A kind of deoxygenation method of combined use of deoxygenation compound agent/uv

An oxygen recombination and medicament technology, which is applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of heavy metals and slow oxygen removal rate, slow oxygen removal rate, expensive catalyst, etc., to achieve no Toxic and harmless formula, fast oxygen removal rate, and the effect of saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

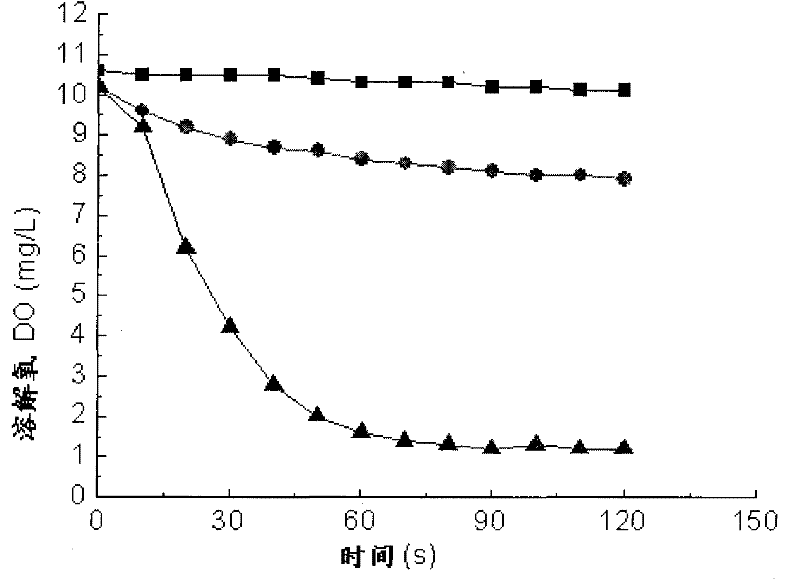

Image

Examples

specific Embodiment approach 1

[0015]Specific Embodiment 1: The deoxygenation method of this embodiment combined with oxygen-scavenging compound agent / UV is carried out in the following manner: add oxygen-scavenging compound agent (ORC) to the reaction system, and then irradiate with ultraviolet UV light to complete the oxygen-scavenging process ; Wherein the oxygen-scavenging composite agent is composed of sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, ammonium sulfite, sulfurous acid, sodium pyrosulfite, lithium pyrosulfite, potassium pyrosulfite, magnesium pyrosulfite, Calcium dithionite, ammonium dithionite, sodium dithionite, lithium dithionite, potassium dithionite, magnesium dithionite, calcium dithionite, ammonium dithionite, sodium nitrite, nitrous acid Potassium, ammonium nitrite, sodium nitrate, potassium nitrate, ammonium nitrate, sodium azide, potassium azide, ammonium azide, sodium hydroxide, potassium hydroxide, potassium iodide, sodium iodide, magnesiu...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the reaction system is industrial water supply, boiler water supply, air used in the food industry, air and water used in the petrochemical industry, water used in the textile industry, and used in the metallurgical industry. The air and water used in the electronics industry, the air and water used in the anaerobic sewage treatment industry. Others are the same as in the first embodiment.

[0023] In this embodiment, the reaction system should have better penetrability, and it is required to have less particulate matter in the reaction system, that is, less dust in the air and good visibility; less particulate matter in the water body, or turbidity < 1NTU.

[0024] In this embodiment, oxygen refers to oxygen in any concentration range, and the temperature, partial pressure and other physical and chemical properties of oxygen are not limited.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the ultraviolet UV light irradiation adopts a light source with emission wavelength<400nm, and the light source is a low-pressure mercury lamp, a medium-pressure mercury lamp, a high-pressure mercury lamp, an amalgam ultraviolet lamp, a vacuum lamp, etc. UV lamp, halogen lamp, black lamp or xenon lamp. Others are the same as in the first embodiment.

[0026] In this embodiment, the light source needs to be equipped with appropriate electrical control equipment and power supply.

[0027] In this embodiment, the power of ultraviolet UV light irradiation can be selected arbitrarily, and it needs to be determined according to the actual needs of the system (system oxygen concentration, oxygen removal rate and operating cost).

[0028] In this embodiment, the ultraviolet UV light irradiation adopts the immersion type or the surface irradiation type; if the immersion type is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com