Preparation method of carbide-reinforced TiAl-based nano composite material

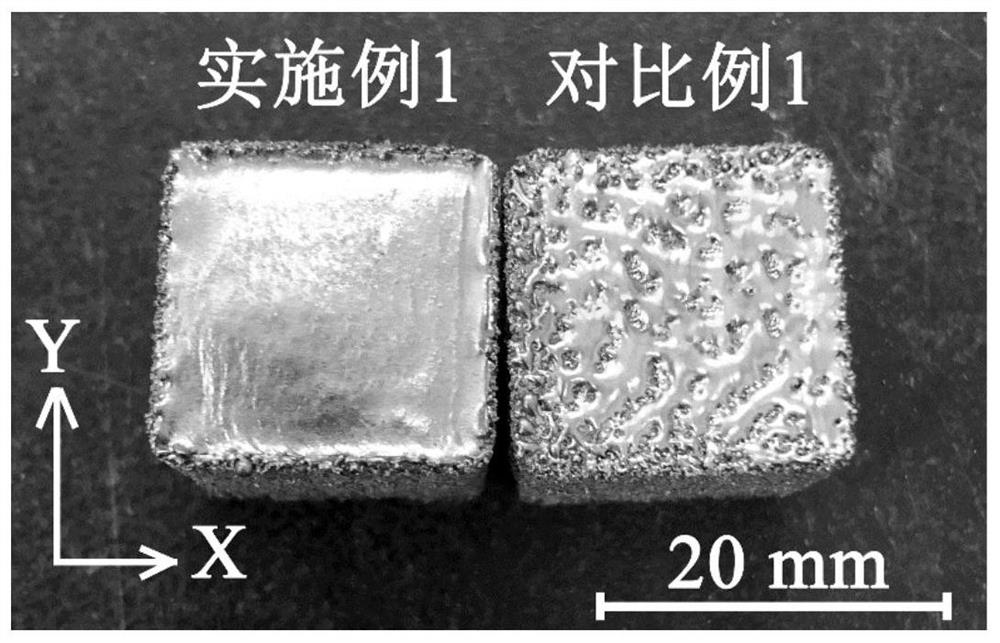

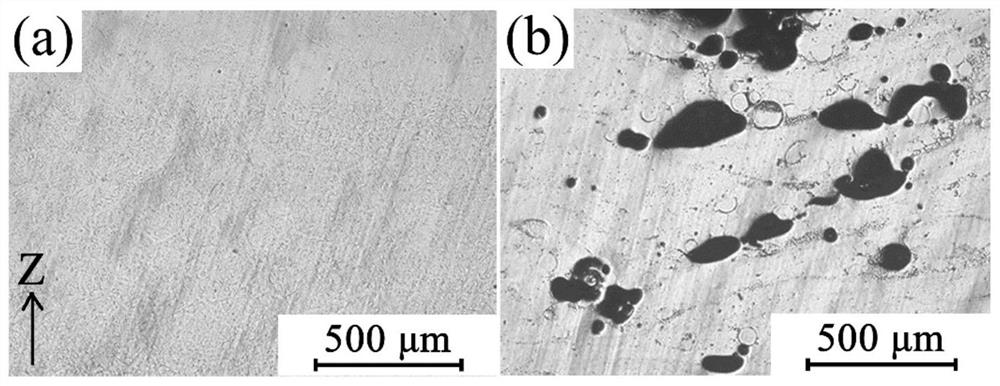

A nano-composite material and carbide technology, applied in additive processing, additive manufacturing, metal processing equipment, etc., can solve problems such as reduced power supply life, material porosity, powder unfused, etc., to optimize distribution uniformity and increase lubrication. Wetness, agglomeration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A carbide-reinforced TiAl-based nanocomposite material and a preparation method thereof. The high-Nb-TiAl alloy is used as a matrix, and TiC ceramic particles with a purity of more than 99.9% and an average particle size of 200nm are used as additional particles.

[0035] The matrix material is a high Nb-TiAl alloy powder with a particle size of 45-150 μm, and the D50 is 87 μm. It is prepared by a plasma rotating electrode method. The chemical composition of the high Nb-TiAl alloy is: 47.17at.%Al, 7.41at.%Nb, 0.86at.%Cr, 1.90at.%V, the balance is Ti.

