Non-supported mesoporous hydrodeoxygenation catalyst, preparation and application thereof

A deoxygenation catalyst, unsupported technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, hydrocarbon production from oxygen-containing organic compounds, etc. Complex process and other problems, to achieve the effects of excellent water resistance, high deoxidation rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] At the same time, the invention also discloses a method for preparing a non-supported mesoporous hydrodeoxygenation catalyst, the catalyst is prepared by mixing soluble nickel salt, soluble niobium salt and organic acid, ultrasonic oscillation, drying, roasting and reduction, Specifically include the following steps:

[0033] S1, dissolving soluble nickel salt and organic acid in ethanol solution, dissolving soluble niobium salt in water, mixing with each other, stirring evenly, adding nitric acid to adjust pH value to form a mixture;

[0034] S2. Heat the above mixture to 60-100°C, stir until viscous, and then oscillate ultrasonically for 10-30min;

[0035]S3. Put the viscous mixture in an oven and dry it in an environment of 80-120°C for 4-10 hours to obtain a dried mixture;

[0036] S4, heating the dried mixture in a muffle furnace at a rate of 2-10°C / min to 400-600°C for 3-6h;

[0037] S5. Place the calcined precursor in a tube furnace at 300-500°C under 10vol% H ...

Embodiment 1

[0041] Embodiment 1 mesoporous catalyst preparation

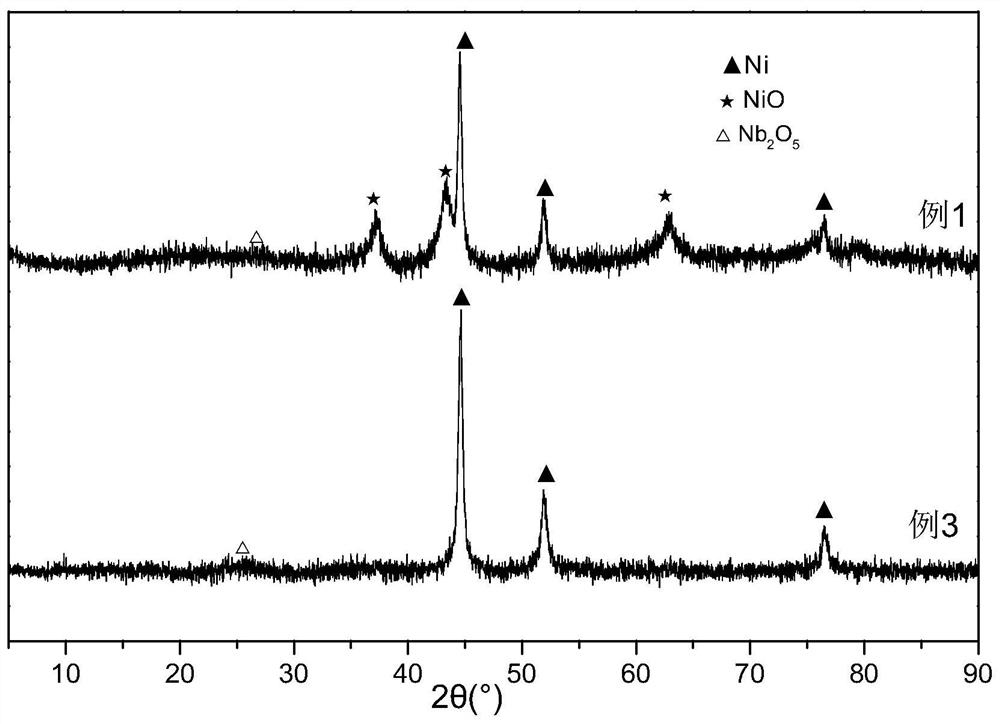

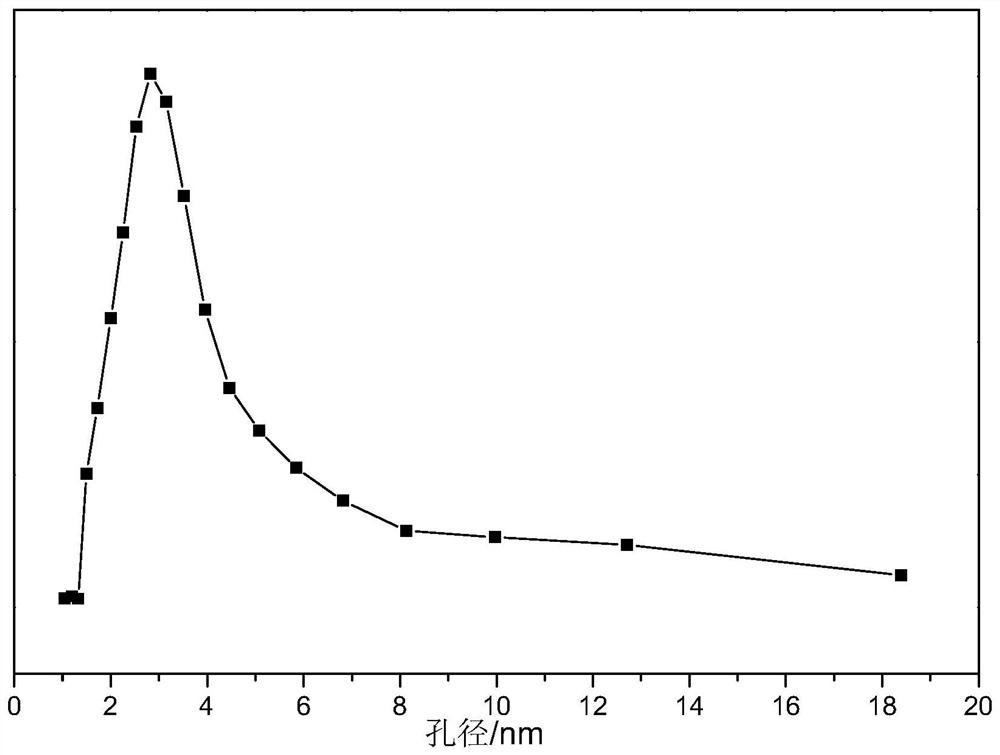

