Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "High deoxygenation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

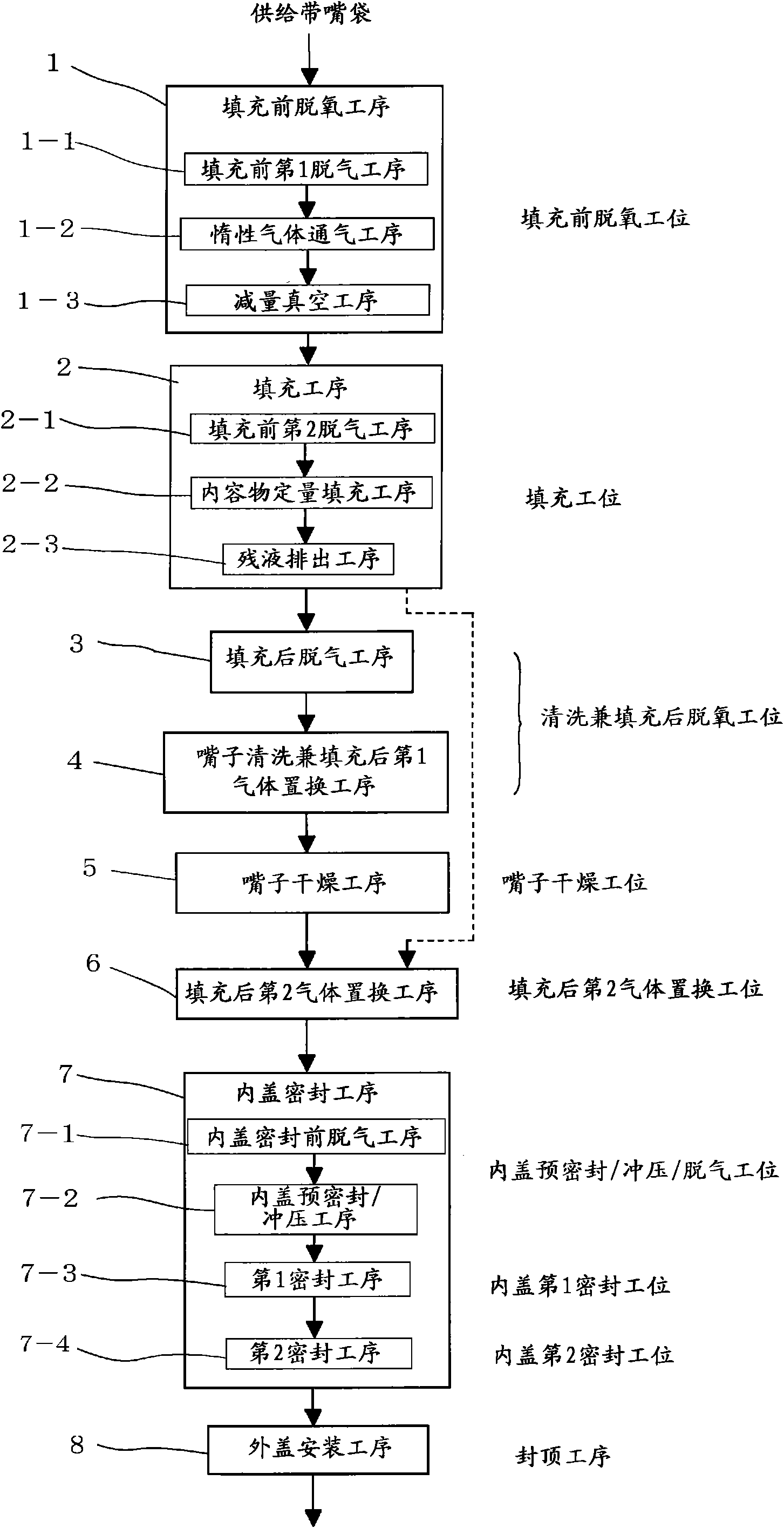

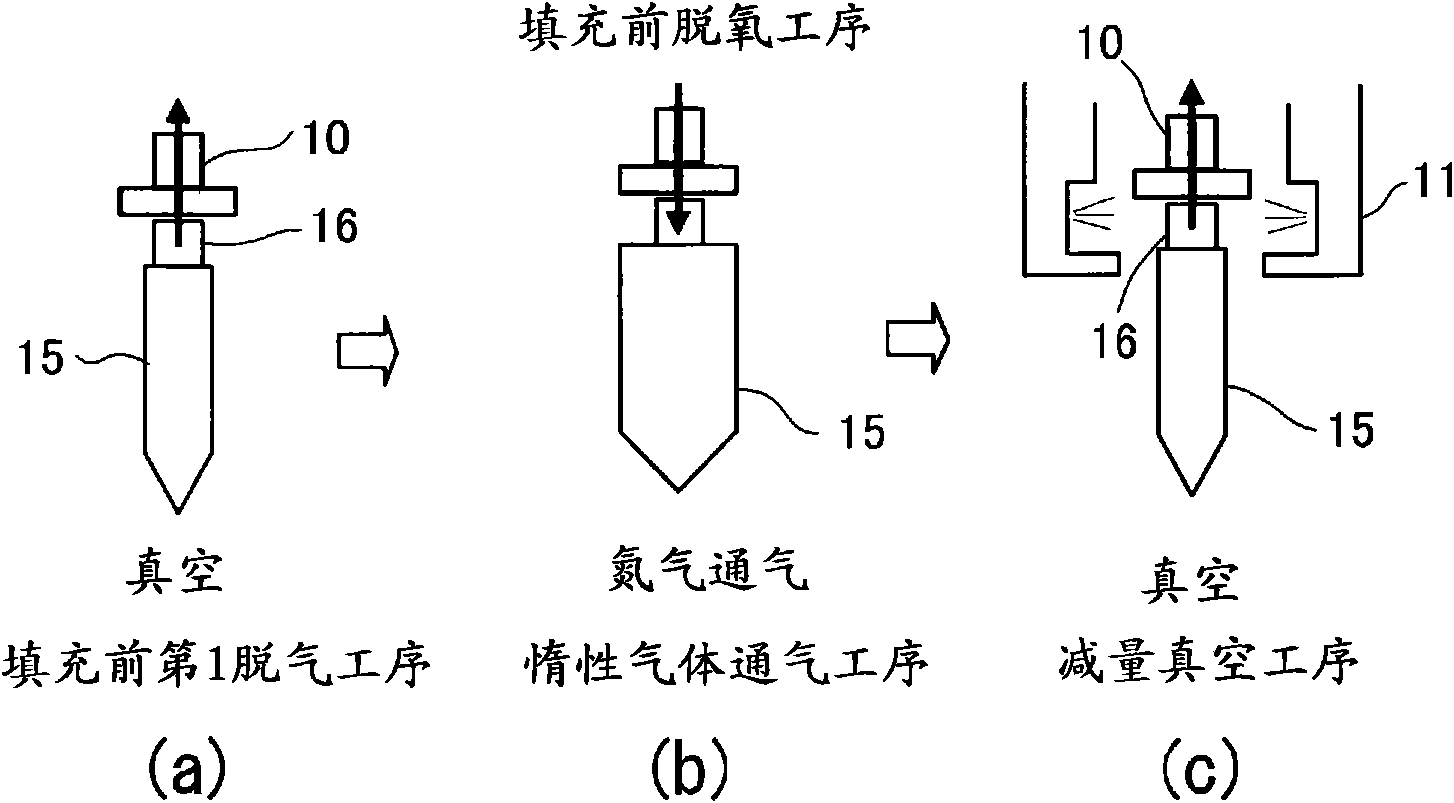

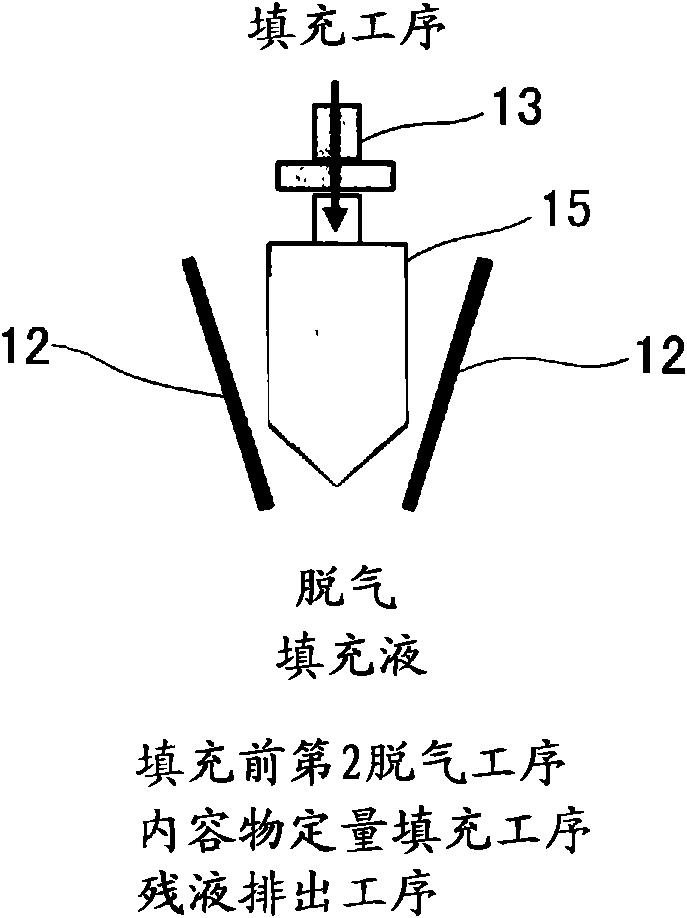

Method of packing liquid filling into spouted pouch and sealing the pouch and apparatus therefor

InactiveCN101588968AImprove qualityHigh deoxygenation ratePackaging by pressurising/gasifyingPackaging protectionLiquid stateProduct gas

To obtain a spouted-pouch package having a high degree of deoxidation by a method in which even a liquid filling which readily lathers can be packed while being inhibited from lathering. [MEANS FOR SOLVING PROBLEMS] A before-packing deoxidation step (1) is performed before a liquid filling is packed into a pouch. The step (1) comprises: a vacuum step (1-1) in which the pouch is evacuated under vacuum; an inert-gas blow step (1-2) in which an inert gas is blown into the pouch after the vacuum step; and a gas-diminishing vacuum step (1-3) in which the gas in the pouch after the inert-gas blow step is discharged under vacuum to diminish the gas in the pouch to a given amount. Thereafter, the pouch is evacuated in a second before-packing evacuation step (2-1) and then packed with the filling. After the packing, gas replacement is conducted.

