Synthesis method of high conversion food grade styrene butadiene rubber

A technology of styrene-butadiene rubber and synthesis method, which is applied in the field of polymer elastomer synthesis, can solve problems such as patents or other technical materials that have not yet been seen, and achieve controllable gel content, shorten degassing time, and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

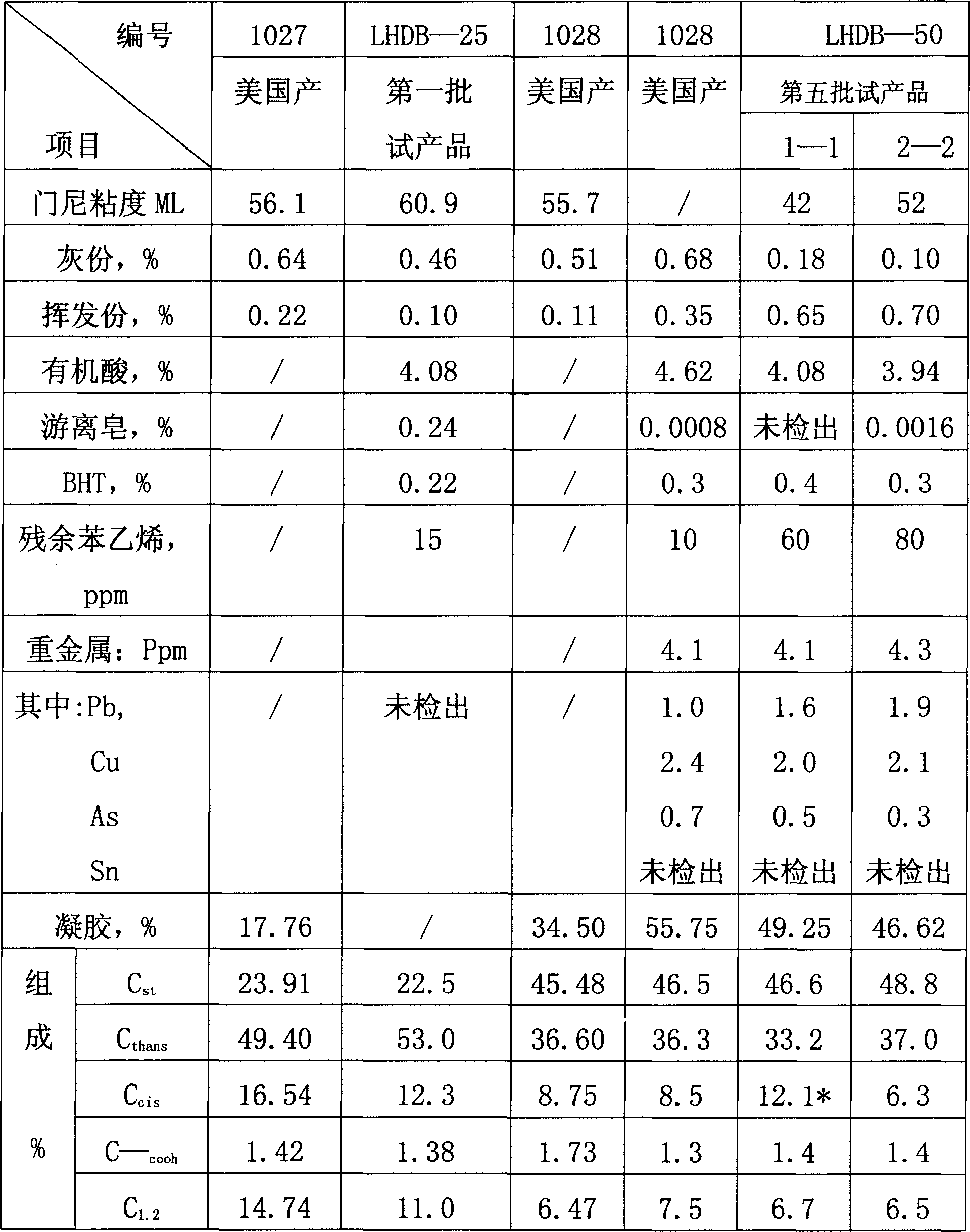

Image

Examples

Embodiment 1

[0024] Example 1: In a 10-liter polymerizer with stirring, nitrogen inlet and outlet, material inlet and outlet, temperature and pressure measurement ports and jacket, 2000 ml of deionized water and deionized water containing 115 g of fatty acid soap and 6 g of potassium chloride were added. Add 2500ml of aqueous solution, add 1750ml of styrene, 9ml of dodecanethiol, and 500ml of an aqueous solution of 13.5g of potassium persulfate, start the vacuum pump, evacuate for 30 minutes, then add 1250g of butadiene, and send hot water to the jacket of the polymerizer to increase the temperature. For polymerization, keep the polymerization temperature at 50-65°C. When the conversion rate is more than 45%, add 500g of butadiene and 9ml of dodecyl mercaptan to the gathering kettle continuously or in 3-5 times. When the conversion rate is more than 90% , To terminate.

[0025] After flash degassing and vacuum degassing of the polymer emulsion, the unreacted butadiene has been completely remov...

Embodiment 2

[0026] Example 2: In the above polymerization reactor, 2500ml of deionized water solution containing 2000ml of deionized water, 135g of fatty acid soap and 7.5g of potassium phosphate were added, and an aqueous solution of 950ml of styrene, 9ml of dodecyl mercaptan and 15.0g of potassium persulfate were added. 500ml, start the vacuum pump, evacuate for 30 minutes, then add 1700g butadiene, feed hot water into the jacket of the polymerization kettle, raise the temperature for polymerization, keep the polymerization temperature at 50-55℃, when the conversion rate is ≥55%, transfer to the party kettle Add 450 g of butadiene, 12 ml of dodecyl mercaptan, and 7.5 g of mercaptopropionic acid continuously or in 2-6 times, and stop when the conversion rate is ≥90%.

[0027] After flash degassing and vacuum degassing of the polymer emulsion, the unreacted butadiene has been completely removed. When the residual styrene content is less than 65ppm, add 35ml of dicumyl hydrogen peroxide and re...

Embodiment 3

[0029] Example 3: According to the method and feeding amount of Example 2, only butadiene and regulator are added at one time for polymerization, and when the conversion rate is ≥90%, it is terminated. After flash degassing and vacuum degassing of the polymer emulsion, the unreacted butadiene has been completely removed. Add 45ml of cumene hydroperoxide and react at 50-60°C for four hours under stirring, then coagulate and dry. Mooney viscosity (ML 100 1+4 ) 85, the gel content is 51%, and the residual styrene content is less than 25 ppm. This product cannot be processed into chewing gum and bubble gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com