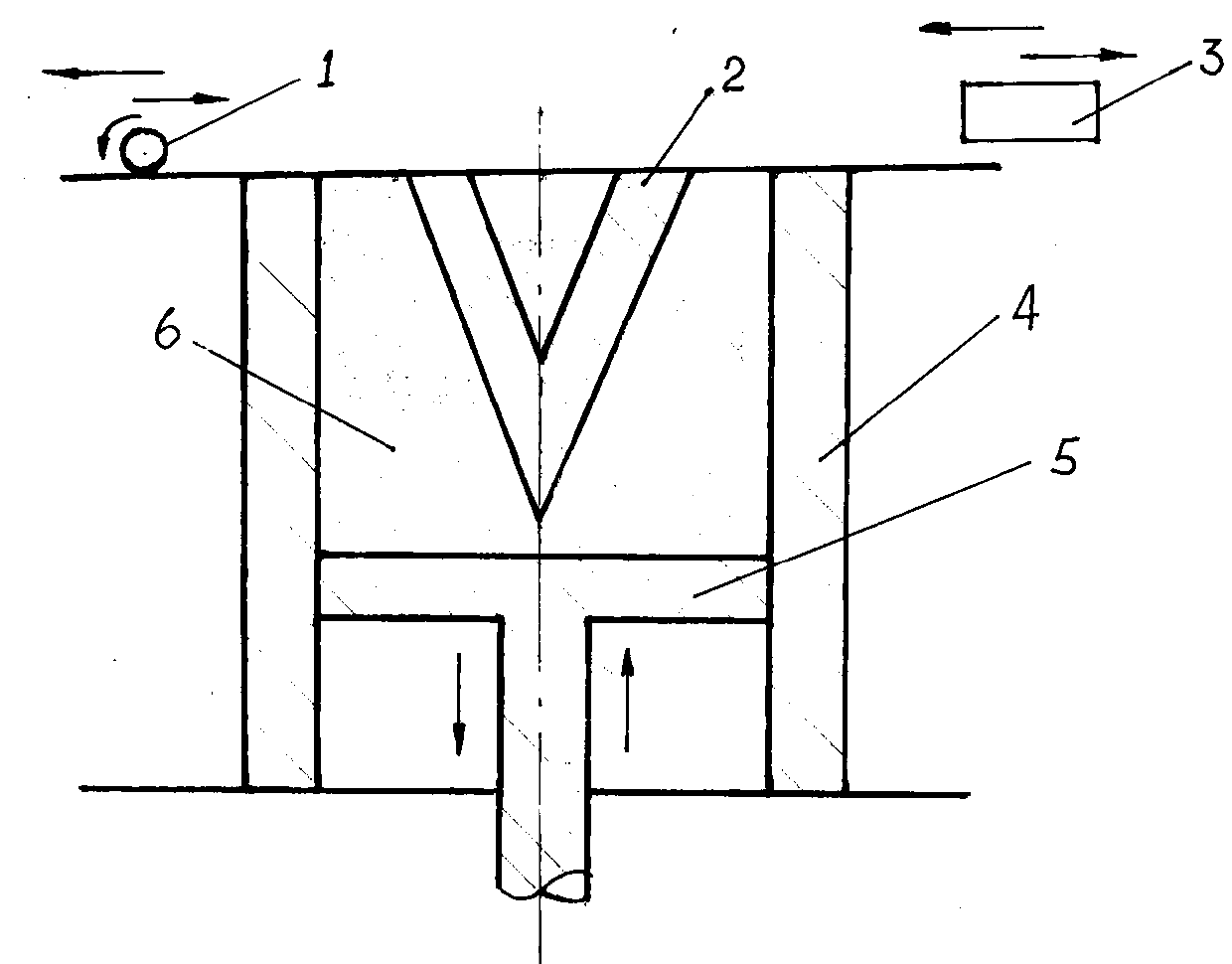

Hydrodynamic inclined-wire stock discharge box

InactiveCN102154893AGood formation and air permeabilityOvercoming long fiber forming problemsMachine wet endWire frameSizing

The invention discloses a hydrodynamic inclined-wire stock discharge box. The stock discharge box is arranged above an inclined wire part of an inclined wire machine, and comprises an adjusting mechanism, a box, a supporting seat, more than two groups of damping elements, more than one set of transverse-amplitude water diluting device and more than one set of section amplifying device, wherein the box is connected to the upper part of the supporting seat through a flange; the lower part of the supporting seat is arranged on an inclined wire frame through a hinge; and under the action of external force, the stock discharge box is rotated, and the angle of the stock discharge box and the distance between the stock discharge box and the inclined wire part are adjusted. The hydrodynamic inclined-wire stock discharge box can be applied to single-layer sizing and multi-layer sizing, is particularly suitable for the inclined wire machine, and has the advantages of compact structure, small floor area, easiness and convenience for operation and the like. The hydrodynamic inclined-wire stock discharge box can be used for manufacturing long fibered pulp with low concentration together with an inclined wire former and producing special paper with high uniformity and high air permeability.