Owner:TOYO SEIKAN KAISHA LTD

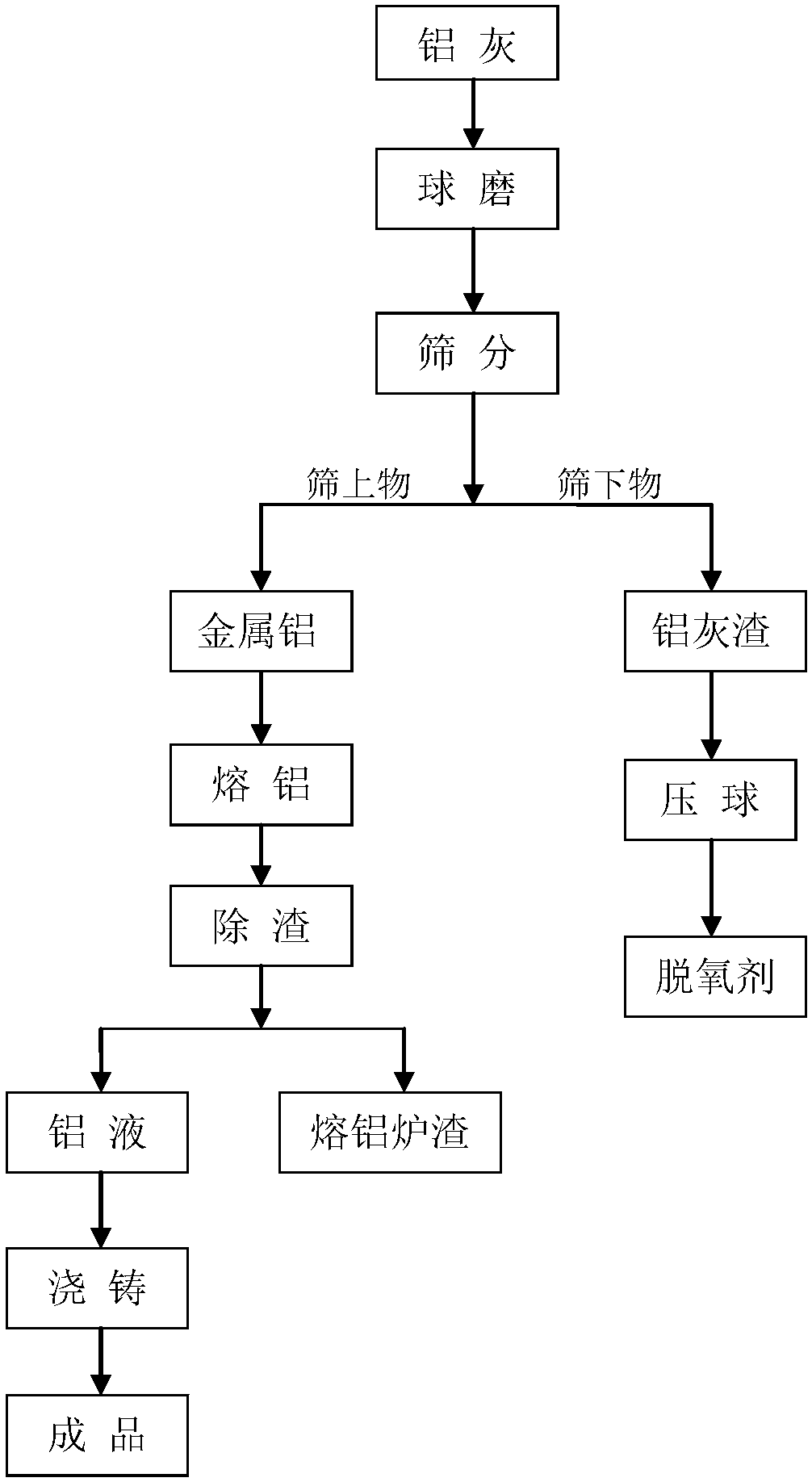

Metallic aluminum deoxidizing agent and preparation method thereof

InactiveCN108285949AHigh deoxygenation rateGood deoxidation operabilityProcess efficiency improvementMetallic aluminumMolten steel

The invention relates to the technical field of metallurgy, in particular to a metallic aluminum deoxidizing agent and a preparation method thereof. The deoxidizing agent is made of aluminum scruff ash, aluminum ash clinker is obtained by means of ball milling and screening and then is put into a ball pressing machine for pressing and curing, and accordingly the metallic aluminum deoxidizing agentcan be obtained. When the method is used for preparing the deoxidizing agent, the technology is simple, wasting of resources can be effectively reduced, cost input of deoxidizing ingredients is reduced, and waste can be recycled and reutilized. The deoxidizing agent obtained through the method can be applied to the working procedures of ladle refining and molten steel purifying of steel works, deoxidizing and desulfuration capacity is high and the metallic aluminum deoxidizing agent can be widely applied and popularized.

Owner:青海源通工贸有限公司

Deoxidation and organic sulfur hydro-conversion bifunctional catalyst, and preparation method and application thereof

ActiveCN105435806ALow oxygen contentEasy to prepareHeterogenous catalyst chemical elementsDispersed particle separationOperabilityOxygen

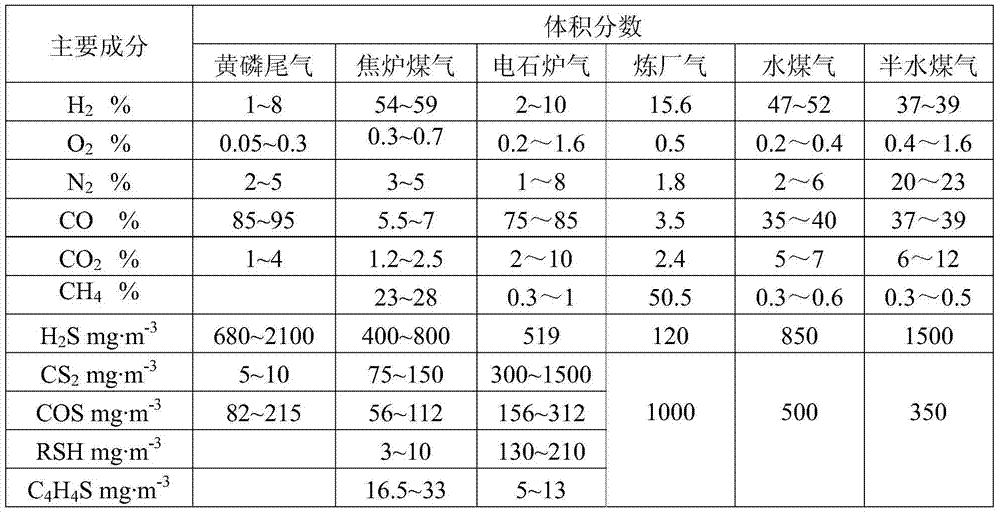

The invention relates to a deoxidation and organic sulfur hydro-conversion bifunctional catalyst, and a preparation methods and an application thereof, and belongs to the technical field of gas purification. The catalyst, by oxide, comprises, by mass, 1-50 parts of an active component, 0.1-20 parts of an active assistant and 30-89.1 parts of a carrier. The invention also relates to three preparation methods of the catalyst. The catalyst has deoxidation and organic sulfur hydro-conversion bifunctions, and can be used in the purification process of raw gases of sulfur-containing and CO-and-H2-containing industrial coal-to-water gas, semi-water gas, coke oven gas and carbide furnace gas. The catalyst can simultaneously realize deoxidation and organic sulfur hydro-conversion purposes, shortens the process flow, simplifies the flow, reduces the energy consumption and saves the cost. The preparation methods of the catalyst have the advantages of simplicity, strong operability and low preparation condition requirements. The catalyst has a high deoxidation rate and a high organic sulfur hydro-conversion rate, and allows the volume content of oxygen in an obtained product obtained after deoxidation to be lower than 100ppm and the organic sulfur conversion rate to be greater than 95%.

Owner:HAO HUA CHENGDU TECH

Low cost sulfur transformation resistant deoxidizing agent and process for preparing the same

InactiveCN1464037AHigh strengthImprove stabilityGas purification by catalytic conversionActive componentSulfur

The deoxidizing agent has magnesia alumina spinel as carrier, and Co and Mo as active component, where CoO accounts for 0.3-3.0 wt% of the deoxidizing agent and MoO3 3-15 wt%. The deoxidizing agent has deoxidizing rate similar to available industrial deoxidizing agent but obviously raised strength, strength stability and impact corrosion resistance. The present invention solves the powdering problem of deoxidizing agent in some degree.

