Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Shorten degassing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cross-linking agent

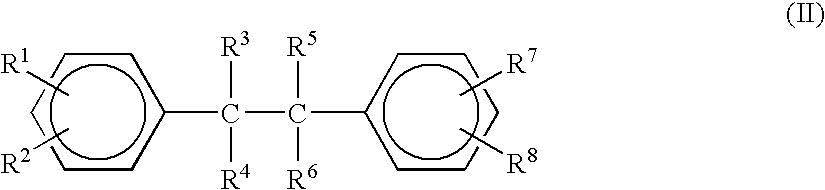

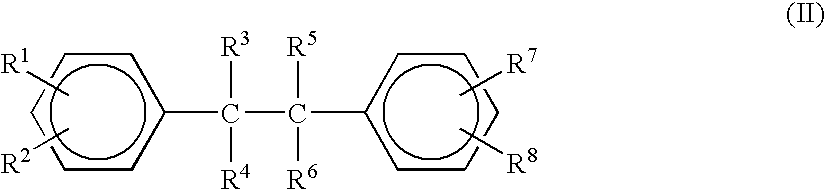

ActiveUS20100108357A1Improved crosslinkable polymer compositionReduce generationPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The present invention relates to a crosslinkable polymer composition comprising an unsaturated polyolefin having a total amount of carbon-carbon double bonds / 1000 carbon atoms of at least 0.38, and at least one crosslinking agent being a carbon-carbon initiator that is free of peroxide groups and capable of thermally decomposing into carbon-based free radicals by breaking at least one carbon-carbon single bond, such as 3,4-dimethyl-3,4-diphenylhexane.

Owner:BOREALIS TECH OY

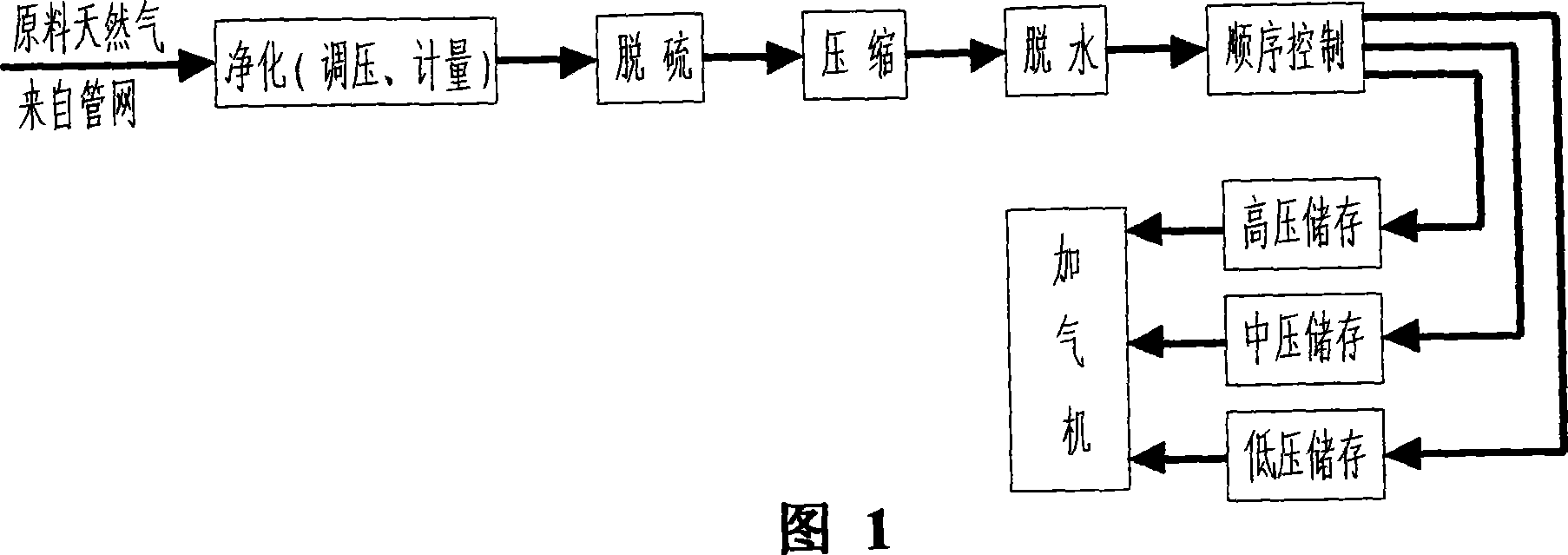

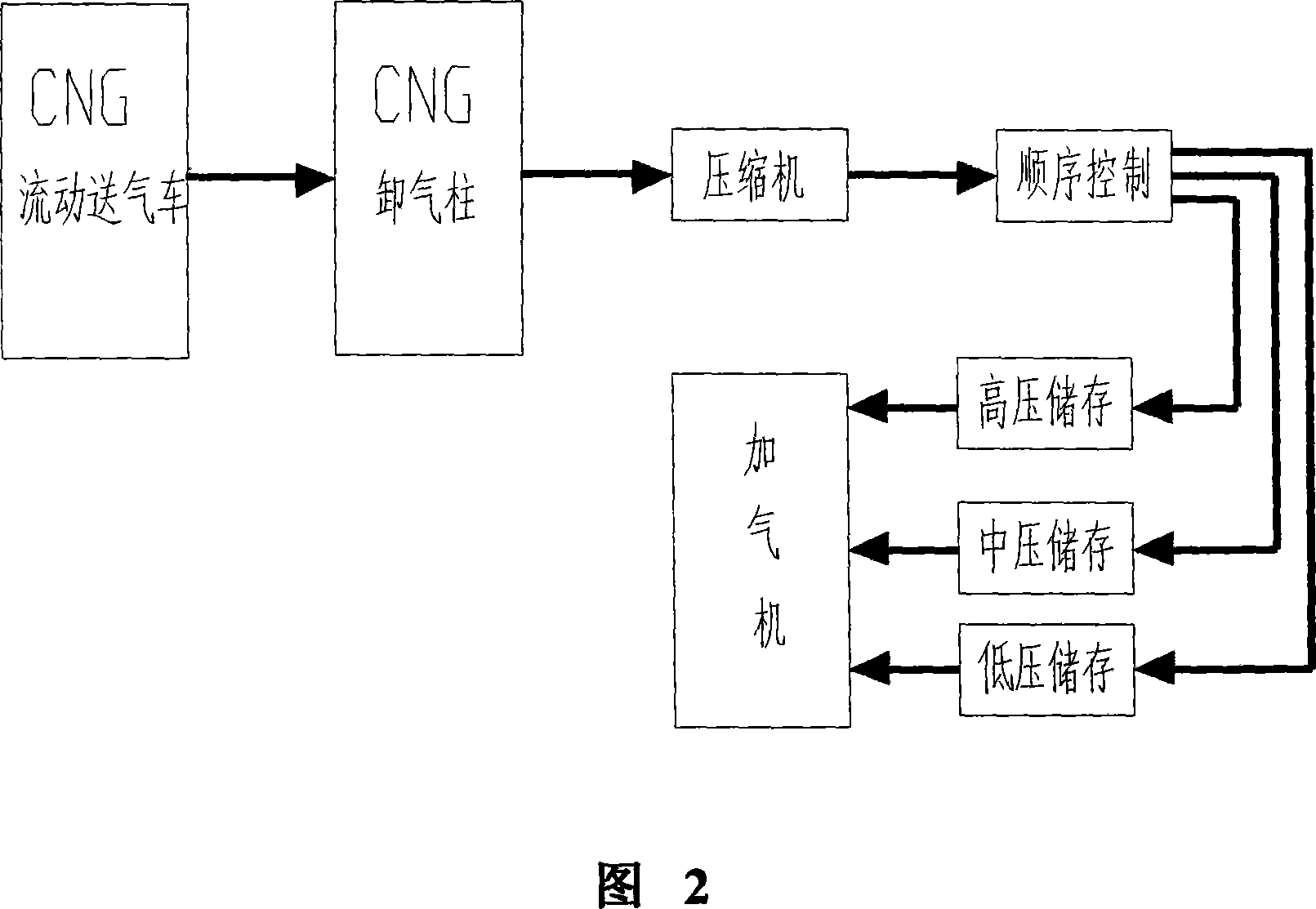

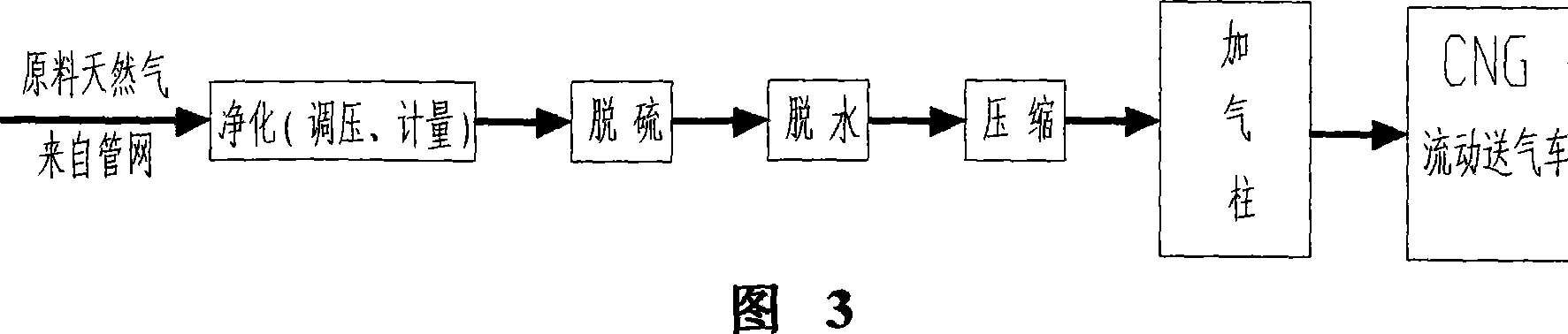

Gas-supply method of CNG gas-charging station for automobile

InactiveCN101059203AGuaranteed refueling serviceFull degassingPipeline systemsContainer filling under pressureProcess engineeringHigh pressure

The present invention discloses a gas supply method for vehicle CNG gas station (including ordinary, standard, sub-station gas stations) which is supplied gas by the natural gas pipe network or CNG mobile gas supply vehicles one by one. Said CNG mobile gas supply vehicles supply gas for the CNG gas station through gas releasing device; the high pressure gas releasing mouth of said gas releasing device is equipped with two gas releasing channels which supply gas to the high pressure gas storing device and the gas station separately; the medium (low )pressure gas releasing mouth of said gas releasing device is equipped with two gas releasing channels which supply gas for the medium or low pressure gas storing device and the gas station; said gas releasing device is equipped with residual gas releasing channel which is connected with the inlet of CNG gas station compressor technology system and supplies gas for the compressor. The advantages are: the CNG gas station has the function of CNG sub-station gas station at the same time, the CNG mobile gas supply vehicles can supply gas when the pipe network can not supply gas, the gas releasing speed is fast and the gas releasing is exhaustive. The operation is controlled intelligently and the operation is safe and reliable. So the disposition number of the CNG mobile gas supply vehicles is reduce, the CNG gas station technology and equipment resources are used fully and the CNG sub-station costs are reduced.

Owner:李富国

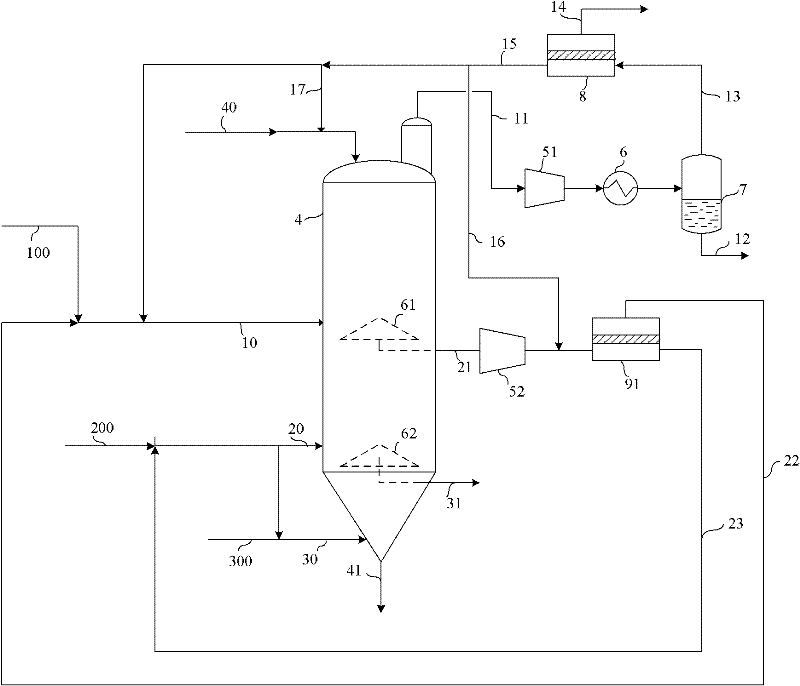

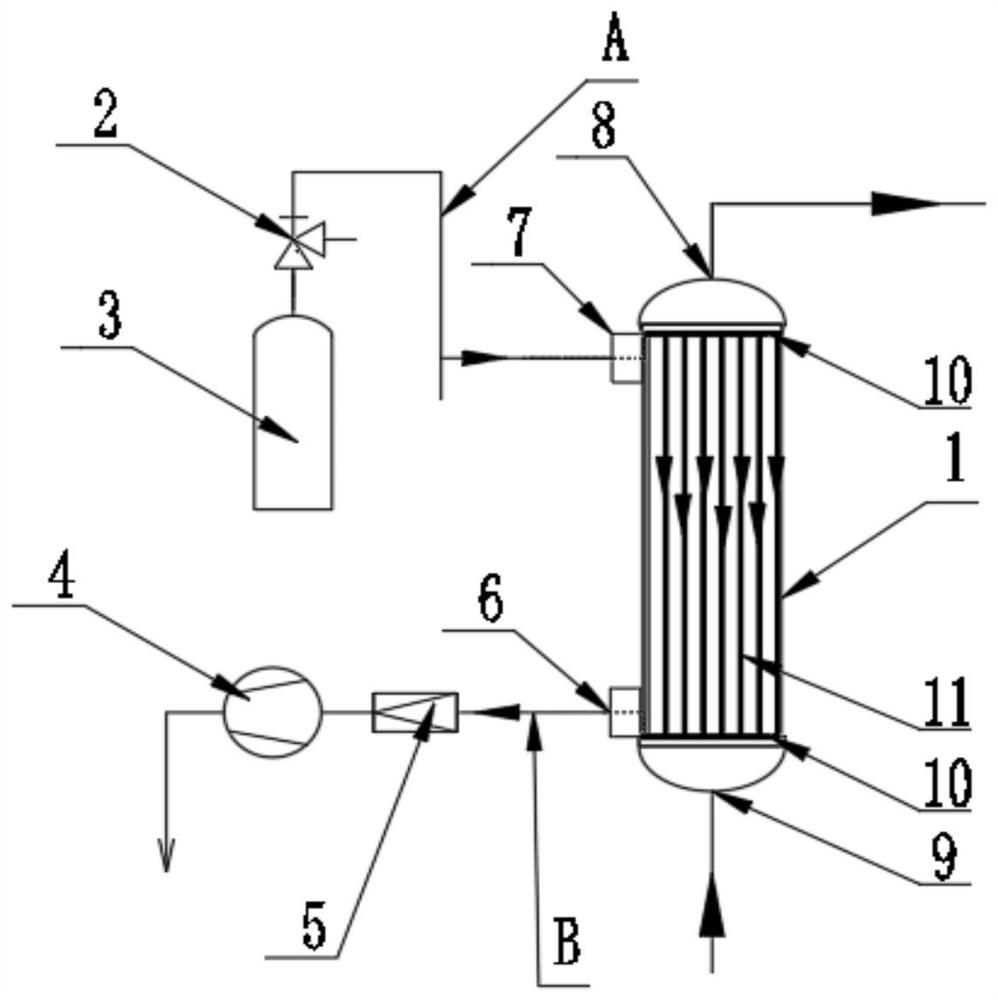

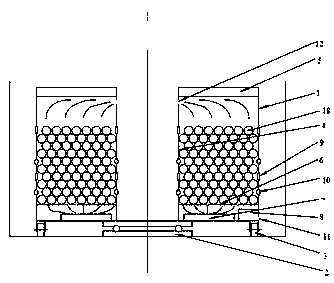

Oil spraying vacuum degassing device for online monitoring of oil chromatogram and application method

PendingCN108627601AIncrease flow rateReduce volumeComponent separationInternal pressureSolenoid valve

The invention discloses an oil spraying vacuum degassing device for online monitoring of an oil chromatogram and an application method and relates to the field of separating materials through a chromatography. The oil spraying vacuum degassing device comprises a degassing cylinder for degassing, wherein the degassing cylinder is provided with an oil feeding opening for feeding oil and an oil returning opening for discharging the oil; the oil spraying vacuum degassing device further comprises a vacuum pump for realizing negative pressure of the degassing cylinder and a circulating solenoid valve for realizing circulating oil; the oil feeding opening and the oil returning opening are connected through a pipeline provided with the circulating solenoid valve; the oil feeding opening is connected with a spraying structure. When the oil spraying vacuum degassing device is used, pressure in the degassing cylinder is pumped to a complete vacuum negative-pressure state and then transformer oilis injected; then a plurality of times of circulation are carried out and filtered gas is pumped to finish concentration detection work; finally, an oil sample is recycled. The oil spraying vacuum degassing device disclosed by the invention has the beneficial effects that the degassing efficiency is improved and the degassing time is shortened; a bottom-end side face in the degassing cylinder is set to be a reversed tapered surface, so that the volume of residual oil can be effectively reduced and a condition that impurities deposited at the bottom of the inner side of the degassing cylinder are pumped into the pipeline can be avoided.

