A method and device for degassing solid polymer

A technology of solid polymer and degassing device, applied in the field of solvent and unreacted monomer in polyolefin resin, can solve the problems of low degassing efficiency, unfriendly environment, large consumption of raw materials, etc. Application value, effect of reducing degassing time, reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

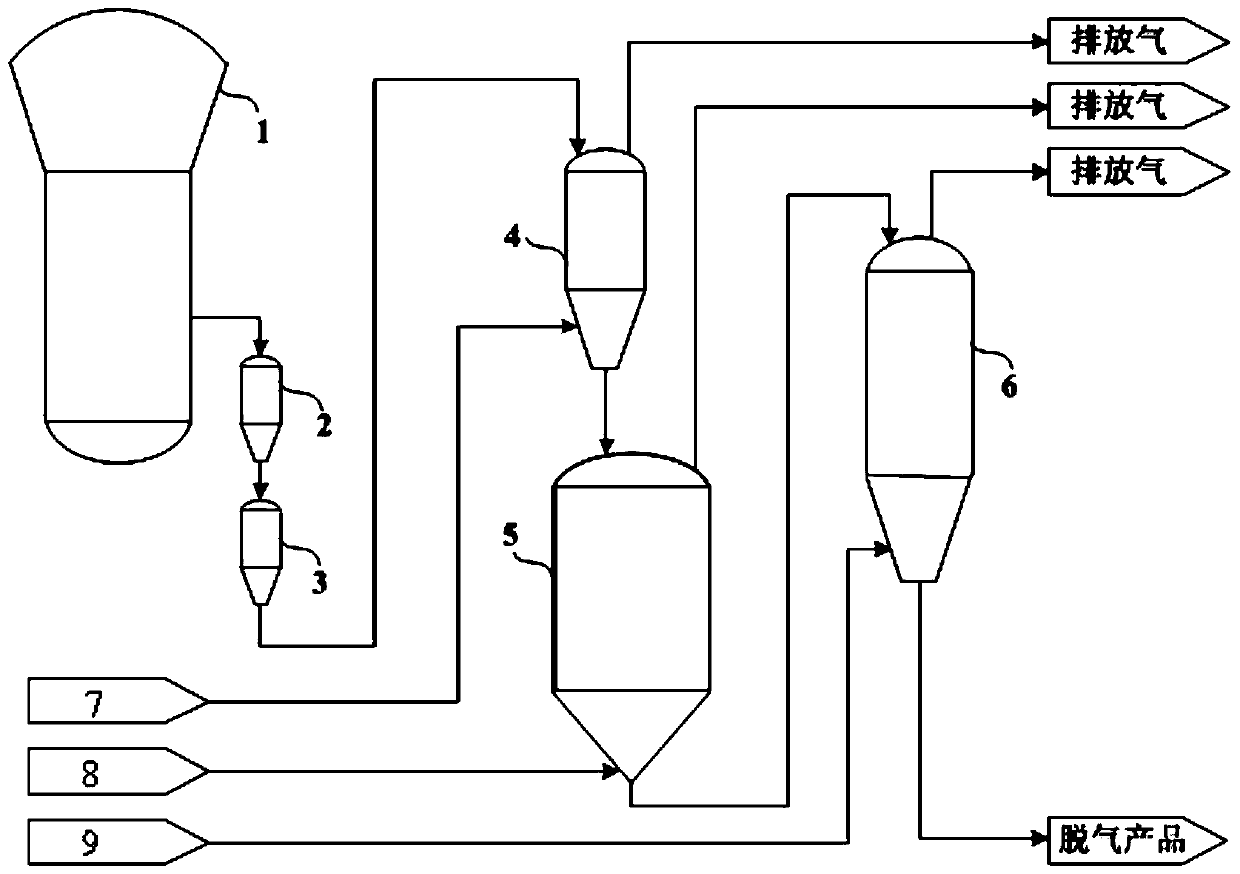

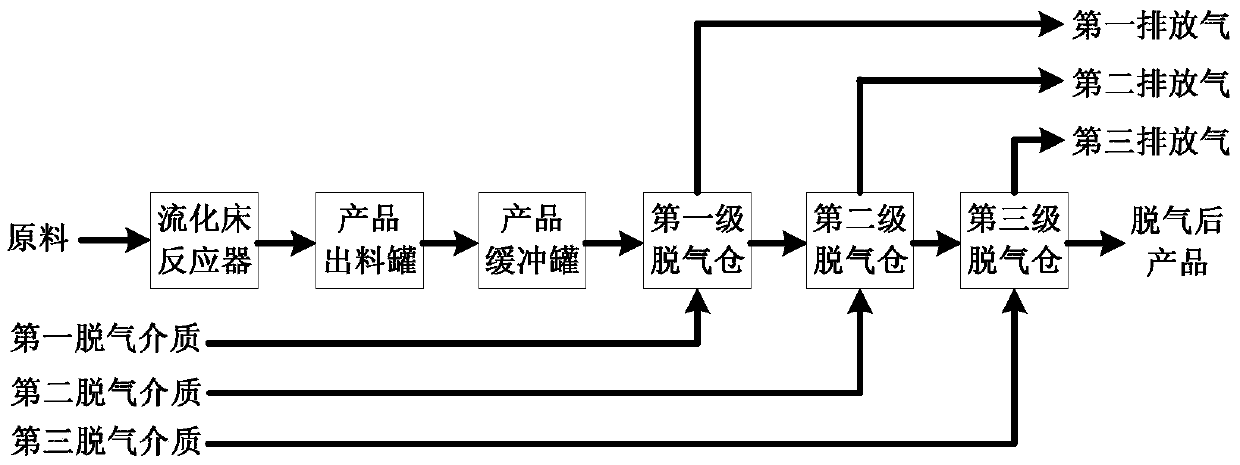

Embodiment 1

[0053] Using the above-mentioned device, the ethylene-butene copolymerized linear low-density polyethylene (LLDPE) product is produced by the gas phase fluidized bed process. The reaction temperature of the fluidized bed reactor 1 is 88 ° C, the reaction pressure is 2.1 MPa, and non-condensing operation is adopted. The flow rate of each component in the discharge stream is: LLDPE powder 40t / h, nitrogen 200kg / h, hydrogen 3kg / h, ethylene 2600kg / h, 1-butene 2500kg / h. Among them, ethylene and 1-butene are unreacted monomers without solvent. The LLDPE product discharged from the fluidized bed reactor 1 first enters the product discharge tank 2 driven by the conveying gas, and then enters the product buffer tank 3 at a pressure of 0.7 MPa to remove part of the hydrocarbons adsorbed on the surface of the polyethylene particles, and then Enter the three-stage degassing process. Nitrogen is used as the first-stage degassing medium, and the flow rate of the first-stage degassing medium...

Embodiment 2

[0056] Using the same device as in Example 1, the ethylene-hexene copolymerized linear low-density polyethylene (LLDPE) product was produced by a gas phase fluidized bed process. The reaction temperature of the fluidized bed polymerization reactor 1 was 88 ° C, and the reaction