Owner:QILU PETRO CHEM - SINOPEC

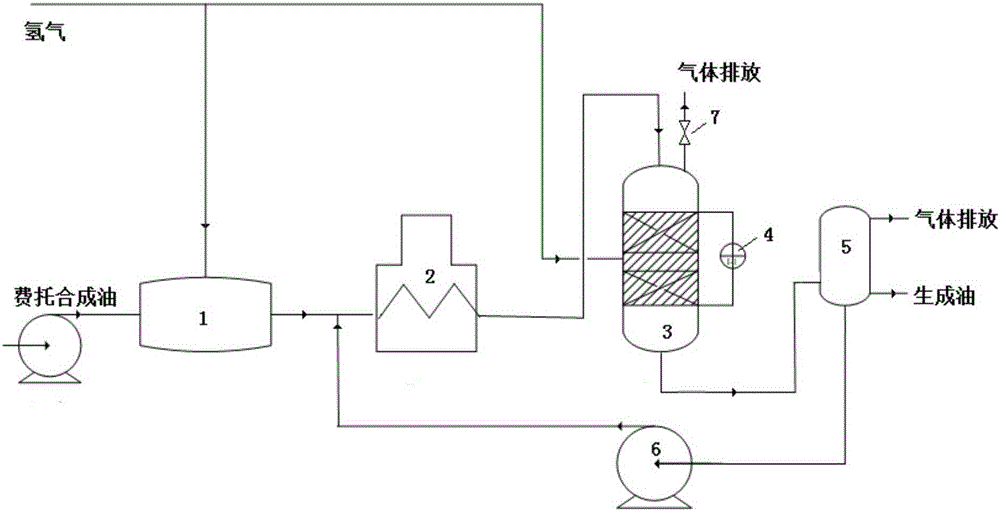

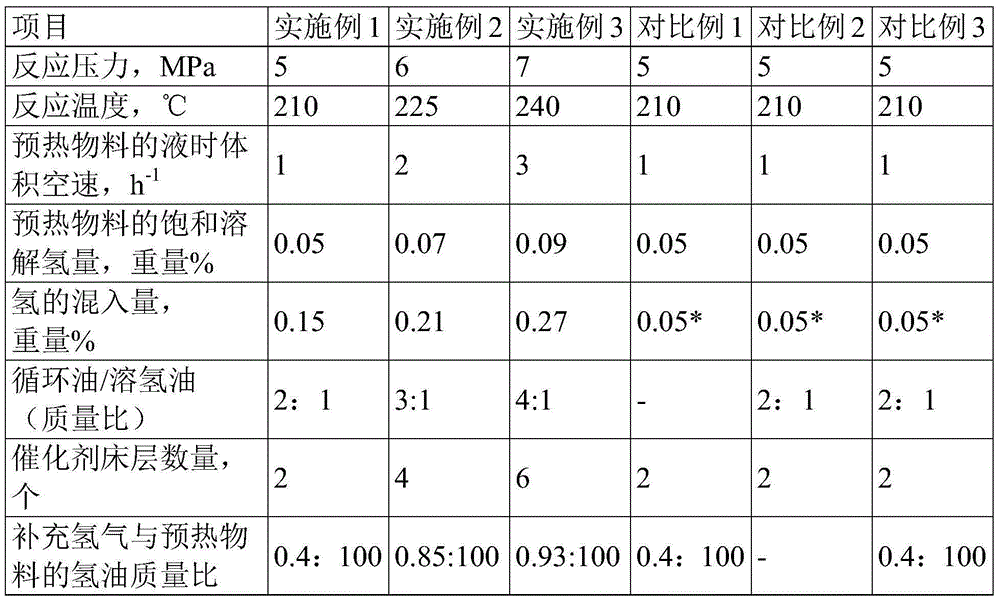

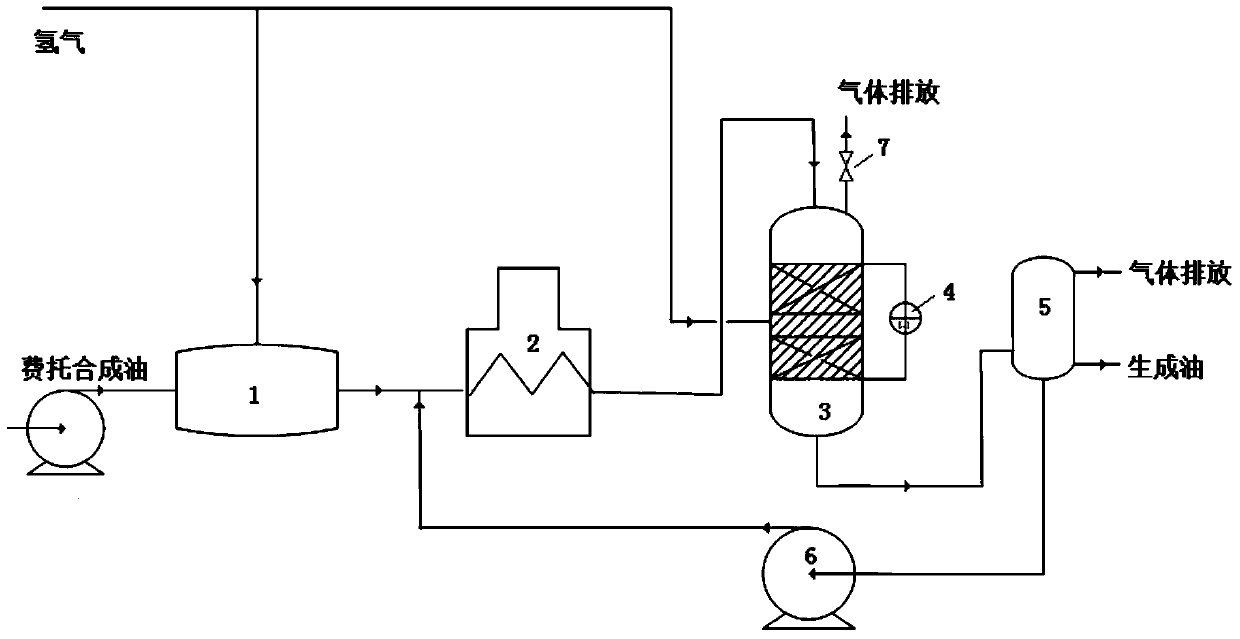

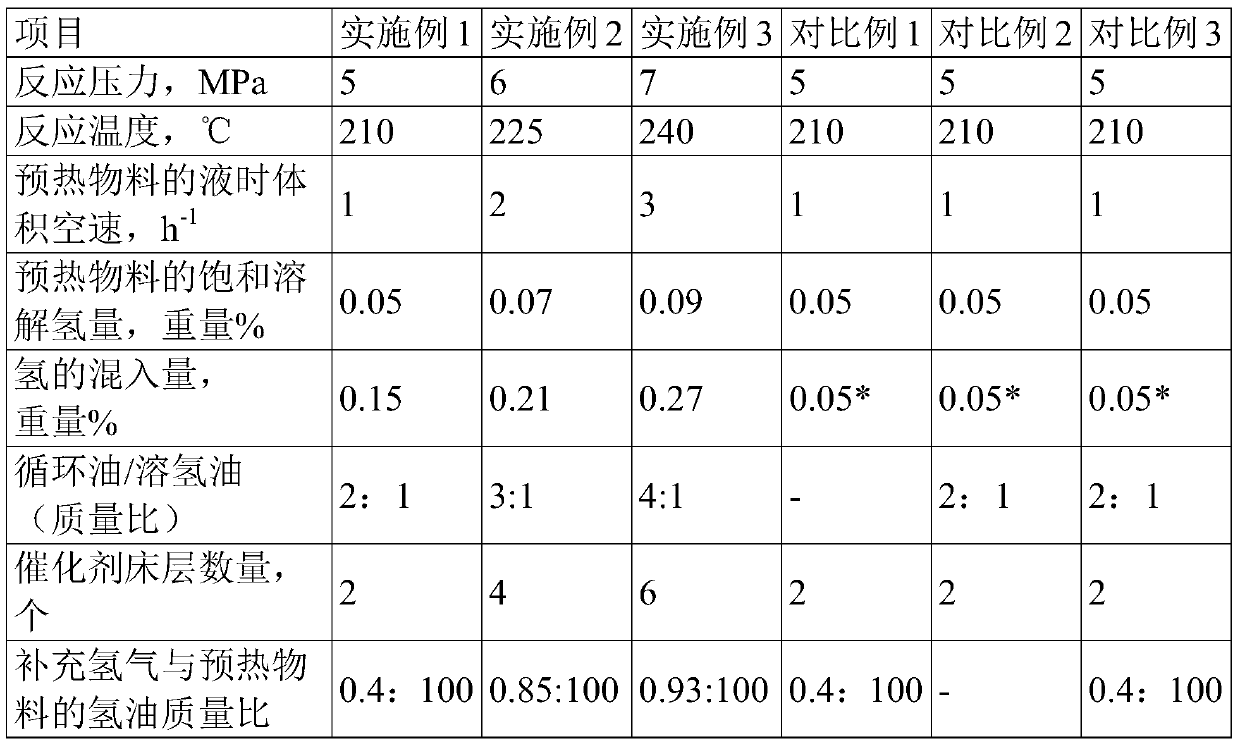

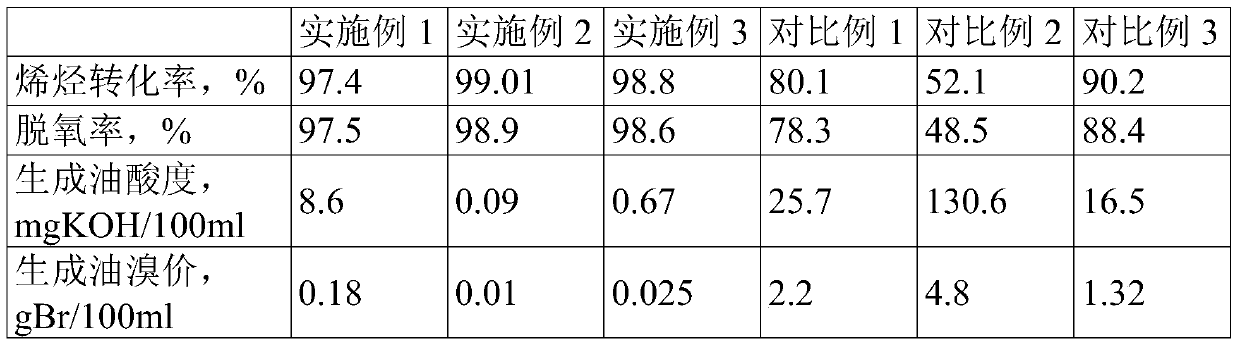

Method and system for low temperature liquid phase hydrofinishing of Fischer-Tropsch syncrude

ActiveCN106590732AImprove conversion rateHigh deoxygenation rateRefining to eliminate hetero atomsControl valvesHydrogen bubble

The invention relates to a method and system for low temperature liquid phase hydrofinishing of Fischer-Tropsch syncrude. The method comprises the following steps: (1) Fischer-Tropsch syncrude and hydrogen are uniformly mixed in a hydrogen oil mixer in order to prepare a gas-liquid two-phase mixture of hydrogen bubbles and dissolved hydrogen oil, and the gas-liquid two-phase mixture is preheated in order to obtain a preheated material; (2) under a condition of low temperature liquid phase hydrofinishing reaction, the preheated material is added from the top of a fixed bed reactor with a liquid level control valve through a catalyst bed layer which is arranged in the fixed bed reactor from top to bottom, at the same time supplemented hydrogen is added into a catalyst bed layer, and reaction products are obtained at bottom of the fixed bed reactor; (3) reaction products are added into a low pressure separator for carrying out separation, separated reaction oil part is used as cycle oil and added into the gas-liquid two-phase mixture obtained in the step (1); wherein the temperature for the low temperature liquid phase hydrofinishing reaction is 200-249 DEG C. The method can guarantee low temperature alkene reduction and deoxidation, and equipment is saved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Fischer-Tropsch synthesis oil hydrofining method

InactiveCN110028987AGood deoxidation effectAvoid inactivationTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionReaction temperature

The invention provides a Fischer-Tropsch synthesis oil hydrofining method which comprises the following steps: S1, mixing Fischer-Tropsch synthesis oil with hydrogen, carrying out a low-temperature pre-hydrogenation reaction, and converting unsaturated olefins in the Fischer-Tropsch synthesis oil into corresponding saturated hydrocarbons to obtain a pre-hydrogenation product; S2, performing a deephydrodeoxygenation reaction on the pre-hydrogenation product to obtain a hydrofining product; and S3, circulating a part of the hydrofining product, conducting mixing with Fischer-Tropsch synthesis oil, and then carrying out a low-temperature pre-hydrogenation reaction. Through circulation of a part of the hydrofining product, reaction temperature rise can be reduced, coking carbon deposition andinactivation of a catalyst are prevented, stable operation of the reaction is easy to maintain, and a high olefin conversion rate and a high oxygen-containing compound conversion rate are maintainedfor a long time.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