Owner:SOUTH CHINA UNIV OF TECH

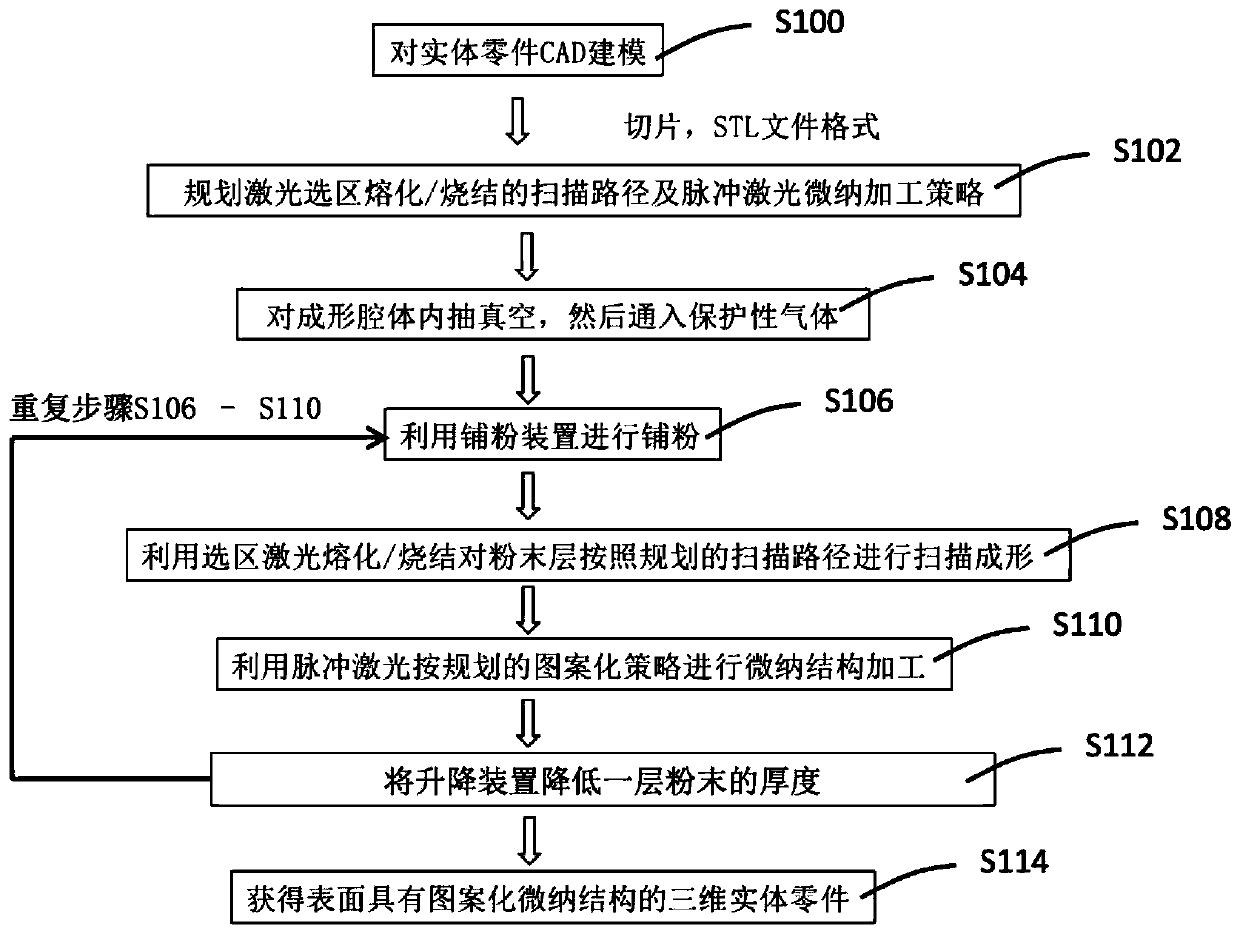

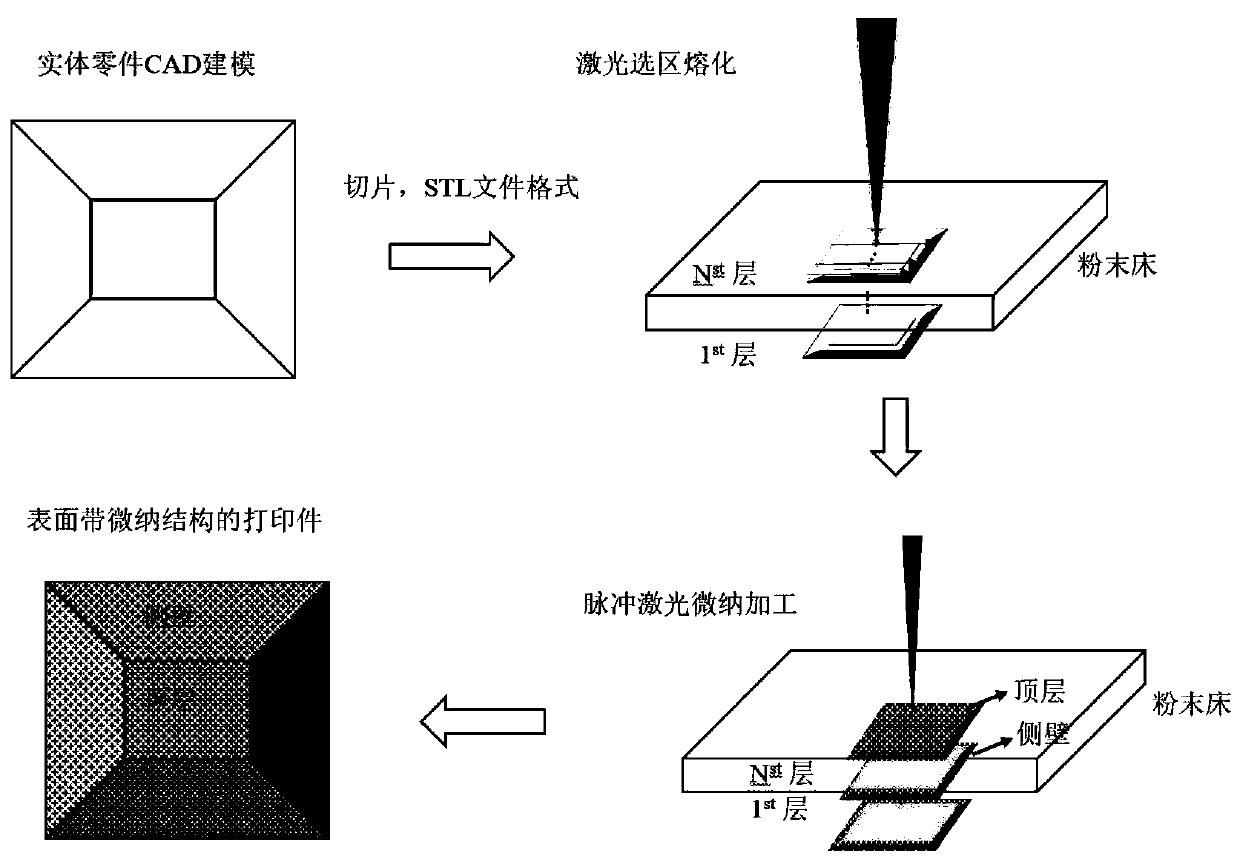

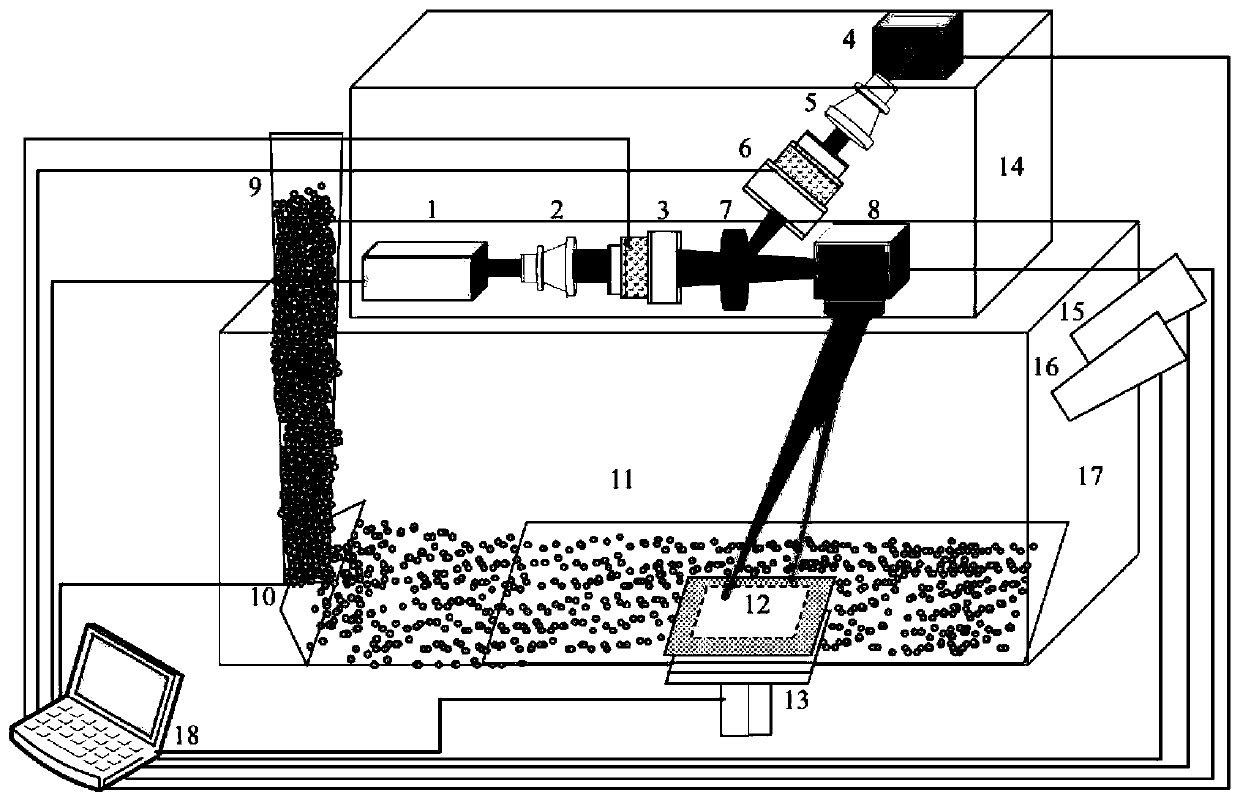

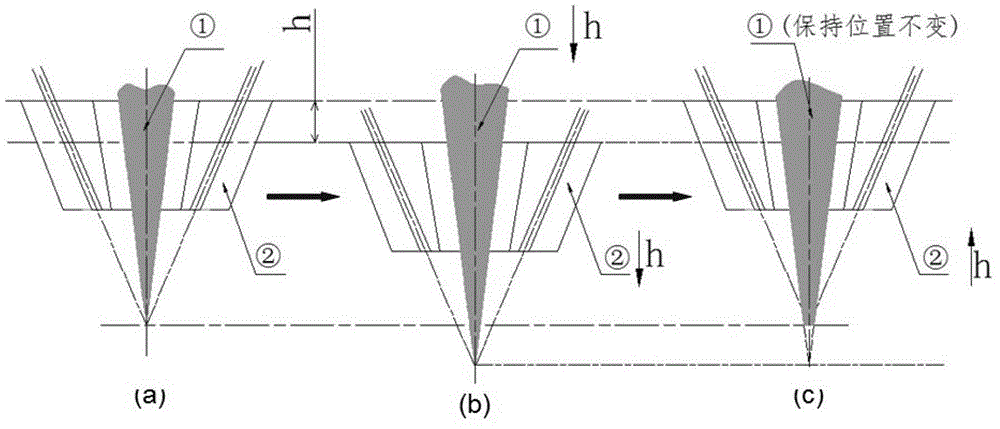

Laser additive manufacturing and laser micro-nano processing integrated device and method

InactiveCN111390167ASolve forming problemsSolve functionAdditive manufacturing apparatusGlass shaping apparatusPhysicsEngineering