pressure was 2.1 MPa. Use non-condensing operation. The flow rate of each component in the discharge stream is: LLDPE powder 40t / h, nitrogen 180kg / h, hydrogen 3kg / h, ethylene 2600kg / h, hexene 2000kg / h. Among them, ethylene and hexene are unreacted monomers without solvent. The LLDPE product discharged from the fluidized bed reactor 1 firstly enters the product discharge tank 2 driven by the conveying gas, and then enters the product buffer tank 3 to remove part of the hydrocarbons adsorbed on the surface of polyethylene particles, and then enters the third stage degassing process. Nitrogen is used as the first-stage degassing medium, and the flow rate of the first-stage degassing medium is 300kg / h, an...

Embodiment 3

[0059] Using the same device as in Example 1, the ethylene-butene copolymerized linear low density polyethylene (LLDPE) product is produced by the gas phase fluidized bed process, the reaction temperature of the fluidized bed reactor 1 is 88 ° C, and the reaction pressure is 2.1 MPa. Condensation operation. The flow rate of each component in the discharge stream is: LLDPE powder 40t / h, nitrogen 160kg / h, hydrogen 3kg / h, ethylene 2580kg / h, 1-butene 2300kg / h, isopentane 2500kg / h. Wherein ethylene and 1-butene are unreacted monomers, and isopentane is a solvent. The LLDPE product discharged from the fluidized bed reactor 1 firstly enters the product discharge tank 2 driven by the conveying gas, and then enters the product buffer tank 3 to remove part of the hydrocarbons adsorbed on the surface of polyethylene particles, and then enters the third stage degassing process. Nitrogen is used as the first-stage degassing medium, and the flow rate of the first-stage degassing medium is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com