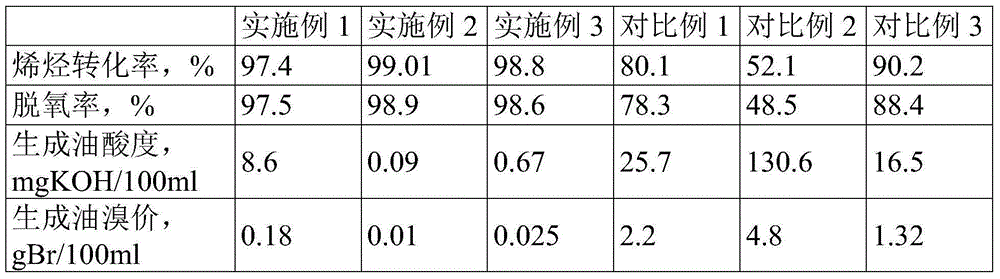

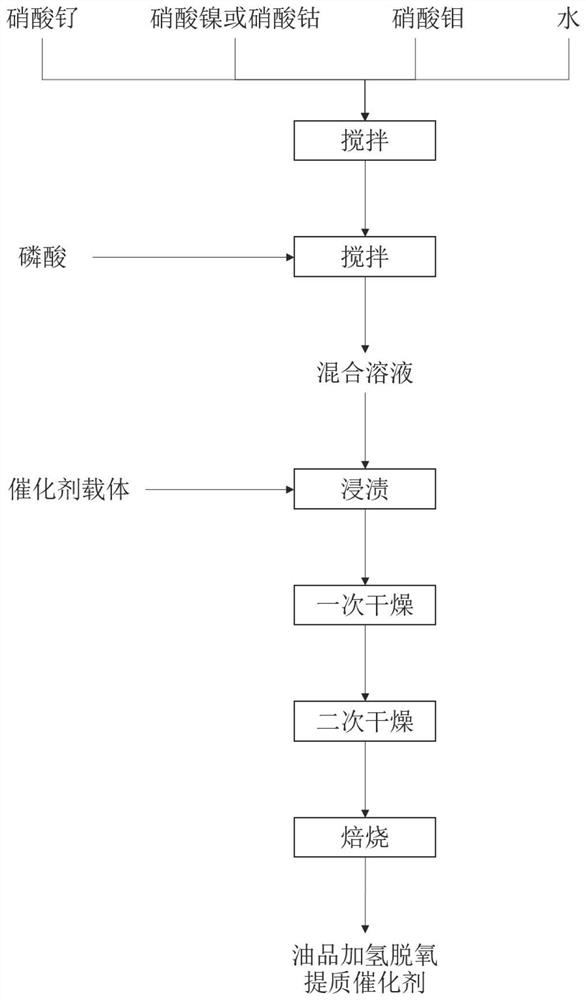

Oil product hydrodeoxygenation upgrading catalyst and preparation method and application thereof

ActiveCN112044465APrevent sinteringInhibitory activityMolecular sieve catalystsCatalyst activation/preparationPtru catalystHigh activity

The invention discloses an oil product hydrodeoxygenation upgrading catalyst and a preparation method and application thereof. The oil product hydrodeoxygenation upgrading catalyst comprises a catalyst carrier, and an active component and an auxiliary agent which are loaded on the catalyst carrier, wherein the active component comprises ruthenium oxide, molybdenum oxide, nickel oxide and / or cobaltoxide; the catalyst carrier comprises gamma aluminum oxide, zeolite and activated carbon; the auxiliary agent comprises phosphorus oxide; in the active component, the molar ratio of ruthenium oxide to molybdenum oxide to nickel oxide and / or cobalt oxide is (0.2-1): (10-28): (2-10). The oil product hydrodeoxygenation upgrading catalyst has the characteristics of high activity and conversion rate of low-temperature hydrodeoxygenation, good selectivity, repeated long-term recycling, good stability, strong coking resistance, good hydrothermal stability and good acid and water resistance, and thepreparation method is simple and wide in application prospect.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

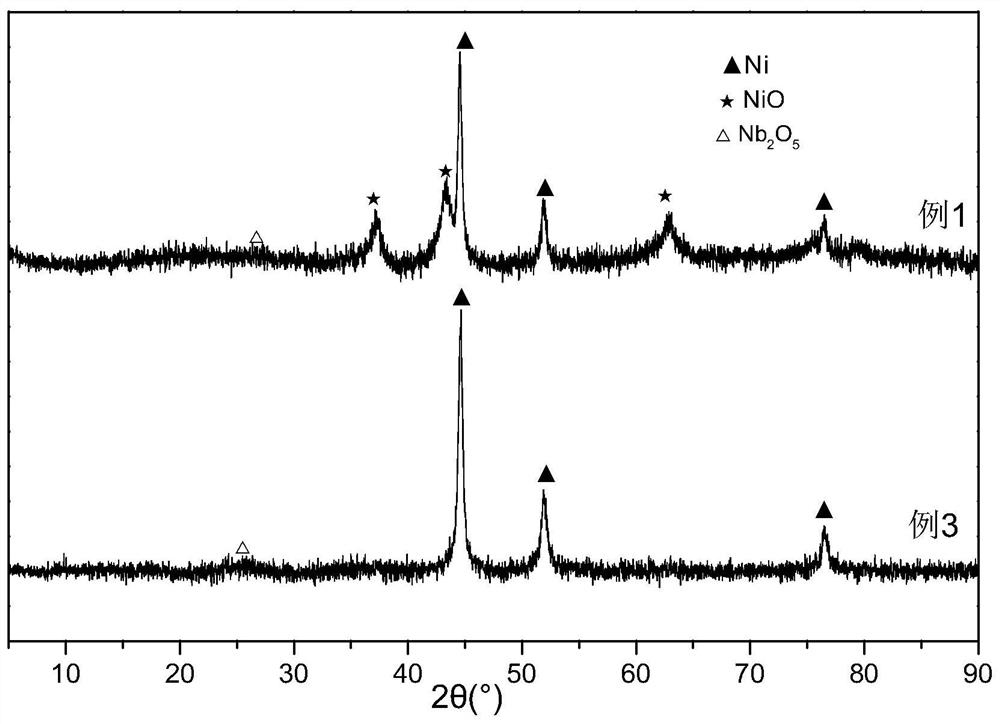

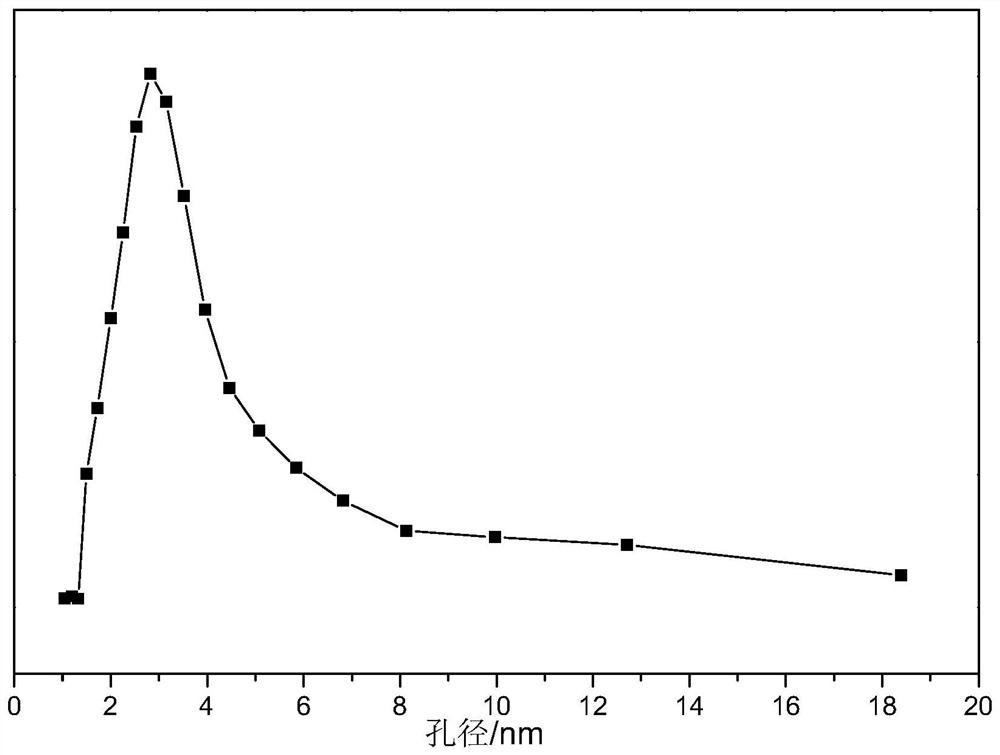

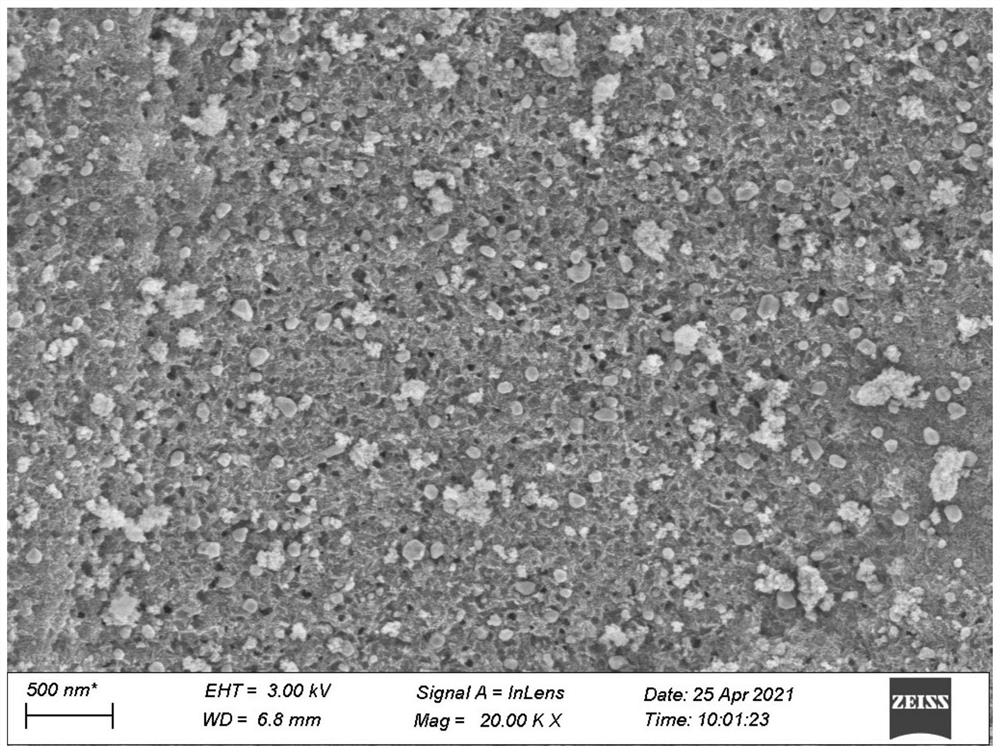

Non-supported mesoporous hydrodeoxygenation catalyst, preparation and application thereof