The invention belongs to the field of three-dimensional printing and fine processing manufacturing, and particularly relates to a laser additive manufacturing and laser micro-nano processing integrated device and method. According to the device and method, laser additive manufacturing and surface structuring processing are carried out on line at the same time, so that the problems of part formingand surface functionalizing are integrally solved, and the procedures are simplified; additive manufacturing and micro-nano processing are both carried out on a two-dimensional plane based on a layering technology, so that the whole processing process is in an open space and is not limited by a solid three-dimensional space; furthermore, according to a coaxial dynamic focusing scanning system designed by the device and system, additive manufacturing and micro-nano processing are in the same coordinate system so that accurate positioning and controlling can be carried out; and the compatibilityis good, and adjusting and controlling are easy.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Hydroxyalkyl cationic guar gum and its preparation method and application

InactiveCN1318694CSolve forming problemsImprove adsorption capacityPaper/cardboardRetention agents additionAlcoholGraft reaction

A process for preparing the cationic hydroxyalkyl guar gum includes such steps as dispersing the raw powder of guar gum in the aqueous solution of low-carbon alcohol, adding high-alkaline catalyst, immersing, adding cationic etherifying agent, cationic graft reaction, adding phase-transfer catalyst and alkoxy etherifying agent, hydro-xyalkylating reaction, neutralizing and filtering. It can be used as the retention aid or filter aid of paper pulp.

Owner:SOUTH CHINA UNIV OF TECH

Coaxial powder delivery nozzle applied to variable spot technique

InactiveCN103060801BPrecise automatic control of up and down moving distancePrecise guarantee of verticalityMetallic material coating processesLaser beam welding apparatusTemporary variableSpray nozzle

The invention relates to a coaxial powder delivery nozzle applied to a variable spot technique. The nozzle consists of three parts, wherein a first part is a structure for automatically regulating the collection position of powder in the nozzle in the vertical direction, and the part further comprises a cooling water loop and a gas protecting device; a second part is a structure for manually regulating the collection position of the powder in the horizontal diameter direction; and a third part is a powder delivery sprayer structure. The coaxial powder delivery nozzle disclosed by the invention is applicable to the field of material increase manufacturing, and especially applicable to an application place adopting a defocusing manner to realize temporary variable spot formation of laser for realizing both formation efficiency and precision. The coaxial powder delivery nozzle disclosed by the invention can also be applied to the field of laser welding.

Owner:XI AN JIAOTONG UNIV +1

Vaginal acid-base buffer gel and preparation method thereof

ActiveCN110575431AIncrease the chance of infectionIncrease productivityAerosol deliveryInorganic non-active ingredientsBenzoic acidWhite petrolatum

The invention provides a vaginal acid-base buffer gel and a preparation method thereof, and specifically relates to the pharmaceutical field. The vaginal acid-base buffer gel consists of the followingcomponents (by mass): 1%-39% of an oil phase, 60-99% of a water phase, 0.001-2% of a pH regulator and 0.05-5% of a bacteriostat, wherein the oil phase is white petrolatum or liquid paraffin or glyceryl behenate or Span or Tween or glycerol or propylene glycol; the water phase is hydroxypropyl methylcellulose or carbomer or sodium carboxymethylcellulose or polycarbophil or polyethylene glycol or azone or gelatin or purified water; the pH regulator is citric acid or sodium citrate or sodium hydroxide or hydrochloric acid or triethanolamine or boric acid or borax or sodium dihydrogen phosphate or disodium hydrogen phosphate; the bacteriostat is benzoic acid or sodium benzoate or benzyl alcohol or benzalkonium bromide or benzalkonium chloride or sorbic acid or potassium sorbate or nipalgin. The product prepared by the invention can effectively regulate the original vaginal environment of inflammation, remove vaginal odor and improve symptoms such as increased vaginal secretions or itching.

Owner:NANJING SKY LONG PHARMA

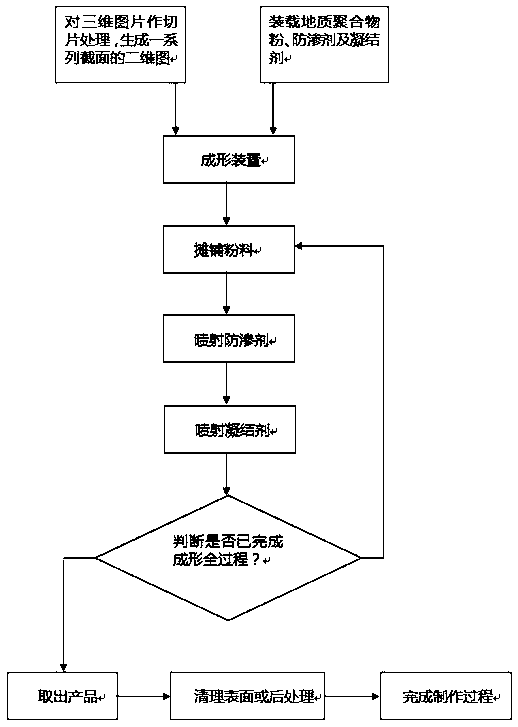

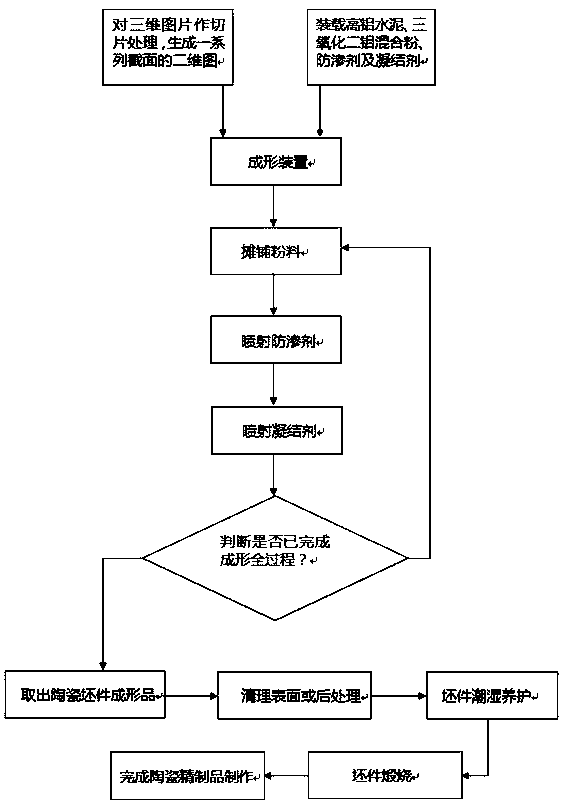

Forming device and method for additive manufacturing of inorganic cementing material products