[0036] Described a kind of carbide reinforced TiAl-based nanocomposite material and its preparation method, the steps are as follows:

[0037] (1) Using TiC ceramic particles and TiAl alloy powder as raw materials, the added TiC content is 0.7wt.%;

[0038](2) The two materials are mixed by a mechanical ball milling method to obtain a premixed powder in which TiC nanoparticles are evenly distributed on the surface of the...

Embodiment 2

[0050] What is different from Example 1 is: the preheating process is two-step preheating in the belonging step (3), the scanning speed of the first step preheating is 16000mm / s, and the electric current is 22mA, and the scanning speed of the second step preheating is 18000mm / s, the current is 22mA, and the forming temperature is kept at 1030°C. The scanning speed used in the semi-melting process is 4000mm / s, the current is 7mA, the line spacing is 0.03mm, and the defocus is 50mA. The scanning speed of the melting process is 11000mm / s, the current is 10mA, the line spacing is 0.02mm, and the defocus is 20mA. Others remain unchanged.

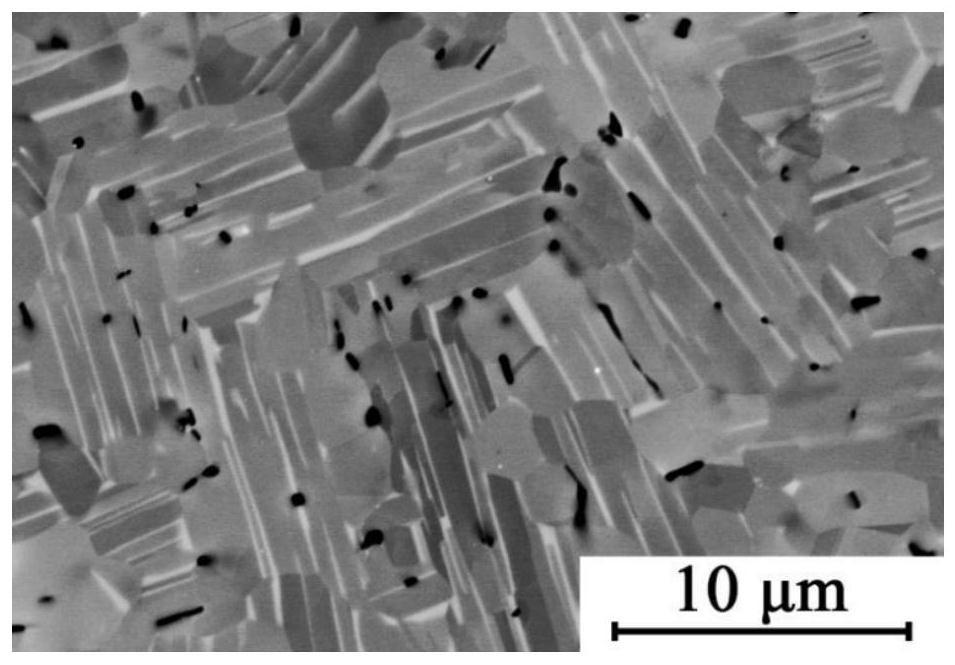

[0051] image 3 Shown is the SEM photo of the microstructure of the carbide-reinforced TiAl-based nanocomposite prepared in Implementation 2. It can be seen that the microstructure of the TiAl alloy matrix prepared by EBM is uniform and is a two-state structure. The black particles are carbides dispersed on the matrix at the nanometer scale. ...

Embodiment 3

[0054] The difference from Example 2 is that the scanning speed of the melting process in step (3) is 8000mm / s, the current is 10mA, the line spacing is 0.05mm, and the defocus is 20mA. Others remain unchanged.

[0055] After testing, the carbide-reinforced TiAl-based nanocomposite prepared in Example 3 has a microhardness of 440HV 0.2 , The tensile strength is 568MPa, the compressive yield strength is 1160MPa, the compressive strength is 2795MPa, and the compressive breaking strain is 24.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com