PendingCN113663682ASimple preparation processHigh deoxygenation rateFatty acid hydrogenationCatalystsNickel saltPtru catalyst

The invention relates to a non-supported mesoporous hydrodeoxygenation catalyst, which comprises elemental nickel and diniobium pentaoxide, wherein a molar ratio of the elemental nickel to the diniobium pentaoxide is 7:2-18:1. The preparation method comprises the following steps: dissolving a nickel salt and citric acid in an ethanol solution, dissolving a niobium salt in water, mixing, adjusting the pH value to 1-4 by using nitric acid, placing in an oil bath at a temperature of 80-100 DEG C, heating and stirring until the mixture is viscous, ultrasonically oscillating for 15-30 minutes, drying at a temperature of 80-120 DEG C for 4-10 hours, roasting at a temperature of 400-600 DEG C for 3-6 hours, and reducing at a temperature of 300-500 DEG C for 3-5 hours in a 10vol% H2 / Ar atmosphere, wherein BET determination results show that the catalyst is of a mesoporous structure; and putting the catalyst and bio-oil into a batch reactor, and carrying out hydrodeoxygenation reaction for 1-8 hours at a hydrogen pressure of 1-4 MPa and a temperature of 180-250 DEG C to obtain a bio-oil hydrodeoxygenation product. The method is simple and efficient in synthesis and mild in reaction condition.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Biodiesel hydrogenation and deoxygenation process

InactiveCN107245349AHigh deoxygenation rateReduce catalytic activityHydrocarbon oils refiningHydrocarbon oils treatmentBiodieselHydrogen pressure

The invention discloses a biodiesel hydrodeoxygenation process, which is characterized in that the process adopts a fixed bed reactor, and the fixed bed reactor is filled with a hydrodeoxygenation catalyst, and the catalyst includes a carrier and an active component; the carrier is Synthesis of MCM-41 doped with heteroatom Co2+ in the framework structure; the active component is a mixture of dimolybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the catalyst also contains a catalytic promoter , the catalytic promoter is a mixture of TiO2, CeO2, V2O5 and NbOPO4, and the reaction conditions of the fixed bed reactor are: the reaction temperature is 300-450°C, the hydrogen pressure is 2.5-3.5MPa, and the hydrogen-oil volume ratio is 500-800 , volumetric space velocity 1.0‑2.5h‑1. The hydrodeoxygenation of biodiesel by the process can be controlled at a relatively high deoxygenation rate (above 99.8%) and the catalytic activity does not decrease significantly after 500 hours of continuous operation.

Owner:锡山区绿春塑料制品厂

Hydrodeoxygenation process for biodiesel

InactiveCN106118710AHigh deoxygenation rateReduce catalytic activityPhysical/chemical process catalystsBiofuelsBiodieselHydrogen pressure

The invention discloses a hydrodeoxygenation process for biodiesel. The hydrodeoxygenation process is characterized in that a fixed bed reactor filled with a hydrodeoxygenation catalyst is adopted, and the hydrodeoxygenation catalyst comprises a carrier and an active component; the carrier is SAPO-5 doped with a heteroatom Cu<2+> in a synthetic skeleton structure; the active component is a mixture of dimolybdenum nitride Mo2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the catalyst further contains a catalysis aid which is a mixture of TiO2, CeO2, V2O5 and NbOPO4; and the reaction conditions of the fixed bed reactor are as follows: the reaction temperature is 300-450 DEG C, the hydrogen pressure is 2.5MPa-3.5MPa, the volume ratio of hydrogen to oil is 500 to 800, and the volume space velocity is 1.0h<-1>-2.5h<-1>. According to the hydrodeoxygenation process, the hydrodeoxygenation of the biodiesel can be maintained at a relatively high deoxidizing ratio (99.8% or above), and the catalytic activity is not obviously decreased after the continuous working for 500 hours.

Owner:锡山区绿春塑料制品厂

Biodiesel hydrodeoxygenation technique

InactiveCN106244187AHigh deoxygenation rateReduce catalytic activityMolecular sieve catalystsBiofuelsBiodieselHydrogen pressure

The invention discloses a biodiesel hydrodeoxygenation technique. The technique is characterized by adopting a fixed-bed reactor, wherein the fixed-bed reactor is filled with a hydrodeoxygenation catalyst, and the catalyst comprises a support and an active component. The support is MCM-41 doped with heteroatom Cu<2+> in a synthetic skeleton structure. The active component is a mixture of dimolybdenum nitride Mo2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC. The catalyst also contains a catalytic aid, and the catalytic aid is a mixture of TiO2, CeO2, V2O5 and NbOPO4. The reaction conditions of the fixed-bed reactor are as follows: the reaction temperature is 300-450 DEG C, the hydrogen pressure is 2.5-3.5 MPa, the hydrogen / oil volume ratio is 500-800, and the volumetric space velocity is 1.0-2.5 h<-1>. When the technique is used for biodiesel hydrodeoxygenation, the deoxygenation rate can be up to 99.8% or above, and the catalytic activity after 500-hour continuous operation does not obviously decrease.

Owner:锡山区绿春塑料制品厂

Deoxidizing alloying agent and preparation method thereof

The invention discloses a deoxidizing alloying agent. The deoxidizing alloying agent is prepared from an aluminum electrolyte waste inner lining brick. The particle size of the aluminum electrolyte waste inner lining brick is broken to be 5 mm or less firstly, the aluminum electrolyte waste inner lining brick obtained in the step (1) is dried under the temperature below 300 DEG C till the water content of the aluminum electrolyte waste inner lining brick is smaller than 1% of the total weight of the inner lining brick, and then the deoxidizing alloying agent is obtained. According to the deoxidizing alloying agent and a preparation method thereof, the deoxidizing alloying agent is prepared from the aluminum electrolyte waste inner lining brick, the aluminum electrolyte waste inner lining brick mainly adopts a furnace slag method for deoxidizing to make quickly contact with oxygen in steel slag, thus the speed of the deoxidizing reaction is high, and the deoxidizing rate is high; and the component of the deoxidizing alloying agent is stable, meanwhile smelting energy consumption is low, and production cost is low, so that recycling for aluminum electrolyte waste silicon-carbide brick solid waste is achieved, and additional value of the solid waste is promoted.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Hydrogenation and deoxygenation process of biodiesel

InactiveCN106350096AHigh deoxygenation rateNo significant decrease in catalytic activityMolecular sieve catalystsBiofuelsDeoxygenationFixed bed

The invention disclsoes a hydrogenation and deoxygenation process of biodiesel. The hydrogenation and deoxygenation process is characterized in that the process adopts a fixed bed reactor; the fixed bed reactor is filled with a hydrogenation and deoxygenation catalyst; the catalyst comprises a carrier and an active component; the carrier is a compound or mixture of MSU-G, SBA-15 and HMS (Hexagonal Mesoporous Silica); the active component is a mixture of dimolybdenum nitride (MO2N), tungsten nitride (W2N), molybdenum carbide (Mo2C) and tungsten carbide (WC); the catalyst further contains a catalytic auxiliary agent; the catalytic auxiliary agent is a mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4; reaction conditions of the fixed bed reactor are as follows: the reaction temperature is 300 DEG C to 450 DEG C, the hydrogen pressure is 2.5MPa to 3.5MPa, the hydrogen-oil volume ratio is 500 to 800 and the volume space velocity is 1.0h<-1> to 2.5h<-1>. By adopting the process provided by the invention, the hydrogenation and deoxygenation of the biodiesel can be controlled to be a relatively high deoxygenation rate (99.8 percent or more) and the catalytic activity does not fall significantly after 500 hours of continuous operation.

Owner:过冬

Double-activity Ni2P/Zr-SBA-15 catalyst and preparation method and application thereof

ActiveCN109046438AHas isomerization activityWith hydrodeoxygenation (HDO) performanceMolecular sieve catalystsLiquid hydrocarbon mixture productionIsomerizationCombustion

The invention discloses a double-activity Ni2P / Zr-SBA-15 catalyst and a preparation method and application thereof. The active component of the catalyst is Ni2P, and a carrier is Zr-SBA-15. The double-activity Ni2P / Zr-SBA-15 catalyst has the advantages that the preparation is simple, and the price is low; the activities of hydrodeoxygenation and isomerization are high, the anti-carbon accumulationability is strong, the oxygen removal rate reaches 98% or above, and the curcas oil with low price can be converted into biofuel with high content of straight-chain paraffin, high calorific heat andhigh price; after reaction is finished, the coking rate of the catalyst is lower than 1.66%; the main components of the biofuel are petroleum diesel and aviation kerosene, the combustion property is good, the stability is high, the petroleum diesel and aviation kerosene can be replaced, and the good industrial application prospect is realized.

Owner:HAINAN UNIVERSITY

Biodiesel hydrodeoxygenation process

InactiveCN106190253AHigh deoxygenation rateReduce catalytic activityMolecular sieve catalystsHydrocarbon oils refiningBiodieselHydrogen pressure

The invention discloses a biodiesel hydrodeoxygenation process. The biodiesel hydrodeoxygenation process is characterized in that a fixed bed reactor is adopted for the process and filled with a hydrodeoxygenation catalyst, and the catalyst comprises a carrier and an active component; the carrier is SAPO-5 with heteroatom Co2+ doped in a synthetic skeleton structure; the active component is a mixture of molybdenum nitride (MO2N), tungsten nitride (W2N), molybdenum carbide (Mo2C) and tungsten carbide (WC); the catalyst further contains a catalytic promoter, the catalytic promoter is a mixture of TiO2, CeO2, V2O5 and NbOPO4; according to the reaction conditions of the fixed bed reactor, the reaction temperature ranges from 300 DEG C to 450 DEG C, the hydrogen pressure ranges from 2.5 MPa to 3.5 MPa, the hydrogen-oil volume ratio ranges from 500 to 800, and the volume air speed ranges from 1.0 h<-1> to 2.5 h<-1>. By means of the process, hydrodeoxygenation on biodiesel can be controlled at a high deoxidation rate (99.8% or above), and catalytic activity is not obviously reduced after continuous operation is carried out for 500 hours.

