A kind of preparation method of algae oil production hydrocarbon fuel

A technology for producing hydrocarbons and algae oil, which is used in the preparation of liquid hydrocarbon mixtures, biological raw materials, petroleum industry, etc., can solve the problems of poor ignition performance, high viscosity, low calorific value, etc., and achieves high deoxygenation rate and liquid hydrocarbon yield. , mild reaction conditions, high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

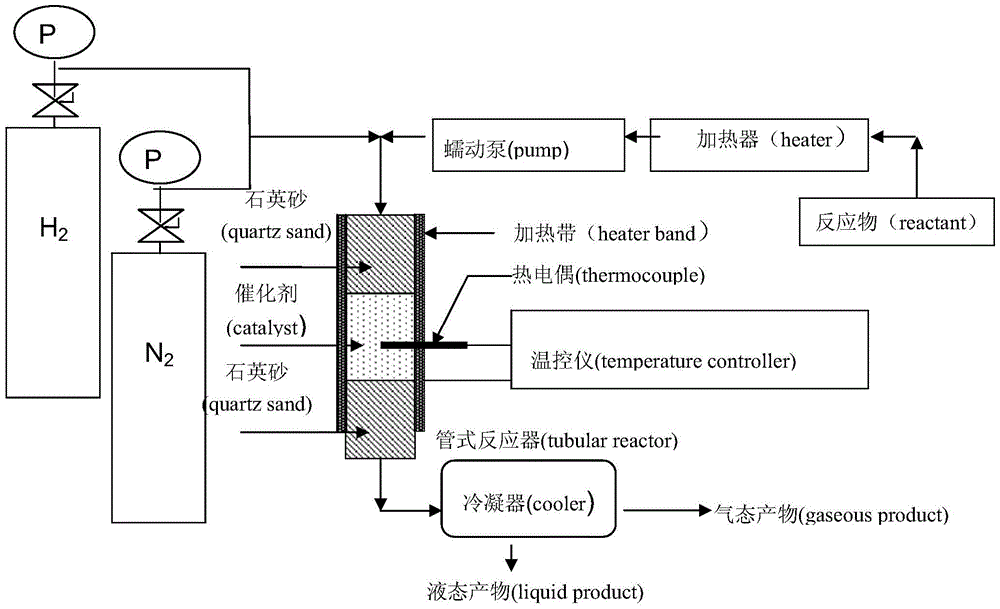

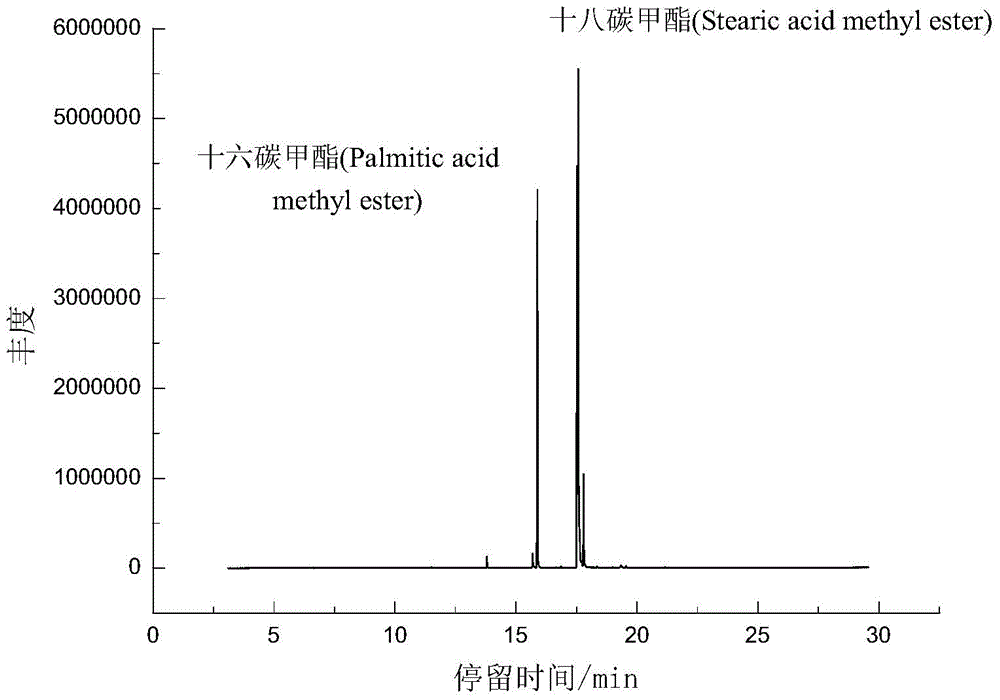

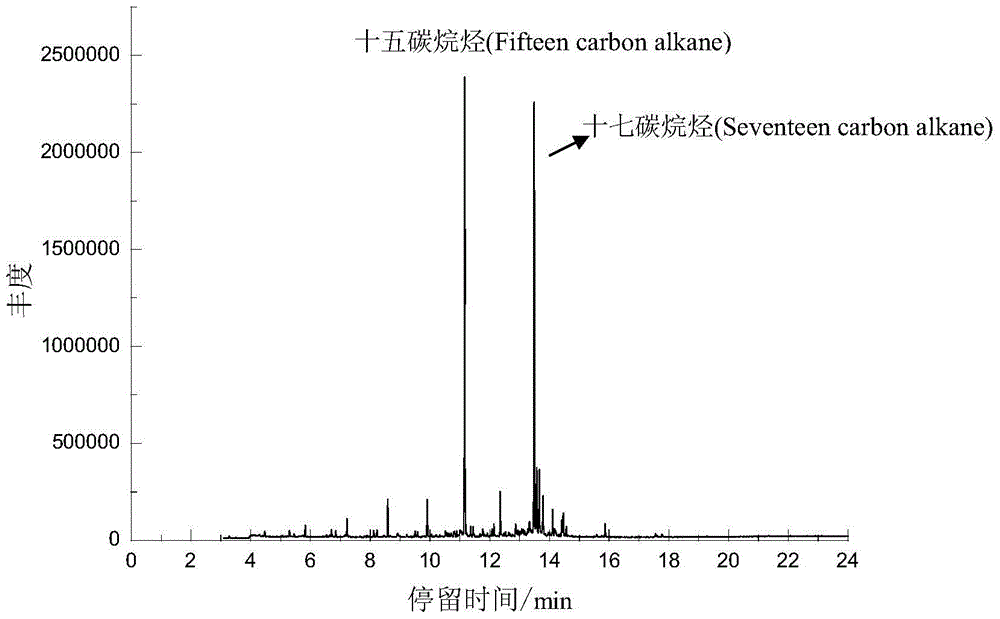

[0014] The invention discloses a preparation method for producing hydrocarbon fuel from algae oil. The method comprises the following steps: in a nitrogen atmosphere, transporting oily compounds to a tubular reactor equipped with a loaded molybdenum catalyst through a pump to carry out catalytic decarboxylation reaction to obtain hydrocarbon fuel; the reaction atmosphere of the decarboxylation and deoxygenation reaction is nitrogen, the reaction pressure is normal pressure, the reaction temperature is 300-360°C, the reaction time is 1.5-3.0h, and the feed rate is 0.03-0.30g / (cm 2 ﹒ min); wherein the supported molybdenum catalyst uses molybdenum as the active metal and activated carbon as the catalyst carrier.

[0015] In the present invention, the oil is extracted from microalgae.

[0016] The supported molybdenum catalyst uses metal molybdenum as an active component, and at the same time, the catalyst carrier uses activated carbon with a large specific surface area, and th...

Embodiment 1

[0022] Add 30 g of ammonium molybdate tetrahydrate into 100 mL of distilled water, stir and dissolve to obtain ammonium molybdate aqueous solution.

[0023] Add 20 g of dried activated carbon carrier into the ammonium molybdate solution, stir and impregnate at 25°C for 2h, let it stand overnight, remove the supernatant by suction filtration, and dry the obtained filter cake to constant weight at 70°C, and its press figure 1 The process shown is packed into a tubular reactor. Calcination at 400 °C for 2 h with nitrogen, and reduction with hydrogen at 400 °C for 3 h to obtain a Mo-C catalyst with a loading rate of 40%.

Embodiment 2

[0025] Add 20 g of ammonium molybdate tetrahydrate into 100 mL of distilled water, stir and dissolve to obtain ammonium molybdate aqueous solution.

[0026] 20 g of dried activated carbon carrier was added to the ammonium molybdate solution, and other operations were the same as in Example 1 to obtain a Mo-C catalyst with a loading rate of 27%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com