Owner:SHANDONG WUYUE ELECTRICAL APPLIANCES

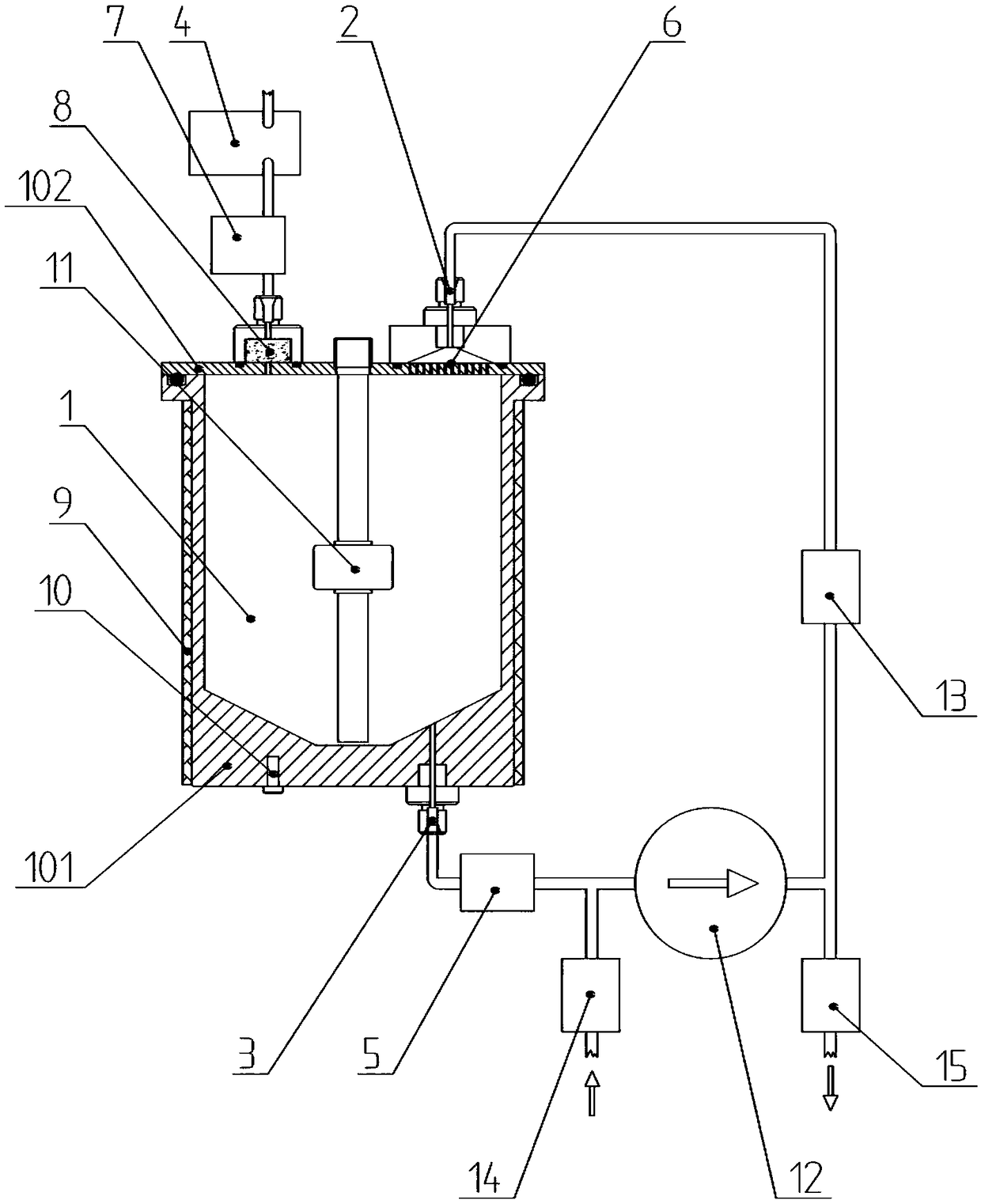

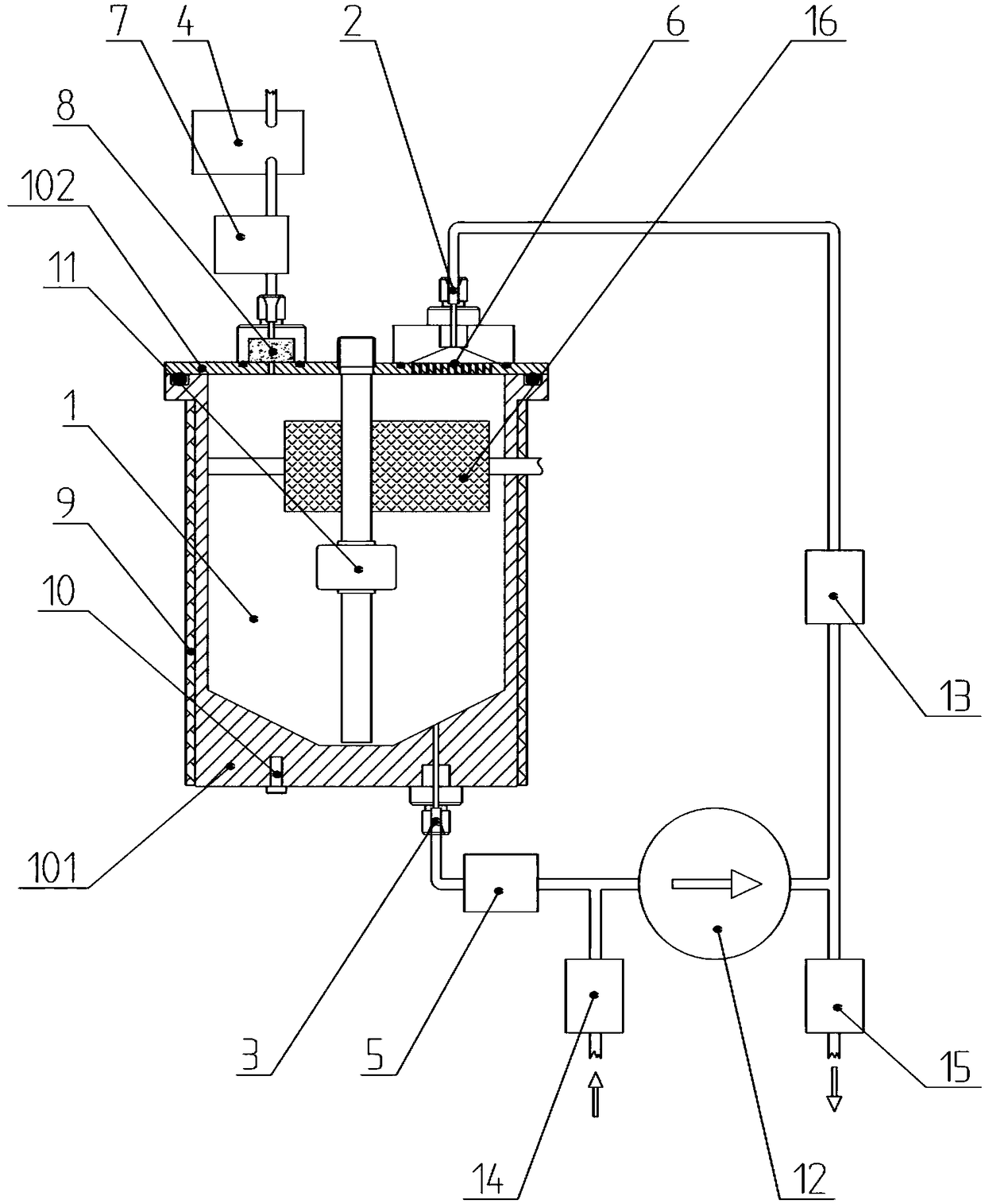

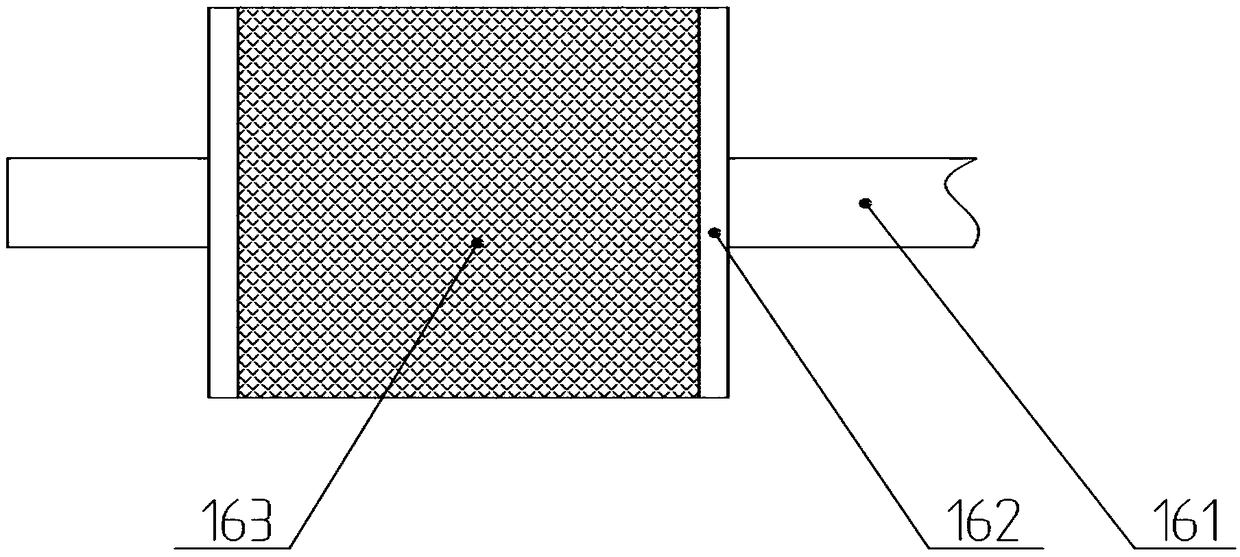

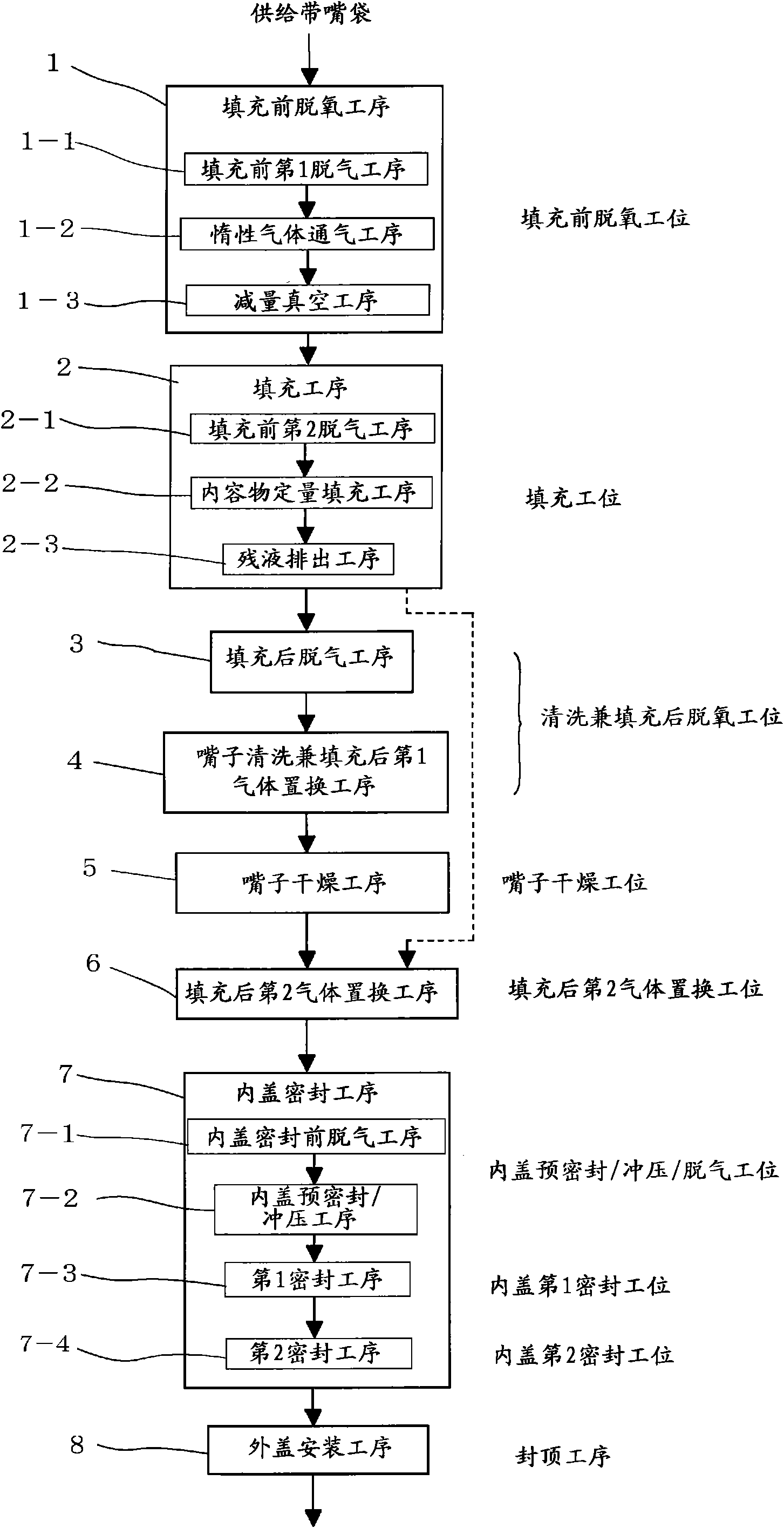

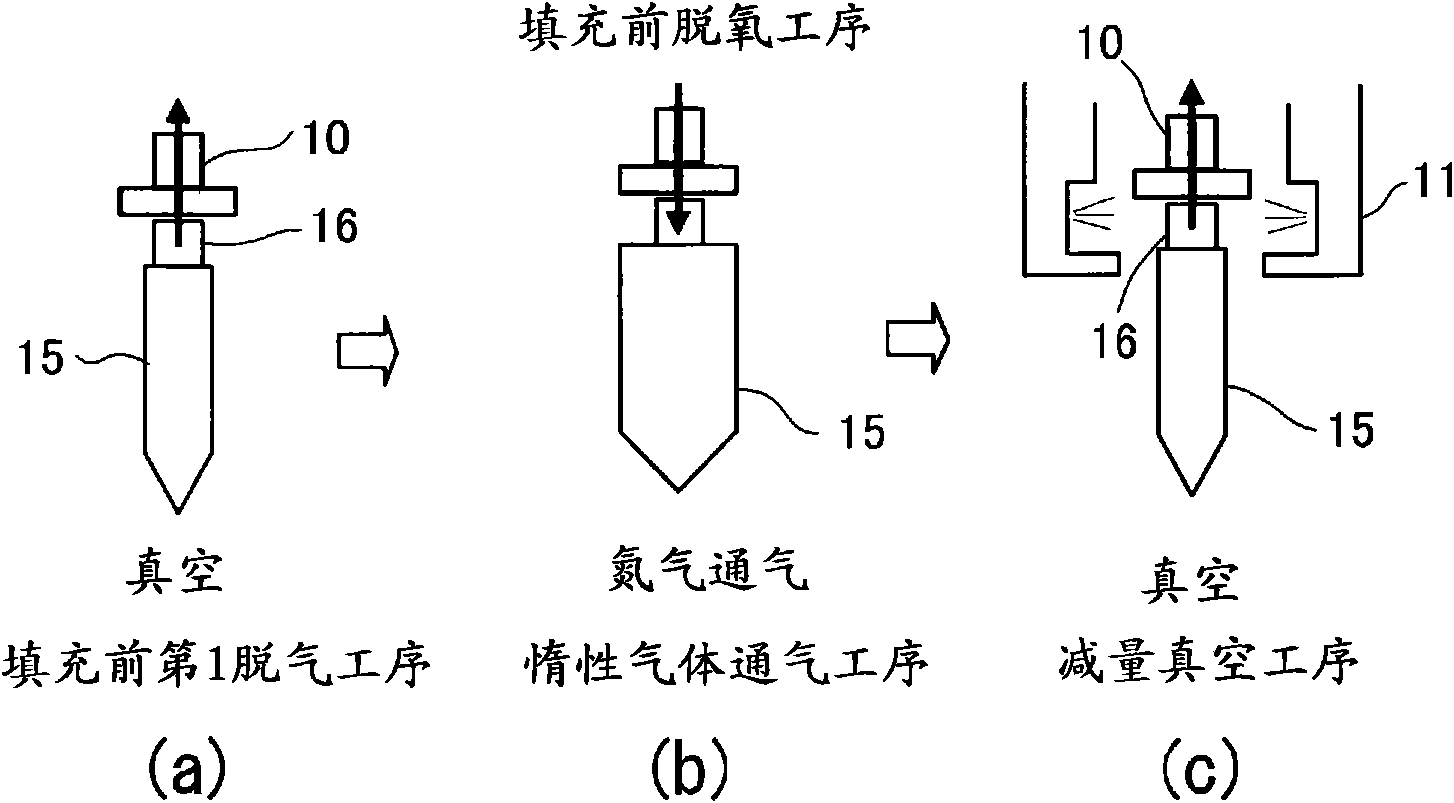

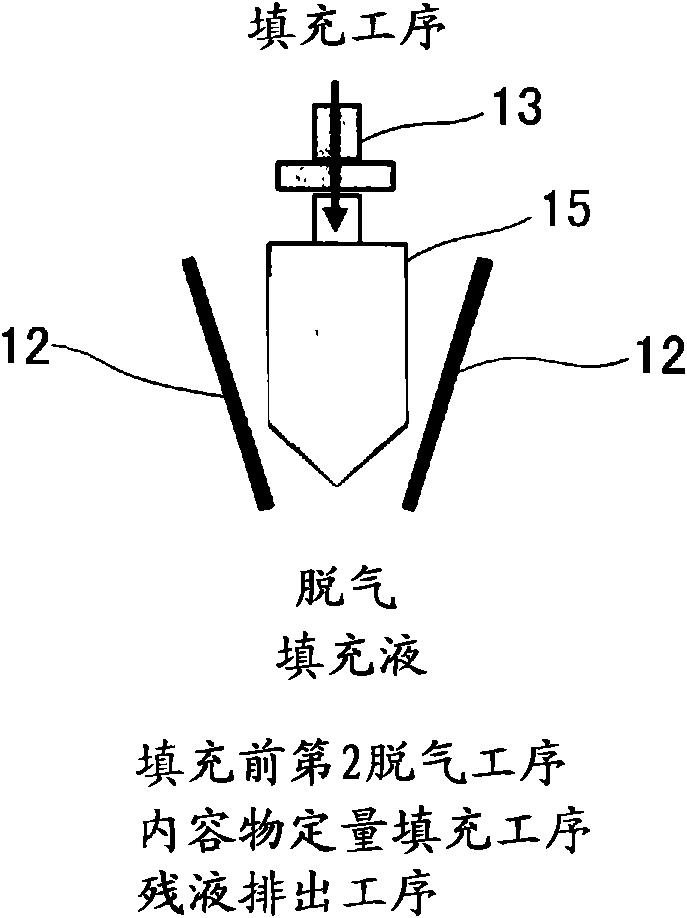

Method of packing liquid filling into spouted pouch and sealing the pouch and apparatus therefor

InactiveCN101588968AImprove qualityHigh deoxygenation ratePackaging by pressurising/gasifyingPackaging protectionLiquid stateProduct gas

To obtain a spouted-pouch package having a high degree of deoxidation by a method in which even a liquid filling which readily lathers can be packed while being inhibited from lathering. [MEANS FOR SOLVING PROBLEMS] A before-packing deoxidation step (1) is performed before a liquid filling is packed into a pouch. The step (1) comprises: a vacuum step (1-1) in which the pouch is evacuated under vacuum; an inert-gas blow step (1-2) in which an inert gas is blown into the pouch after the vacuum step; and a gas-diminishing vacuum step (1-3) in which the gas in the pouch after the inert-gas blow step is discharged under vacuum to diminish the gas in the pouch to a given amount. Thereafter, the pouch is evacuated in a second before-packing evacuation step (2-1) and then packed with the filling. After the packing, gas replacement is conducted.

Owner:TOYO SEIKAN KAISHA LTD

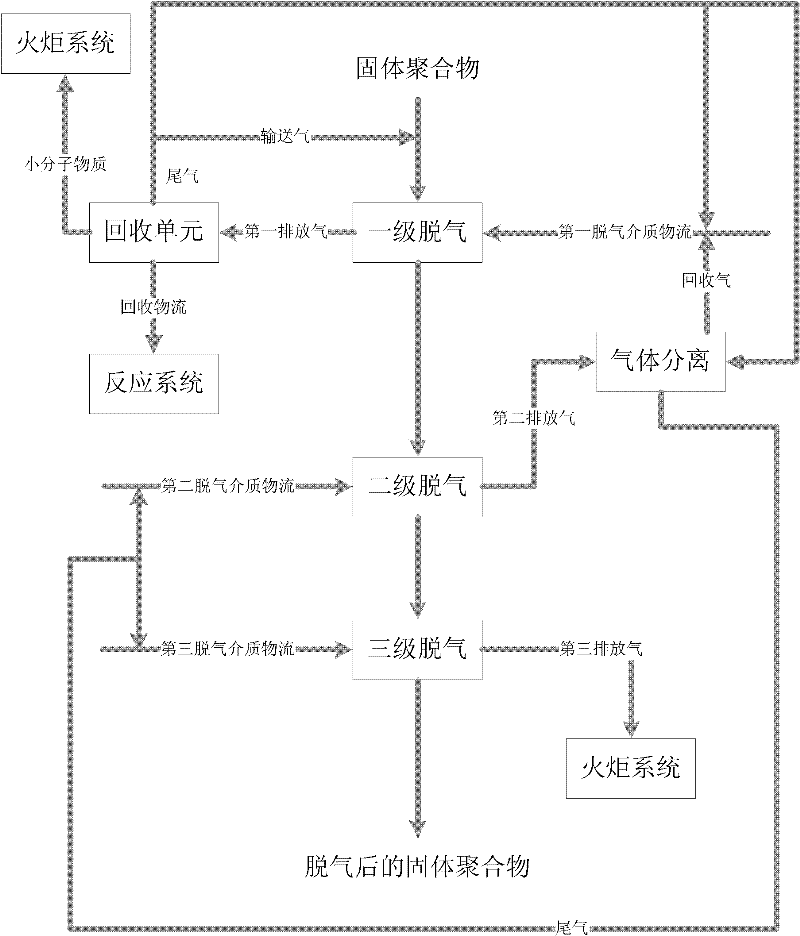

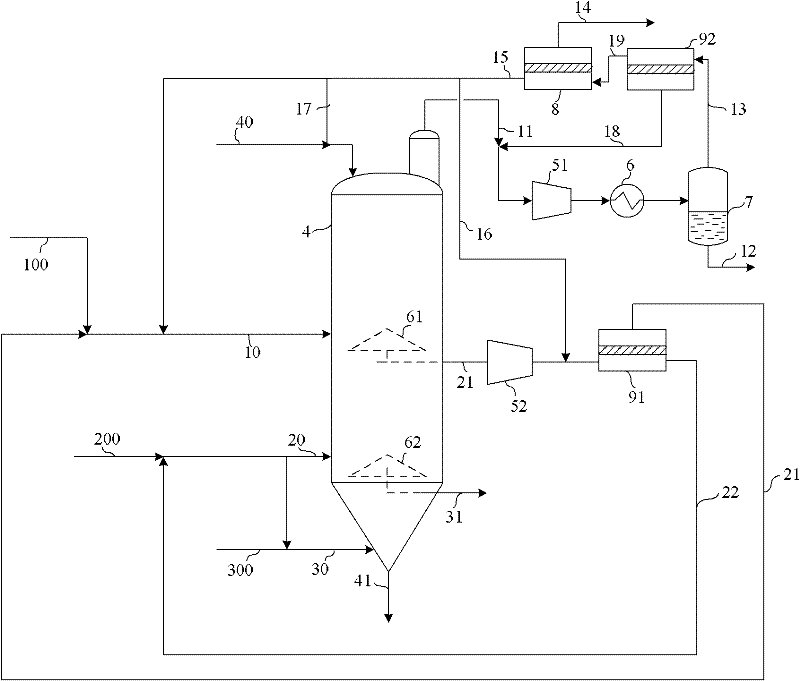

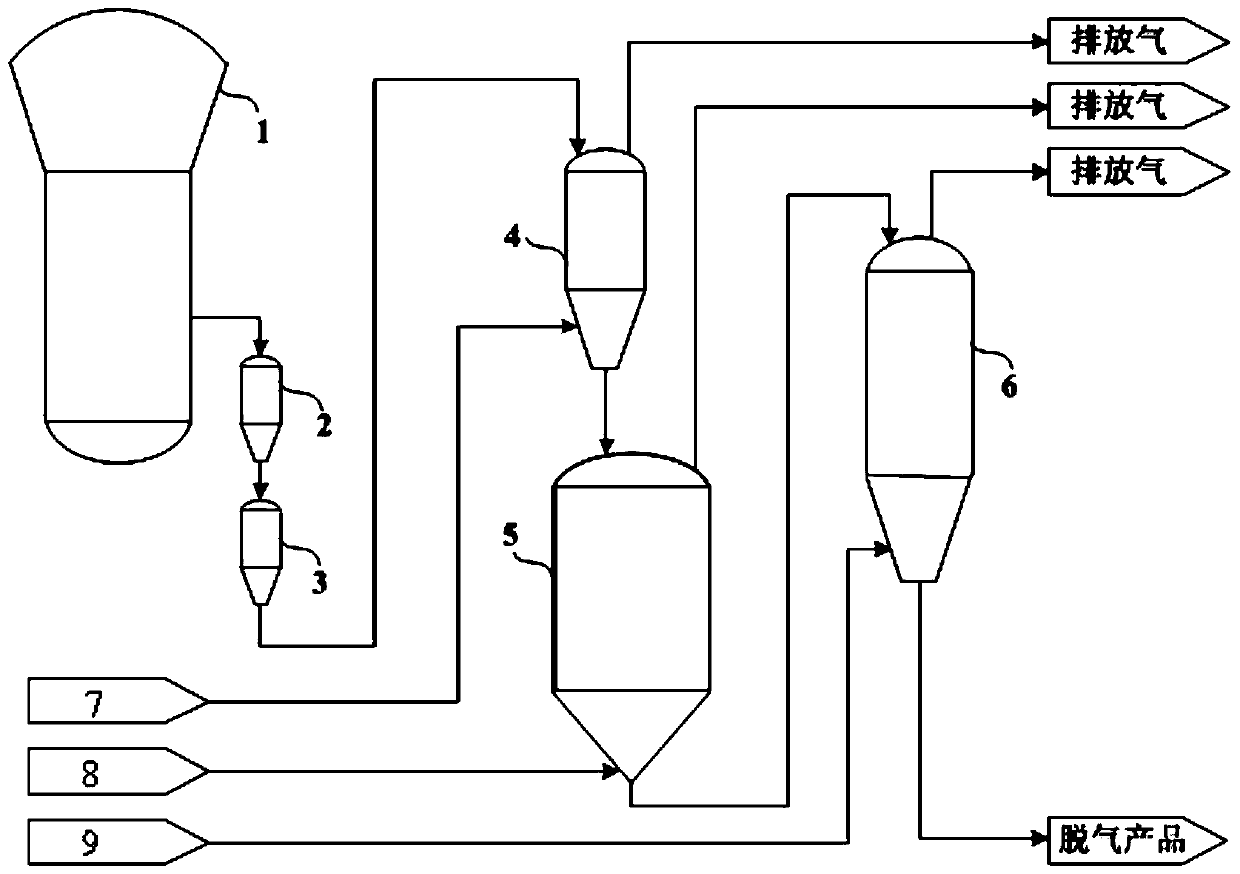

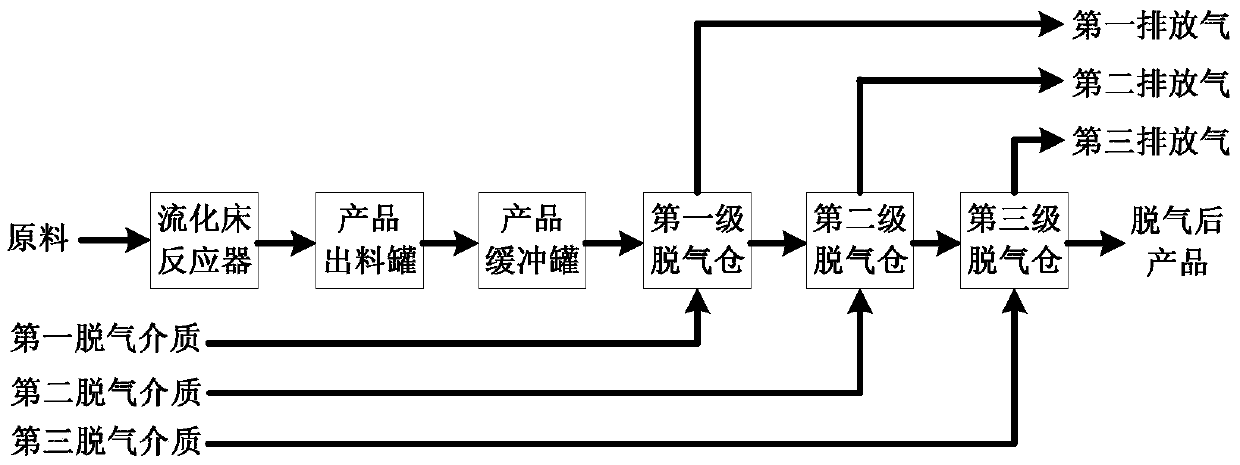

Method and device for degassing solid polymer and recovering effluent gas