Owner:锡山区绿春塑料制品厂

Hydrodeoxygenation process of biodiesel

InactiveCN106244188AHigh deoxygenation rateReduce catalytic activityMolecular sieve catalystsBiofuelsBiodieselHydrogen pressure

The invention discloses a hydrodeoxygenation process of biodiesel. The hydrodeoxygenation process of the biodiesel is characterized in that the process adopts a fixed bed reactor, the fixed bed reactor is filled with a hydrodeoxygenation catalyst, and the catalyst comprises a carrier and an active component; the carrier is SAPO-5 which is doped with heteroatoms Co<2+> in a synthetic skeleton structure; the active component is a mixture of MO2N, W2N, Mo2C and WC; the catalyst also comprises a catalytic promoter, wherein the catalytic promoter is a mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4; the reaction conditions of the fixed bed reactor are that the reaction temperature is 300 to 450 DEG C, the hydrogen pressure is 2.5-3.5 MPa, the volume ratio of hydrogen to the oil is 500 to 800, and the volume space velocity is 1.0 to 2.5 h<-1>. The process can control hydrodeoxygenation of the biodiesel in a higher deoxidation rate (99.8% or above) and the catalytic activity is not decreased obviously after 500-hour continuous operation.

Owner:锡山区绿春塑料制品厂

Biodiesel hydrodeoxygenation process

InactiveCN106221744AHigh deoxygenation rateNo significant decrease in catalytic activityMolecular sieve catalystsTreatment with hydrotreatment processesBiodieselHydrogen pressure

The invention discloses a biodiesel hydrodeoxygenation process which is characterized by comprising a fixed bed reactor filled with hydrodeoxygenation catalysts, the catalysts include carriers, active components and catalytic auxiliaries, the carriers are KIT-1 with synthetic skeleton structures doped with heteroatoms Co2+, the active components are molybdous nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC mixture, and the catalytic auxiliaries are TiO2, CeO2, V2O5 and NbOPO4 mixture. The reaction condition of the fixed bed reactor includes reaction temperature of 300-450 DEG C, hydrogen pressure of 2.5-3.5MPa, hydrogen to oil volume ratio of 500-800, and volume space velocity of 1.0-2.5h<1>. By the process, the hydrodeoxygenation rate of biodiesel can be controlled to be high (99.8% or more), and catalytic activity cannot be obviously reduced in continuous running for 500 hours.

Owner:锡山区绿春塑料制品厂

A dual-functional catalyst for deoxygenation and organic sulfur hydrogenation conversion and its preparation and application

ActiveCN105435806BLow oxygen contentEasy to prepareDispersed particle separationPerfluorocarbons/hydrofluorocarbons captureSulfurCoke oven

The invention relates to a dual-functional catalyst for deoxidation and organic sulfur hydrogenation conversion and its preparation and application, belonging to the technical field of gas purification. The catalyst includes the following components in parts by mass in terms of oxides: 1-50 parts of active components, 0.1-20 parts of active auxiliary agents, and 30-89.1 parts of carriers. The present invention also relates to three preparation methods of the catalyst. The catalyst of the present invention has dual functions of deoxidation and hydrogenation conversion of organic sulfur, and can be used in the purification process of raw material gases such as industrial coal water gas, semi-water gas, coke oven gas, and calcium carbide furnace gas containing sulfur, CO, and H2. The catalyst of the invention can simultaneously realize the purposes of deoxidation and hydrogenation conversion of organic sulfur, shorten the technological process, simplify the process, reduce energy consumption and save cost. The preparation method of the catalyst of the invention is simple, has strong operability and requires low preparation conditions. The catalyst of the invention has high deoxidation rate and high organic sulfur hydrogenation conversion rate, the oxygen volume content of the product obtained after deoxidation is lower than 100ppm, and the organic sulfur conversion rate is greater than 95%.

Owner:HAO HUA CHENGDU TECH

Biodiesel hydrodeoxygenation process

InactiveCN106318448AHigh deoxygenation rateReduce catalytic activityMolecular sieve catalystsHydrocarbon oils refiningBiodieselHydrogen pressure

The invention discloses a biodiesel hydrodeoxygenation process. The biodiesel hydrodeoxygenation process is characterized in that a fixed bed reactor is adopted in the process, the fixed bed reactor is filled with a hydrodeoxygenation catalyst, and the catalyst comprises a carrier and an active component; the carrier is KIT-1 formed by doping heteroatom Cu2+ in a synthetic framework structure. The active component is a mixture of molybdenum nitride (MO2N), tungsten nitride (W2N), molybdenum carbide (Mo2C) and tungsten carbide (WC). The catalyst further comprises a catalytic promoter, and the catalytic promoter is a mixture of TiO2, CeO2, V2O5 and NbOPO4. According to the reaction conditions of the fixed bed reactor, the reaction temperature ranges from 300 DEG C to 450 DEG C, the hydrogen pressure ranges from 2.5 MPa to 3.5 MPa, the hydrogen-oil volume ratio ranges from 500 to 800, and the volume air speed ranges from 1.0 h<-1> to 2.5 h<-1>. According to the process, hydrodeoxygenation of biodiesel can be controlled at a high deoxygenation rate (99.8% or above), and catalytic activity is not obviously reduced after the process continuously runs for 500 hours.

Owner:锡山区绿春塑料制品厂

A method and system for low-temperature liquid-phase hydrotreating of Fischer-Tropsch synthetic oil

ActiveCN106590732BImprove conversion rateHigh deoxygenation rateRefining to eliminate hetero atomsFixed bedControl valves

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Biodiesel hydrodeoxygenation process

InactiveCN106221723AHigh deoxygenation rateReduce catalytic activityMolecular sieve catalystsBiofuelsBiodieselHydrogen pressure

The invention discloses a biodiesel hydrodeoxygenation process. The process is characterized in that a fixed bed reactor is adopted, a hydrodeoxygenation catalyst is filled into the fixed bed reactor, the catalyst contains a carrier and an active component; the carrier is KIT-1 doped with heteroatom Cu2+ in a synthetic skeleton structure; the active component is the mixture of molybdous nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the catalyst further contains a catalytic promoter, the catalytic promoter is the mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4; the reaction conditions of the fixed bed reactor are as follows: the reaction temperature is 300-450 DEG C, the hydrogen pressure is 2.5-3.5MPa, the hydrogen oil volume ratio is 500-800, and the volume space velocity is 1.0-2.5h-1. Through the adoption of the process disclosed by the invention, the catalytic activity has no obvious decrease when the hydrodeoxygenation energy to the biodiesel is controlled at high deoxygenation rate (99.8% and more) and the hydrodeoxygenation is continuously operated for 500 hours.

Owner:锡山区绿春塑料制品厂

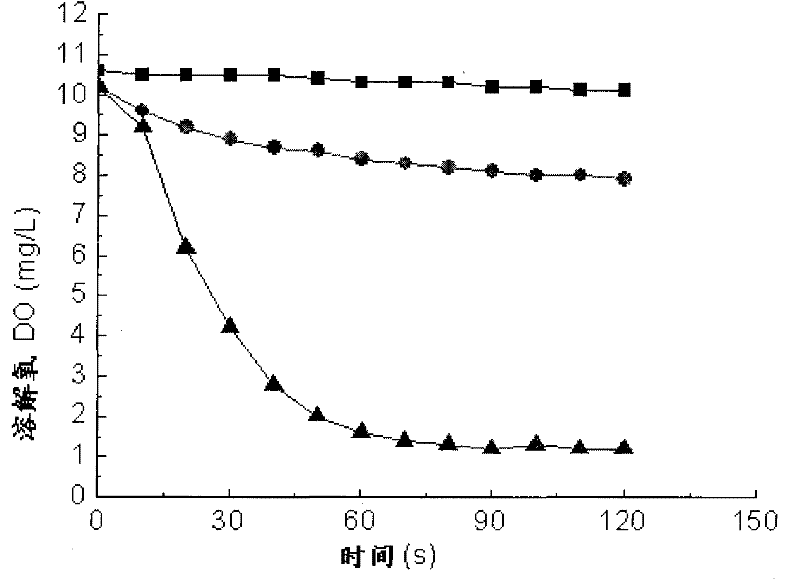

A kind of deoxygenation method of combined use of deoxygenation compound agent/uv

InactiveCN101716450BEfficient and stable removalLow costDispersed particle separationWater/sewage treatmentWater qualityDeaerator

The invention relates to a deoxygenation method combined with deoxygenation compound agent / UV, which relates to a deoxygenation method. It solves the problems of expensive equipment, complicated operation and slow deoxygenation rate in the existing physical deoxygenation technology, and the problems of expensive catalyst, large dosage, heavy metal content and slow deoxygenation rate in the chemical deoxygenation technology. Method: Add oxygen-removing compound agent to the reaction system, and then irradiate with ultraviolet light to complete the oxygen-removal. The invention can efficiently and stably remove dissolved oxygen in air and water, does not require expensive equipment and components, is simple and safe to operate, has a fast deoxygenation rate, does not require expensive catalysts, does not contain heavy metals, and has a small dosage. Cost saving, less impact on water quality, no special requirements on water quality indicators such as air impurities in the reaction system, pH value, temperature, salinity and organic matter in the water body, so it can be widely used in air and water oxygen removal.

