Degassing device and method for power electronic cooling system

A technology of cooling system and power electronics, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve the problems of long operation time, low degassing efficiency, waste of time, etc., and achieve increased contact area, degassing Good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

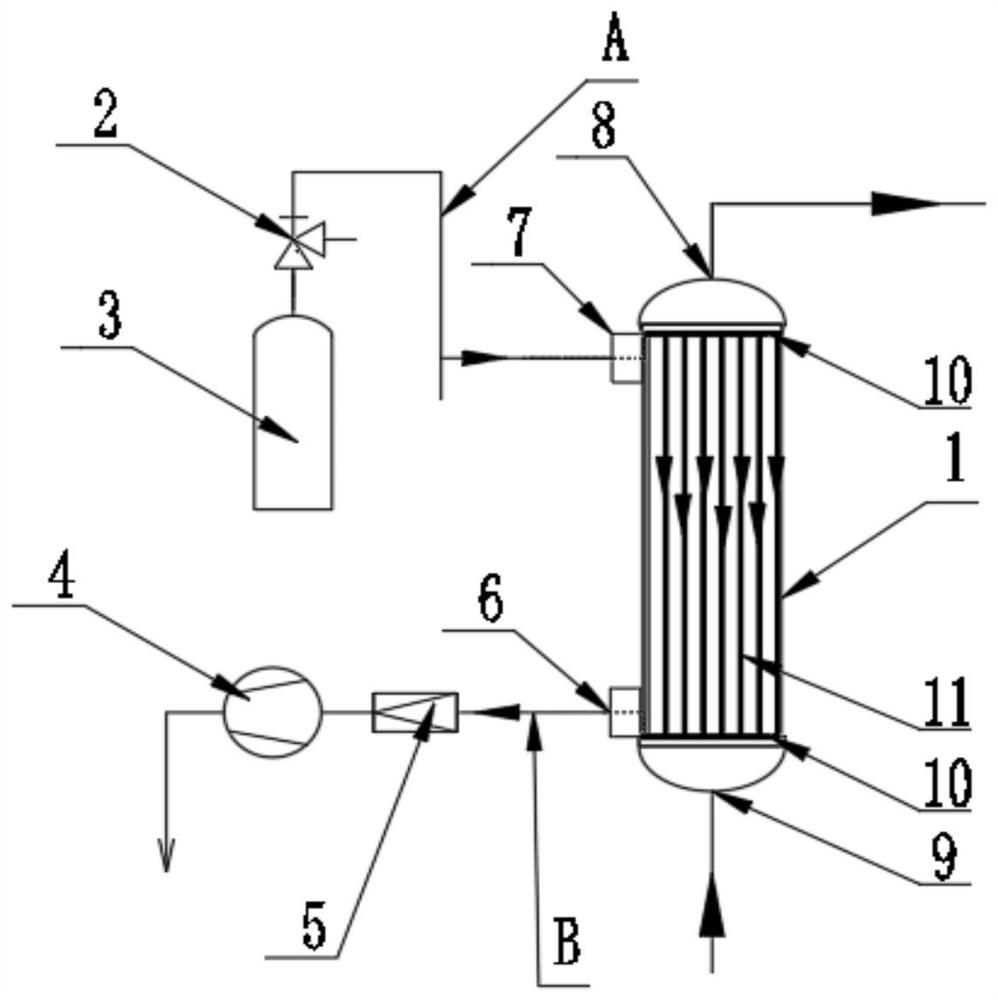

[0030] The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

[0031] Usually, the gas in the gas storage tank is directly released into the liquid. The present disclosure utilizes the hollow fiber 11 in the degassing membrane tube for degassing. The contact area with the liquid is larger, and the gas in the liquid is removed faster and more effectively.

[0032] like figure 1 shown. The degassing membrane tube 1 includes hollow fiber filaments 11 inside. The inside of the hollow fiber 11 is used to remove gas, and the liquid to be degassed in the degassing membrane tube 1 is outside the hollow fiber 11 . The two ends of the degassing film tube 1 have a liquid inlet 9 and a liquid outlet 8, and the sides near the two ends have an air inlet 7 and an air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com