Liquid phase connected die forging integral forming method of material

A liquid phase connection and die forging technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult material connection and low strength, and achieve the improvement of physical and chemical properties of the interface, high performance and low forming temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

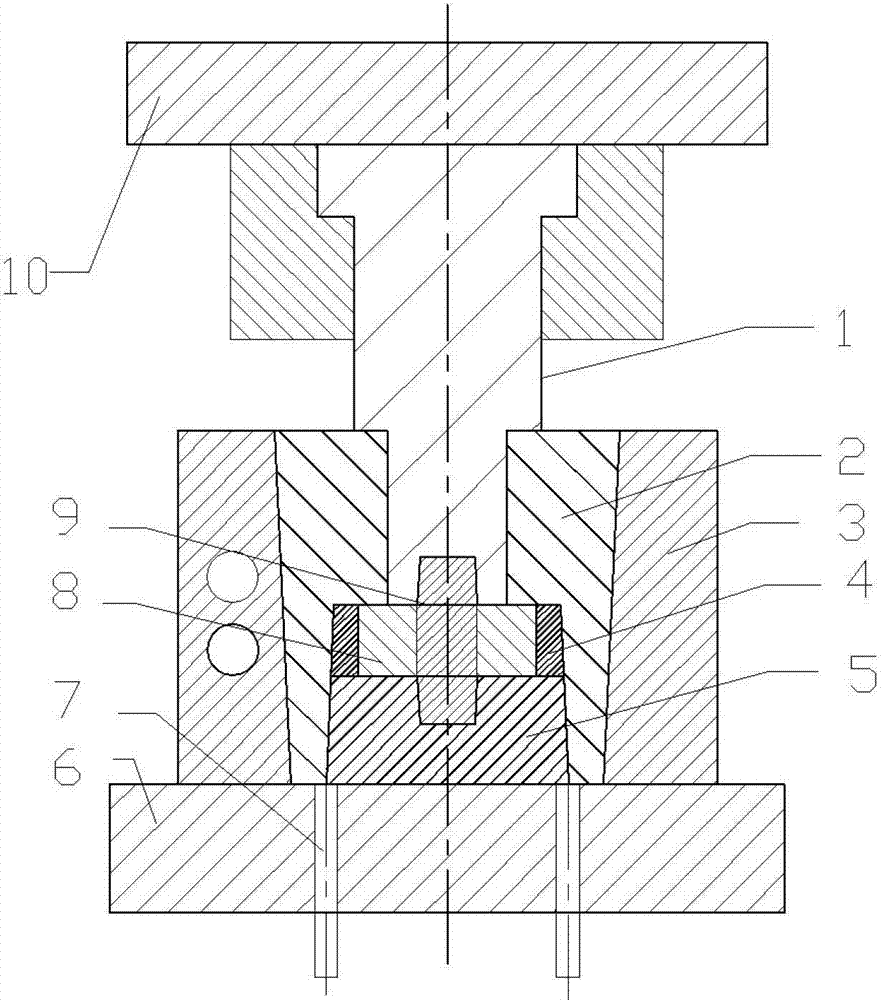

[0016] Specific implementation mode 1: In this implementation mode, a material liquid phase connection die forging integrated forming method is carried out according to the following steps:

[0017] 1. Remove oil and impurities from the surfaces to be connected of the materials to be connected;

[0018] 2. Heat the materials to be connected after step 1 to their plastic deformation temperature under the protection of vacuum or inert gas, and keep them warm until the temperature of each part of the materials is consistent; continue heating to make the temperature of the materials to be connected rise rapidly. to their melting point temperature and keep warm to melt the surface of the material;