The invention discloses a method for degassing a solid polymer and recovering effluent gas. A solid polymer enters a degassing container for decompression and is subjected to three degassing processes: 1) the solid polymer fully contacts with a gaseous reacting substance to remove the most of a solvent and an unreacted monomer in the solid polymer; 2) the processed solid polymer fully contacts with inert gas to remove the gaseous reacting substance and further remove the solvent and the unreacted monomer; and 3) the processed solid polymer fully contacts with the inert gas containing a catalyst deactivator. The effluent gas discharged in the degassing steps 1) and 2) is separated and processed from gas after being recovered, and the solvent, the unreacted monomer and a degassing medium are all recovered and utilized. The invention also discloses a device for implementing the method. With the method disclosed by the invention, degassing time for a polymer is shortened, the use amount of the degassing medium is reduced, the solvent and the unreacted monomer can be effectively recovered, and the degassing medium is recycled, thereby preventing micromolecules from being accumulated, reducing emission amount and lowering energy consumption. The method has the advantages of strong realistic significance and application value.

Owner:ZHEJIANG UNIV

Cross-linking agent

ActiveUS8247696B2Reduce generationSimple compositionPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

A crosslinkable polymer composition of an unsaturated polyolefin having a total amount of carbon-carbon double bonds / 1000 carbon atoms of at least 0.38, and at least one crosslinking agent being a carbon-carbon initiator that is free of peroxide groups and capable of thermally decomposing into carbon-based free radicals by breaking at least one carbon-carbon single bond, such as 3,4-dimethyl-3,4-diphenylhexane.

