Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Reduce the possibility of disconnection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

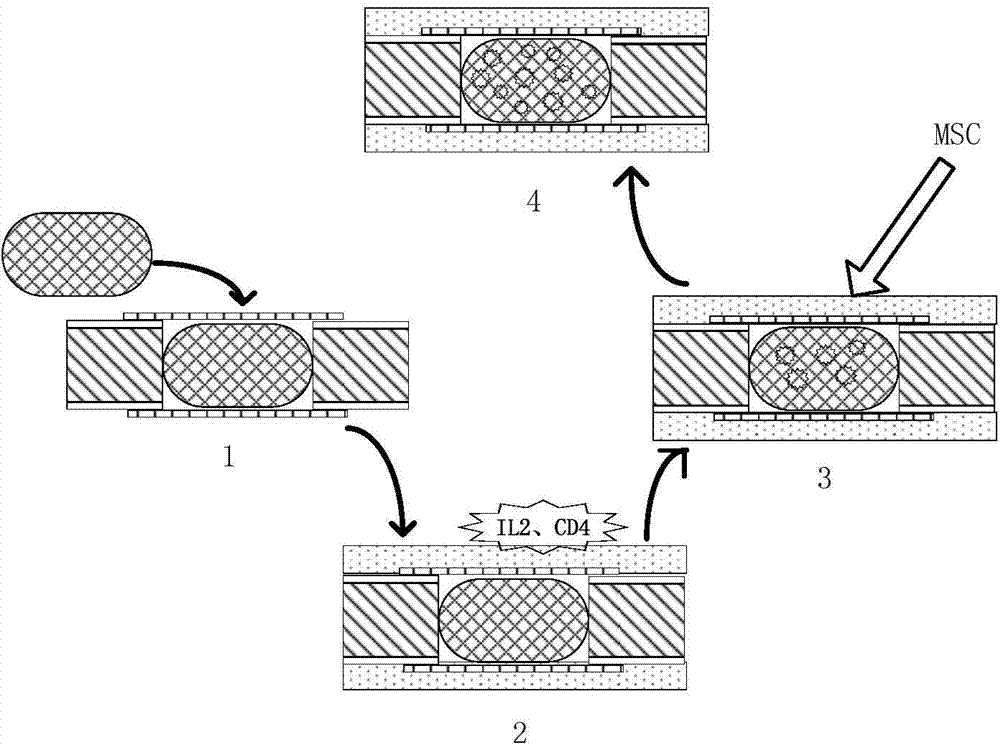

Step-by-step tissue engineering bone building method

InactiveCN104740686AAvoid attack repulsionMaximize survivalAdditive manufacturing apparatusTissue regenerationBone tissue engineeringBone tissue

The invention relates to the technical field of bone tissue engineering, and discloses a step-by-step tissue engineering bone building method. The method comprises the following steps of: (1) stent repair and pre-vascularization: building a tissue engineering bone sent at a bone defect part, and performing pre-vascularization; (2) later embedding of bone tissue engineering seed cells: after inflammatory reaction stage, embedding the seed cells, subjected to osteogenic induction, into the tissue engineering bone sent at the bone defect part based on growth-in time of capillaries, wherein the later embedding of bone tissue engineering seed cells in the step (2) is carried out 7-14 days later after the stent repair and pre-vascularization in the step (1). In the method provided by the invention, the sent promoting growth of vessels is firstly embedded, the seed cells for osteogenesis are embedded later, thus, a great segment of tissue engineering bone can be built quickly, application amount of the bone tissue engineering seed cells needed for repairing per unit volume of bone tissue is reduced greatly, and utilization rate of the seed cells is improved.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

