Preparation method of high-strength and high-plasticity Inconel718 alloy based on SLM

A high plasticity and alloy technology, applied in the field of alloy additive manufacturing, can solve the problems of micro cracks, large local thermal stress, unsatisfactory effect, etc., achieve high material utilization rate, uniform structure, and solve the effect of forming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing an SLM-based high-strength and high-plasticity Inconel718 alloy, comprising the following steps:

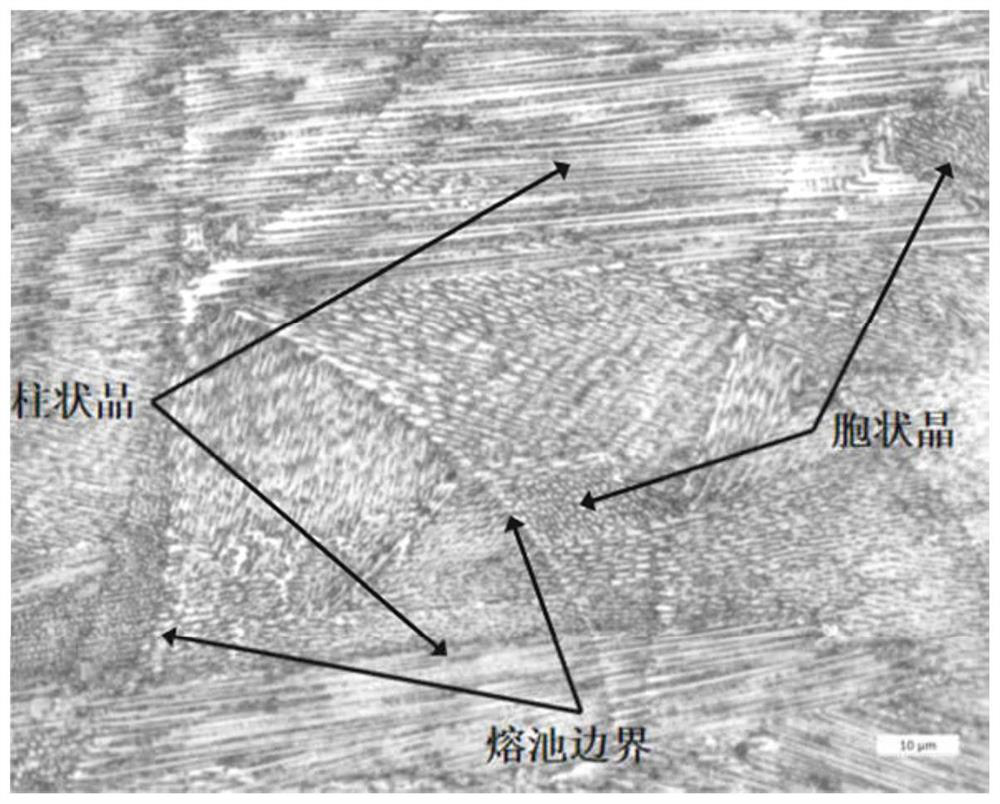

[0046] S1. Laser selective melting and forming: print Inconel718 alloy blanks by laser selective melting. The particle size of Inconel718 alloy powder used in laser selective melting and forming is 45-60 μm. The printing parameters are: printing power 200W, layer height 30 μm, scanning The speed is 900mm / s, and the scanning distance is 1mm; take the printed Inconel718 alloy blank sample and observe its microstructure, see figure 1 ;