Owner:BOREALIS TECH OY

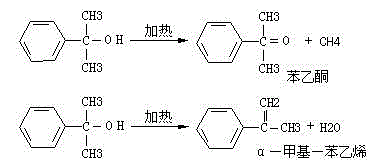

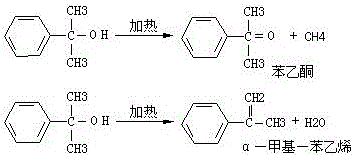

Environment-friendly curtain adhesive for hair product and preparation method thereof

ActiveCN101892028AAvoid pollutionReduce energy consumptionNon-macromolecular adhesive additivesWigsPolyurethane adhesiveDecomposition

The invention relates to an environmental-friendly curtain adhesive for a hair product and a preparation method thereof. The environmental-friendly curtain adhesive for a hair product is compatibly dissolved and synthesized by the following raw materials in parts by weight: 0.05 part of alcohol-soluble polyurethane adhesive b, 0.04 to 0.15 part of sugar ester, 0.05 to 0.25 part of rosin, 0.05 to 0.4 part of curing agent of alcohol-soluble polyurethane adhesive, 0.01 to 0.08 part of sodium persulfate and 0.15 to 0.75 part of absolute ethyl alcohol. In the preparation method, the thermal decomposition type sodium persulfate is used as the initiator to avoid pollution caused by a decomposition product remained in the adhesive when the organic peroxide is used as the initiator; the high-temperature polymerization replaces the low-temperature polymerization to reduce the energy consumption; the conversion rate of the polymerization reaction is improved and the quantity of the recovered monomer is reduced; the physical degasification and the chemical degasification are combined, so that the degasification time is shortened and the energy consumption is reduced.

Owner:XUCHANG HENGYUAN HAIR PROD

Preparation method of poly(p-phenylene benzobisoxazole) fibers

ActiveCN112760737AReduce accumulationReduce decreaseMonocomponent synthetic polymer artificial filamentFiberSpinning

The invention belongs to the field of high-performance fibers, and particularly relates to a preparation method of poly(p-phenylene benzobisoxazole) fibers. The preparation method comprises the following steps of taking frozen polyphosphoric acid powder, phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid as raw materials, putting the phosphorus pentoxide into a reaction system step by step in a reasonable proportion in a proper time period, and detecting and regulating the apparent viscosity of the materials in real time in a prepolymerization process to ensure that a prepolymer with uniform apparent viscosity is obtained; performing post-polymerization to obtain PBO spinning slurry; and performing dry-jet wet spinning and post-spinning to obtain the finished PBO fibers. The method overcomes the defects that traditional solid raw materials are poor in solvent mixing and dispersing effect, easy to agglomerate and incapable of uniformly reacting, ensures the consistency of a prepolymerization reaction end point, and reduces the process errors. The intrinsic viscosity of the polymer in the same batch in different time periods is small in change and high, the mechanical property of the fibers can be obviously improved, and the quality stability is also improved.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

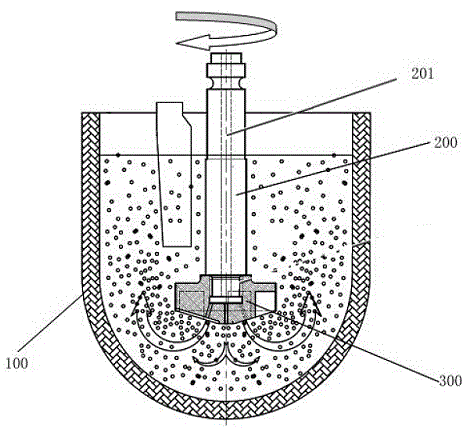

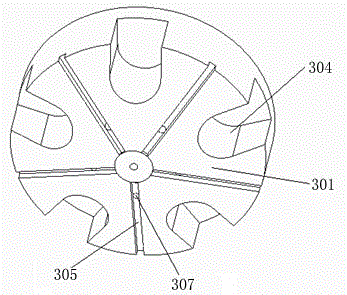

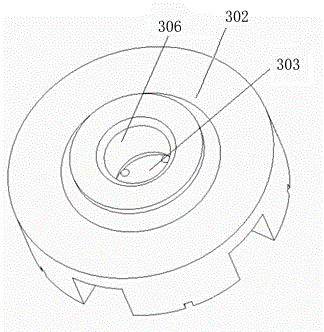

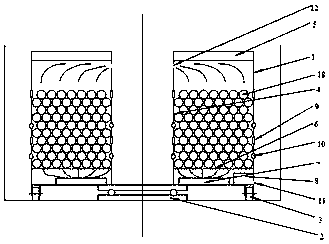

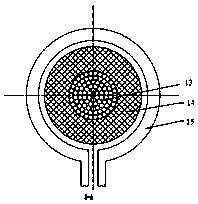

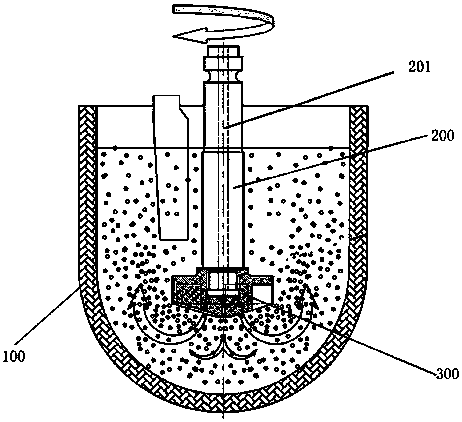

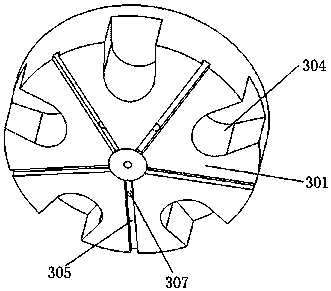

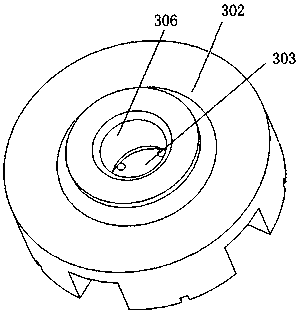

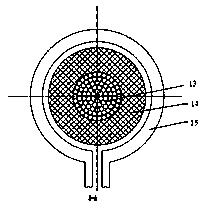

Degassing rotor structure with sealed gas accumulation function

The invention discloses a degassing rotor structure with a sealed gas accumulation function. The degassing rotor structure comprises a rotating rod and a rotor body, wherein a gas inlet channel is formed in the rotating rod; the rotor body is a disc-like rotating table; the rotating table comprises a first end surface and a second end surface; a plurality of gas outlet grooves are formed in the first end surface; a gas accumulation cavity which is positioned in the center of the first end surface but not communicated with the first end surface is formed in the table body of the rotating table, communicated with the gas inlet channel through a gas inlet hole in the second end surface, and communicated with the gas outlet grooves through a plurality of gas outlet channels distributed uniformly in the circular direction. On one hand, gas flow in the gas accumulation cavity is stable, and gas passes through the uniformly distributed gas outlet channels, is distributed into all the gas outlet grooves under uniform pressure, and then is subjected to uniform shearing to form bubbles, so that the purpose of efficient degassing can be fulfilled; on the other hand, the gas accumulation cavity is prevented from being impacted by the abrasion of the rotor body, impact on the degassing effect is avoided, and the blockage possibilities of the gas outlet channels are low.

Owner:SUZHOU MINGZHI TECH

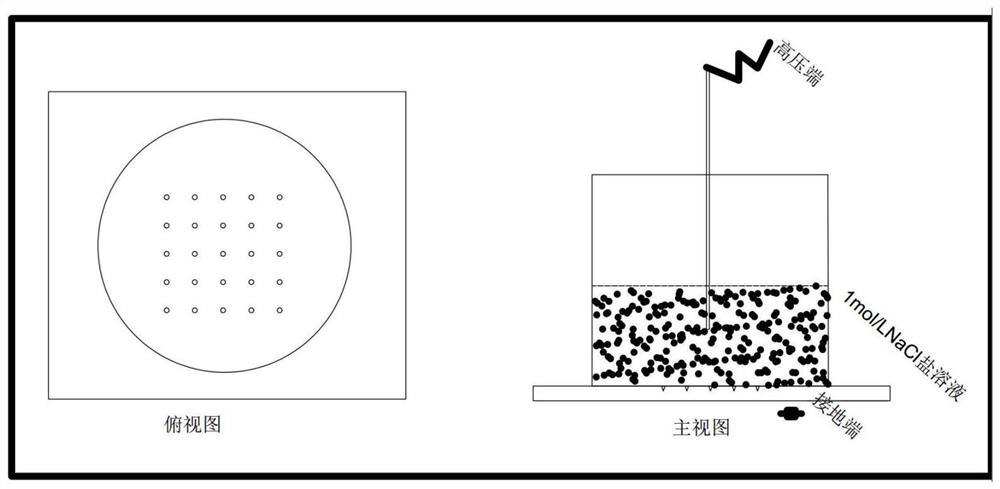

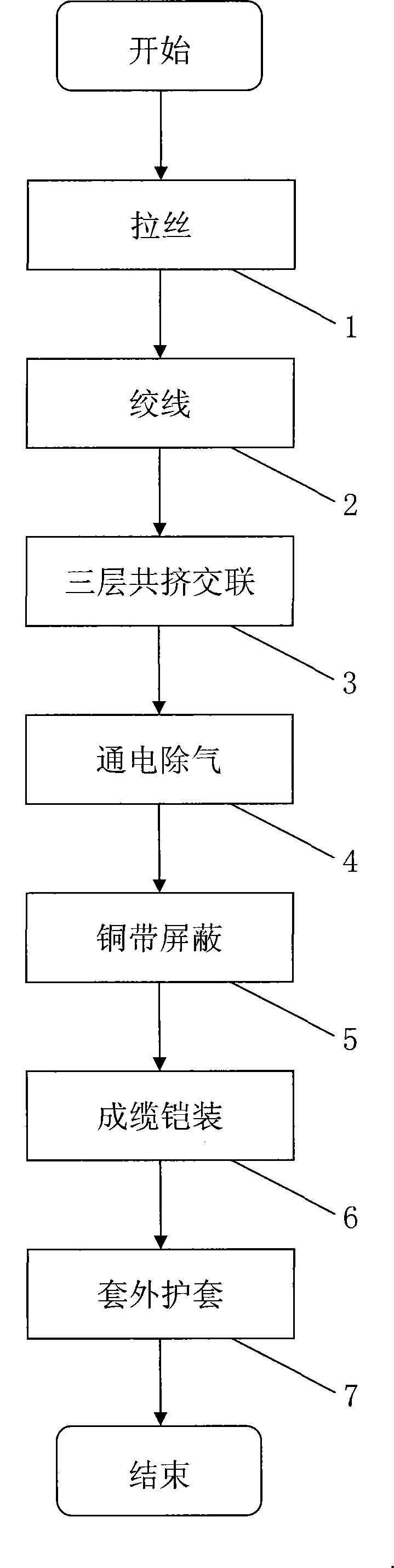

66-500kv crosslinked cable short-degassing online treatment process

ActiveCN104979051AFast degassing rateGood effectInsulating conductors/cablesElectrical conductorNitrogen

The invention discloses a 66-500kV crosslinked cable short-degassing online treatment process. A process flow comprises conductor preparing; three-layer co-extruding and insulating and online degassing; and degassing in a drying room, wherein the step of three-layer co-extruding and insulating and online degassing specifically comprises three-layer co-extruding of a conductor shielding layer, an insulating layer and an insulating shielding layer; crosslinking; cooling; secondary heating; and cooling; the secondary heating is carried out under protection of nitrogen atmosphere, the nitrogen concentration of the nitrogen atmosphere is controlled over 98%, the nitrogen temperature is controlled at 220+ / -5 DEG C, and the conductor temperature is controlled at 90 DEG C. According to the 66-500kV crosslinked cable short-degassing online treatment process disclosed by the invention, the insulating layer is not aged during degassing, the degassing rate is high, the byproduct removal effect is good, the degassing time of the drying room can be greatly shortened, the production period is shortened, and energy is saved and emission is reduced.

Owner:浙江万马股份有限公司

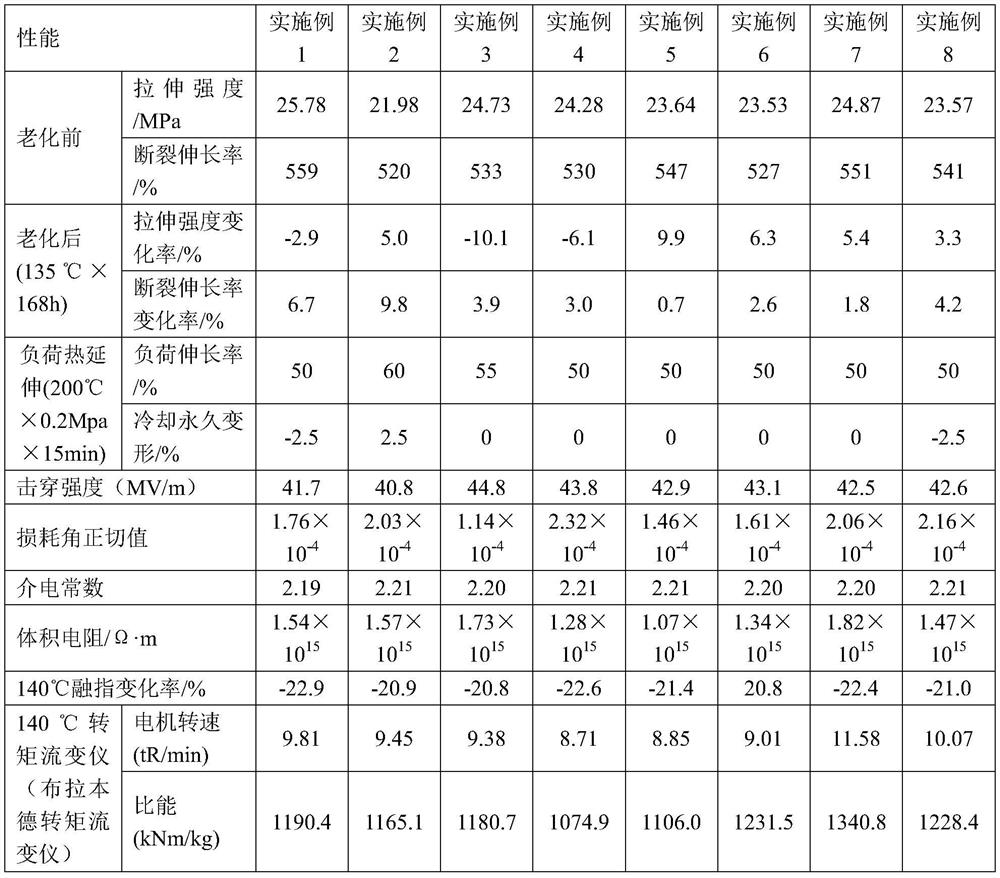

High-voltage cable insulating material and preparation method and application thereof

PendingCN111635569AImprove insulation performanceExcellent breakdown strength stabilityLow-density polyethyleneCross linker

The invention provides a high-voltage cable insulating material and a preparation method and application thereof. The high-voltage cable insulating material comprises the components in parts by weight: 100 parts of low density polyethylene; 0.1 to 0.3 part, preferably 0.15 to 0.20 part, of an antioxidant; 1.0 to 2.0 parts, preferably 1.0 to 1.5 parts, of a cross-linking agent; 0.5 to 5.0 parts, preferably 0.5 to 2.0 parts, of a polybutadiene auxiliary agent; and 0.5-10.0 parts, preferably 0.5-5.0 parts, of a high polymer material additive. The high-voltage cable insulating material disclosed by the invention is excellent in comprehensive insulating property; the high-voltage cable insulating material disclosed by the invention has excellent breakdown strength stability, and meanwhile, an excellent water-tree-resistant effect is obtained, so that the long-term use stability of the material can be obviously improved. Furthermore, the preparation method of the high-voltage cable insulating material can greatly reduce the use amount of the cross-linking agent, has lower processing energy consumption, effectively reduces the cost, is suitable for industrial long-time stable production,and indirectly shortens the degassing time.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

