Metallic aluminum deoxidizing agent and preparation method thereof

A technology of aluminum deoxidizer and deoxidizer, applied in the field of metallurgy, can solve problems such as imperfection, and achieve the effects of reducing treatment costs, reducing costs, and realizing recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a metal aluminum deoxidizer, the deoxidizer is prepared from waste aluminum ash, mainly comprising the following steps:

[0030] (1) Ball milling: the screened aluminum ash is ground through a ball mill to obtain aluminum ash powder with a particle size of 1 to 7 mm;

[0031] (2) Screening: the ground aluminum ash powder is screened by a drum sieve, and is divided into metal aluminum on the sieve and aluminum ash slag on the undersieve;

[0032] (3) Melting aluminum: put the sieved metal aluminum into an electric melting aluminum furnace to heat and melt, and the temperature is controlled at 700-720°C;

[0033] (4) Slag removal: after the metal aluminum is melted, remove the molten aluminum slag formed on the surface of the metal aluminum melt, and transfer the aluminum liquid;

[0034] (5) Casting: casting the molten aluminum in step (4) to form finished aluminum ingots;

[0035] (6) Ball briquetting: putting the aluminum ash sieved in step (2)...

Embodiment 1

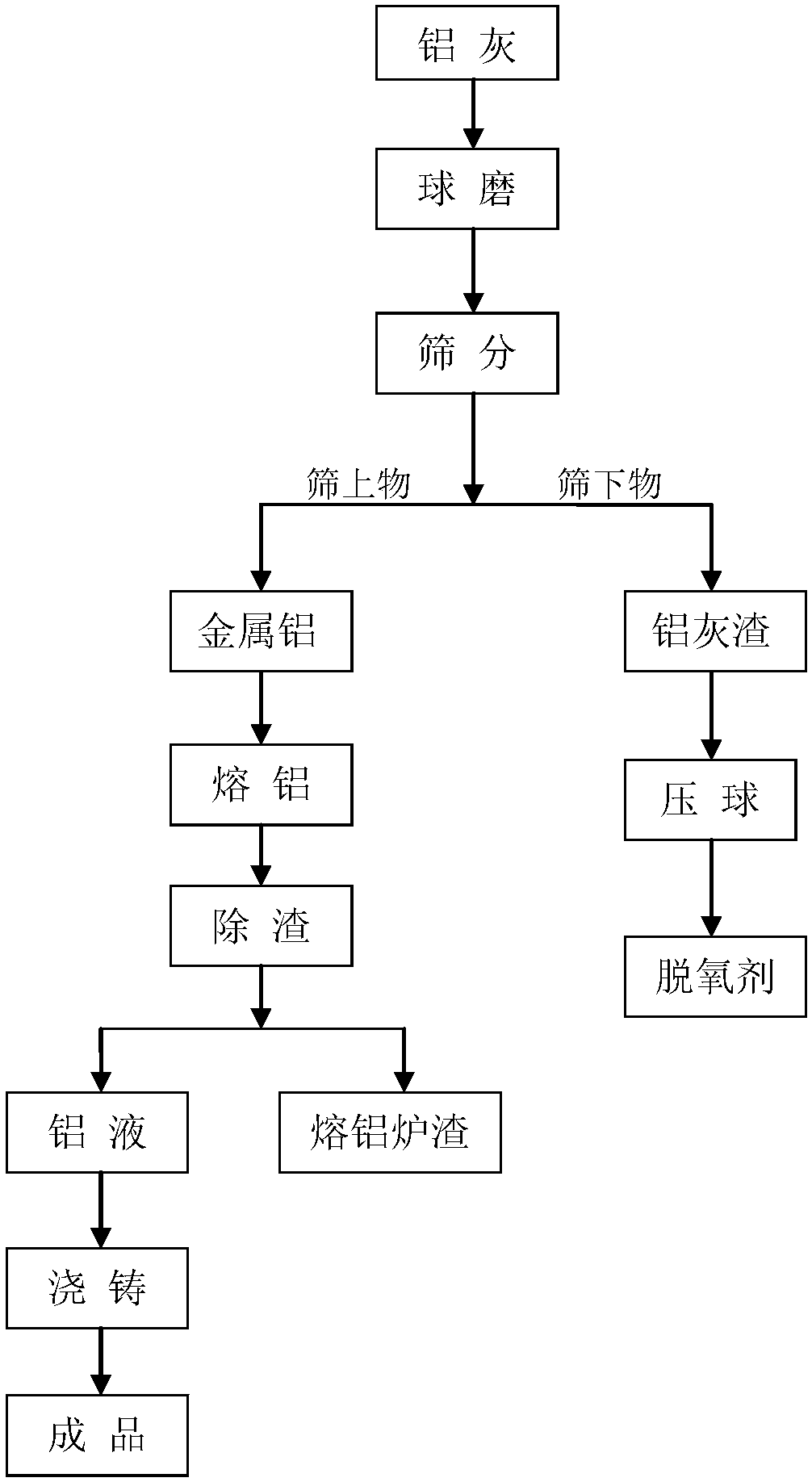

[0041] like figure 1 Shown, be the production process flowchart of the present invention:

[0042] When preparing the metal aluminum deoxidizer, waste aluminum ash is selected as raw material, and the waste aluminum ash mainly includes the following components: 15% Al, 40% Al 2 o 3 and 15% metal oxide, SiO 2 , MgO and CaO.

[0043] First of all, the waste aluminum ash is ball milled, and the metal aluminum particles in the aluminum ash are continuously smashed together due to the good ductility of aluminum, while the components (aluminum slag) in the aluminum ash other than metal aluminum are not ductile. And be further pulverized, pulverized to the aluminum ash powder that particle diameter is 1mm;

[0044] Secondly, use the drum sieve to sieve the ground material, and divide it into metal aluminum on the sieve and aluminum ash slag on the sieve.

[0045] Put the sieved metal aluminum into the electric melting aluminum furnace to heat and melt, and the melting temperatur...

Embodiment 2

[0049] like figure 1 Shown, be the production process flowchart of the present invention:

[0050] When preparing the metal aluminum deoxidizer, waste aluminum ash is selected as raw material, and the waste aluminum ash mainly contains the following components: 25% Al, 30% Al 2 o 3 and 7% metal oxide, SiO 2 and MgO.

[0051] First of all, the waste aluminum ash is ball milled, and the metal aluminum particles in the aluminum ash are continuously smashed together due to the good ductility of aluminum, while the components (aluminum slag) in the aluminum ash other than metal aluminum are not ductile. And be further pulverized, pulverized to the aluminum ash powder that particle size is 7mm;

[0052] Secondly, use the drum sieve to sieve the ground material, and divide it into metal aluminum on the sieve and aluminum ash slag on the sieve.

[0053] Put the sieved metal aluminum into the electric melting aluminum furnace to heat and melt, and the melting temperature is 720°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com