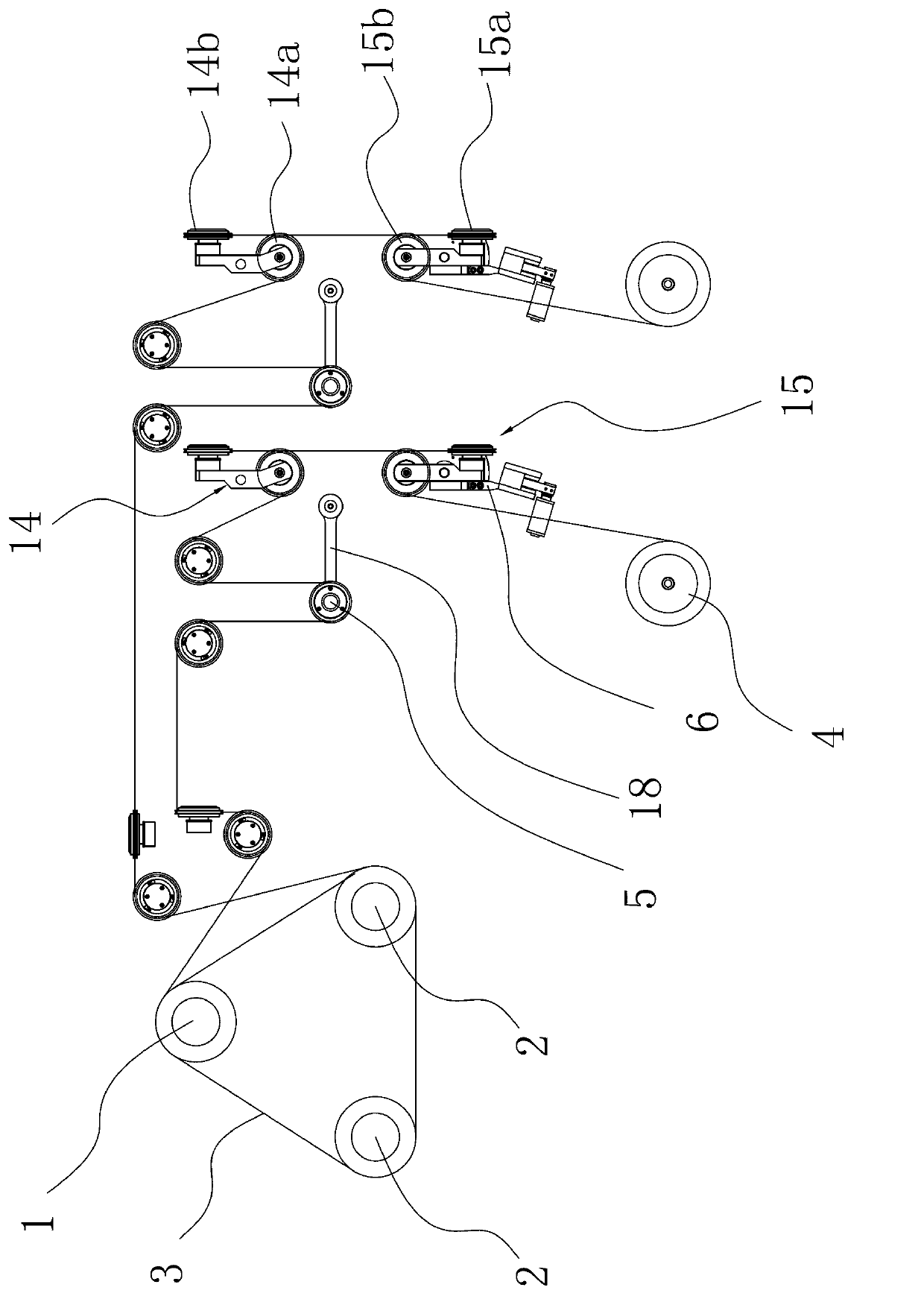

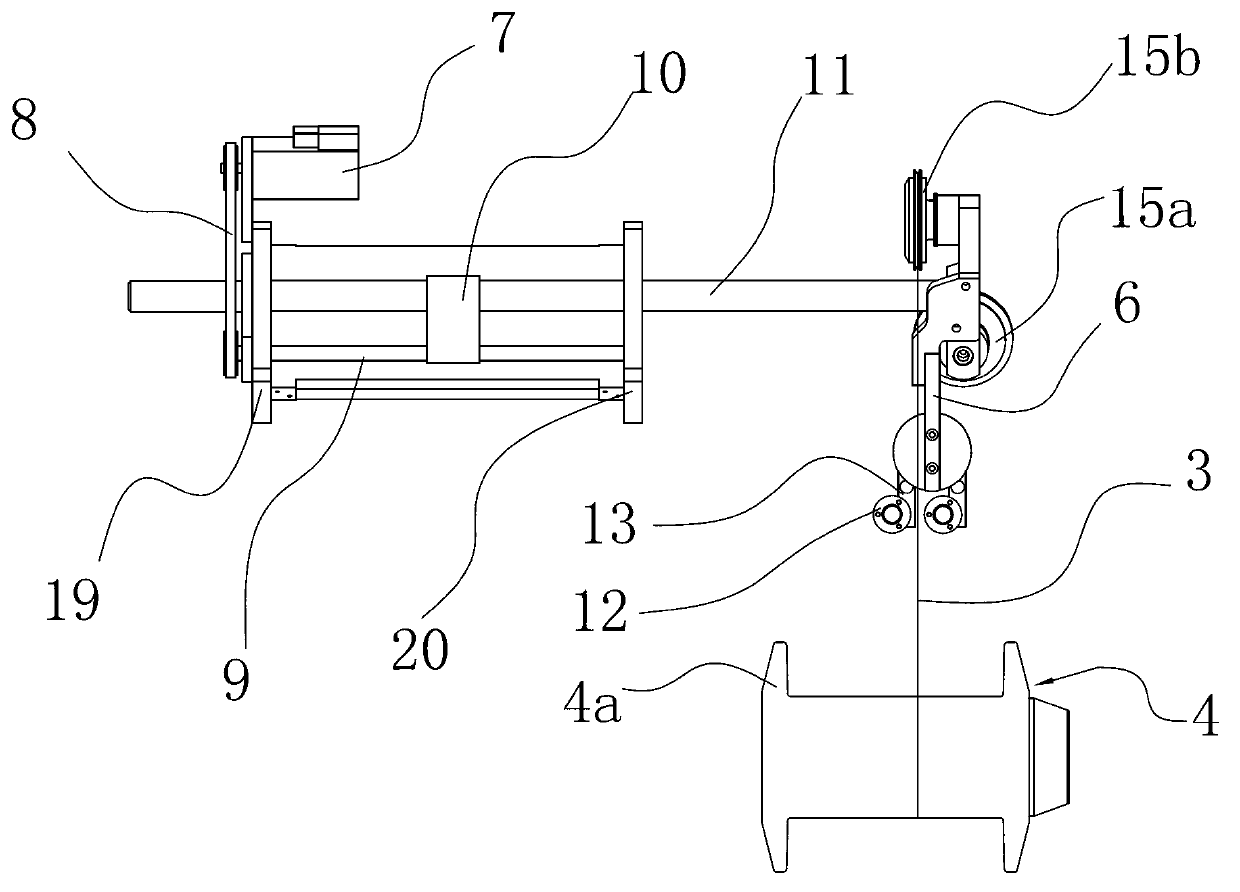

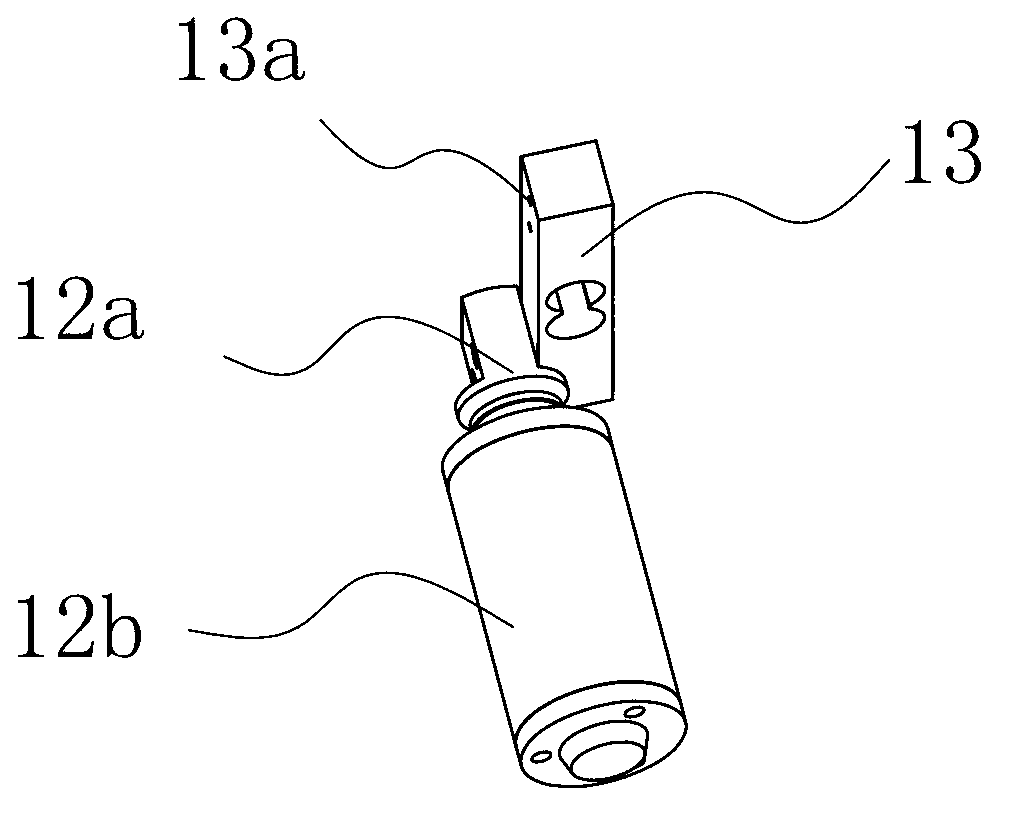

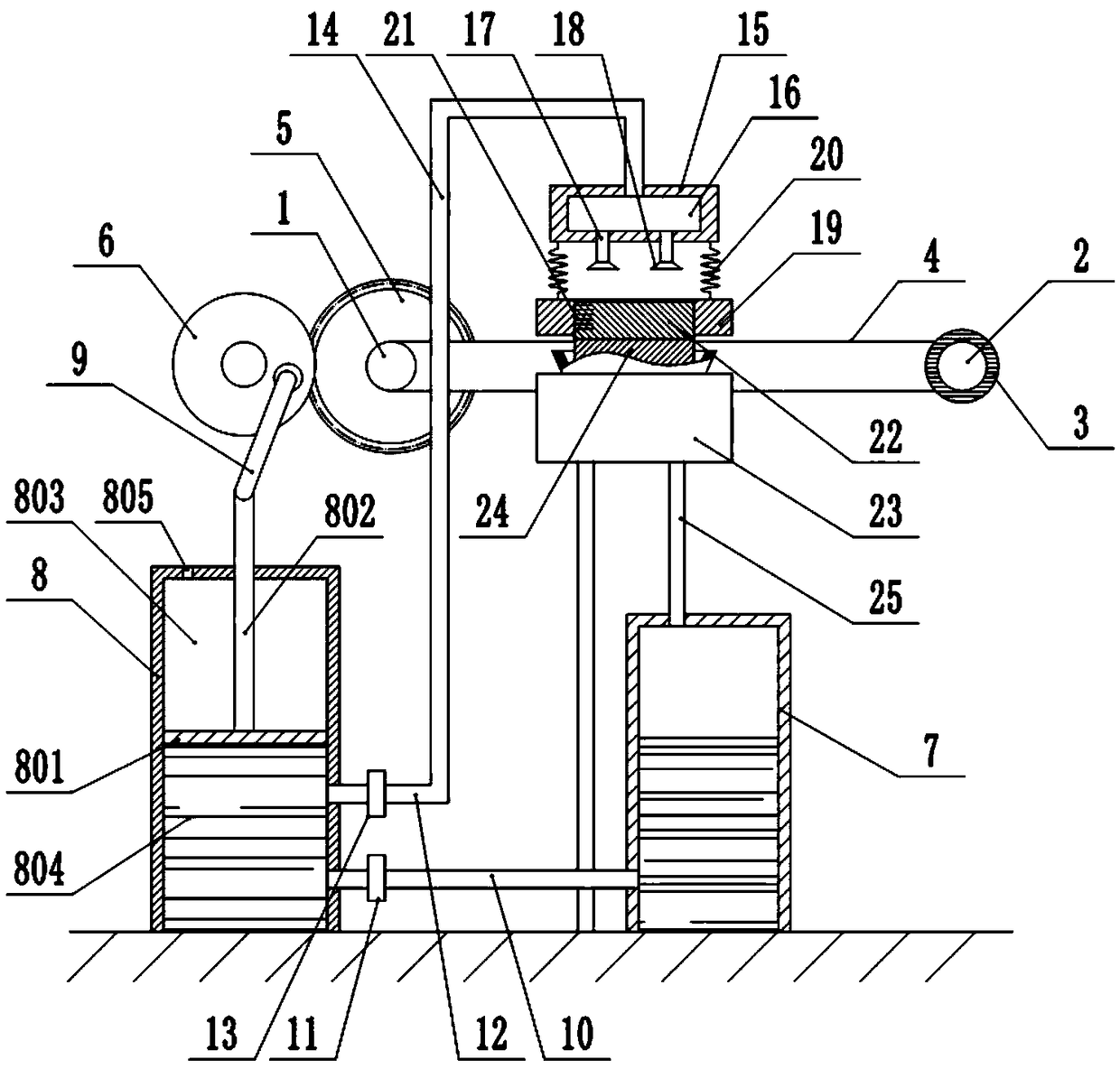

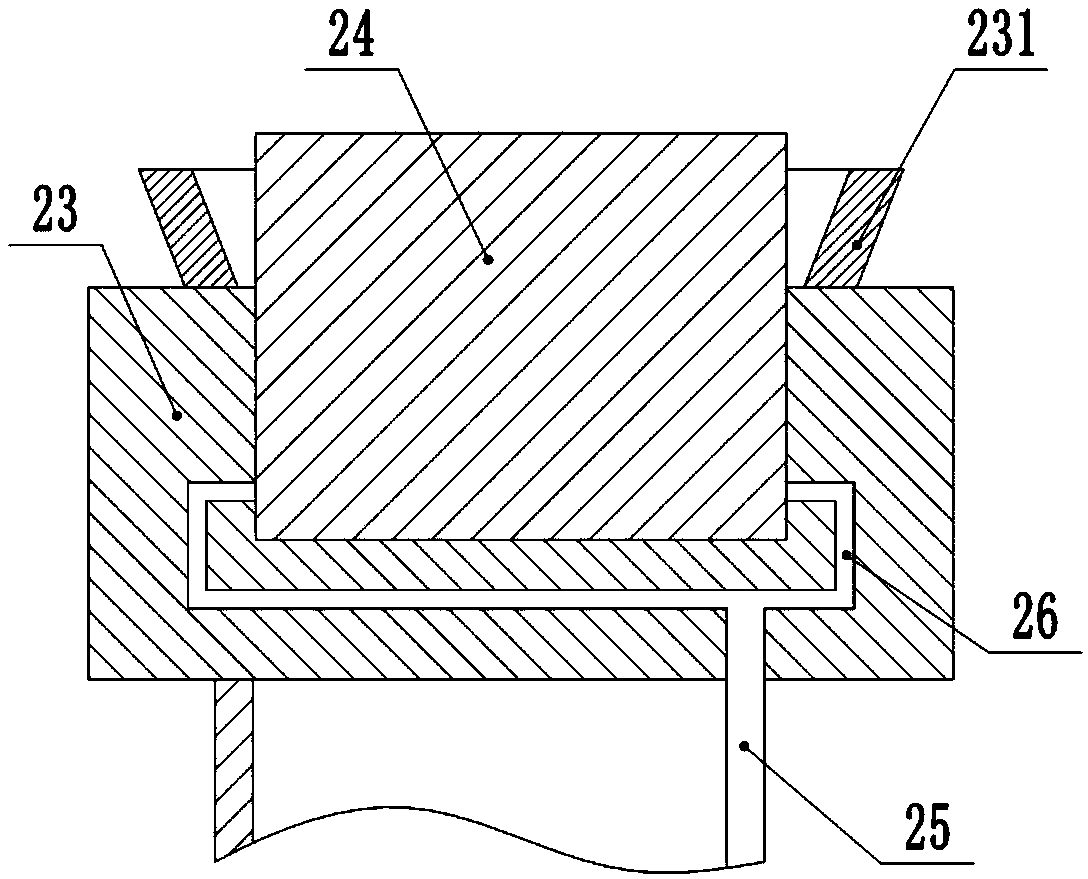

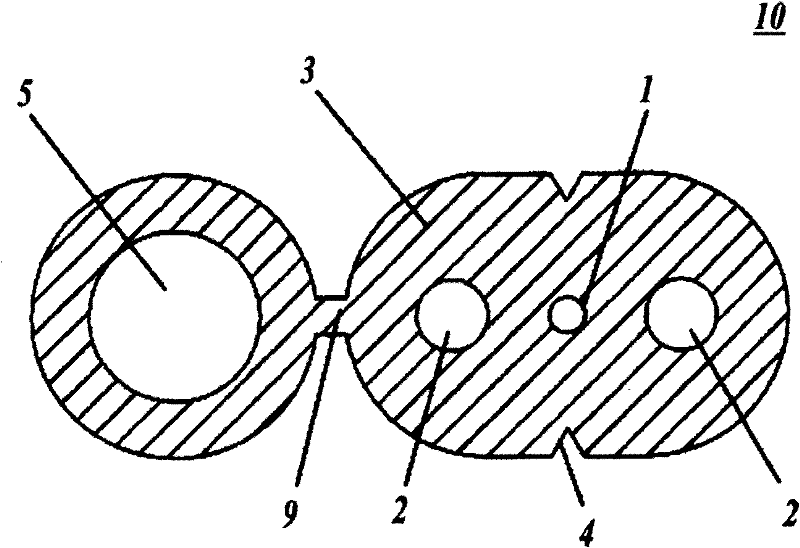

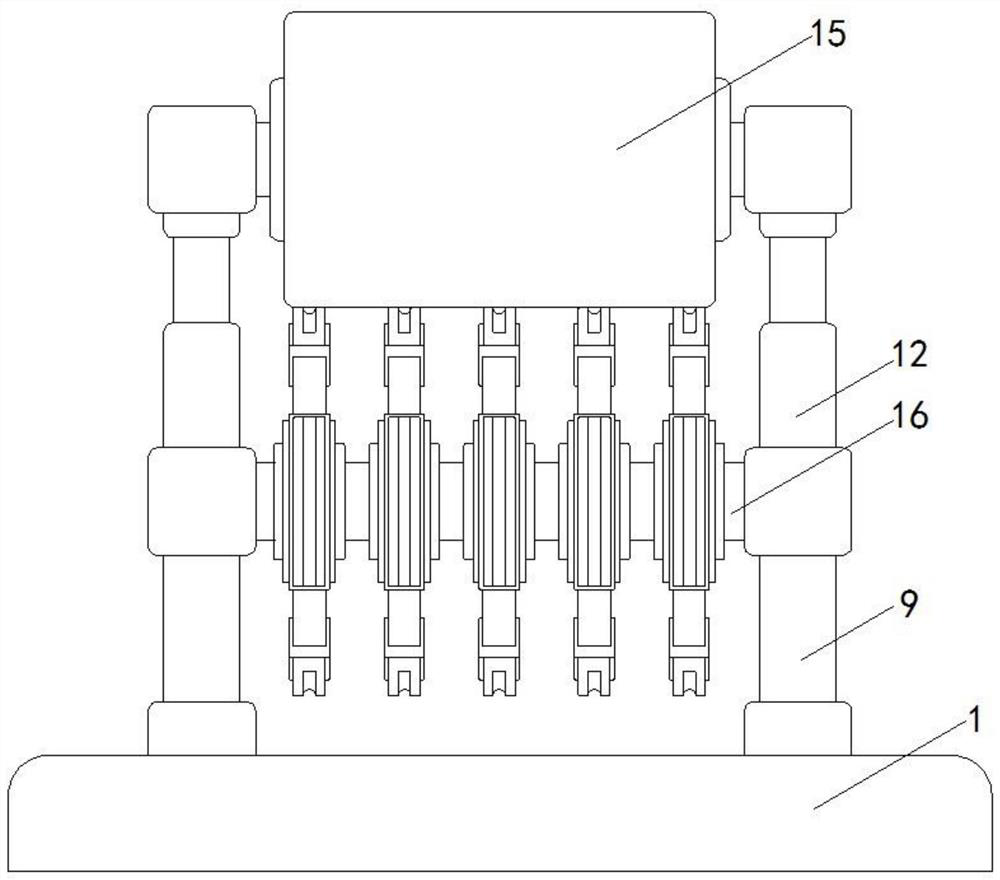

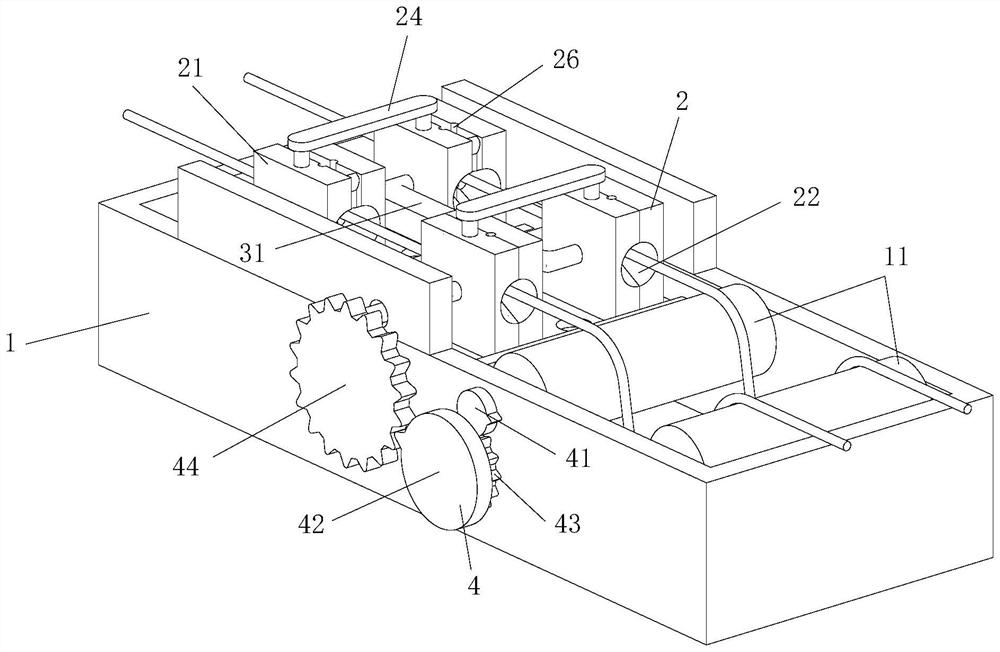

Bidirectional wire arranging device of multi-wire cutting machine and control method of bidirectional wire arranging device

ActiveCN103274264AGuaranteed uniformitySolve the problem of overlapping linesFilament handlingWire cuttingEngineering

The invention provides a bidirectional wire arranging device of a multi-wire cutting machine and a control method of the bidirectional wire arranging device, belongs to the technical field of machinery and solves the problem that cut wires are easy to break due to the fact that wires of existing multi-wire cutting machines are not arranged in place. Two bidirectional wire arranging devices of the multi-wire cutting machine are arranged between a winding and pay-off reel