[0042] The bulk catalyst was prepared by sol-gel method. Take a certain amount of nickel nitrate, niobium oxalate, citric acid in proportion, mol ratio Nb:Ni=0.1:0.9, mol ratio (Nb+Ni): citric acid=1:1 (wherein, " (Nb+Ni) mol " means the sum of moles of niobium element and nickel element), nickel nitrate and citric acid are dissolved in ethanol solution, niobium oxalate is dissolved in water, the above solutions are mixed evenly and the pH value is adjusted to 1 with nitric acid, and the mixed solution is placed Heat in an oil bath at 90°C with magnetic stirring until viscous, oscillate ultrasonically for 15 minutes and then dry at 100°C for 10 hours to obtain a xerogel; put the xerogel in a muffle furnace for 500°C and bake it for 5 hours, then place it in a tube furnace at 400°C 10vol%H 2 / Ar atmosphere for 3 h to obtain the non-supported mesoporous hydrodeoxygenation catalyst. The XRD spectrum of the bulk type Ni-Nb c...

Embodiment 2

[0043] Embodiment 2 mesoporous catalyst preparation

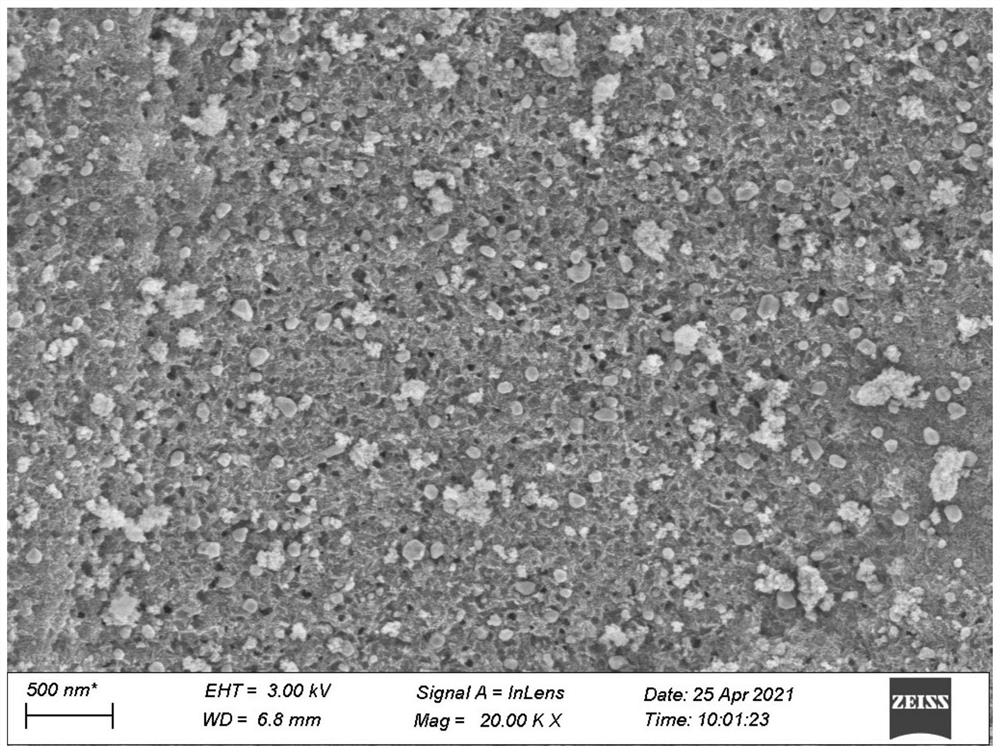

[0044] The bulk catalyst was prepared by sol-gel method. Take a certain amount of nickel chloride, niobium oxalate, citric acid in proportion, mol ratio Nb:Ni=0.2:0.8, mol ratio (Nb+Ni): citric acid=1:2 (wherein, " (Nb+Ni) mol” means the sum of moles of niobium and nickel), nickel chloride and citric acid are dissolved in ethanol solution, niobium oxalate is dissolved in water, and the mixture is placed in an oil bath at 90°C and heated with magnetic stirring until Viscous, ultrasonically oscillated for 15 minutes and then dried at 90°C for 8 hours to obtain a xerogel; put the xerogel in a muffle furnace at 500°C for 4 hours, and then in a tube furnace at 450°C with 10vol%H 2 / Ar atmosphere reduction for 4h to obtain the non-supported mesoporous hydrodeoxygenation catalyst. The XRD spectrum of the bulk type Ni-Nb composite catalyst prepared by the present embodiment is as follows figure 1 Shown; The scanning electron mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com