A degassing rotor structure with convective effect

A rotor structure and function technology, applied in the field of degassing rotor structure, can solve problems such as poor up-and-down convection, insufficient degassing, dead zone, etc., and achieve the effects of improved service life cycle, short processing time, and stable air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

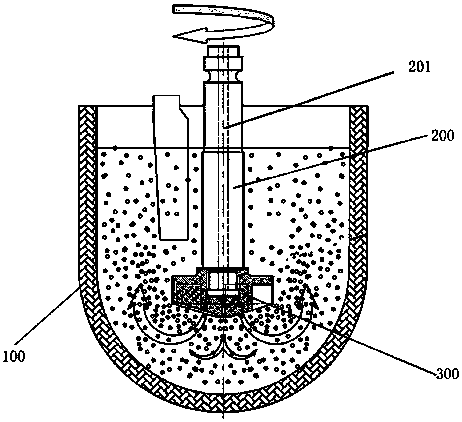

[0025] Embodiment one: see Figure 1 to Figure 3 , as shown in the legend therein, a degassing rotor structure with sealed gas storage is set in a crucible 100 , and the degassing rotor structure includes a rotating rod 200 and a disk-shaped rotating disk 300 .

[0026] The rotating rod 200 has a first end and a second end. The body of the rotating rod 200 is provided with an air intake passage 201, the first end is provided with an external thread, and the second end is connected to the driving device (not shown in the figure). connect;

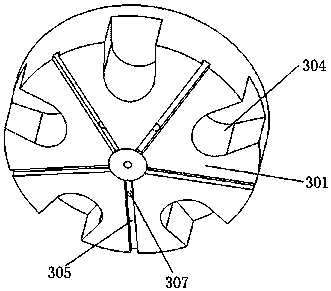

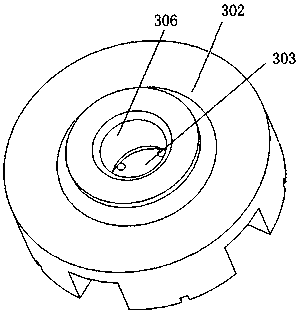

[0027] The turntable 300 has a first end face 301 and a second end face 302. The disc body of the turntable 300 is provided with an air storage chamber 303 located at the center and not connected to the first end face 301. The first end face 301 is in the shape of a truncated conical protrusion. The first end surface 301 is provided with five dividing grooves 304 uniformly distributed in the circumferential direction and extending along the...

Embodiment 2

[0036] The rest is the same as the first embodiment, except that the first end surface is in the shape of a conical protrusion.

Embodiment 3

[0038] The rest is the same as the first embodiment, except that the cone angle of the first end surface is 135 degrees.

[0039] Embodiment three

[0040] The rest is the same as the first embodiment, except that the cone angle of the first end surface is 150 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com