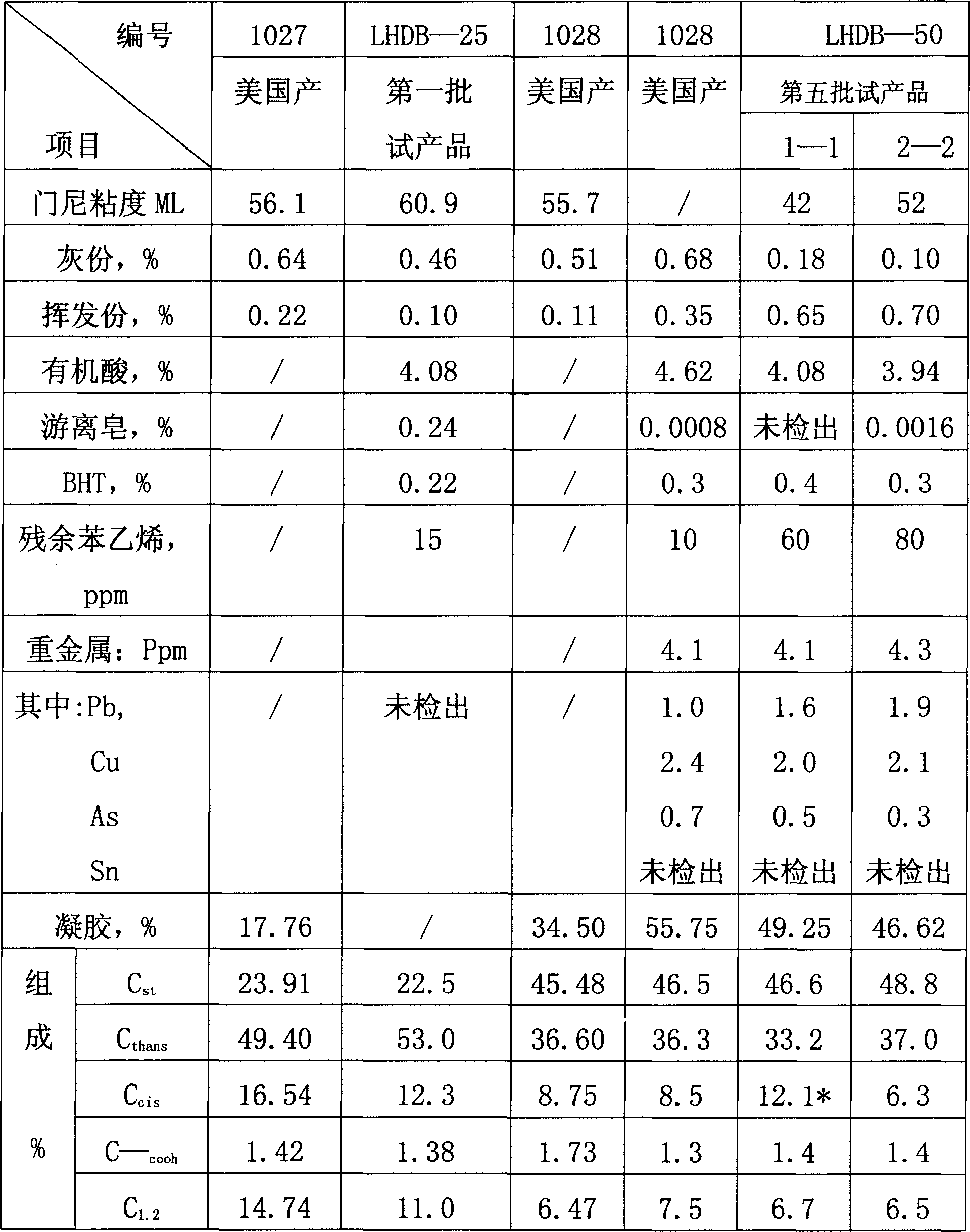

Synthesis method of high conversion food grade styrene butadiene rubber

A process for preparing food-class butadiene-styrene rubber with high conversion rate 85-98% includes such steps as high-temp emulsion polymerizing between conjugated diolefin and styrene, and as well as water-soluble peroxide as trigger and food-class surfactant as emulsifier, vacuum degassing, coagulating, and drying.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

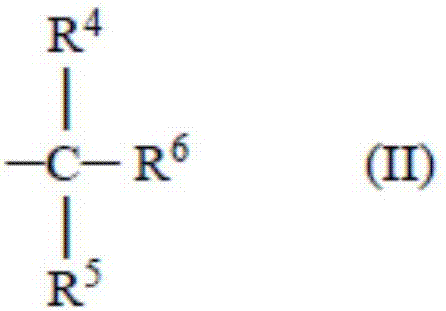

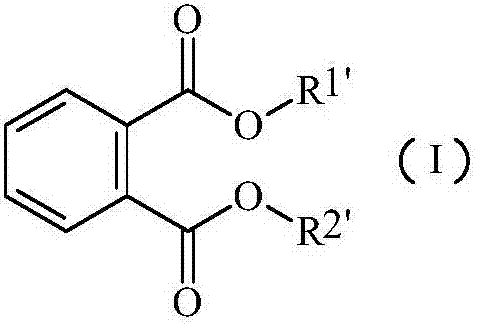

Process for preparing propylene copolymers

The present invention relates to an olefin polymerization process, wherein propylene and 1-butene and optionally ethylene are reacted in the presence of a Ziegler-Natta catalyst system so as to obtain a polypropylene, wherein the polypropylene comprises 1-butene-derived comonomer units in an amount of from 0,5 to 15 wt% and optionally ethylene-derived comonomer units in an amount of up to 3 wt%, and the Ziegler-Natta catalyst system comprises an external donor of the formula (I) (R3)z(R2O)YSi(R1)x (I).

Owner:BOREALIS AG

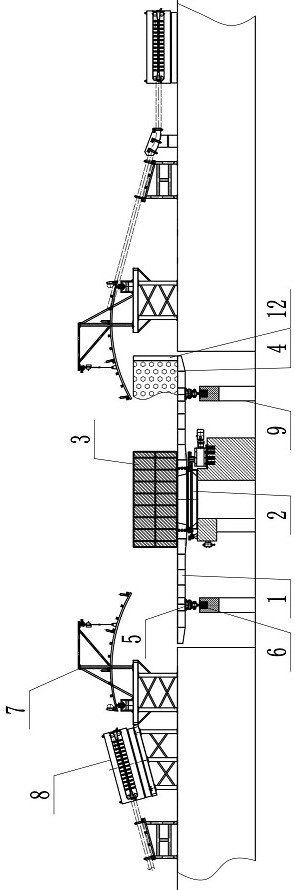

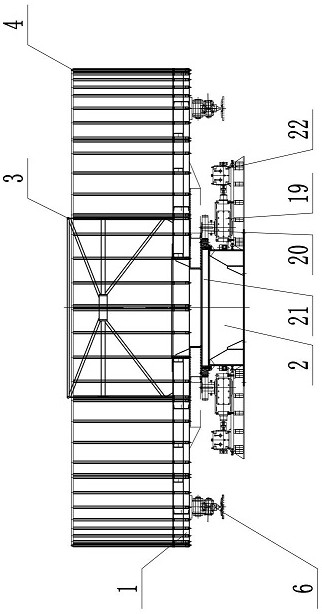

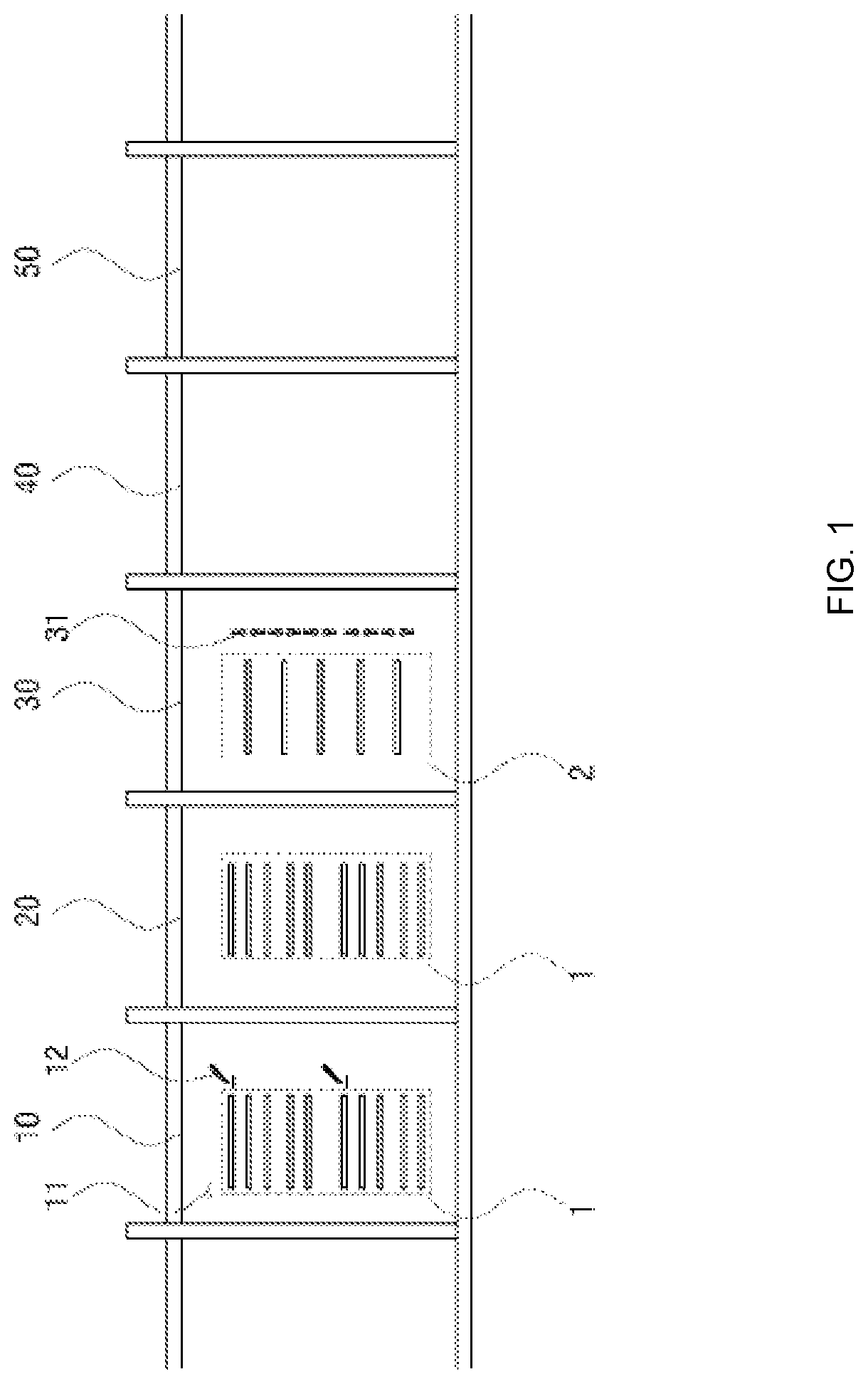

A degassing assembly line for electric cables

ActiveCN109243709AIncrease productivityAchieve online degassing effectApparatus for heat treatmentInsulation layerElectrical conductor

The invention discloses a degassing assembly line for electric cable, comprising a vertical tower extruder and a degassing chamber, wherein, the vertical tower extruder and the degassing chamber are connected with each other through a cable insulation wire core; The cable insulation wire core is composed of a copper core stranded conductor and a shielding insulation layer, and the shielding insulation layer is wrapped on the outer wall of the copper core stranded conductor. A plurality of supporting rollers and the steering supporting rollers are arranged between the vertical tower extruder and the degassing chamber; A plurality of high-frequency heating coils are arranged between the two supporting rollers, the high-frequency heating coils are circular rings with openings at the bottom end, and the cable insulation wire core passes through the high-frequency heating coils. As that high-frequency heat coil heats the cable conductor in the production process of the insulated wire core,the degassing assembly line realizes the heating while producing the insulated wire core, achieves the on-line degassing effect, saves the degassing time, improves the production efficiency of the cable, and has better degassing effect.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD +1

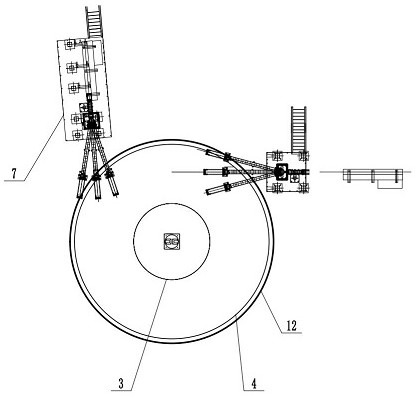

Submarine cable tray degassing chamber

PendingCN112133498ARealize online storageExtended service lifeInsulating conductors/cablesMarine engineeringElectric machinery

The invention discloses a submarine cable tray degassing chamber. The submarine cable tray degassing chamber comprises a rotary disc chassis base; a rotary disc is arranged below the rotary disc chassis base; a side guide rail is arranged on the outer side of the rotary disc; a driving motor is arranged below the rotary disc chassis base; the driving motor is connected with the side guide rail through a driving roller; an inner cylinder and an outer cylinder are arranged above the rotary disc chassis base; a heating air pump is arranged in the inner cylinder; a detachable top cover is arrangedabove the inner cylinder and the outer cylinder; wire arranging devices are arranged on the two sides of the rotary disc chassis base; and tractors are arranged at the outer ends of the wire arranging devices. Compared with the prior art, the submarine cable tray degassing chamber has the beneficial effects of being simple in structure, convenient to use and operate and capable of greatly improving the working efficiency.

Owner:万达集团股份有限公司 +1

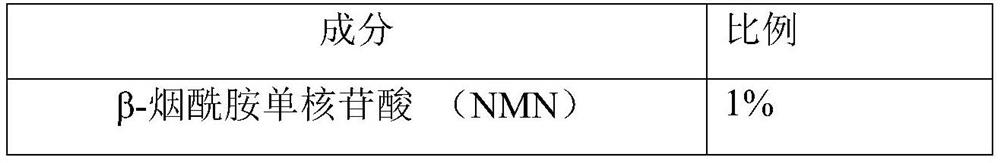

Moisturizing NMN hydrophilic gel and preparation method thereof

PendingCN114129509ASolution to acid instabilityImprove bioavailabilityOrganic active ingredientsAerosol deliveryGlycerolAllergy

The invention discloses a moisturizing NMN hydrophilic gel and a preparation method of the moisturizing NMN hydrophilic gel. The NMN hydrophilic gel is prepared from the following components in percentage by mass: 1-10% of beta-nicotinamide mononucleotide and the balance of water. 2-40% of a gel matrix; 1-13% of a humectant; 0.5%-10% of a penetration enhancer; 0.5-3% of a pH regulator; 0.1-1% of a preservative; 0.1%-1% of a supplement; and the balance of water. The gel matrix is sodium alginate or poloxamer; and the humectant is betaine or glycerol. According to the high-moisture-retention NMN hydrophilic gel disclosed by the invention, through transdermal absorption, the problems that oral NMN is unstable when encountering acid and is easy to degrade and damage are solved, and the bioavailability is directly improved. According to the high-moisture-retention NMN hydrophilic gel disclosed by the invention, proper auxiliary materials are selected, and scientific dosage ratio is combined, so that the obtained gel can be quickly absorbed by skin and takes effect quickly; the effects of abating fever and relieving have a good effect on acute skin injury (such as allergy, acne and bruise), and the patient compliance is good. Due to the jelly state of the NMN hydrophilic gel and the effect of the humectant, medicine components are not prone to water loss and precipitation, and the effect is more lasting.

Owner:药酚享科技北京有限公司

A method and device for degassing solid polymer

The invention provides a method for degassing solid polymers, comprising the following steps: i) first-stage degassing: providing a first-stage degassing medium, so that the first-stage degassing medium is combined with the first-stage degassing medium in the first-stage degassing chamber The solid polymer to be degassed is reversely contacted to obtain the first-stage degassed polymer; ii) the second-stage degassed: the first-stage degassed polymer obtained in step i) is passed into the second-stage degassed chamber performing a periodic pulsed process comprising providing a second stage degassing medium to a second stage degassing chamber where the second stage degassing medium is reversed against the first stage degassing polymer in the second stage degassing chamber Contact to obtain the second degassed polymer; iii) third-stage degassing: provide a third-stage degassed medium, so that the third-stage degassed medium and the second degassed polymer are carried out in the third-stage degassed chamber Reverse contacting yields the final degassed polymer. The present invention also provides a solid polymer degassing device used in the above method.

