Forming device and method for additive manufacturing of inorganic cementing material products

A technology of inorganic cementitious materials and additive manufacturing, which is applied in the direction of manufacturing tools, additive processing, ceramic molding machines, etc., and can solve problems that affect product surface quality and dimensional accuracy, fuzzy boundaries, complex shapes or structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

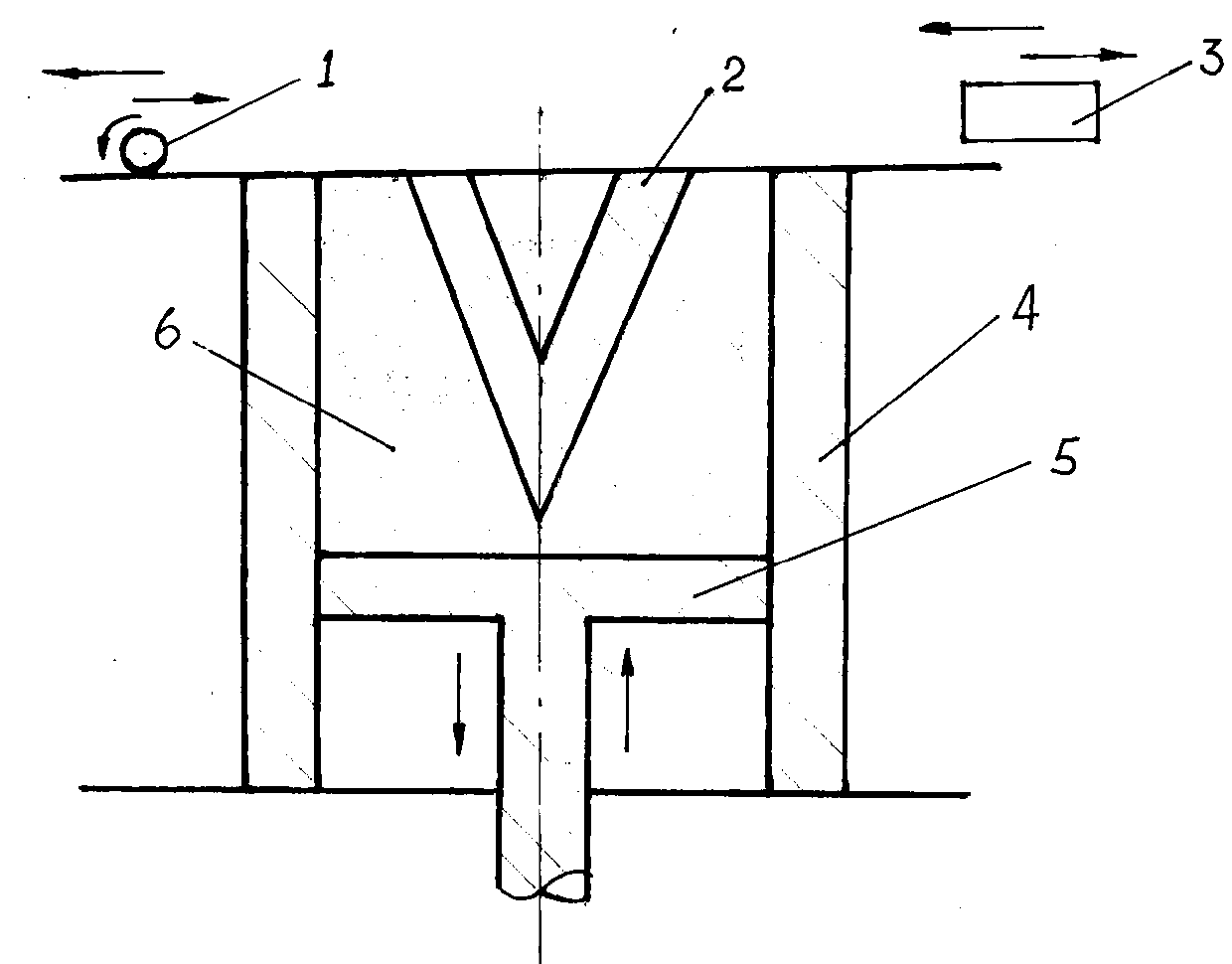

[0042] figure 1 A schematic diagram of the forming device of the present invention in an embodiment is given: the forming device includes an ultrasonic vibrating powder spreading device 1, a nozzle or a nozzle array 3, a forming cylinder 4 and a lift table 5, and the ultrasonic vibrating powder spreading device 1 is used to gel the inorganic The material 6 spreads evenly on the upper surface of the lifting table 5 and vibrates into a plane. The spraying device 3 includes at least two groups of nozzles or two groups of nozzle arrays, wherein one group of nozzles or the array of nozzles 3 is used to spray the corresponding level of the product on the material layer. The outer edge of the cross-sectional solid area is sprayed with anti-seepage agent. Another group of nozzles or nozzle array 3 is used to spray coagulant to the horizontal cross-sectional solid area corresponding to the product on the material layer. The lifting table 5 is placed in the forming cylinder 4, along the ...