PendingCN111015895AHave mechanical strengthSolve forming problemsAdditive manufacturing apparatusCeramic shaping apparatusPhysical chemistryEngineering

The invention discloses forming device and method for additive manufacturing of inorganic cementing material products. The device is provided with no less than two groups of spray heads or spray headarrays which are used for spraying coagulants and permeability-preventing agents into the planes of inorganic cementing materials correspondingly; and combined with the corresponding method, the device is used for manufacturing inorganic cementing material products and special ceramic products which are complex in structural shape and high in dimensional precision and surface quality requirements.The coagulants react with the inorganic cementing materials and are solidified into a whole; a permeability-preventing layer is formed between the permeability-preventing agents and the inorganic cementing materials, and isolation belts for blocking the penetration of the coagulants are formed between the products and powder materials around the products, so that the products have better surfacequality and higher dimensional precision, and the powder materials which are used for forming of the products are not polluted.

Owner:陈勃生 +1

Hot pressing forming mould and hot pressing forming method of super long branch pipe three-way pipe fitting

ActiveCN101704055BGuaranteed tensile deformationSolve forming problemsShaping toolsPipe fittingPhysics

The invention relates to a hot pressing forming mould of a super long branch pipe three-way pipe fitting, comprising a first upper die, a second upper die, a first lower die, a second lower die, a third lower die, a fourth lower die and a draw bar. A primary forming mould consists of the first upper die and the first lower die; a secondary forming mould consists of the first upper die and the second lower die; a third forming mould consists of the first upper die and the third lower die; and a final forming mould consists of the second upper die, the fourth lower die and the draw bar. The invention also relates to a hot pressing forming method which adopts the mould to manufacture the super long branch pipe three-way pipe fitting. Two upper dies and four lower dies are adopted by the invention to be drawn and extruded step by step into a super long branch pipe; in each hot pressing forming process, the tensile deformation of the materials is ensured to be within the tensile rate limitby controlling the root R and the outer diameter D of the branch pipe to be decreased successively, thereby solving the forming problem of super long branch pipe tee (M>1.5C).