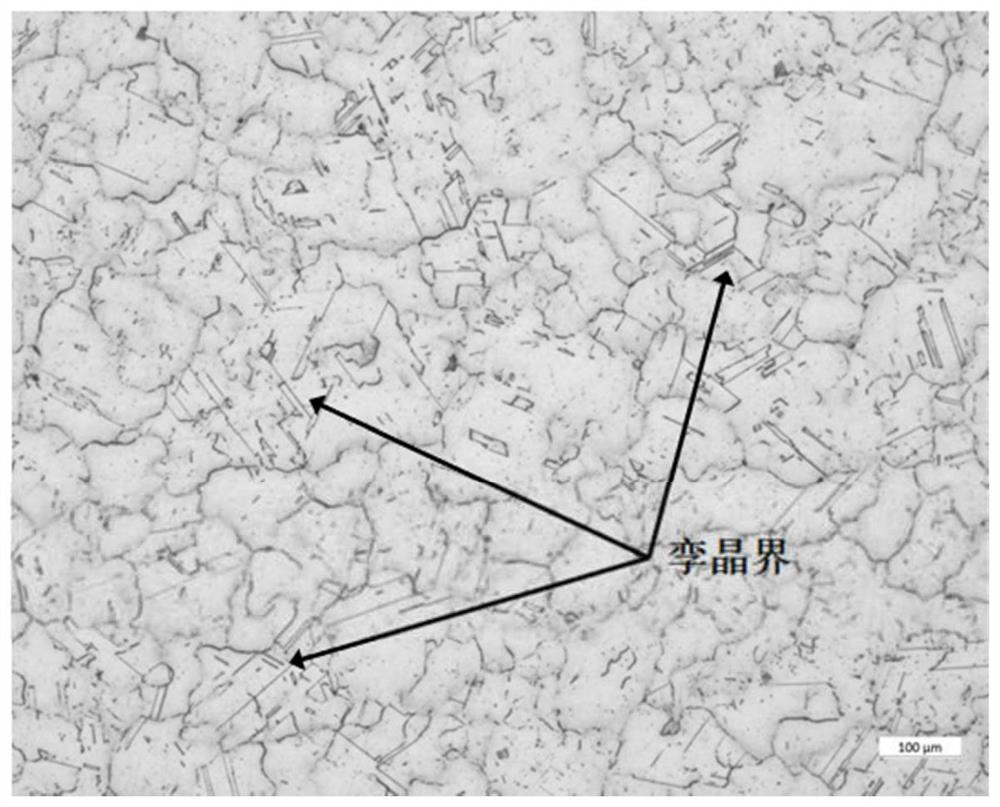

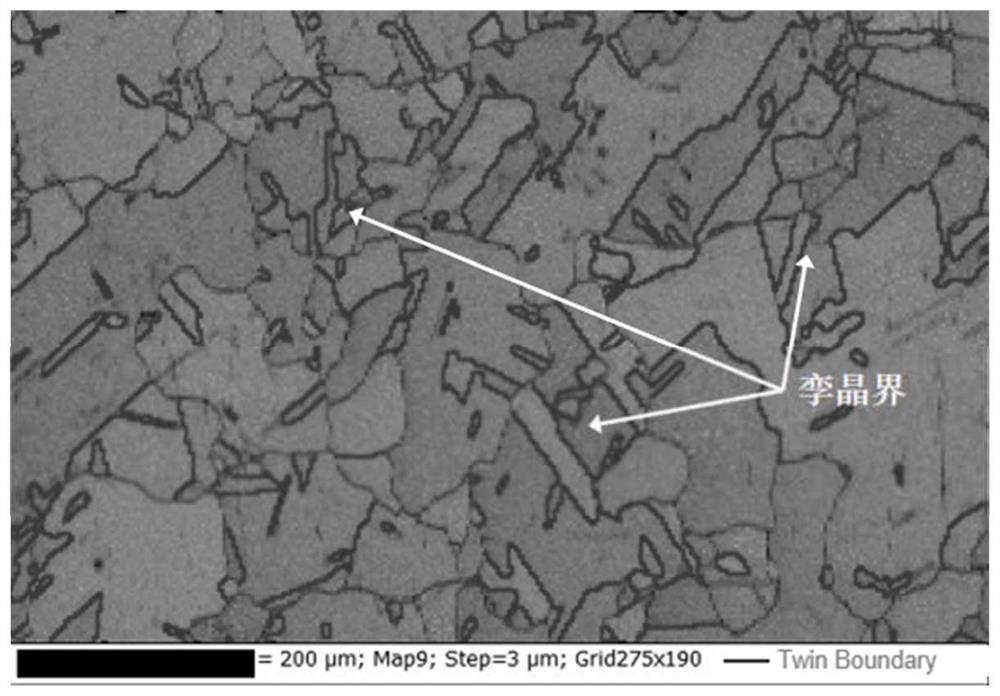

[0047] S2. Isostatic pressing heat treatment: place the Inconel718 alloy blank formed by laser selective melting in the isostatic pressing heat treatment equipment, and vacuumize it at a temperature not higher than 6.67×10 -2 Carry out isostatic pressing heat treatment under the vacuum condition of Pa, hot isostatic pressing heat treatment temperature is 1165 ℃, pressure is 130Mpa, time is 240min, after isostatic press...

Embodiment 2

[0052] A method for preparing an SLM-based high-strength and high-plasticity Inconel718 alloy, comprising the following steps:

[0053] S1. Laser selective melting and forming: print Inconel718 alloy blanks by laser selective melting. The particle size of Inconel718 alloy powder used in laser selective melting and forming is 45-60 μm. The printing parameters are: printing power 200W, layer height 30 μm, scanning The speed is 900mm / s, and the scanning distance is 1mm;

[0054] S2. Isostatic pressing heat treatment: place the Inconel718 alloy blank formed by laser selective melting in the isostatic pressing heat treatment equipment, and vacuumize it at a temperature not higher than 6.67×10 -2 Carry out isostatic pressing heat treatment under the vacuum condition of Pa, the hot isostatic pressing heat treatment temperature is 1170 ℃, the pressure is 130Mpa, the time is 220min, after the isostatic pressing heat treatment, pass argon gas into the isostatic pressing heat treatment e...

Embodiment 3

[0068] A method for preparing an SLM-based high-strength and high-plasticity Inconel718 alloy, comprising the following steps:

[0069] S1. Laser selective melting and forming: print Inconel718 alloy blanks by laser selective melting. The particle size of Inconel718 alloy powder used in laser selective melting and forming is 45-60 μm. The printing parameters are: printing power 190W, layer height 31 μm, scanning The speed is 890mm / s, and the scanning distance is 0.98mm; take the printed Inconel718 alloy blank sample;

[0070] S2. Isostatic pressing heat treatment: place the Inconel718 alloy blank formed by laser selective melting in the isostatic pressing heat treatment equipment, and vacuumize it at a temperature not higher than 6.67×10 -2 Carry out isostatic pressing heat treatment under the vacuum condition of Pa, hot isostatic pressing heat treatment temperature is 1168 ℃, pressure is 125Mpa, time is 270min, after isostatic pressing heat treatment, pass argon gas into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com