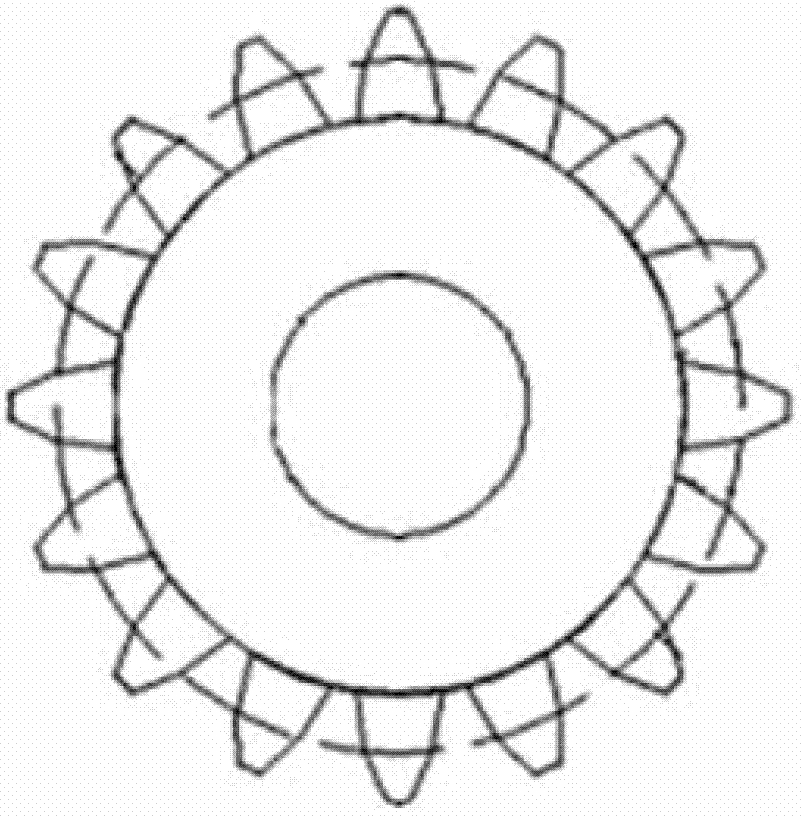

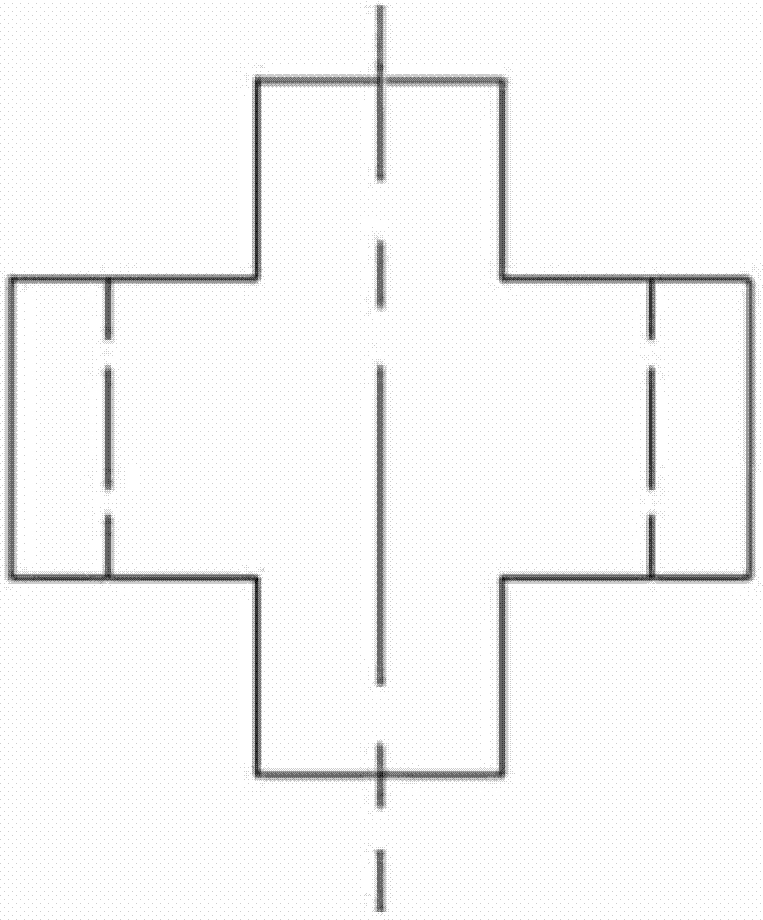

[0019] 3. Place the material to be connected processed in step 2 in the cavity of the hot press for hot pressing, or place the material to be connected in step 2 between the rolls of the roller machine for roll forming to complete the material liquid Connected die forging integrated fo...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment differs from Embodiment 1 in that the materials to be connected in step 1 are metal and metal, metal and composite material, or composite material and composite material. Others are the same as in the first embodiment.

[0023] In this embodiment, the materials to be connected may be the same or different, that is, the same material or different materials.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the inert gas in step 2 is nitrogen or argon. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com