Owner:WUXI XINFENG TUBE IND

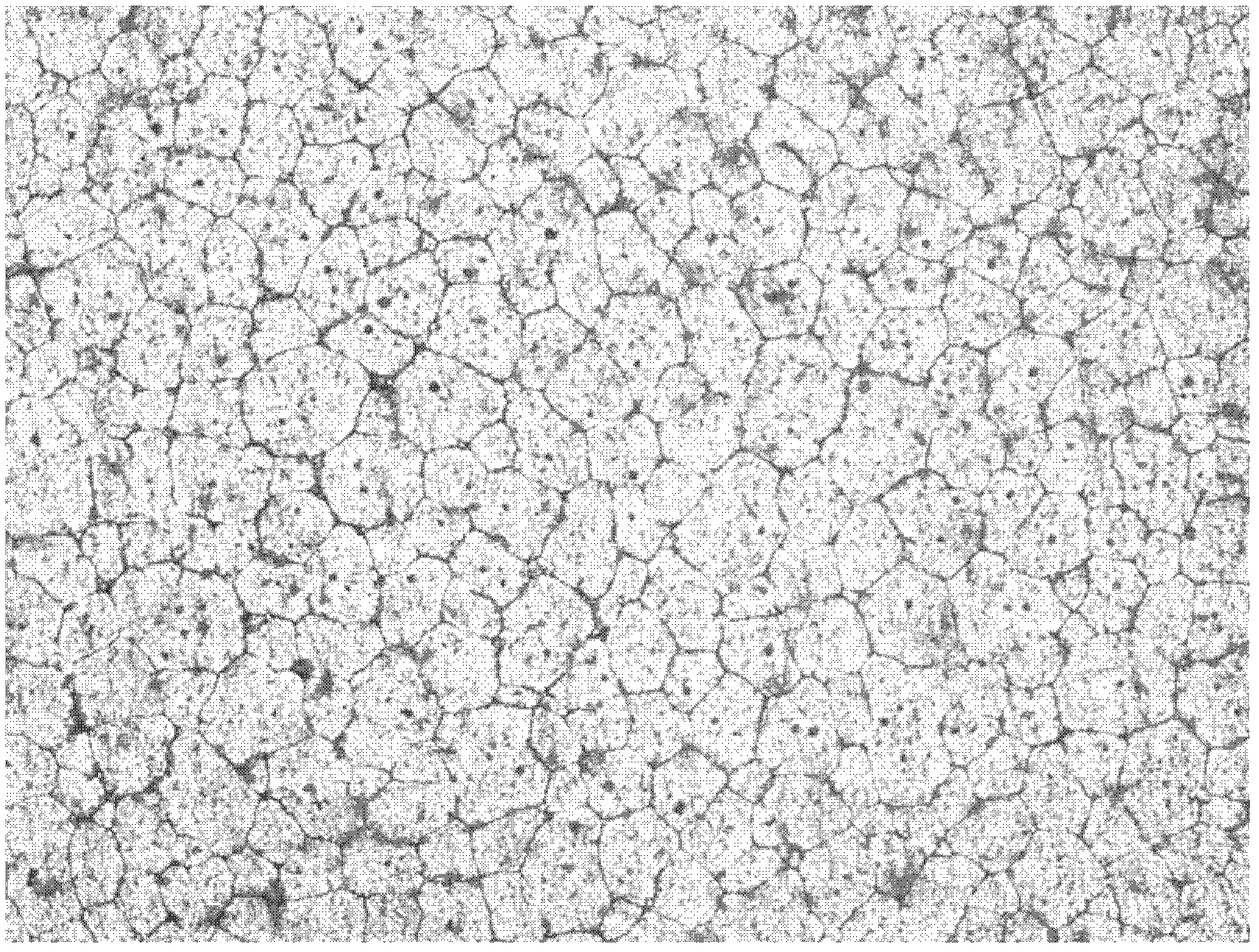

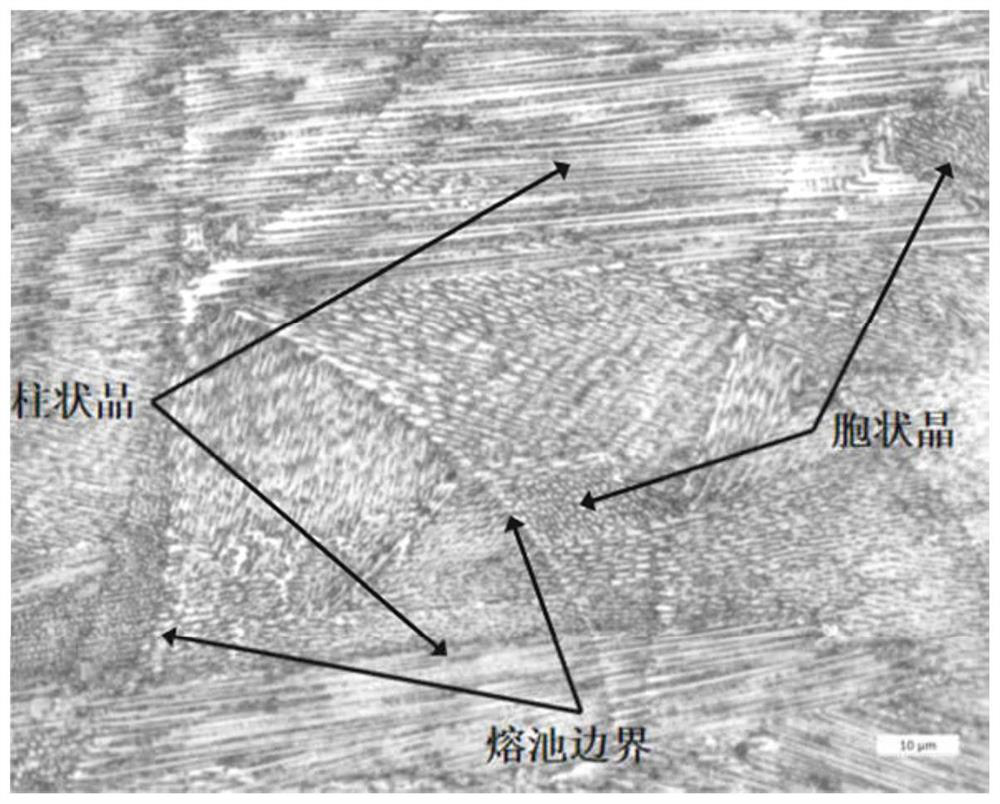

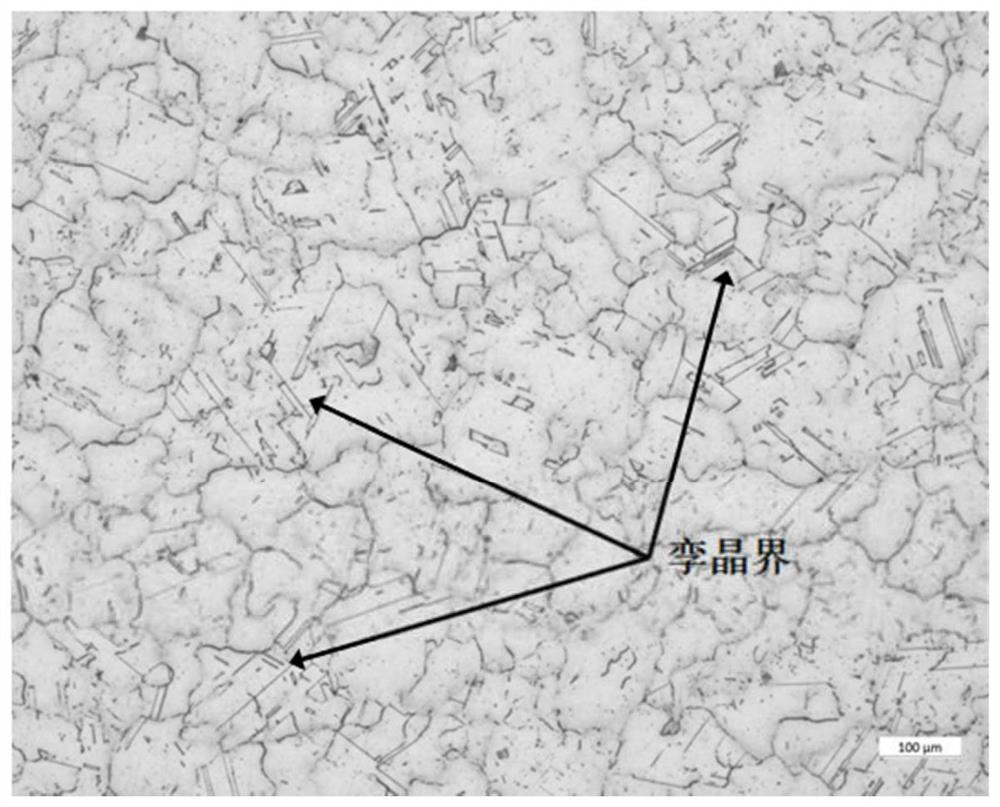

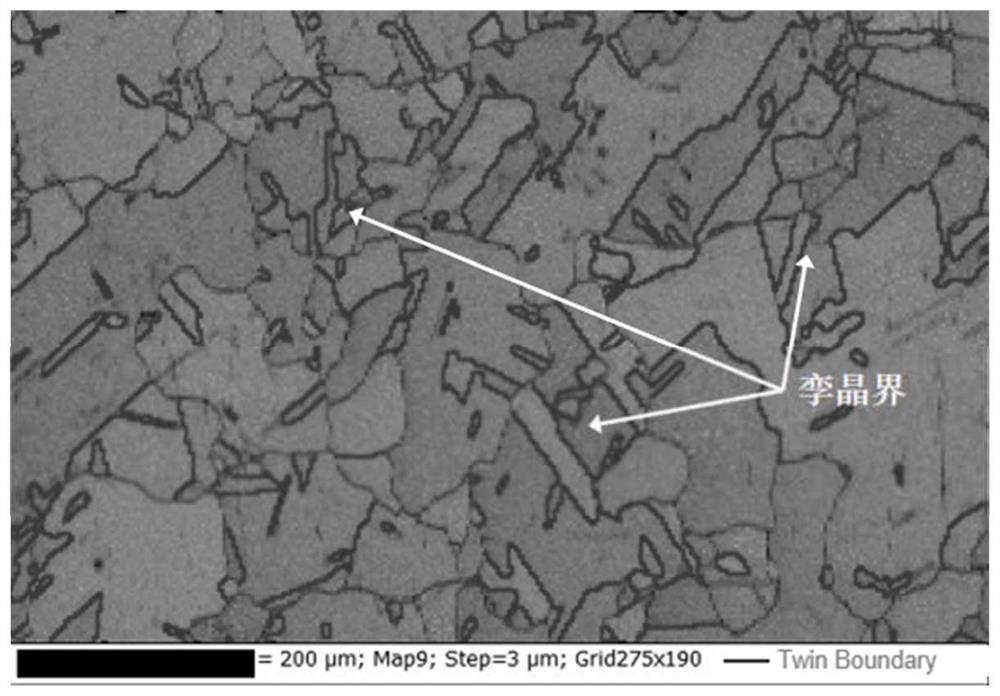

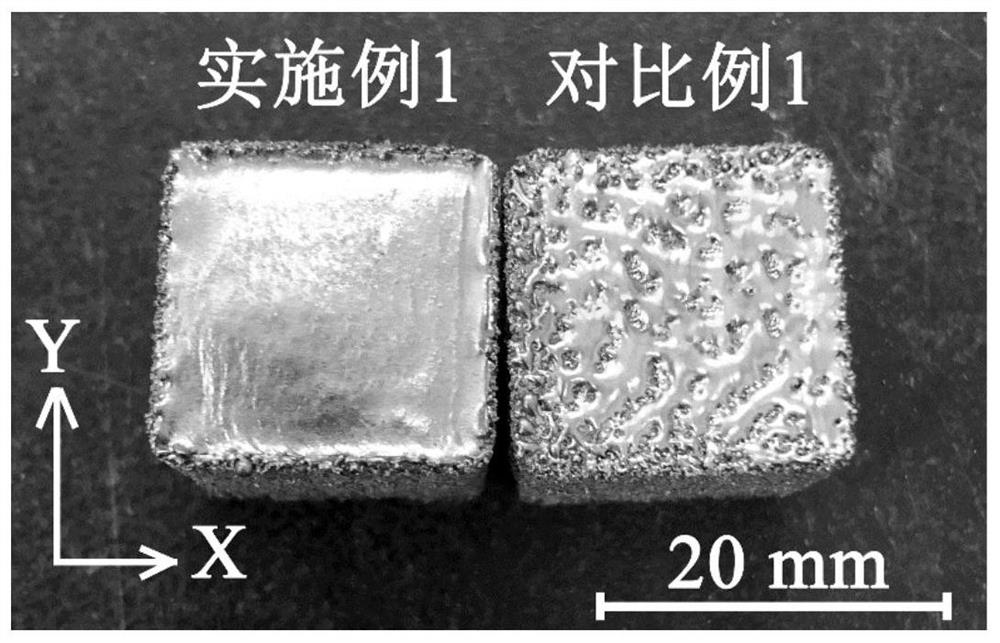

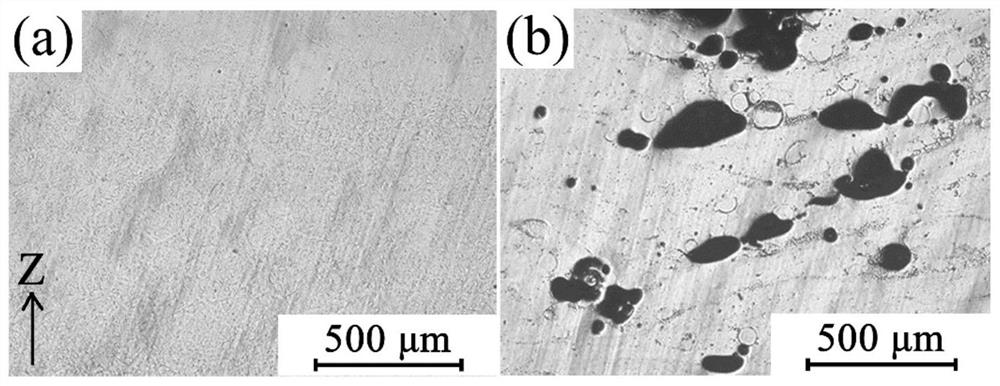

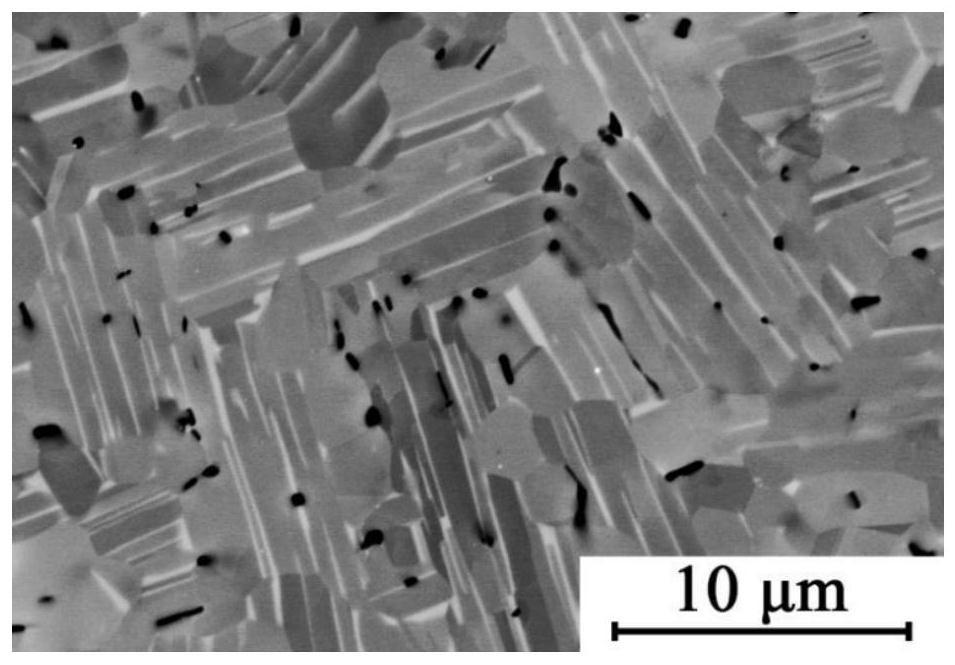

Preparation method of high-strength and high-plasticity Inconel718 alloy based on SLM

ActiveCN113477942AIncrease profitLow costAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSolution treatment

A preparation method of a high-strength and high-plasticity Inconel 718 alloy based on SLM comprises the following steps: S1, selective laser melting forming is conducted, specifically, an Inconel 718 alloy blank is printed through a selective laser melting method; and the Inconel 718 alloy blank is sequentially subjected to step S2: isostatic pressing heat treatment, step S3: stress relief annealing treatment, step S4: solution treatment and step S5: two-stage aging treatment, specifically, the temperature of isostatic pressing heat treatment is 1165-1170 DEG C, the pressure intensity is 125-135 Mpa, and the time is 210-270 min; the temperature of stress relief annealing is 790-810 DEG C, and the time of stress relief annealing is 20-40 min; the temperature of solution treatment is 940-960 DEG C, and the time of solution treatment is 20-40 min; and in two-stage aging treatment, the temperature of first-stage aging treatment is 750-770 DEG C, the time of first-stage aging treatment is 470-490 min, the temperature of second-stage aging treatment is 640-660 DEG C, and the time of second-stage aging treatment is 470-490 min. The Inconel 718 alloy prepared by the method has strength, plasticity and hardness and has excellent comprehensive mechanical properties, and the application of the Inconel 718 alloy can be expanded to the field of more precise and complex structures.