and a tension control pulley, and each of the two bidirectional wire arranging devices is provided with a mounting support, a driving mechanism, a wire arranging guide mechanism, two detecting wheels and a controller, wherein the two detecting wheels are arranged on the mounting support side by side and arranged on two sides of a cutting line, and each detecting wheel is provided with a pressure sensor connected with the controller. By sensing the position of the cutting line through the pressure sensor and adjusting speed of the driving mechanism through the controller, in-place wire arrangement is guaranteed. Besides, the bidirectional wire arranging device is simple in structure, convenient to control and high in accuracy.

Owner:TAIZHUO SHUANGHUI MACHINERY EQUIP

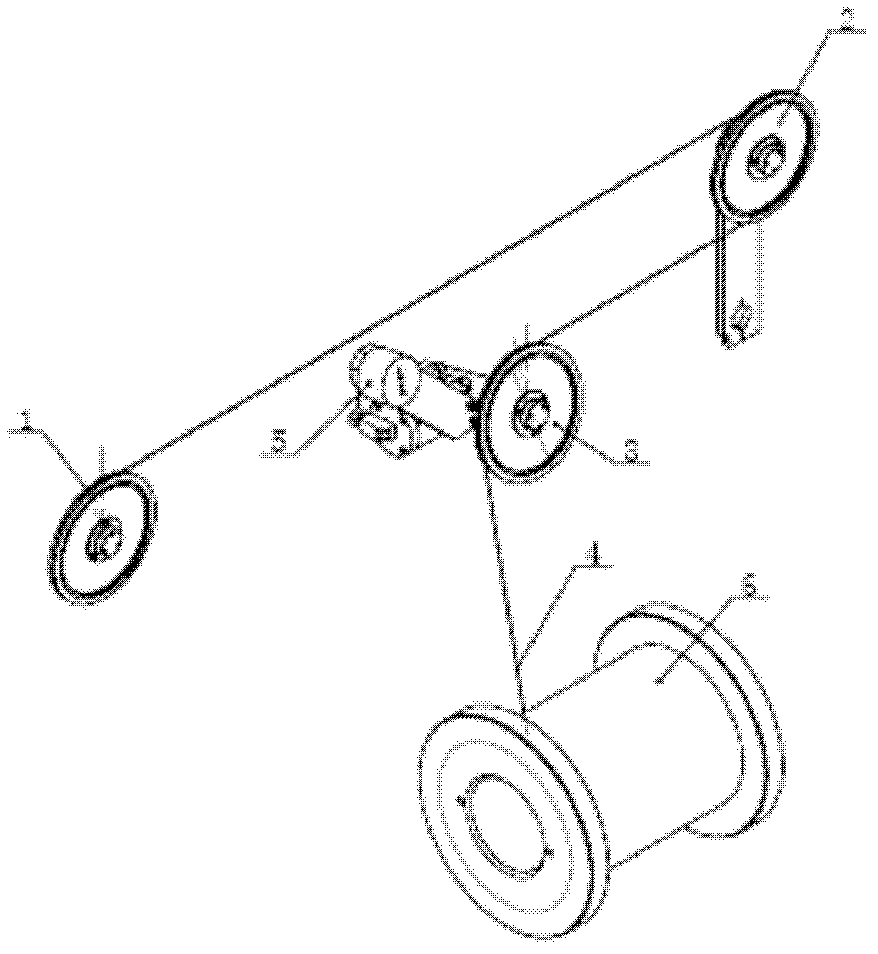

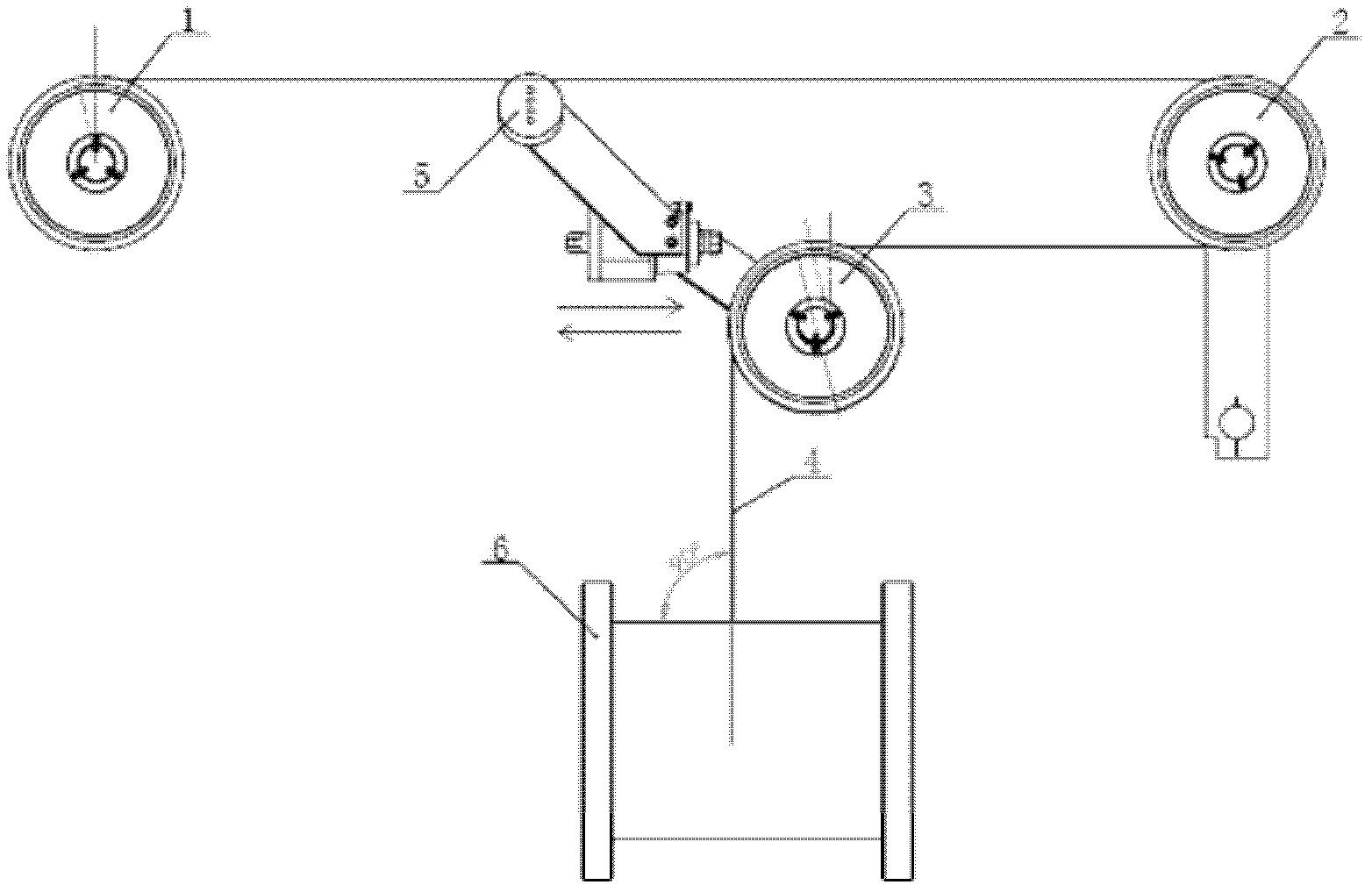

Automatic wire arrangement and balance device of multi-wire cutting machine

InactiveCN102615730AGuaranteed uniformityImprove qualityWorking accessoriesFine working devicesWire cuttingEngineering

