Gas-supply method of CNG gas-charging station for automobile

A technology for gas filling stations and automobiles, which is applied to container filling methods, equipment loaded into pressure vessels, gas/liquid distribution and storage, etc., and can solve problems such as long time, slow gas unloading speed, and inability to completely unload gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

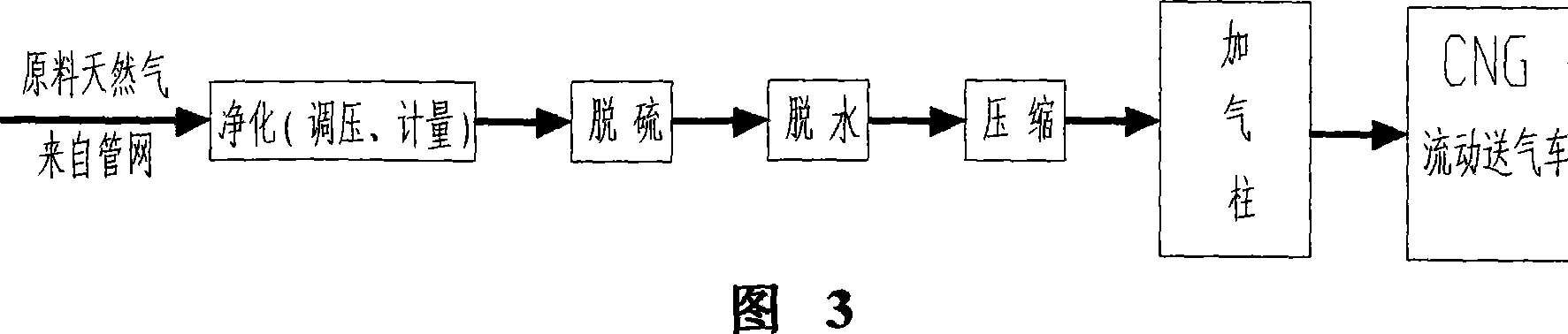

[0027] Referring to FIG. 4 , the present invention is a schematic diagram of the technological process used in the modification of a common CNG gas filling station for automobiles and also has the function of a CNG sub-station gas filling station. It has two gas supply channels, one is connected to the natural gas pipeline network, and the natural gas pipeline network is used to supply gas to CNG general gas filling stations for automobiles; the other is connected to CNG mobile gas supply vehicles. Supply gas to CNG ordinary filling stations in one place. Usually, the gas is supplied by the natural gas pipeline network. When there is a lack of raw natural gas (the pressure of the natural gas pipeline network is low) or the natural gas pipeline network cannot supply gas, the natural gas from the CNG parent station is transported by the CNG mobile gas supply vehicle to supply gas to the ordinary gas filling station. , so as to ensure that the ordinary gas station can provide gas...

Embodiment 2

[0035] Referring to Fig. 5, the present invention is used in the gas filling station of the CNG substation for automobiles, and the gas is supplied by a mobile gas delivery vehicle. Its working process is exactly the same as the gas supply process of the CNG mobile gas supply vehicle in Embodiment 1, so it will not be repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com