Owner:HARBIN INST OF TECH

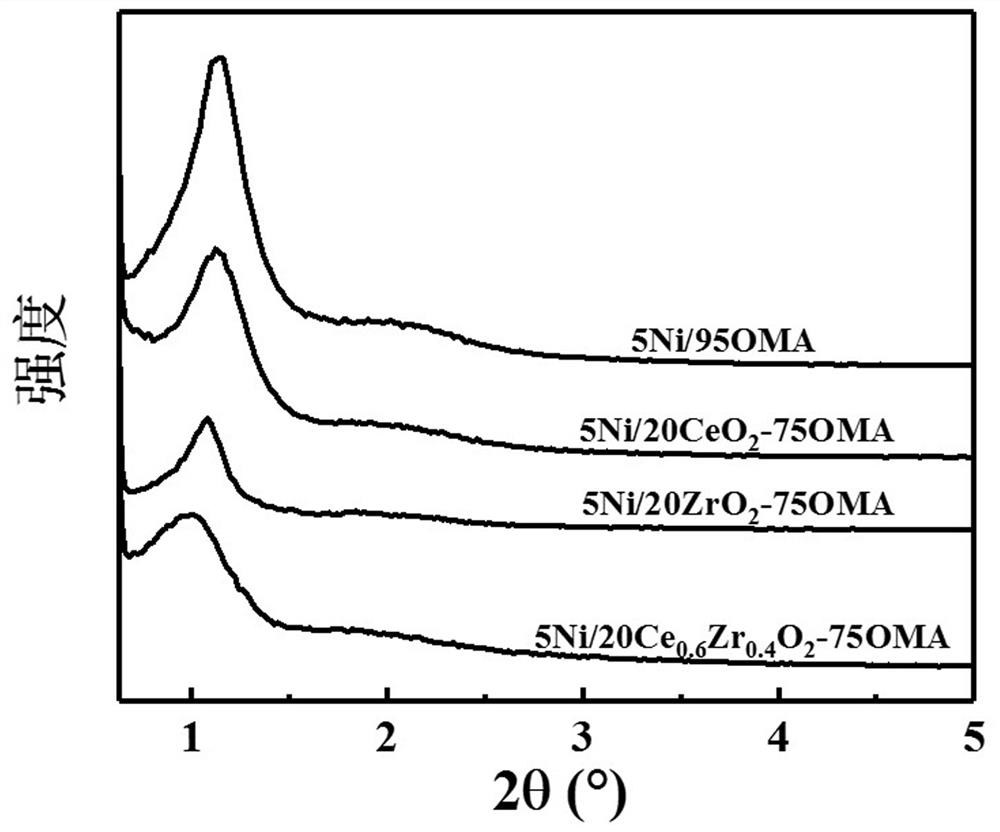

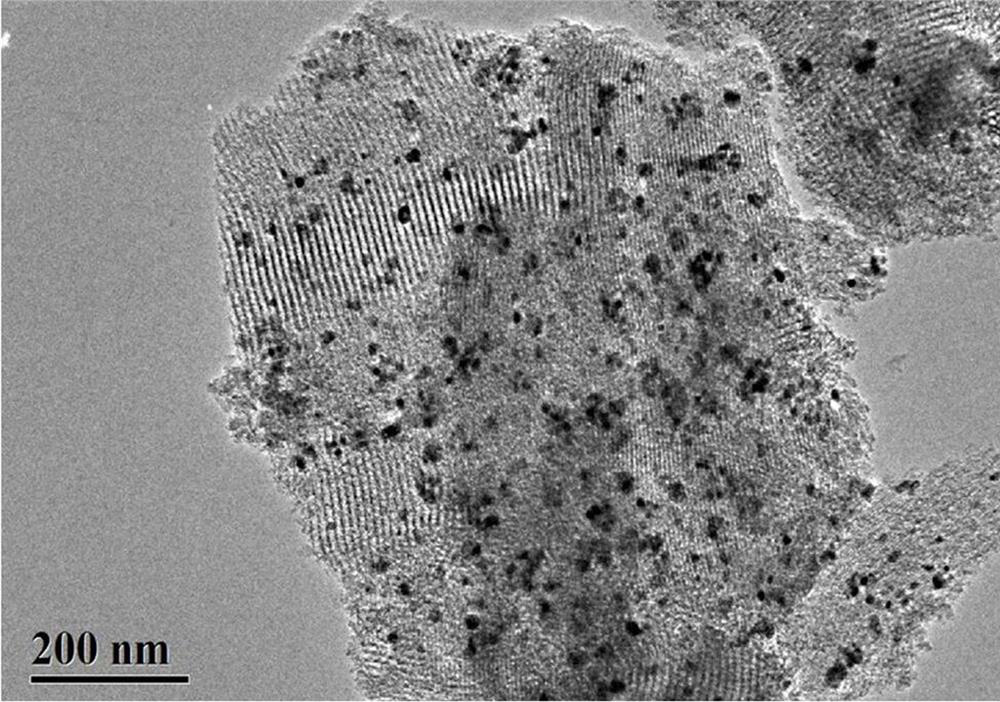

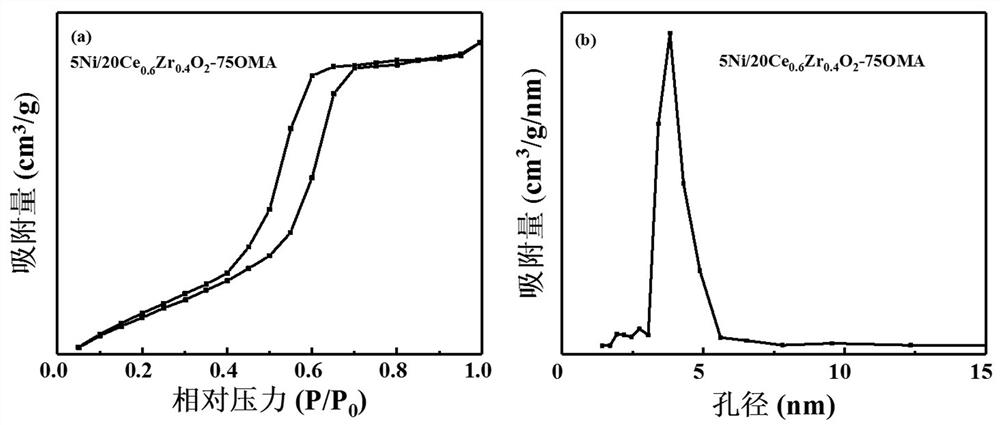

A medium-low temperature coal tar hydrodeoxygenation catalyst and its preparation and application

ActiveCN109759073BImprove catalytic performanceHigh deoxygenation rateMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystOxygen vacancy

The invention discloses a medium-low temperature coal tar hydrodeoxygenation catalyst, which uses transition metal Ni as an active component and ordered mesoporous Al 2 o 3 As a carrier, Ce and Zr are doped into it to form Ce containing a large number of oxygen vacancies 1‑x Zr x o 2 The solid solution is formed as an auxiliary agent and has an ordered mesoporous structure, with the structural formula aNi / bCe 1‑x Zr x o 2 ‑cOMA (x=0.4~0.7) means. The catalyst of the invention has good catalytic performance and high deoxygenation rate, can promote the breaking of C-O bonds in oxygen-containing compounds, and improve the hydrodeoxygenation performance of the catalyst.

Owner:TAIYUAN UNIV OF TECH

Hydrodeoxygenation technology for biodiesel

InactiveCN106433753AHigh deoxygenation rateReduce catalytic activityHydrocarbon oils refiningHydrocarbon oils treatmentBiodieselHydrogen pressure

The invention discloses a hydrodeoxygenation technology for biodiesel. The technology is characterized in that a fixed bed reactor is adopted, a hydrodeoxygenation catalyst is contained in the reactor and prepared from a carrier and an active component, wherein the carrier is KIT-1 formed by doping a synthetic skeleton structure with heteroatom Co<2+>, and the active component is a mixture of dimolybdenum nitride Mo2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC. The fixed bed reactor has the reaction conditions that the reaction temperature ranges from 300 DEG C to 450 DEG C, the hydrogen pressure is 2.5-3.5 MPa, the volume ratio of hydrogen to oil is 500-800, and the volume space velocity is 1.0-2.5 h<-1>. According to the technology, hydrodeoxygenation on the biodiesel can be controlled at high deoxygenation rate (99.8% or above), and the catalytic activity is not obviously reduced after hydrodeoxygenation is continuously operated for 500 hours.

Owner:锡山区绿春塑料制品厂

A kind of preparation method of algae oil production hydrocarbon fuel

InactiveCN103614155BHigh catalytic activityMild reaction conditionsLiquid hydrocarbon mixture productionBio-feedstockHigh rateReaction temperature