Embodiment 2

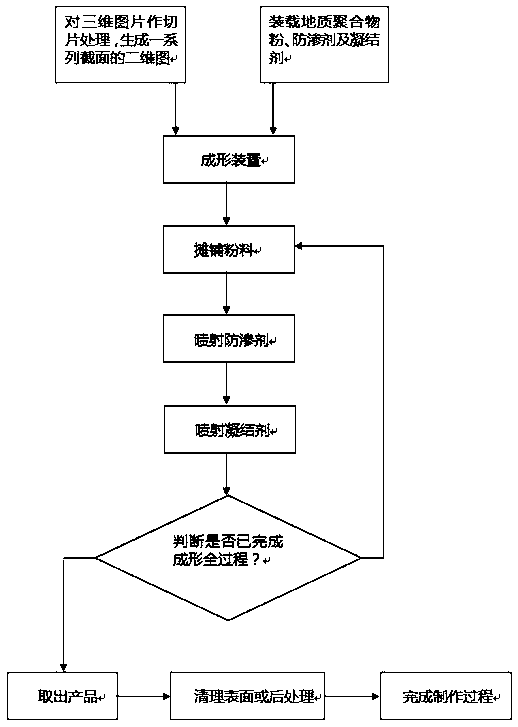

[0044] The present invention provides a forming method of a forming device for additive manufacturing of inorganic gelling material products according to an embodiment, through which the forming of refined products of geopolymer materials can be realized.

[0045] see figure 2 , the forming method comprises the following steps:

[0046] 1. Discrete the three-dimensional design graphics of the product to be processed into a series of two-dimensional horizontal cross-sectional graphics, and input them into the forming device control computer;

[0047] 2. Load raw materials such as powdery geopolymer materials, anti-seepage agent (shellac varnish) and coagulant (NaOH solution) into the forming device;

[0048] 3. The ultrasonic vibrating powder spreading mechanism in the forming device spreads and vibrates the powdery raw materials into a uniform thin layer with a thickness of about 0.1mm;

[0049] 4. The anti-seepage agent nozzle group in the forming device sprays the anti-pe...

Embodiment 3

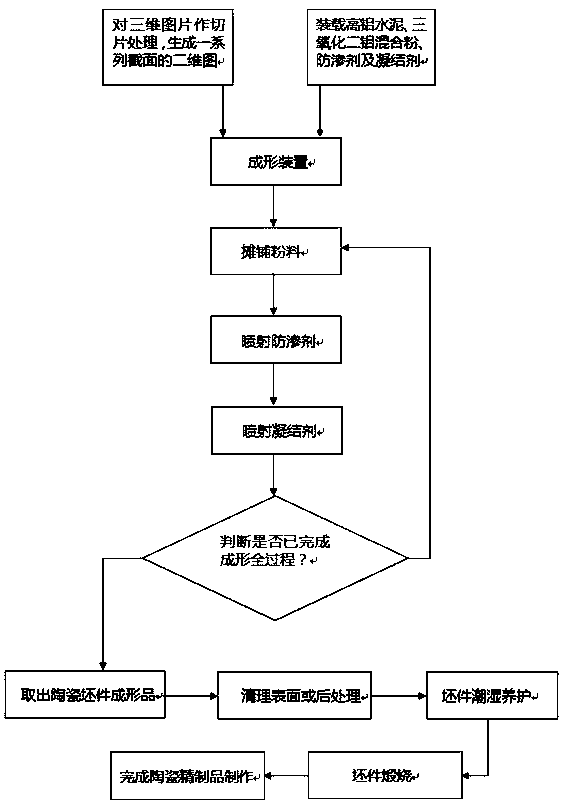

[0057] The present invention also provides another embodiment of the forming method of the forming device used for the additive manufacturing of inorganic cementitious material products, through which the forming of fine ceramic products is realized.

[0058] see image 3 , the method includes the following steps:

[0059] 1. Discrete the three-dimensional design graphics of the product to be processed into a series of two-dimensional horizontal cross-sectional graphics, and input them into the forming device control computer;

[0060] 2. Load the uniform mixture of high alumina cement and aluminum oxide, anti-seepage agent (shellac varnish) and water-based coagulant into the forming device;

[0061] 3. The ultrasonic vibrating powder spreading mechanism in the forming device spreads and vibrates the powdery raw materials into a uniform thin layer with a thickness of about 0.1mm;

[0062] 4. The anti-seepage agent nozzle group in the forming device sprays the anti-permeation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com