High-voltage cable insulating material and preparation method and application thereof

A technology of insulating materials and high-voltage cables, which is applied in the field of insulating materials processing, can solve problems such as unexplained dielectric properties and conventional mechanical properties, long-term safety hazards of high-voltage cables, low cross-linking agent content and high cross-linking degree, etc. Achieve low cost, excellent anti-water tree effect, low processing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a method for preparing the high-voltage cable insulating material according to the present invention, comprising the step of mixing the components of the high-voltage cable insulating material.

[0068] Specifically, the preparation method of the high-voltage cable insulation material includes the following steps:

[0069] Melt and blend low-density polyethylene, antioxidants, polybutadiene additives and polymer material additives, then cool and granulate to obtain granules;

[0070] The particles are mixed with the cross-linking agent and absorbed uniformly to obtain a high-voltage cable insulation material.

[0071] Further, the preparation method of the high-voltage cable insulation material includes the following steps:

[0072] Step 1: Melt and blend low-density polyethylene, antioxidants, polybutadiene additives and polymer material additives, then cool and granulate to obtain granules; wherein, the melt blending equipment incl...

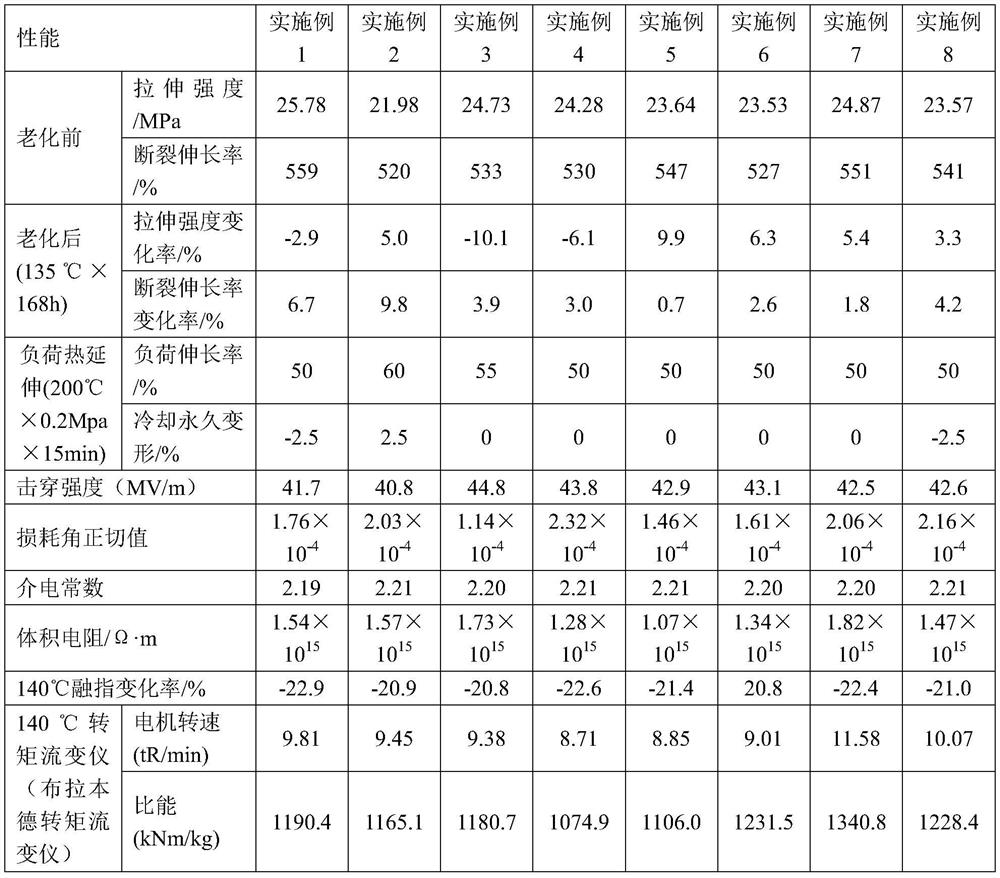

Embodiment 1

[0078] In parts by weight, 100 parts of low-density polyethylene (LDPE), 0.5 parts of liquid polybutadiene (LPB) with a viscosity of 1000mPa·s, 0.5 parts of high-density polyethylene (HDPE), 0.2 parts of 4,4'-sulfur Substituting bis(6-tert-butyl-3-methylphenol) (TBM-6) through a reciprocating single-screw extruder after melt blending, cooling and granulation, and drying to obtain granules;

[0079] Melting temperature process: The temperature of the six zones are: 130, 150, 185, 200, 200, 200°C; the rotating speed is 960RPM; the cooling circulating water is 50°C.

[0080] The particles were mixed with the 1.1 parts of bis(1-methyl-1-phenylethyl)peroxide (DCP) at a constant temperature of 70° C. and absorbed uniformly for more than 16 hours to obtain a high-voltage cable insulation material.

[0081] The air and environment cleanliness meet the necessary conditions for the production of high-voltage cable insulation materials.

Embodiment 2

[0083] In parts by weight, 100 parts of low-density polyethylene (LDPE), 1.0 part of liquid polybutadiene (LPB) with a viscosity of 3000mPa·s, 1.0 part of high-density polyethylene (HDPE), 0.2 part of 4,4'- Thiobis(6-tert-butyl-3-methylphenol) (TBM-6), cooled and granulated after melting and blending by a reciprocating single-screw extruder, and obtained granules after drying;

[0084] Its process and environmental conditions are identical with embodiment 1;

[0085] The particles were mixed with the 1.2 parts of bis(1-methyl-1-phenylethyl)peroxide (DCP) at a temperature of 70° C. and absorbed uniformly at a constant temperature for more than 16 hours to obtain a high-voltage cable insulation material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com