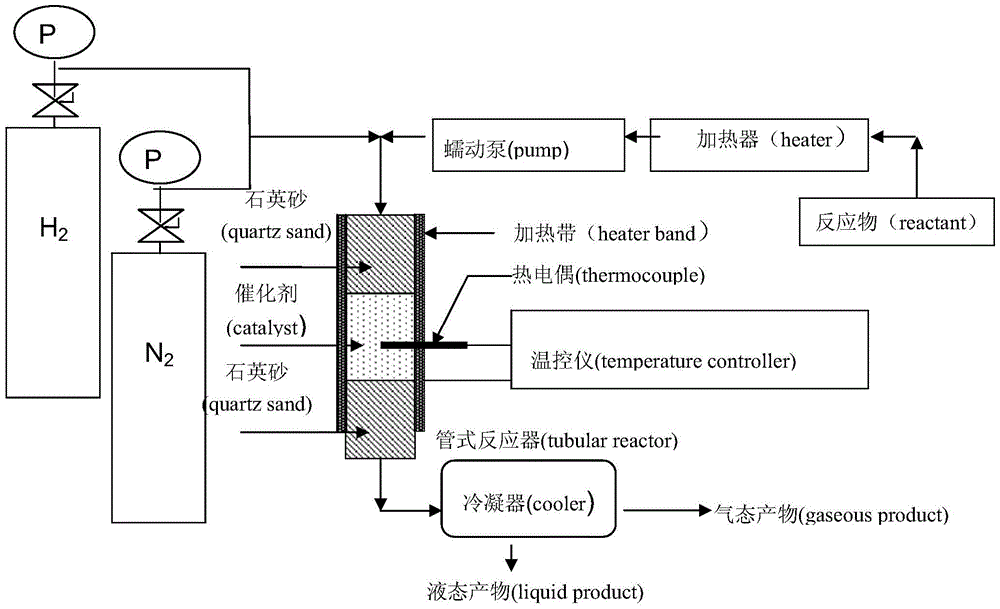

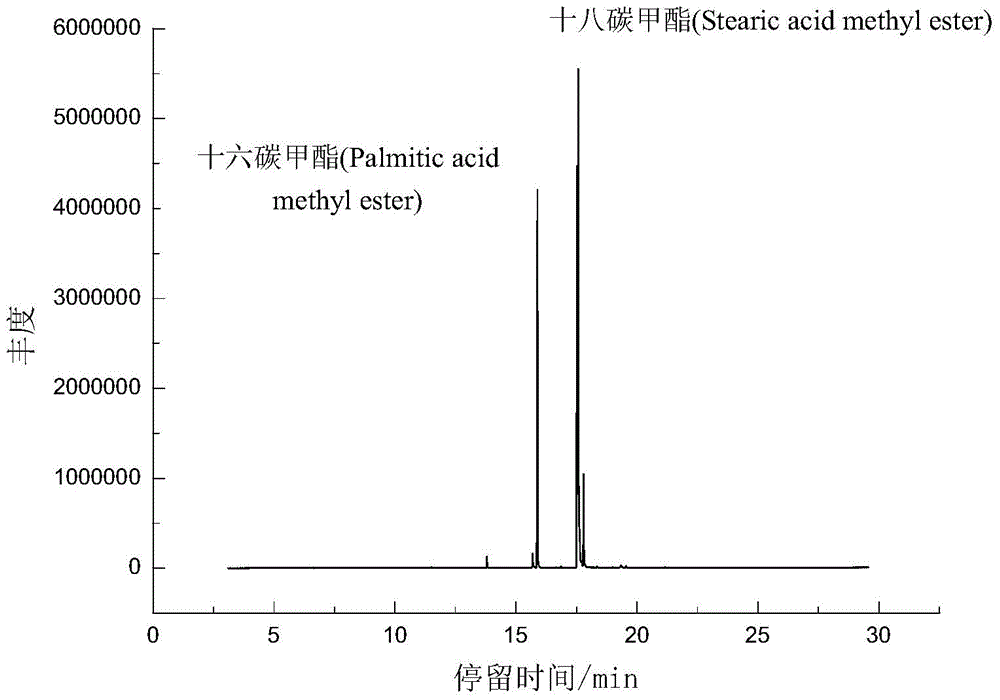

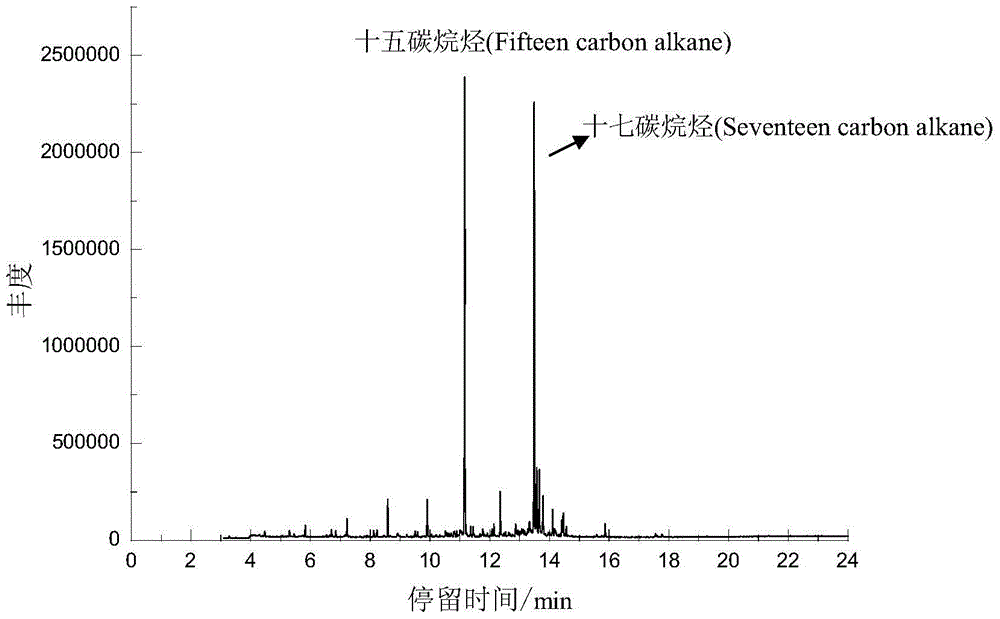

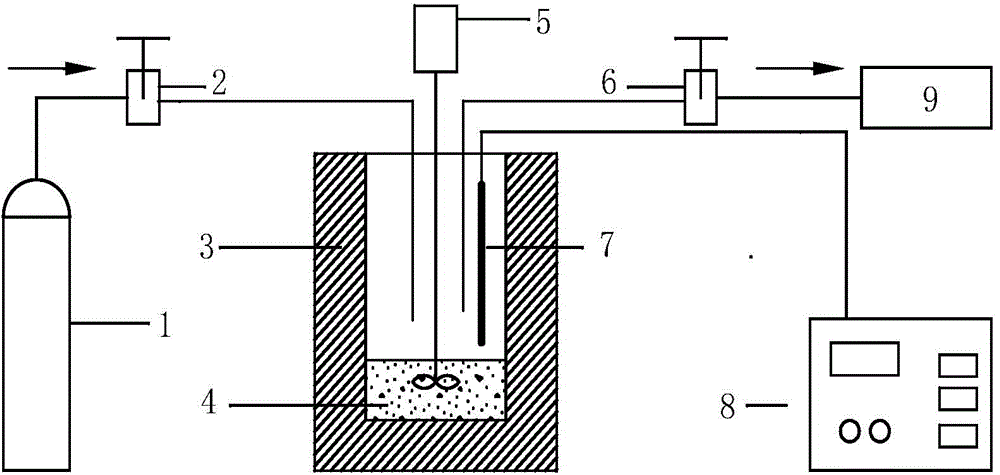

The invention discloses a preparation method for producing hydrocarbon fuel from algae oil. The method comprises the following steps: in a nitrogen atmosphere, oil and fat compounds are pumped to a tubular reactor equipped with a supported molybdenum catalyst for catalytic decarboxylation reaction to obtain hydrocarbon fuel; the reaction atmosphere of the decarboxylation and deoxygenation reaction is nitrogen, the reaction pressure is normal pressure, the reaction temperature is 300-360 ° C, the reaction time is 1.5-3.0h, and the feed rate is 0.03-0.30g / (cm 2 ﹒ min); wherein the supported molybdenum catalyst uses molybdenum as the active metal and activated carbon as the catalyst carrier. Compared with the prior art, since the present invention adopts a supported molybdenum catalyst with activated carbon as a carrier, its catalytic activity is high, the reaction conditions are mild (the reaction does not require hydrogen, and can be carried out under normal pressure), the conversion rate of raw materials and the deoxidation The yield and liquid hydrocarbon yield are higher.

Owner:ZHEJIANG UNIV OF TECH

Biodiesel hydrodeoxygenation process

InactiveCN106221722AHigh deoxygenation rateReduce catalytic activityMolecular sieve catalystsBiofuelsBiodieselHydrogen pressure

The invention discloses a biodiesel hydrodeoxygenation process. The process is characterized in that a fixed bed reactor is adopted, a hydrodeoxygenation catalyst is filled into the fixed bed reactor, the catalyst contains a carrier and an active component; the carrier is MCM-41 doped with heteroatom Cu2+ in a synthetic skeleton structure; the active component is the mixture of molybdous nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the catalyst further contains a catalytic promoter, the catalytic promoter is the mixture of Cr2O3, ZrO2, CeO2, V2O5 and NbOPO4; the reaction conditions of the fixed bed reactor are as follows: the reaction temperature is 300-450 DEG C, the hydrogen pressure is 2.5-3.5MPa, the hydrogen oil volume ratio is 500-800, and the volume space velocity is 1.0-2.5h-1. Through the adoption of the process disclosed by the invention, the catalytic activity has no obvious decrease when the hydrodeoxygenation energy to the biodiesel is controlled at high deoxygenation rate (99.8% and more) and the hydrodeoxygenation is continuously operated for 500 hours.

Owner:锡山区绿春塑料制品厂

Hydrodeoxygenation technology for biodiesel

InactiveCN106221739AHigh deoxygenation rateReduce catalytic activityMolecular sieve catalystsTreatment with hydrotreatment processesDeoxygenationFixed bed

The invention discloses a hydrodeoxygenation technology for biodiesel. The technology is characterized in that a fixed bed reactor is adopted and filled with a hydrodeoxygenation catalyst, and the catalyst is prepared from a carrier and an active component, wherein the carrier is MCM-41prepared by doping a synthetic framework structure with heteroatom Cu<2+>, and the active component is a mixture of dimolybdenm nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; reacting of the fixed bed reactor is conducted under the conditions that the reacting temperature ranges from 300 DEG C to 450 DEG C, the hydrogen pressure ranges from 2.5 MPa to 3.5 MPa, the hydrogen-oil volume ratio is 500-800, and the liquid hourly space velocity is 1.0-2.5 h<-1>. According to the technology, hydrodeoxygenation on the biodiesel can be controlled at high deoxygenation rate (99.8% or above), the catalytic activity is not obviously reduced after operation is continuously conducted for 500 hours.

Owner:锡山区绿春塑料制品厂

Biodiesel hydrodeoxygenation technology

InactiveCN106085496AHigh deoxygenation rateReduce catalytic activityHydrocarbon oils refiningHydrocarbon oils treatmentDeoxygenationChemistry

The invention discloses a biodiesel hydrodeoxygenation technology. The biodiesel hydrodeoxygenation technology is characterized in that a fixed bed reactor is adopted in the technology and filled with a hydrodeoxygenation catalyst, and the catalyst contains a carrier and active ingredients; the carrier is heteroatom Co2+ -doped MCM 41 in a synthesized skeleton structure; the active ingredient is a mixture of dimolybdenum nitride Mo2N, tungsten nitride W2N, molybdenum carbonate Mo2C and tungsten carbonate WC; the reaction conditions of the fixed bed reactor are as follows: the reaction temperature is 300-450DEG C, the hydrogen pressure is 2.5-3.5MPa, the hydrogen-oil volume ratio is 500-800, and the volume idle speed is 1.0-2.5h / l. By adopting the technology, the higher deoxygenation rate (more than 99.8%) of the biodiesel can be controlled in hydrodeoxygenation, and the catalytic activity after continuous running for 500 hours is obviously reduced.

Owner:锡山区绿春塑料制品厂

Low-rank coal alcoholysis deoxidization method

The invention discloses a low-rank coal alcoholysis deoxidization method, which comprises the following steps of weighing 1 part by weight of dry basis low-rank coal and 3 to 10 parts by weight of absolute ethyl alcohol, uniformly mixing the low-rank coal and the absolute ethyl alcohol, and pouring the mixture into a high-pressure reactor; charging N2 with purity of more than 99 percent into the sealed high-pressure reactor to remove oxygen from the reactor, wherein the stirring speed in the high-pressure reactor is 300 to 400rad / min, the heating speed is controlled to be 5 to 10 DEG C per minute, and the temperature is maintained for 30 to 120 minutes after the reaction temperature reaches 220 to 300 DEG C; cooling the high-pressure reactor to room temperature, taking out a reaction product, performing vacuum suction filtration to obtain filtrate and residues respectively, and performing vacuum drying on the residues to obtain deoxidized coal. According to the method, high deoxidization rate can be achieved under the conditions of low temperature and pressure, the production cost is lowered, and the quality of lignite is improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Technology for hydrogenating and deoxidizing biodiesel

InactiveCN106281403AHigh deoxygenation rateReduce catalytic activityMolecular sieve catalystsBiofuelsBiodieselHydrogen pressure

The invention discloses a technology for hydrogenating and deoxidizing biodiesel. The technology is characterized in that a fixed bed reactor is adopted, and a hydrogenating and deoxidizing catalyst is filled into the fixed bed reactor, and comprises a carrier and an active ingredient; the carrier is KIT-1 by doping heteroatom Cu2+ into a synthetic skeleton structure; the active ingredient is a mixture of MO2N (molybdenum nitride), W2N (tungsten nitride), Mo2C (molybdenum carbide) and WC (tungsten carbide); the reaction conditions of the fixed bed reactor are met, namely that the reaction temperature is 300 to 450 DEG C, the hydrogen pressure is 2.5 to 3.5MPa, the volume ratio of hydrogen and oil is 500 to 800, and the volume air speed is 1.0 to 2.5h<-1>. The technology has the advantages that when the biodiesel is hydrogenated and deoxidized, the deoxidizing ratio is higher than 99.8%, and the obvious degrading of catalytic activity is avoided after continuous running of 500h.

Owner:锡山区绿春塑料制品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com