The invention relates to an automatic wire arrangement and balance device of a multi-wire cutting machine. The automatic wire arrangement and balance device is characterized by comprising a conducting wire pulley, a tension control pulley, a swinging conducting wire pulley and a wire coil used for coiling a cutting steel wire; the cutting steel wire is wound on the wire coil sequentially by the conducting wire pulley, the tension control pulley and the swinging conducting wire pulley; and the cutting steel wire is wound on the wire coil in the tangential direction of the peripheral surface of the wire coil. The swinging conducting wire pulley is provided with a balance hammer. The automatic wire arrangement and balance device of the multi-wire cutting machine has the beneficial effects that wires can be arranged automatically, the tension can be balanced automatically, the steel wire can be guaranteed to keep the tangential and vertical winding direction when wound on the wire coil, the uniformity of the arranged wires and the force bearing constancy are guaranteed, the probability of wire breaking is reduced, the phenomenon of fretsaw on a product is eliminated, the cutting effect is guaranteed, and the quality of the cut product is also greatly improved.

Owner:无锡市协清机械制造有限公司

Thread embellishing device for cotton thread

ActiveCN108796887ARealization of running workImprove smoothnessTextile treatment containersTextile treatment machine arrangementsMotor drivePulp and paper industry

The invention relates to the technical field of textile thread embellishing, and particularly discloses a thread embellishing device for cotton thread, which comprises a motor, a take-up roller, a cylinder body, a box body and a fixing block, wherein the motor drives the take-up roller; the cylinder body is in sliding connection with a piston; the piston is connected with a piston rod; the reciprocating movement of the piston rod is driven in the process of driving the take-up roller by the motor, and a thread-embellishing liquid is contained in the box body; a U-shaped pipe is communicated with the cylinder body; the U-shaped pipe is connected with a transverse plate; a cavity is formed in the transverse plate; the U-shaped pipe is communicated with the cavity; the cavity is communicatedwith a spraying pipe; a placing plate is arranged below the transverse plate; a spring is connected between the placing plate and the transverse plate; the placing plate is provided with a through groove; the circumferential wall of the through groove is connected with a first sponge layer; the fixing block is provided with a groove, a second sponge layer is arranged in the groove, the second sponge layer is butted against the first sponge layer, the fixing block is connected with a recovery pipe, a through cavity is formed in the fixing block, the through cavity is communicated with the groove and the recovery pipe, and the recovery pipe is connected to the box body. According to the invention, the thread-embellishing liquid can be recovered, and the waste of the thread-embellishing liquid can be avoided.

Owner:绍兴浩嘉纺织品有限公司

Method for manufacturing semiconductor integrated circuit

ActiveCN102820254AReduce the possibility of disconnectionImprove reliabilitySemiconductor/solid-state device manufacturingPlasma treatmentIntegrated circuit

The invention discloses a method for manufacturing a semiconductor integrated circuit. The method comprises the steps of firstly, providing a substrate, and forming at least one metal hard mask on the substrate; and conducting a patterning step on metal hard masks, patterning metal hard masks to form patterned metal hard masks, and then conducting water plasma treatment on patterned metal hard masks.