Owner:CHINA PETROLEUM & CHEM CORP +2

A degassing rotor structure with convective effect

Owner:SUZHOU MINGZHI TECH

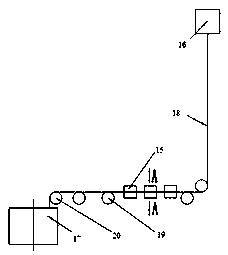

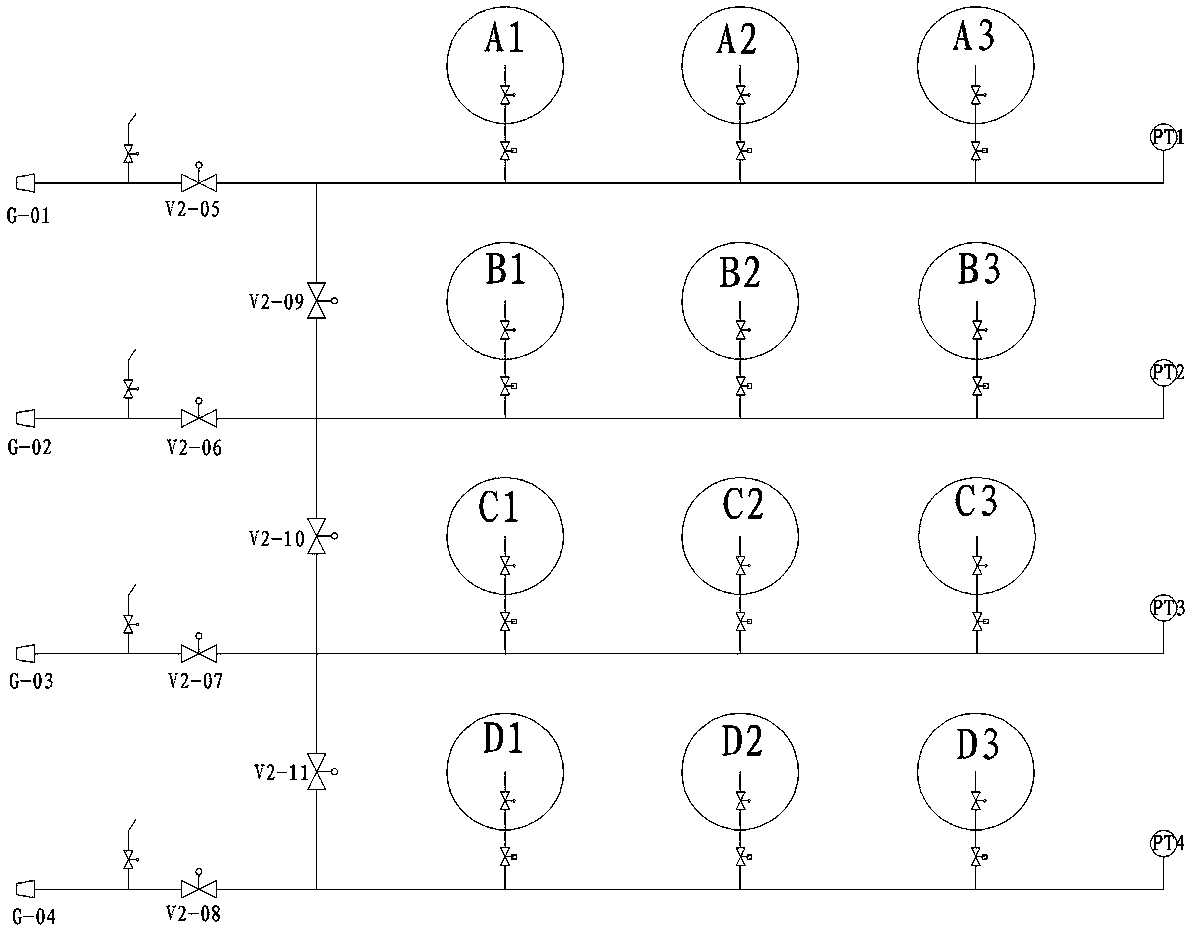

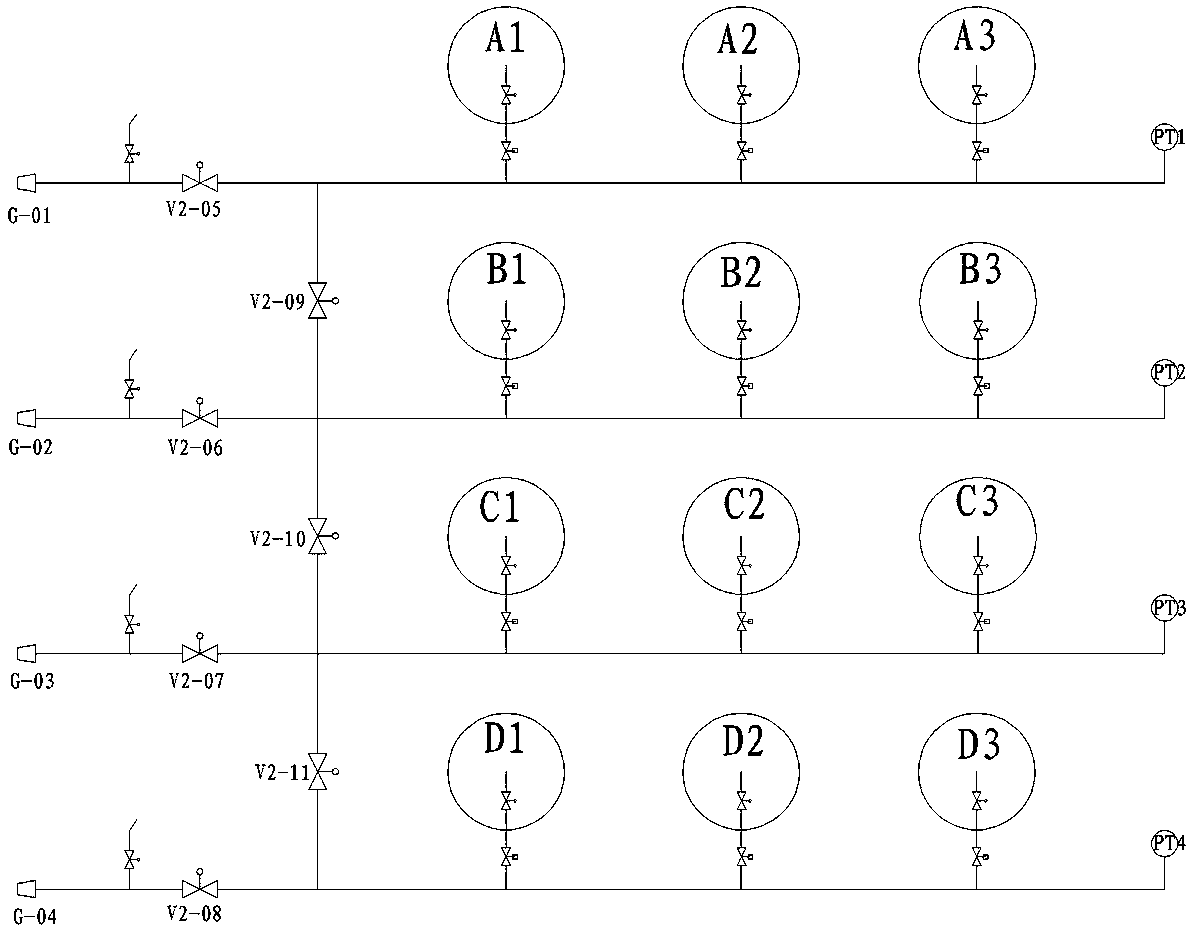

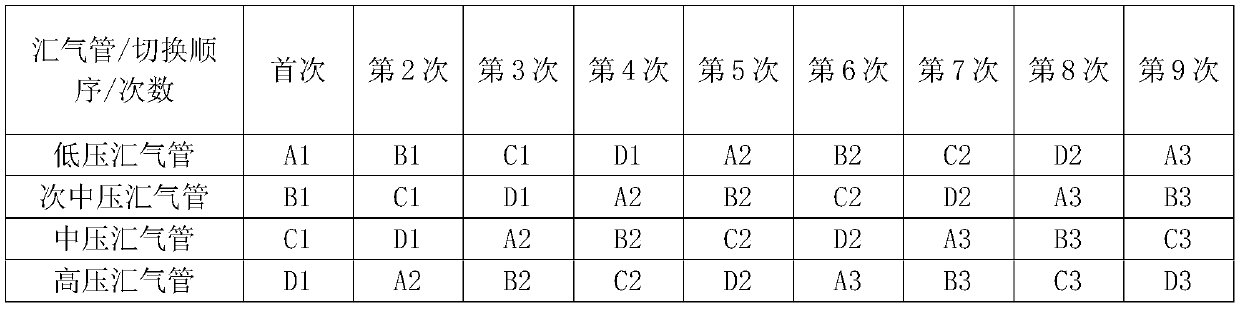

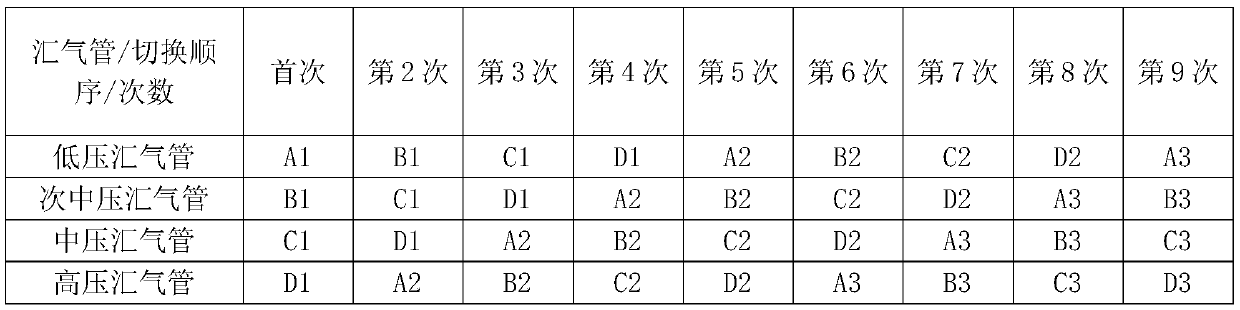

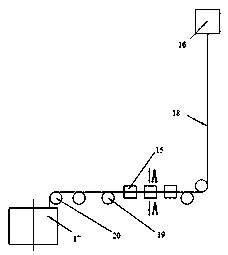

Unpowered natural gas trailer assembly provided with cyclic and alternate control system and control method

ActiveCN107620859AShorten degassing timeRefilling speed is fastContainer discharging methodsContainer filling under pressureControl systemGas cylinder

The invention provides an unpowered natural gas trailer assembly provided with a cyclic and alternate control system and a control method. By adoption of the unpowered natural gas trailer assembly provided with the cyclic and alternate control system and the control method, the technical problems of lower filling efficiency and speed of an existing unpowered gas filling station are solved. According to the technical scheme, based on a high-pressure gas cylinder container provided with an interconnected controllable valve pipeline system, opening-closing regulation and control of valves of independent gas cylinders connected to all gas collection pipes and switching connection between the independent gas cylinders and the gas collection pipes are achieved by detecting the pressure states ofall the gas collection pipes; and the control method also relates to an independent gas cylinder cyclic and alternate switching sequence table and a special memory for pressure switching values. By adoption of the unpowered natural gas trailer assembly provided with the cyclic and alternate control system and the control method, through opening-closing regulation and control of the valve of eachindependent gas cylinder and regulation and control of pipeline valves, the number of combination times of the gas cylinders is increased, the utilization rate of the gas cylinders is increased, the filling speed is increased, the filling time for each trailer is shortened, and the each trailer has more time to travel to a primary filling station for gas filling.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP

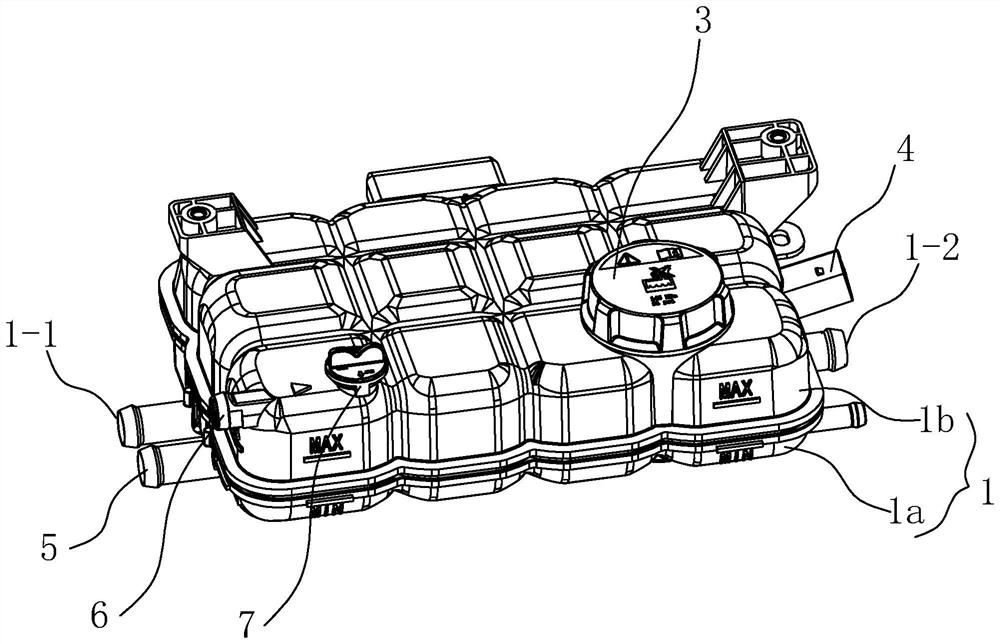

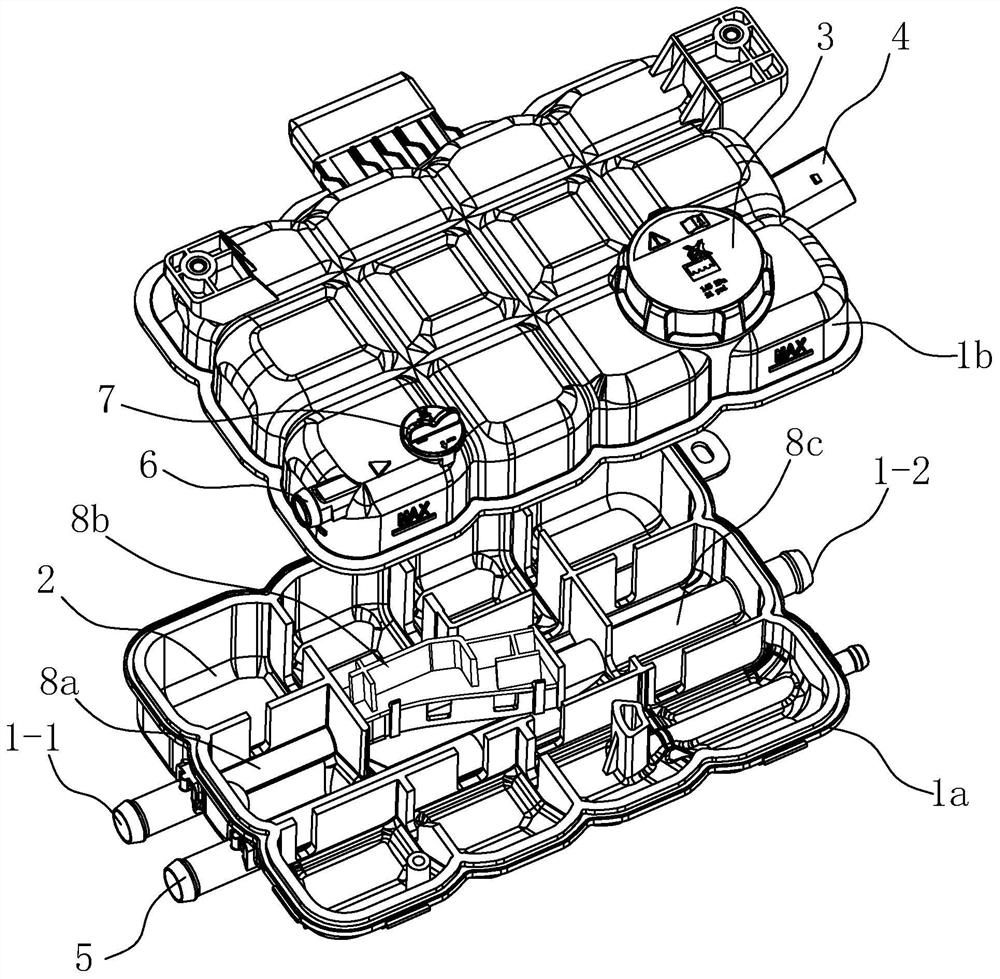

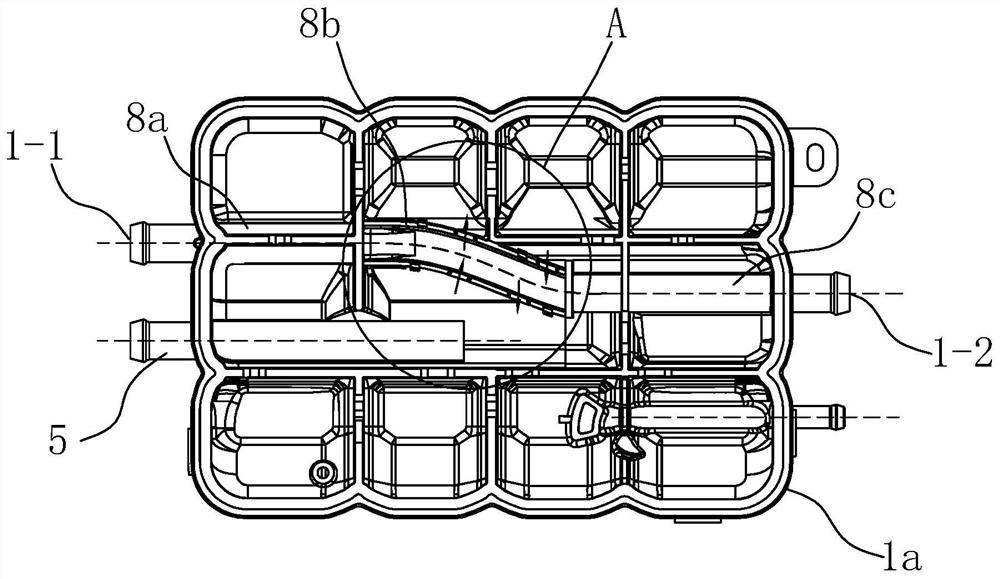

Integrated expansion kettle, cooling system and automobile

ActiveCN114837796AAchieve a separationDoes not affect flow rateMachines/enginesEngine cooling apparatusThermodynamicsElectrical battery