Owner:SOUTHWEST JIAOTONG UNIV

Centrifugal film coating apparatus

ActiveCN101722137BSimple structureEasy to operateLiquid surface applicatorsCoatingsLow noiseGranularity

The invention discloses a centrifugal film coating apparatus, which comprises a base and a centrifugal film coating device arranged on the base. The centrifugal film coating device comprises a film coating tool, a transmission sleeve shaft, a drive motor and a drive control system, wherein the film coating tool is arranged in the horizontal direction, continuously rotates and simultaneously drives internal materials to carry out centrifugal motion; the transmission sleeve shaft is coaxially sleeved outside the film coating tool and drives the film coating tool to continuously rotate; the drive motor is connected with the transmission sleeve shaft; the drive control system controls and adjusts the rotating direction and the rotation of the drive motor; and the left end part and the right end part of the transmission sleeve shaft have openings and the right ends of the left end part and the right end part are assembled with a U-shaped compressing member through a plugging member, and the left end is assembled through a Pi-shaped compressing member. The invention has the advantages of simple structure, simple and convenient using operation, low noise, safe and reliable operation, recyclable slurry, high rotation speed and high efficiency, can completely meet the technical requirement on molding centrifugal classification deposition, and solves the actual problem that the powder with different granularities is deposited in turn.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of carbide-reinforced TiAl-based nano composite material