Owner:UNITED MICROELECTRONICS CORP

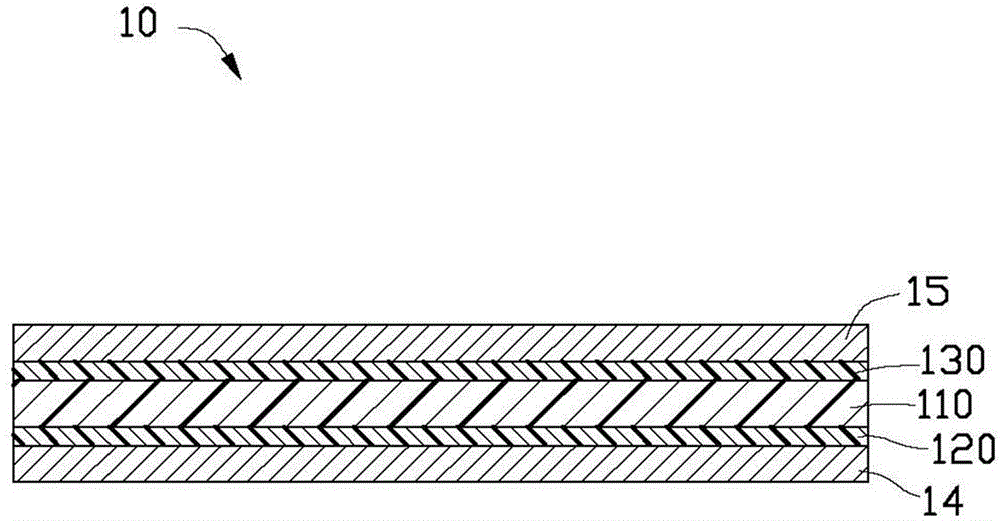

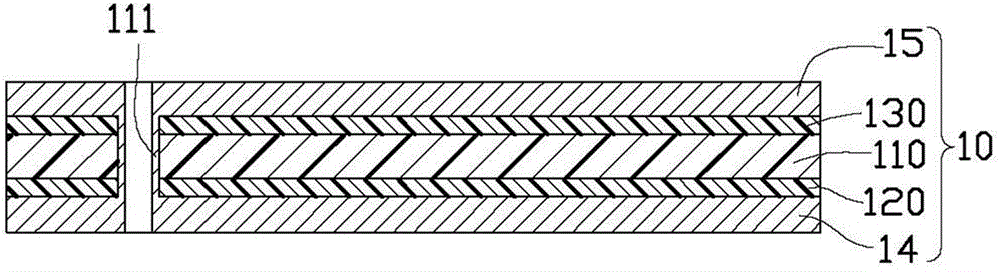

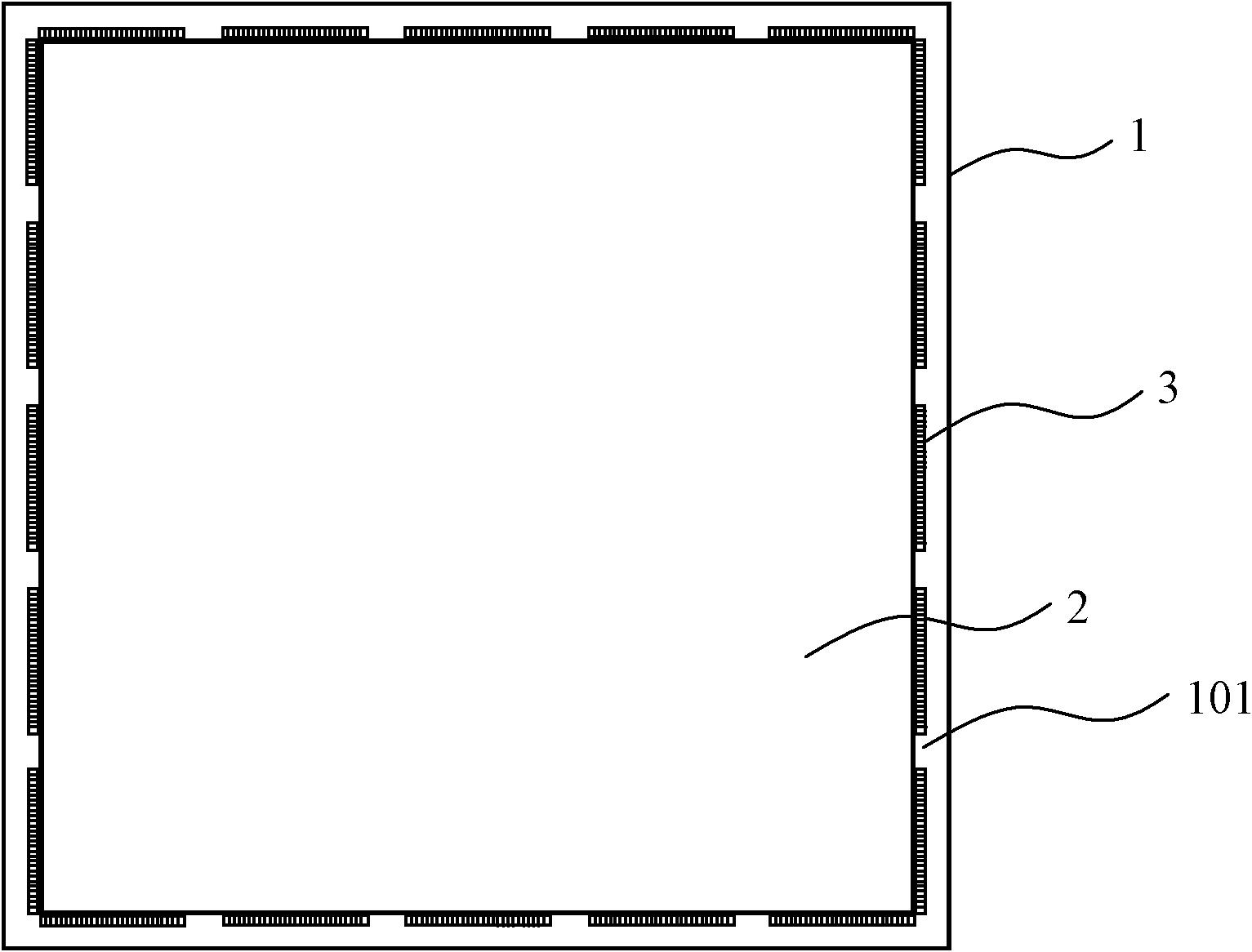

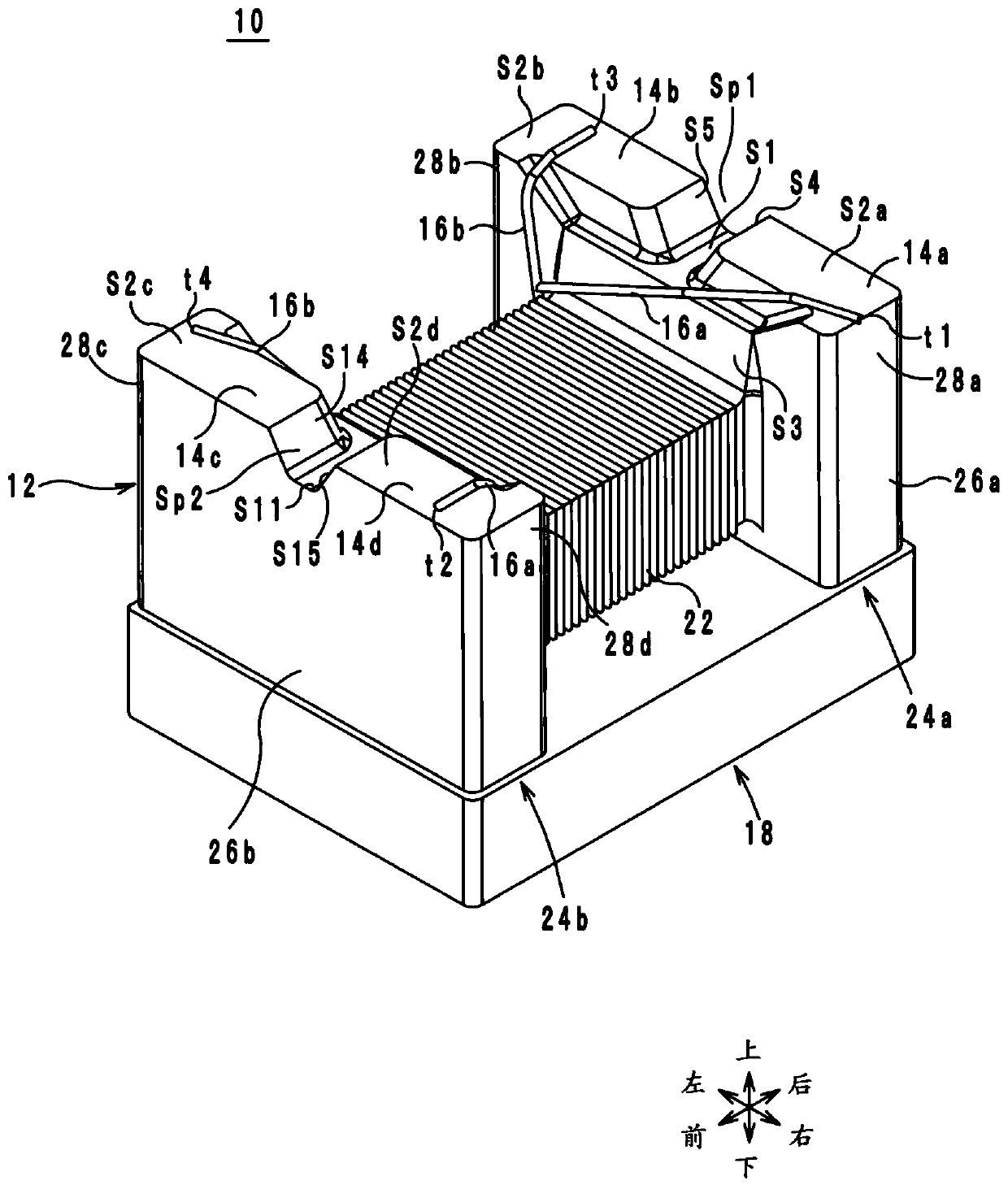

fiber optic cable

InactiveCN102265198AReduce the possibility of disconnectionFibre mechanical structuresFiberEngineering

The present invention aims to provide an optical fiber cable enabling further reduction of possibilities of disconnection of optical fiber due to, for instance, cicada oviposition. The optical fiber cable (10) is provided with: an optical fiber core (1); a tension member (2), which is arranged in parallel to the optical fiber core (1) on one side or on the both sides of the optical fiber core (1); and a sheath (3) which integrally covers the optical fiber core (1) and the tension member (2). At least one portion of the sheath (3) is composed of a polymeric material having a yield point stressof 12 MPa or higher.