The invention provides an integrated expansion kettle which comprises a kettle body, a cooling liquid flow channel penetrating through a cavity is formed in the kettle body, and at least one gas-liquid separation structure is arranged on the cooling liquid flow channel. Each gas-liquid separation structure comprises a first opening and a second opening, wherein the first opening is formed in the cooling liquid flow channel and used for allowing liquid in the cavity to flow into the cooling liquid flow channel, the second opening is used for allowing the liquid in the cooling liquid flow channel to flow into the cavity, and the pressure intensity of the first opening is larger than that of the second opening. The cooling system comprises a motor cooling loop, a battery cooling loop and the expansion kettle. The automobile comprises the cooling system. According to the gas-liquid separator, separation is conducted in two sections, the gas-liquid separation efficiency is guaranteed, abnormal sound is eliminated, the degassing time of gas-liquid separation is shortened on the whole, heat leakage is reduced, and the temperature difference between a liquid inlet and a liquid outlet can be greatly reduced.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Degassing device and method for power electronic cooling system

PendingCN114259758AReduce consumptionShorten degassing timeLiquid degasificationThermodynamicsElectronics cooling

A degassing device of a power electronic cooling system comprises a degassing film pipe and a negative pressure generating device, the degassing film pipe is provided with a liquid inlet and a liquid outlet and used for degassing liquid, and the degassing device is characterized in that a hollow degassing material is arranged in the degassing film pipe and can permeate gas but cannot permeate liquid; the degassing membrane tube is provided with a gas inlet and a gas outlet, and the two ends of the hollow degassing material are connected to the gas inlet and the gas outlet respectively; and the negative pressure generating device is used for generating negative pressure in the hollow degassing material. The method has the beneficial effects that the consumption of nitrogen is reduced, the degassing time is shortened, and the efficiency is relatively high; and the contact area with liquid is increased through the hollow degassing material, so that the degassing effect is good.

Owner:GUANGZHOU GOALAND ENERGY CONSERVATION TECH

Environment-friendly curtain adhesive for hair product and preparation method thereof

ActiveCN101892028BAvoid pollutionReduce energy consumptionNon-macromolecular adhesive additivesWigsPolyurethane adhesiveDecomposition

The invention relates to an environmental-friendly curtain adhesive for a hair product and a preparation method thereof. The environmental-friendly curtain adhesive for a hair product is compatibly dissolved and synthesized by the following raw materials in parts by weight: 0.05 part of alcohol-soluble polyurethane adhesive b, 0.04 to 0.15 part of sugar ester, 0.05 to 0.25 part of rosin, 0.05 to 0.4 part of curing agent of alcohol-soluble polyurethane adhesive, 0.01 to 0.08 part of sodium persulfate and 0.15 to 0.75 part of absolute ethyl alcohol. In the preparation method, the thermal decomposition type sodium persulfate is used as the initiator to avoid pollution caused by a decomposition product remained in the adhesive when the organic peroxide is used as the initiator; the high-temperature polymerization replaces the low-temperature polymerization to reduce the energy consumption; the conversion rate of the polymerization reaction is improved and the quantity of the recovered monomer is reduced; the physical degasification and the chemical degasification are combined, so that the degasification time is shortened and the energy consumption is reduced.

Owner:XUCHANG HENGYUAN HAIR PROD

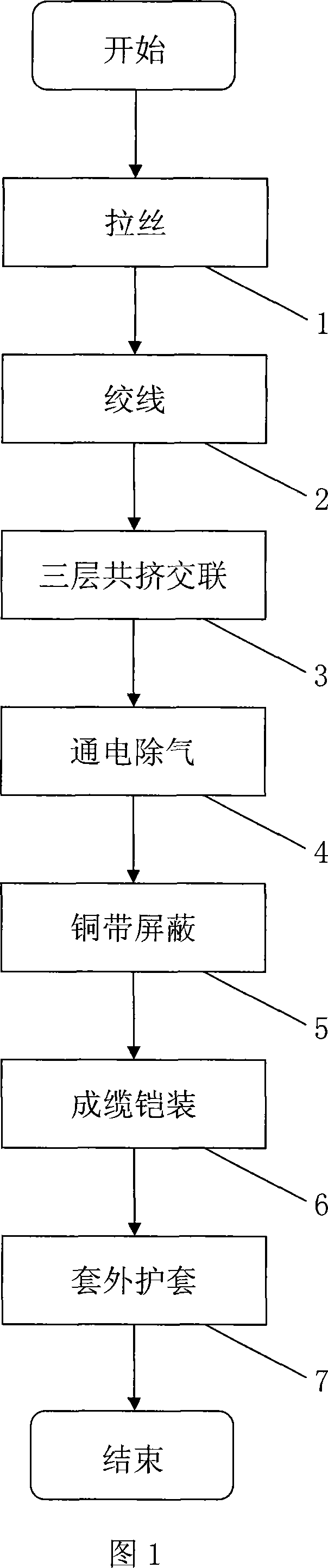

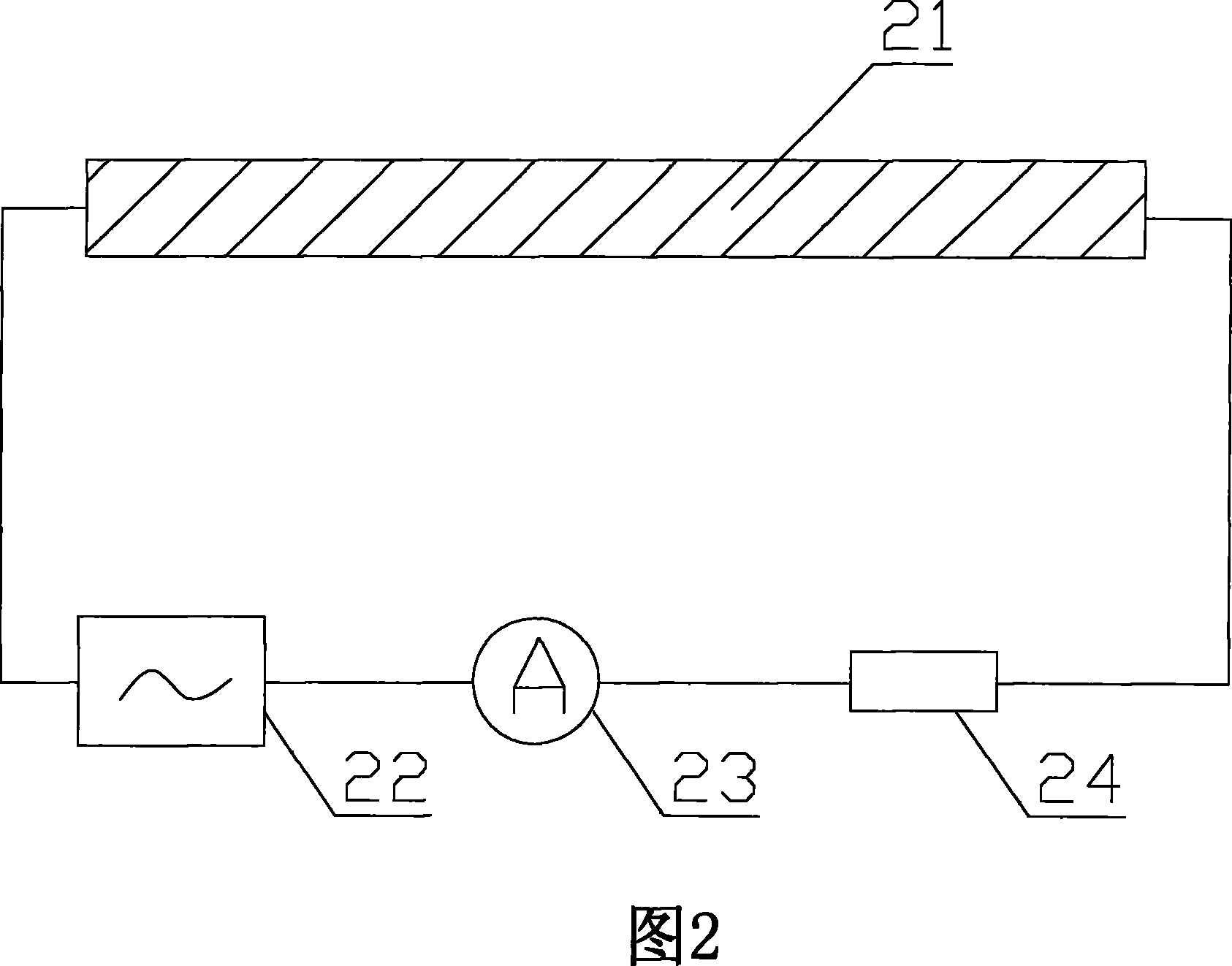

Processing method of power cable

ActiveCN101339828BIncrease productivityImprove production efficiencyPower cables with screens/conductive layersCable/conductor manufacturePower cableClosed loop

The invention discloses a power cable processing method which sequentially comprises the following steps: wire drawing, stranding, three-layer co-extrusion and crosslinking, copper strip shielding, cabling armoring and covering an oversheath; before the step of the three-layer co-extrusion and crosslinking and after the step of the copper strip shielding, the method further comprises a step of electrifying and degassing; the electrifying and degassing step means that the two ends of the cable are connected with a power source to form a closed loop, and the residual gas of the internal crosslinking by-product is removed after electrifying the cable for some time. The method of the invention electrifies and degasses the cable after the step of the three-layer co-extrusion and crosslinking; compared with most present degassing processes of drying rooms, the electrifying and degassing step of the invention greatly reduces the degassing time, and generally the degassing process can be finished in less than one day; the power cable processing method has the advantages that the degassing efficiency is high, the production efficiency of the whole cable processing is improved, the deliveryperiod is shortened, the energy source and the production space are economized, and the production benefit of enterprises is improved.

Owner:ZHEJIANG CHENGUANG CABLE CO LTD

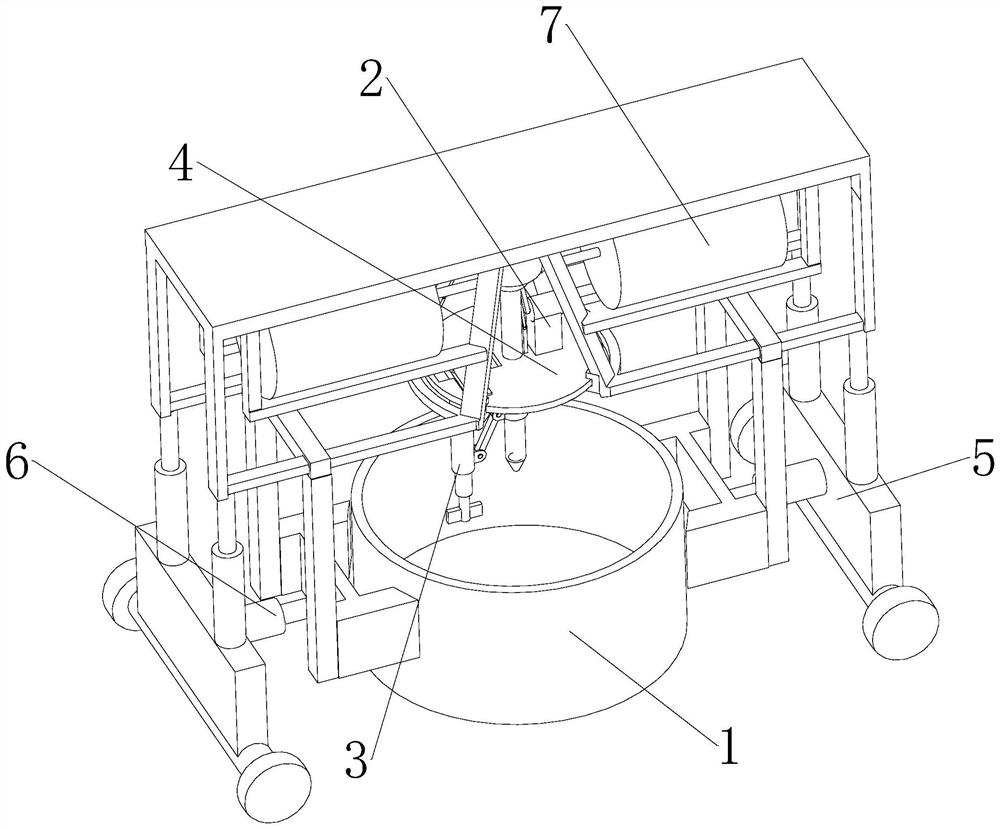

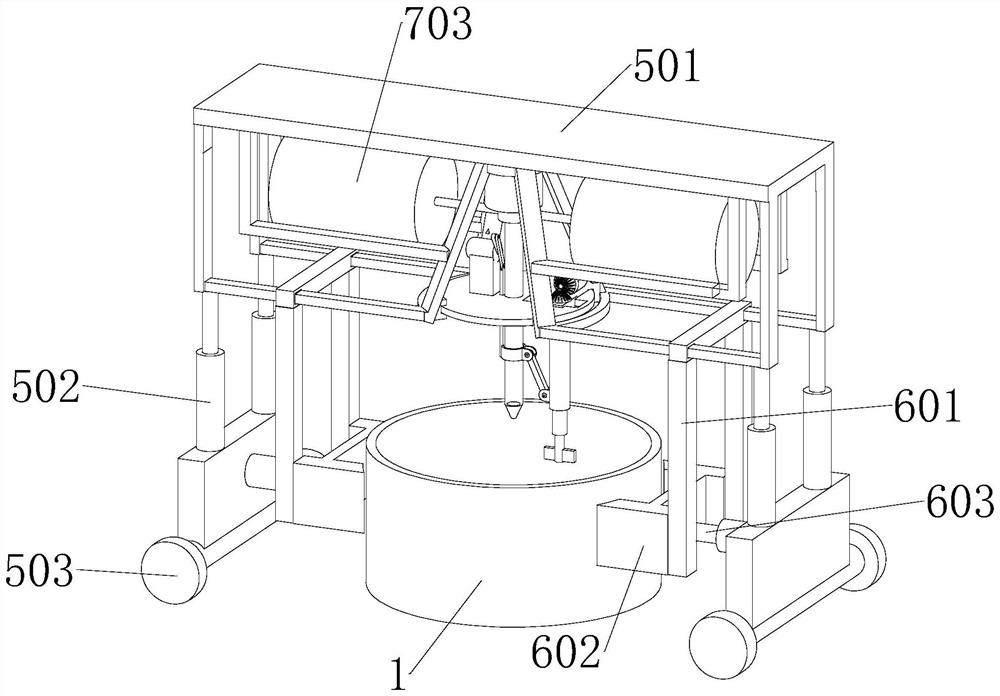

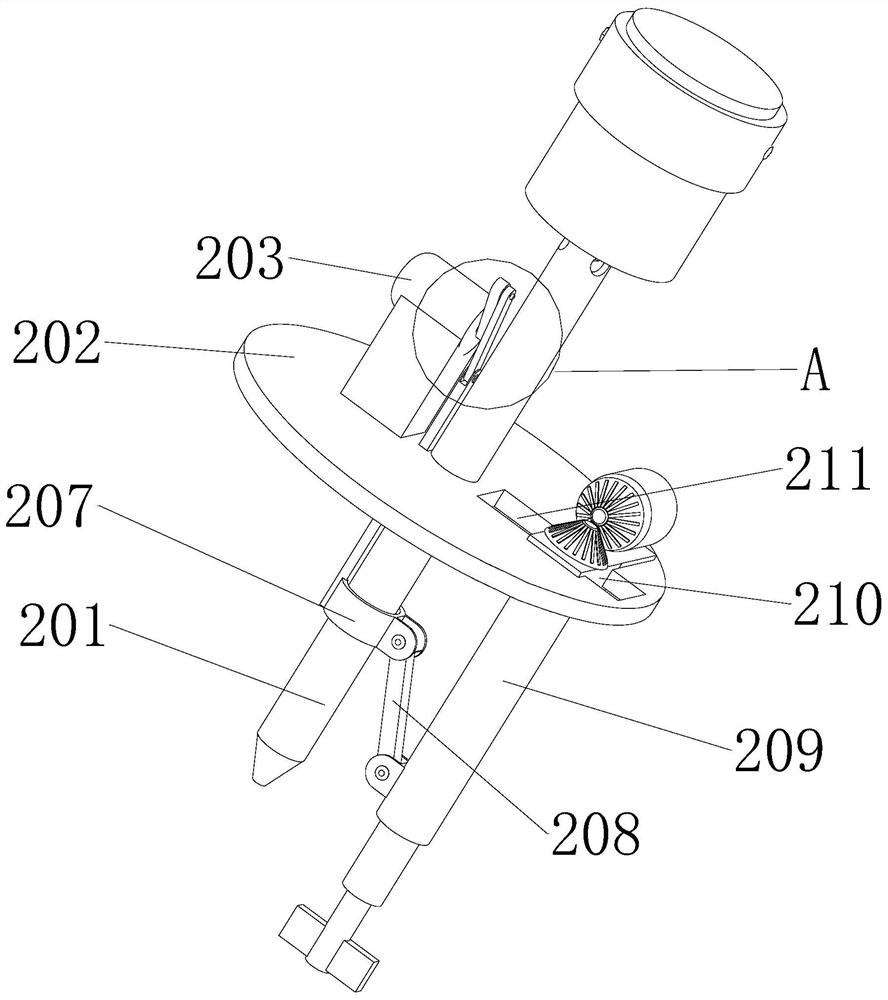

Movable degassing machine

InactiveCN112301229AUniform degassing effectShorten degassing timeStirring devicesEngineeringElectric machine