PendingCN113210627AWon't breakUniform adhesionAdditive manufacturing apparatusTransportation and packagingNanoparticleCarbide

The invention discloses a preparation method of a carbide-reinforced TiAl-based nano composite material. The preparation method comprises the following steps: (1) selecting TiC ceramic particles with the purity of more than 99.9% and the particle size of 50-500 nm and TiAl alloy powder with the particle size of 45-150 [mu]m as raw materials; (2) mixing the two kinds of materials through a mechanical ball milling method, and obtaining premixed powder with TiC nano-particles evenly distributed on the surface of the TiAl alloy powder, wherein the weight of the TiC nano-particles accounts for 0.7-1.2 wt.% of the total weight of the mixed powder; and (3) preparing the TiAl-based nano composite material through layer-by-layer forming by means of the electron beam melting technology till a three-dimensional block sample is machined. A semi-melting step is added in the electron beam melting forming process, and finally the nearly-fully-compact carbide-reinforced TiAl-based nano composite material is obtained. In the forming process, the adjustable range of technological parameters is large, a matrix microscopic structure is uniform, a reinforcing phase is fine and dispersively distributed, and the mechanical property is good. The preparation method of the TiAl-based nano composite material has the characteristics and advantages of electron beam additive manufacturing, so that the preparation method has huge application potential in the field of aerospace.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com