Owner:FURUKAWA ELECTRIC CO LTD

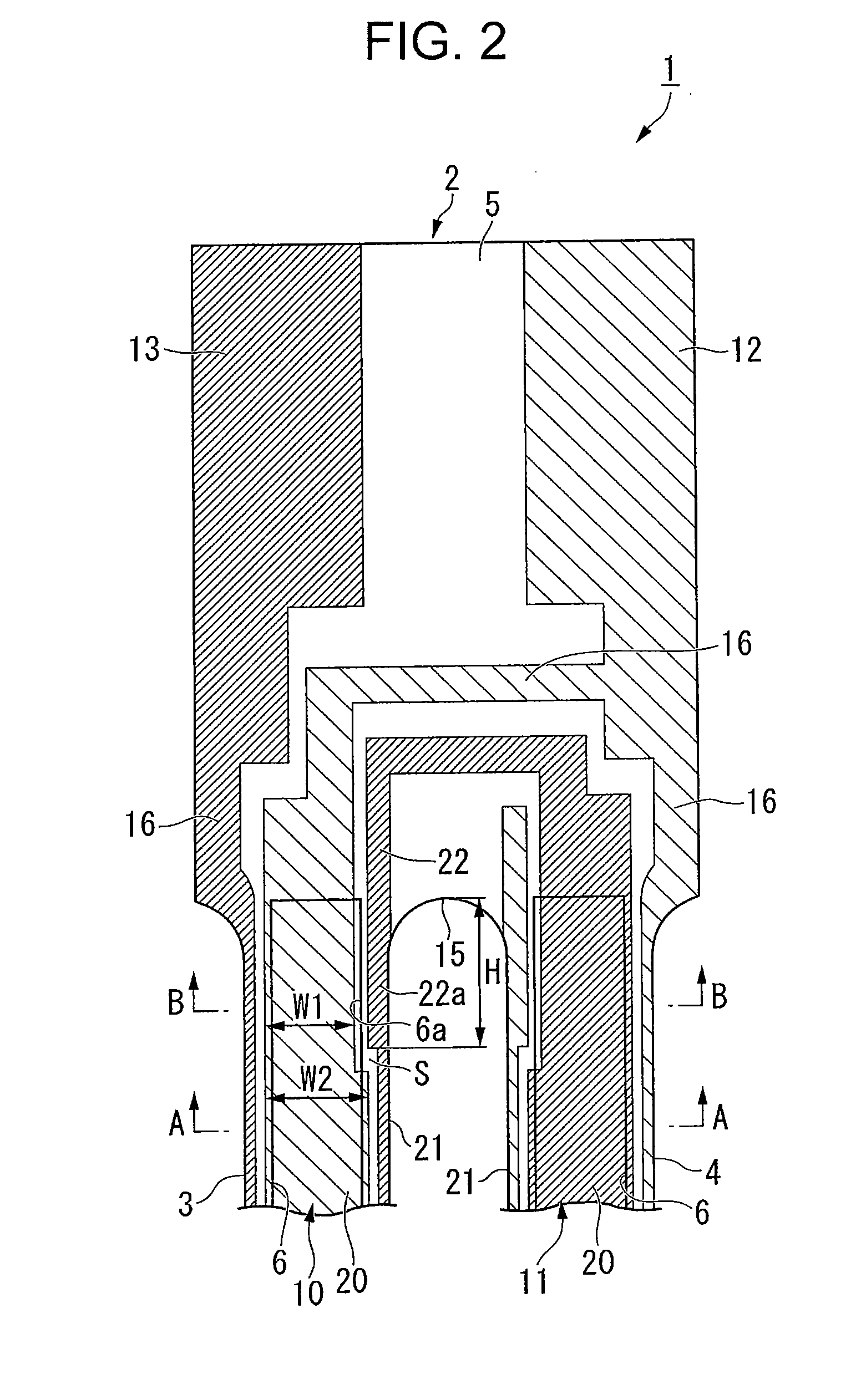

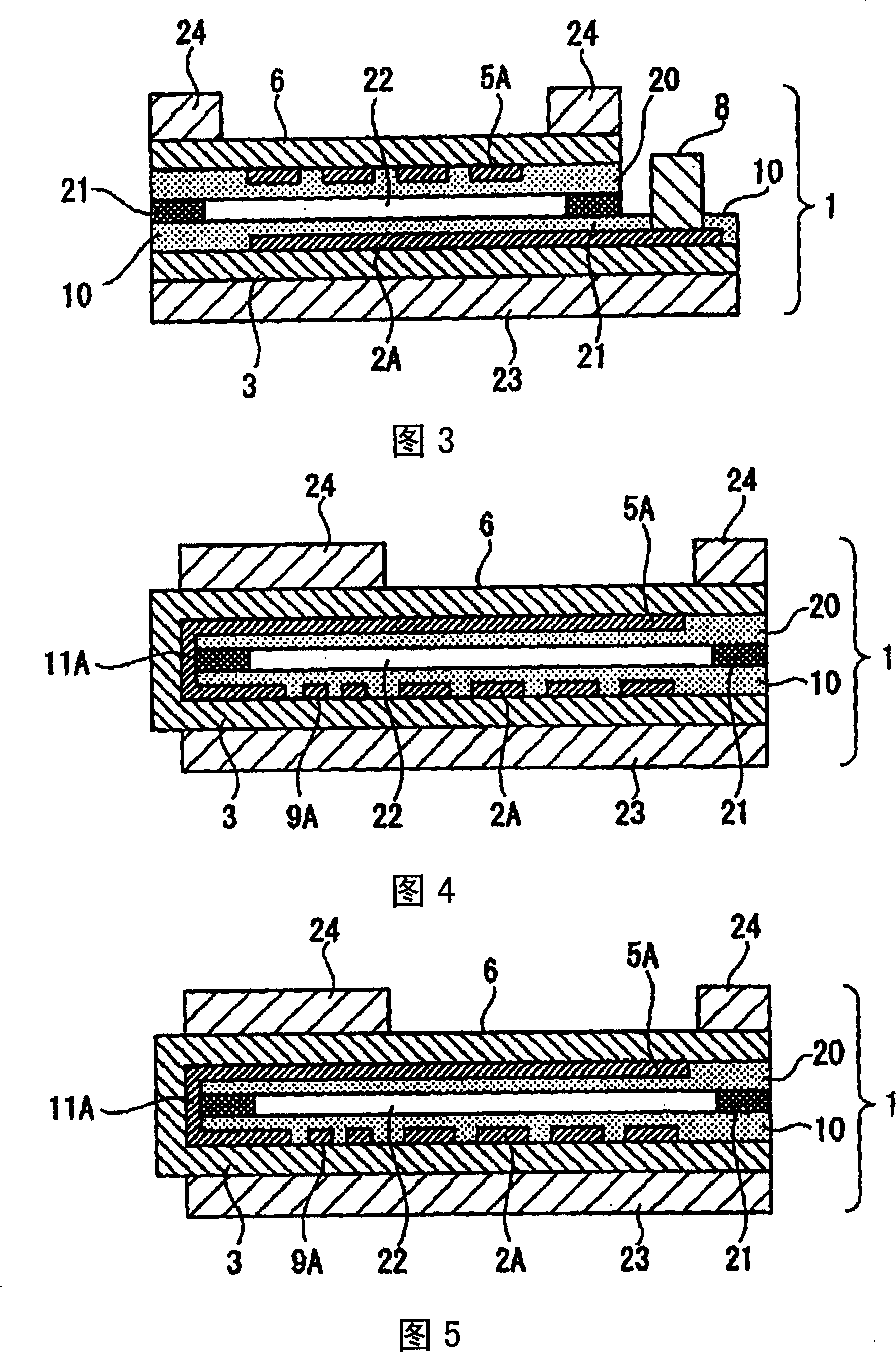

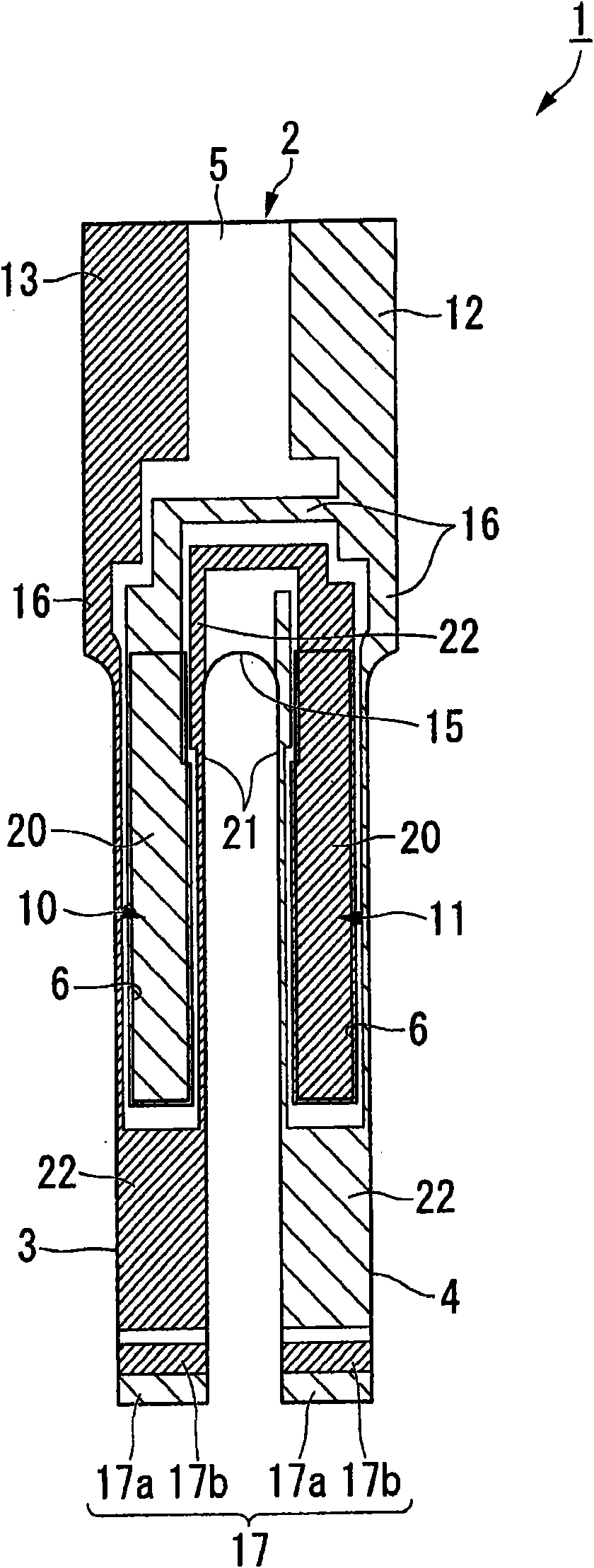

Piezoelectric vibrating reed, piezoelectric vibrator, oscillator, electronic device, radio-controlled clock, and method for manufacturing piezoelectric vibrating reed

ActiveUS20110018402A1Improve reliabilityQuality improvementPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectricityMechanical engineering

Providing a piezoelectric vibrating reed which has low disconnection possibility and ensures reliability for stable operation without requiring strict exposure position accuracy. A piezoelectric vibrating reed 1 including: a piezoelectric plate which includes vibrating arms 3 and 4, a base portion 5 to which base ends of vibrating arms are integrally fixed, and groove portions 6 which are formed on principal surfaces of vibrating arms; and excitation electrodes 10 and 11 to which vibrating arms are vibrate, wherein the excitation electrodes each include: a principal electrode portion 20, a side electrode portion 21 and a connection electrode portion 22, wherein the principal electrode portions are formed such that a horizontal width W1 on the base end sides of the vibrating arms is smaller than a horizontal width W2 in other portions so that a vacant area S is secured on a portion of the principal surface of each of the vibrating arms in the vicinity of a fork portion 15, and wherein the connection electrode portion is formed to have a large width on the principal surface of each of the vibrating arms so as to come close to an opening end side of each of the groove portions by occupying the vacant area.

Owner:SII CRYSTAL TECH

Circuit board and circuit board manufacturing method

InactiveCN104684240AReduce gapReduce the possibility of disconnectionPrinted circuit manufactureConductive pattern layout detailsResistEngineering

The invention relates to a circuit board, which comprises a substrate, a first conductive line layer, a second conductive line layer, a first covering film and solder resist ink, wherein the first conductive line layer and the second conductive line layer are arranged at two opposite sides of the substrate; the second conductive line layer is provided with a connection area; the connection area is internally distributed with multiple electrical contact pads; the first conductive line layer comprises multiple first conductive lines; multiple gaps exist between the first conductive line layer and the first conductive lines in the region corresponding to the connection area; the first covering film covers the first conductive line layer; the region in the connection area corresponding to the first covering film is provided with multiple openings; the first openings and the gaps are in one-to-one correspondence so as to enable corresponding gaps to be exposed; and the solder resist ink fills the multiple first openings and the multiple gaps. The invention also relates to a circuit board manufacturing method.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

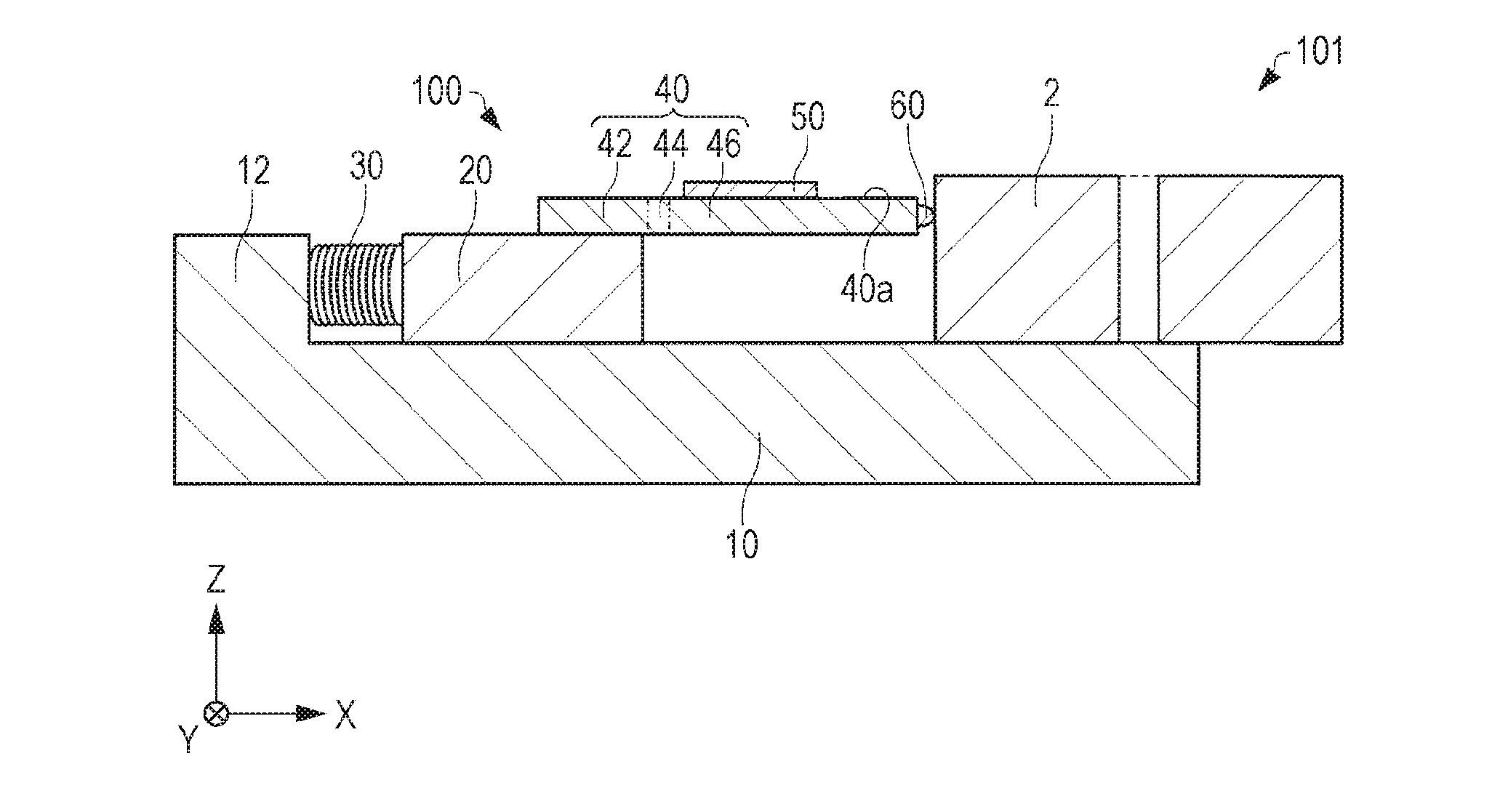

Sewing machine

ActiveCN103140617APull out smoothlyReduce the possibility of disconnectionSewing measuring devicesThread-break detectorsYarn tensionEngineering

Disclosed is needle yarn tension control device that can control the amount of tension in a needle yarn for each stitch, can draw out the needle yarn, provides little risk of yarn breakages, readily and accurately detects any yarn breakages, and has no excess or insufficient amount of accumulated yarn from pulling out the needle yarn. Said needle yarn tension control device comprises an upstream grip (40) that grips the needle yarn, a downstream grip (60), and a rotating section (80) that rotates the needle yarn. In a torque control section, a balance (12a) applies rotational force to a rotating arm in accordance with a torque value such that tension is applied to the needle yarn against the direction that the needle yarn is pulled, while an upstream grip main body (41) is closed and a downstream grip main body (61) is open. In the position control section, the balance applies rotational force to the rotating arm (81) in accordance with position data for the angle of a needle yarn motor (86) such that the needle yarn motor angle returns to an initial position for the needle yarn motor (86) angle, while the upstream side grip main body (41) is open and the downstream side grip main body (61) is closed.