The invention discloses a movable degassing machine, and relates to the technical field of molten aluminum purification treatment equipment. The machine comprises a stirring container, an adjusting device, a stirring device, a rotating device, a moving device, a fixing device and a ventilation device; the moving device and the fixing device are placed on two sides of the stirring container; the rotating device is placed above the stirring container and is connected with the fixing device and the moving device; the adjusting device, the stirring device and the ventilation device are arranged onthe rotating device; the adjusting device comprises a supporting column, a rotating disc, an adjusting motor, a driving connecting rod, a driven connecting rod, an extensible rod, an adjusting pipe,an adjusting rod, a moving pipe, a moving sliding block and a moving sliding groove; the supporting column penetrates through the center of the rotating disc and is fixedly connected with the rotatingdisc; and a supporting base is fixed to the position, close to the supporting column, on the upper end surface of the rotating disc. The adjusting motor rotates to drive the moving pipe to move on the rotating disc, the stirring position of the stirring device can be adjusted, the stirring device can adapt to larger stirring containers, and the one-time stirring amount is greatly increased.

Owner:芜湖良仕机械科技有限公司

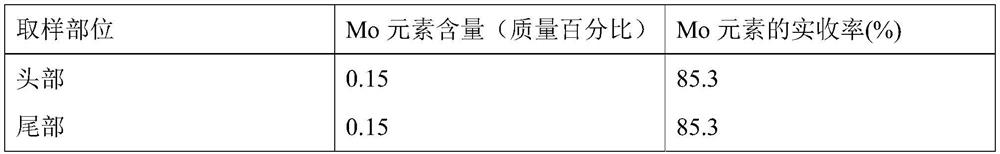

Smelting preparation method suitable for Mo 4000 series aluminum alloy cast ingot

The invention discloses a smelting preparation method suitable for a Mo 4000 series aluminum alloy cast ingot, and relates to the technical field of nonferrous metal material preparation. The invention aims at solving the problem that the casting yield is low due to the fact that the Mo element segregation condition is prone to occurring in the traditional casting process of the Mo-containing aluminum alloy. The method comprises the following steps: heating an aluminum ingot and an Al-Si20 intermediate alloy until the aluminum ingot and the Al-Si20 intermediate alloy are completely molten, adding Al-Mo5 intermediate alloy particles, keeping the temperature, adding an Al-Sr10 intermediate alloy, modifying an aluminum alloy melt, stirring, continuously heating, analyzing and adjusting alloy components, refining and degassing by using inert gas after the components are qualified, filtering, and casting, and a grain refiner is added during casting, and homogenization treatment is carried out after casting is completed, so that the Mo 4000 series aluminum alloy cast ingot is obtained. The smelting preparation method suitable for the Mo 4000 series aluminum alloy cast ingot can be obtained.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Unpowered natural gas filling station with cycle alternate control system and control method

ActiveCN107620866BIncrease the number of combinationsReduce the number of combinationsPipeline systemsGas cylinderControl system

The invention provides an unpowered natural gas filling station provided with a cyclic and alternate control system and a control method. Based on a cylinder twining pipe bundle type container trailerassembly provided with an interconnected controllable valve pipeline system, opening-closing regulation and control of valves of independent gas cylinders connected to all gas collection pipes and switching connection between the independent gas cylinders and the gas collection pipes are achieved by detecting the pressure states of all the gas collection pipes, switching of pipelines and gas cylinders between trailers are achieved, and an independent gas cylinder cyclic and alternate switching sequence table and a special memory for pressure switching values are stored in a valve management and control module of the trailer assembly. According to the unpowered natural gas filling station provided with the cyclic and alternate control system and the control method, the time for parking twotrailers at the same time is shortened, and the trailers can have more time to travel to a primary filling station for gas filling.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP

66-500kv cross-linked cable short degassing on-line treatment process

ActiveCN104979051BShorten degassing timeShorten the timeInsulating conductors/cablesElectrical conductorNitrogen atmosphere

The invention discloses a 66-500kV crosslinked cable short-degassing online treatment process. A process flow comprises conductor preparing; three-layer co-extruding and insulating and online degassing; and degassing in a drying room, wherein the step of three-layer co-extruding and insulating and online degassing specifically comprises three-layer co-extruding of a conductor shielding layer, an insulating layer and an insulating shielding layer; crosslinking; cooling; secondary heating; and cooling; the secondary heating is carried out under protection of nitrogen atmosphere, the nitrogen concentration of the nitrogen atmosphere is controlled over 98%, the nitrogen temperature is controlled at 220+ / -5 DEG C, and the conductor temperature is controlled at 90 DEG C. According to the 66-500kV crosslinked cable short-degassing online treatment process disclosed by the invention, the insulating layer is not aged during degassing, the degassing rate is high, the byproduct removal effect is good, the degassing time of the drying room can be greatly shortened, the production period is shortened, and energy is saved and emission is reduced.

Owner:浙江万马股份有限公司

Nonferrous metal liquid nine-column uniform purifying device

InactiveCN105803214ARemove evenlyEliminate the influence of human factorsNonferrous metalProduction quality

The invention discloses a nonferrous metal liquid nine-column uniform purifying device, and relates to the technical field of metallurgy. The device comprises a degassing rake and degassing rods, one end of the degassing rake is fixedly provided with a plurality of degassing rods, the other end of the degassing rake is connected with inert gas, the degassing rake is connected with the degassing rods, and the degassing rods are uniformly distributed on the degassing rake. The nonferrous metal liquid nine-column uniform purifying device has the advantages of simple structure, reasonable design, uniform and thorough degassing, small artificial factor influences, degassing time saving, and improvement of the production efficiency and the production quality.

Owner:河北立中有色金属集团有限公司

A degassing line for cables

ActiveCN109243709BIncrease productivityAchieve online degassing effectApparatus for heat treatmentThermodynamicsInsulation layer

The invention discloses a degassing water line for cables, which comprises: a vertical tower extruder and a degassing room, the vertical tower extruder and the degassing room are connected through an insulated cable core; the The cable insulation core is composed of a copper core stranded conductor and a shielding insulation layer, and the shielding insulation layer is wrapped on the outer wall of the copper core stranded conductor; Several idler rollers and the steering idler rollers; among them, several high-frequency heating coils are installed between the two idler rollers, and the high-frequency heating coils are circular rings with openings at the bottom, and the insulated wire cores of the cables pass through The high frequency heating coil. Through the above method, the present invention provides a degassing line for cables. During the production process of the insulated core, the degassed line heats the cable conductor through the high-frequency heating coil, so as to realize the heating of the insulated core during production and achieve the online degassing effect. The degassing time can be saved, the cable production efficiency can be improved, and the degassing effect is better.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD +1

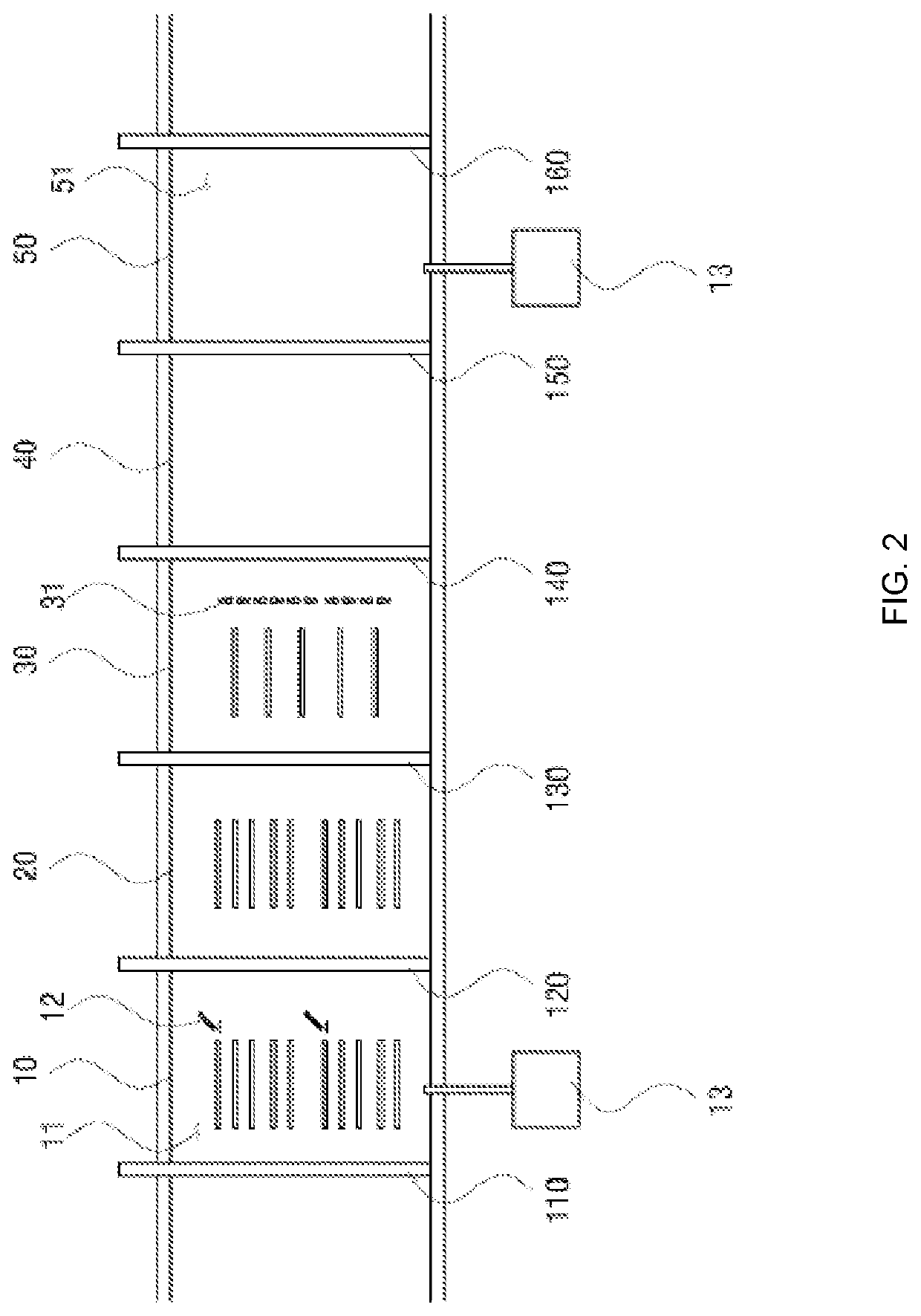

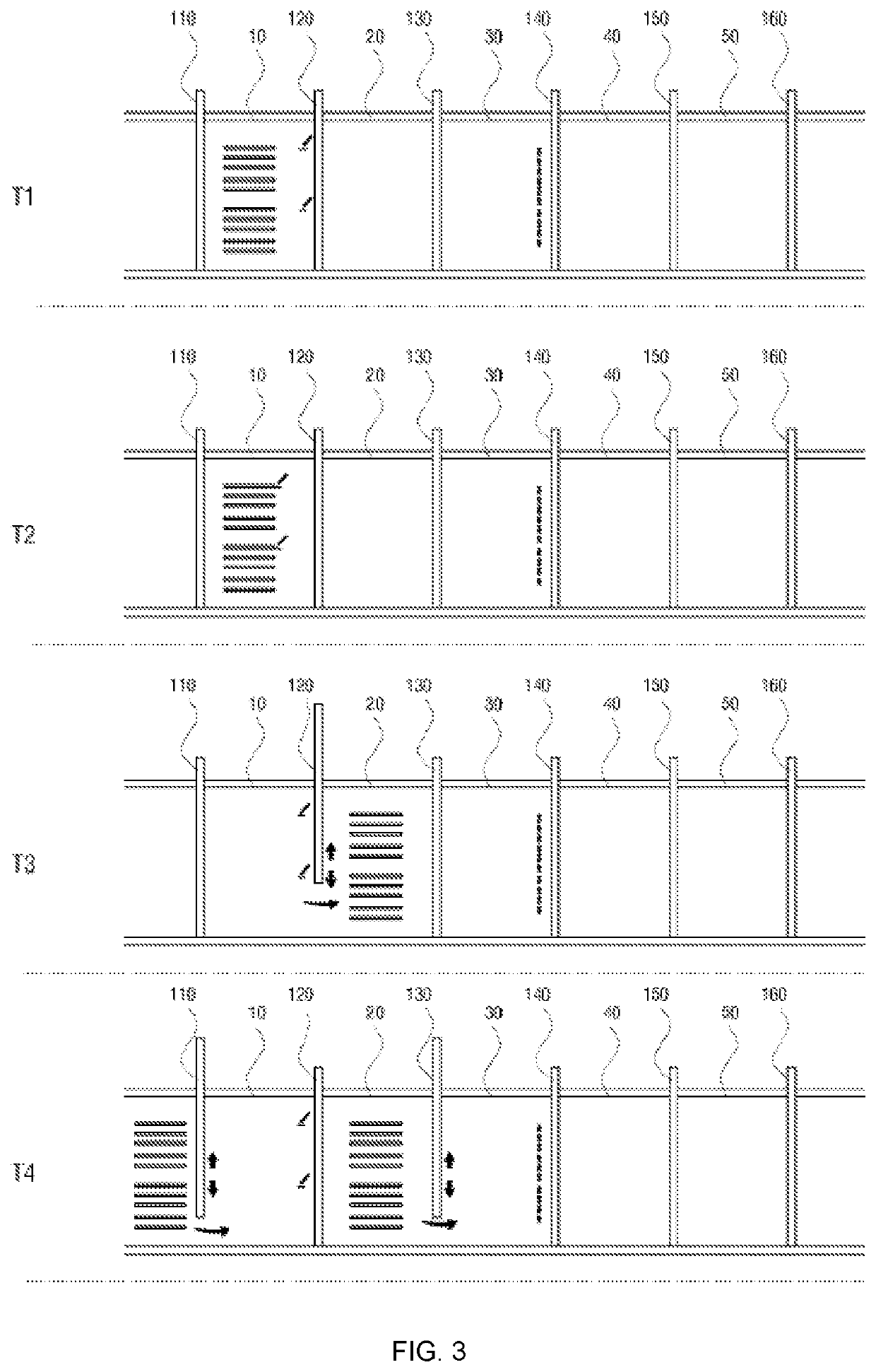

Degassing device for preparing secondary battery

PendingUS20220271323A1Shorten degassing timeSufficient evacuation timeAssembling battery machinesFinal product manufactureThermodynamicsVacuum pressure

Disclosed is a degassing device for preparing a secondary battery, the degassing device including a piercing chamber configured to accommodate a first amount of degassing target pouches and having an internal space in which a pressure is selectively controlled to a vacuum pressure or an atmospheric pressure, the piercing chamber including a piercing unit configured to form inner gas discharge paths in the first amount of degassing target pouches, a first buffer chamber having an internal pressure maintained as the vacuum pressure and configured to accommodate the first amount of degassing target pouches unloaded from the piercing chamber, a sealing chamber having an internal pressure maintained as the vacuum pressure and having a sealing unit configured to receive the first amount of degassing target pouches accommodated in the first buffer chamber while sequentially receiving a second amount of degassing target pouches smaller than the first amount of degassing target pouches.

Owner:CLEVER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com