Owner:NSD

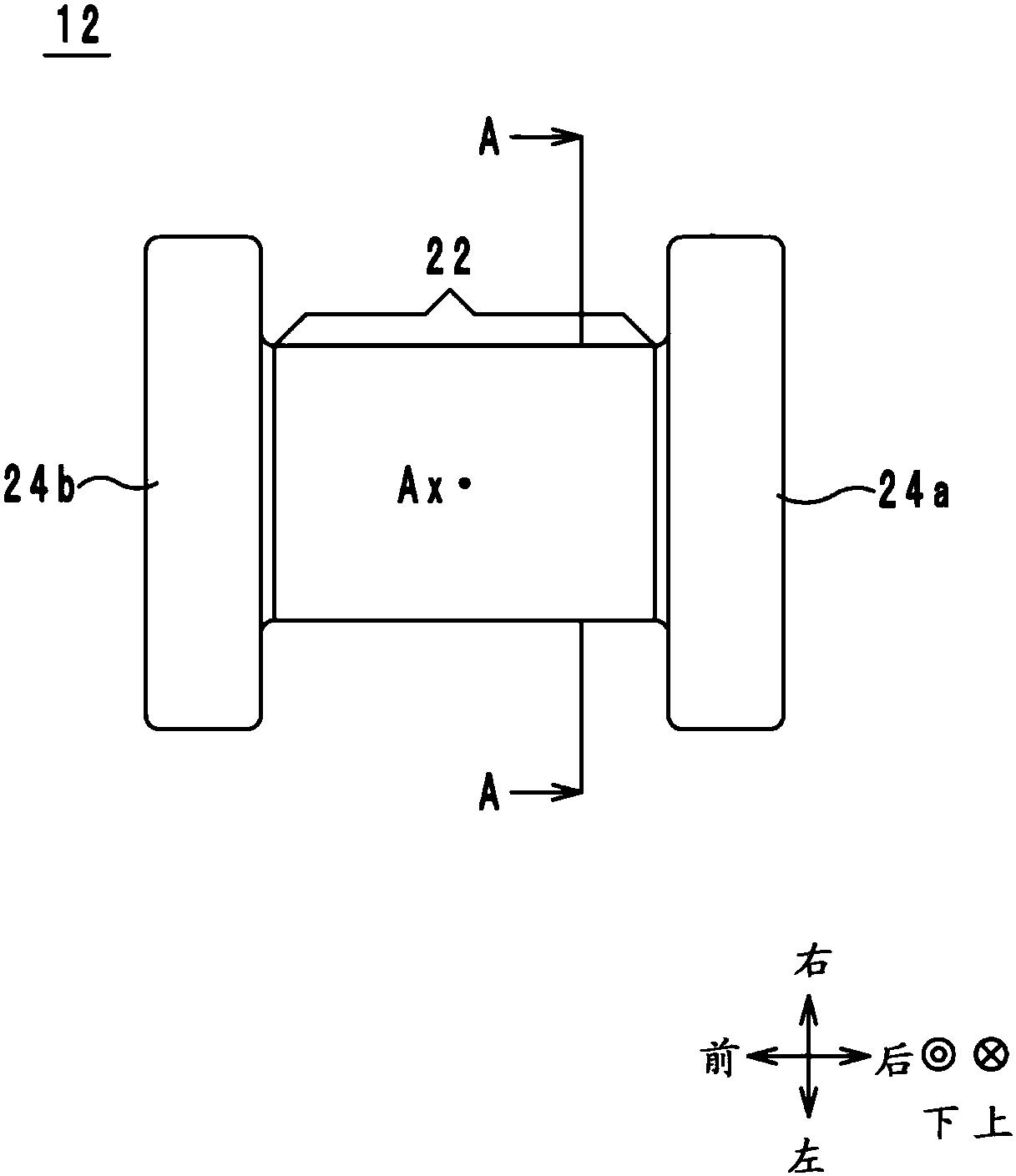

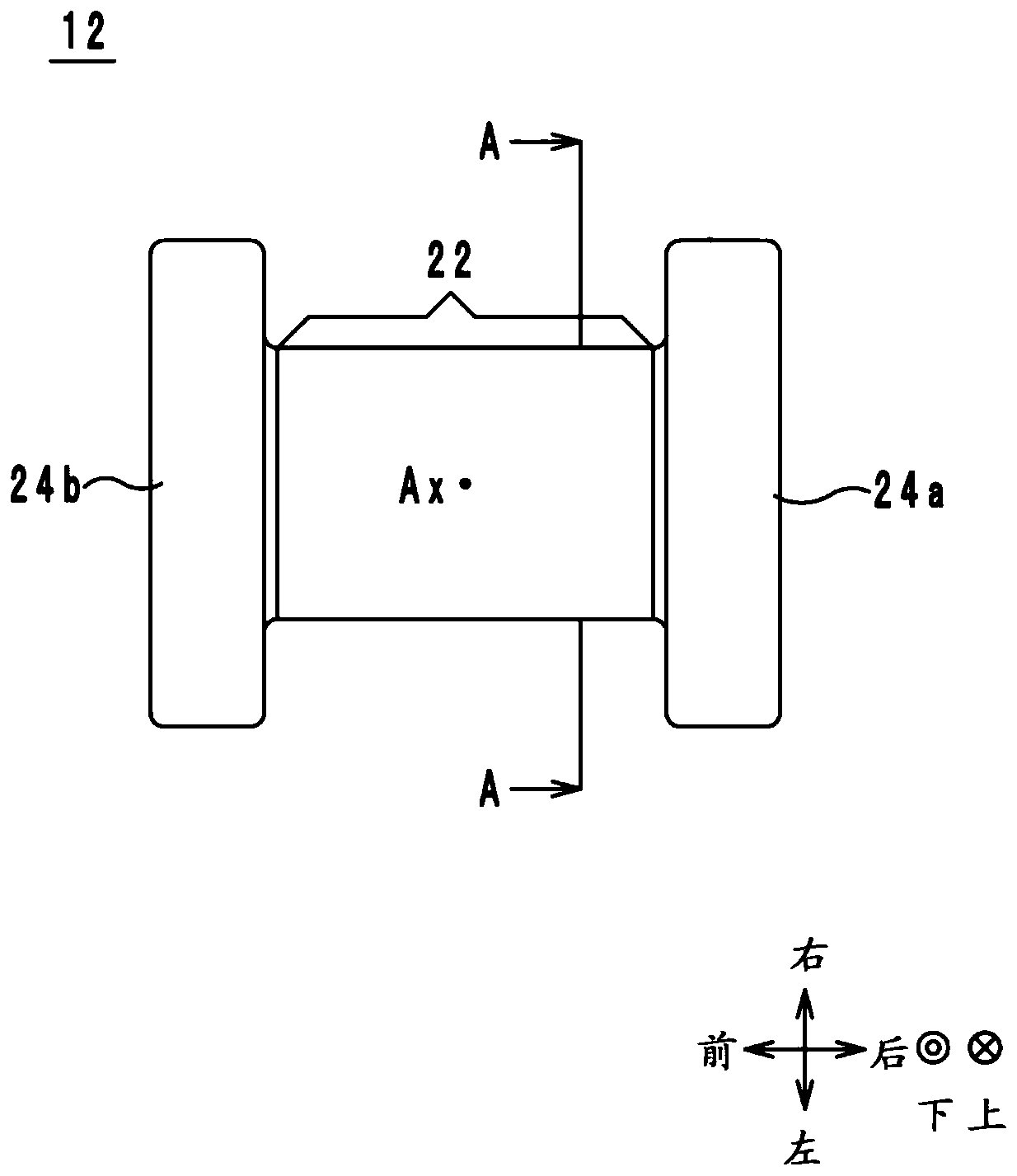

Electronic component and circuit module

ActiveCN107622862AReduce the possibility of disconnectionPrinted circuit assemblingThin/thick film capacitorEngineeringFlange

An electronic component and a circuit module which can reduce the possibility of line breakage during line winding are provided. The electronic component includes an iron core, a first winding, and anouter electrode. A flange of the iron core includes a body having a first surface that faces a top side and is located on the top side of a winding core of the iron core, and first and second electrode formation portions protruding toward the top side of the first surface. The outer electrode is provided on a second surface of the first electrode formation portion and is connected to the first winding. Slot space surrounded by the first and second electrode formation portions and the first surface is formed. A predetermined section between a point where the winding is separated from the winding core and a point where the winding comes into contact with the outer electrode extends toward the upper right side as viewed from the front, and does not include a portion of the first winding an entire line width of which overlaps the slot space.

Owner:MURATA MFG CO LTD

Piezoelectric driving device for motor, motor, robot, and pump

ActiveUS20160365809A1Increase productionReduce impactProgramme-controlled manipulatorPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectric motor

Owner:SEIKO EPSON CORP

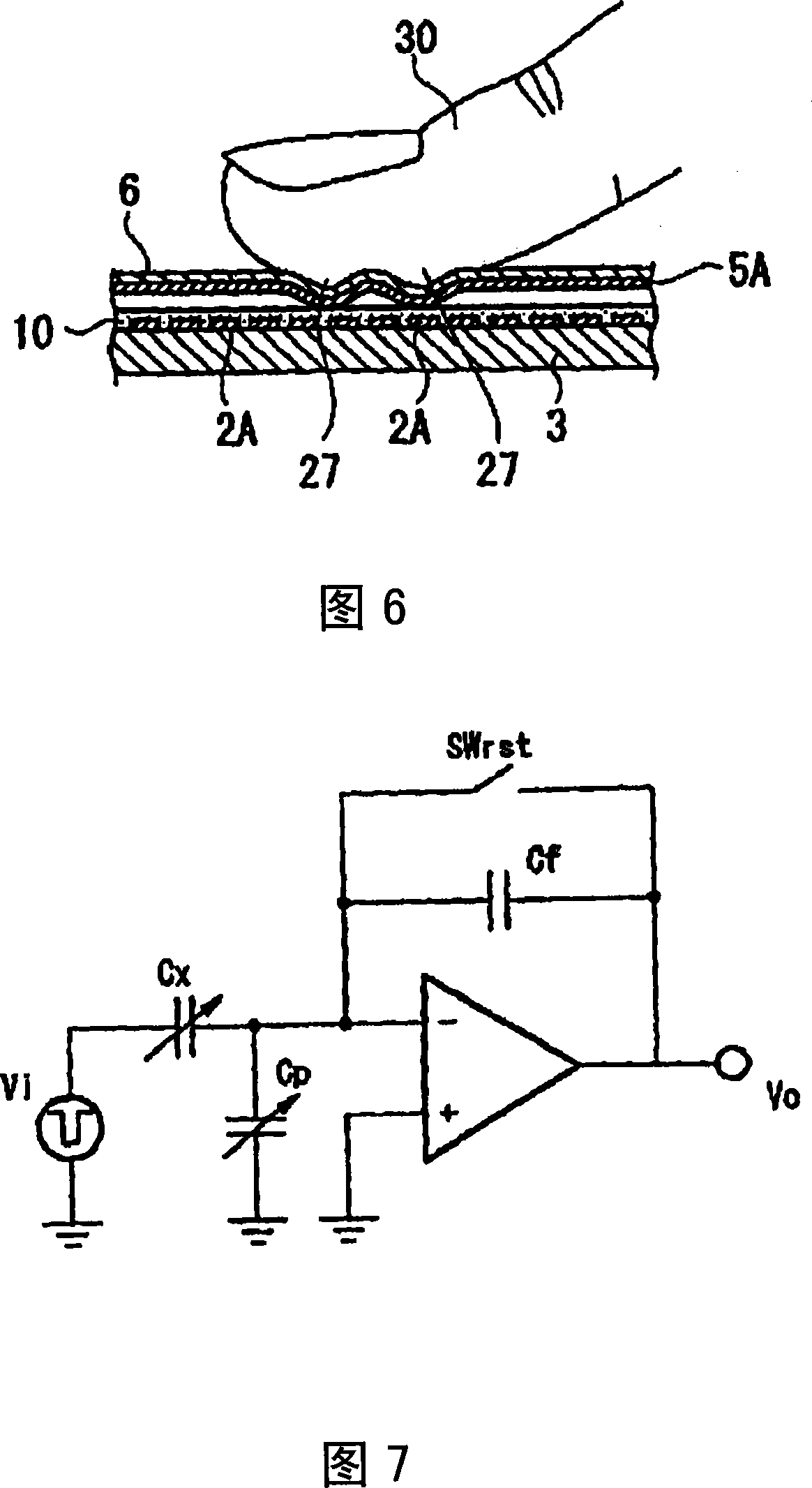

Surface pressure distribution sensor

InactiveCN101208587AReduce the possibility of disconnectionImprove reliabilityForce measurementElectric/magnetic contours/curvatures measurementsElectrical conductorSurface pressure

Owner:ALPS ALPINE CO LTD

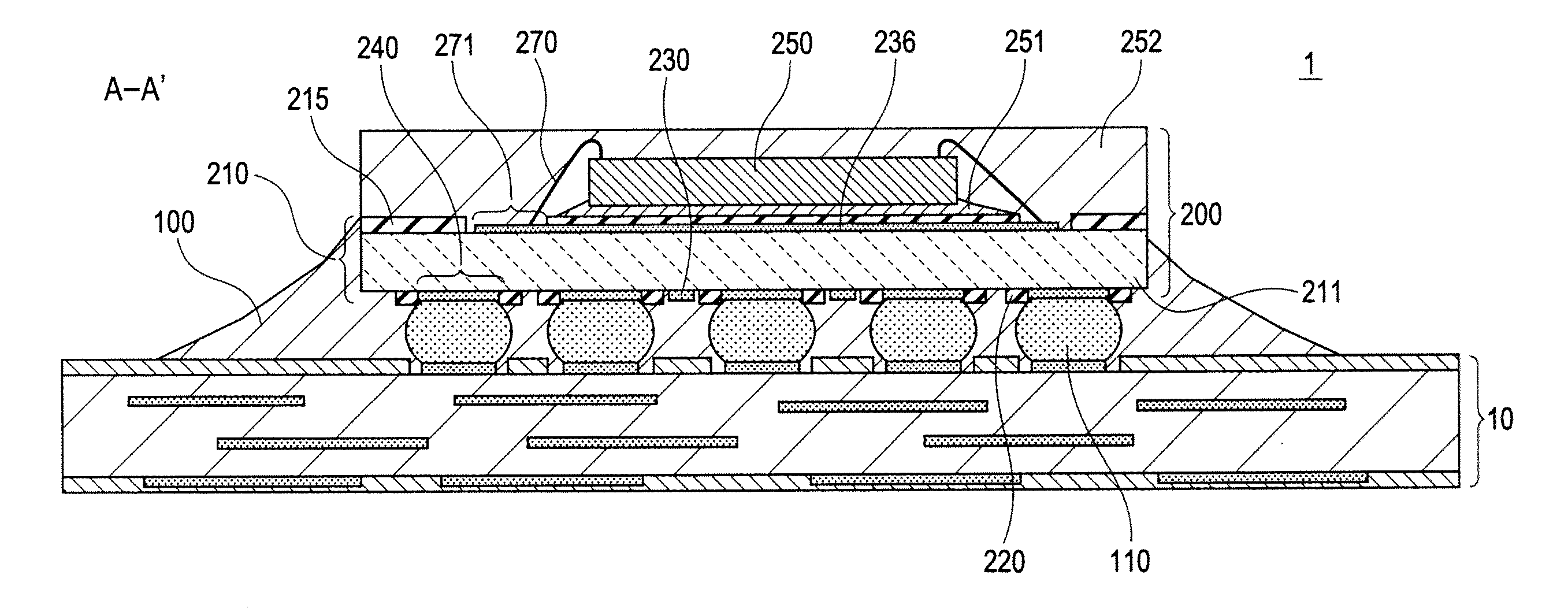

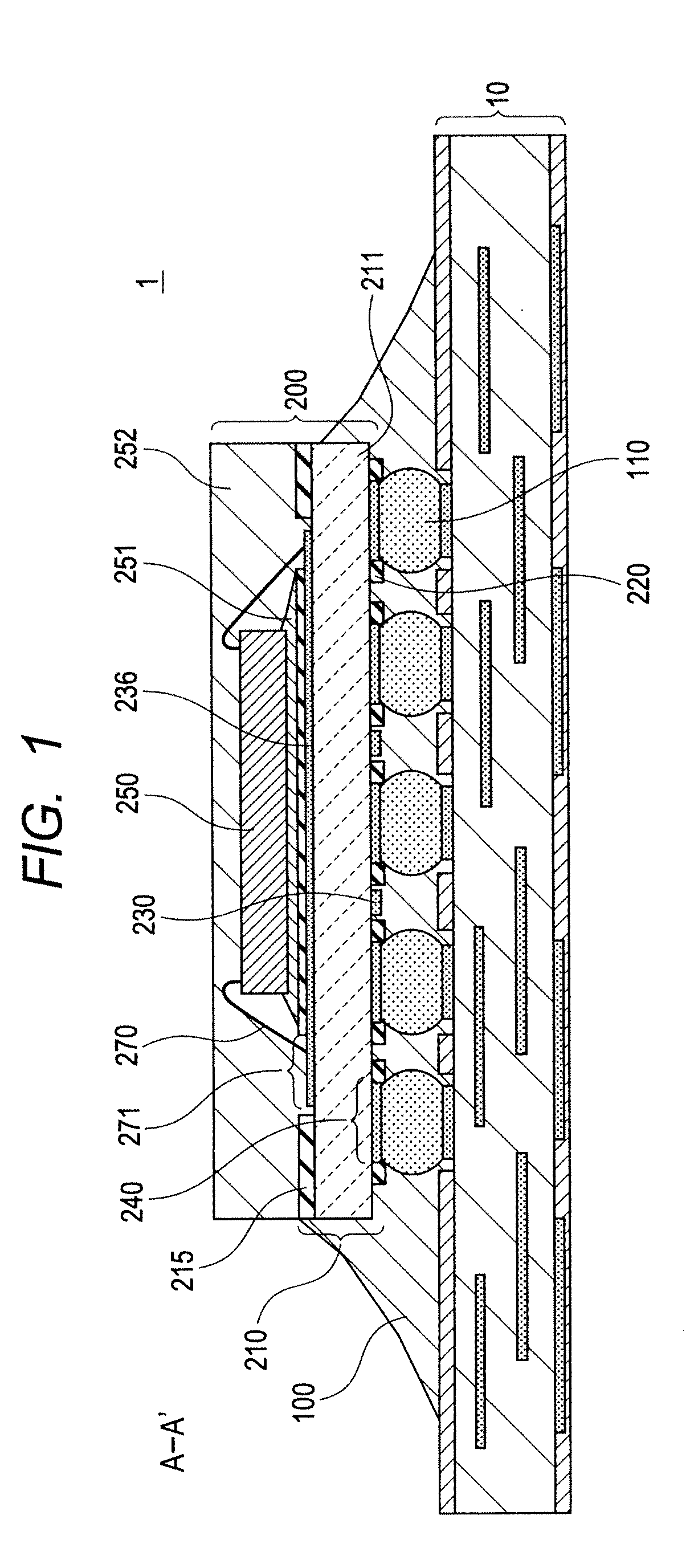

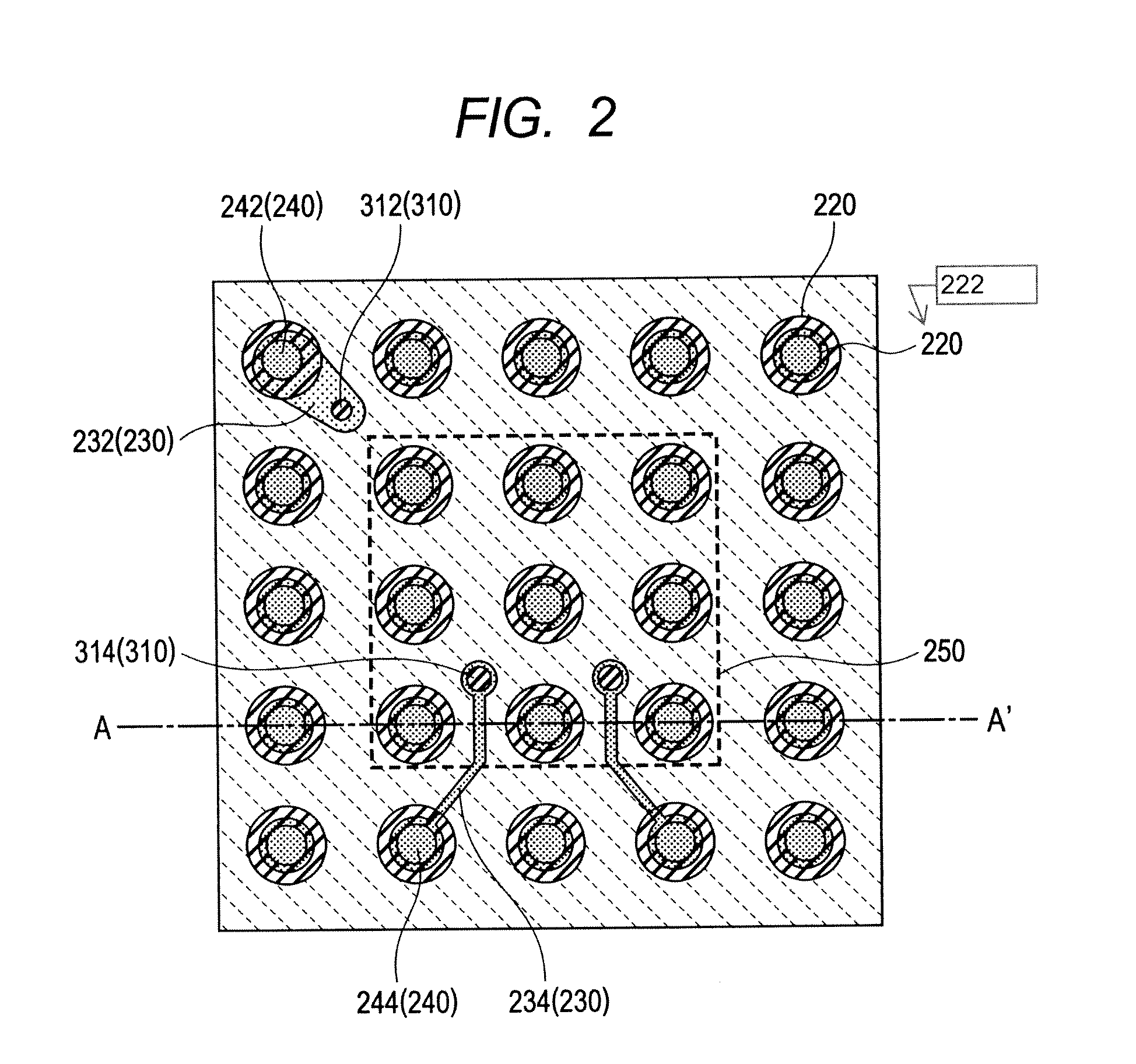

Semiconductor device, semiconductor package, interposer, semiconductor device manufacturing method and interposer manufacturing method

InactiveUS8258617B2Small widthReduce the possibilitySemiconductor/solid-state device detailsPrinted circuit aspectsResistSolder mask

Owner:RENESAS ELECTRONICS CORP

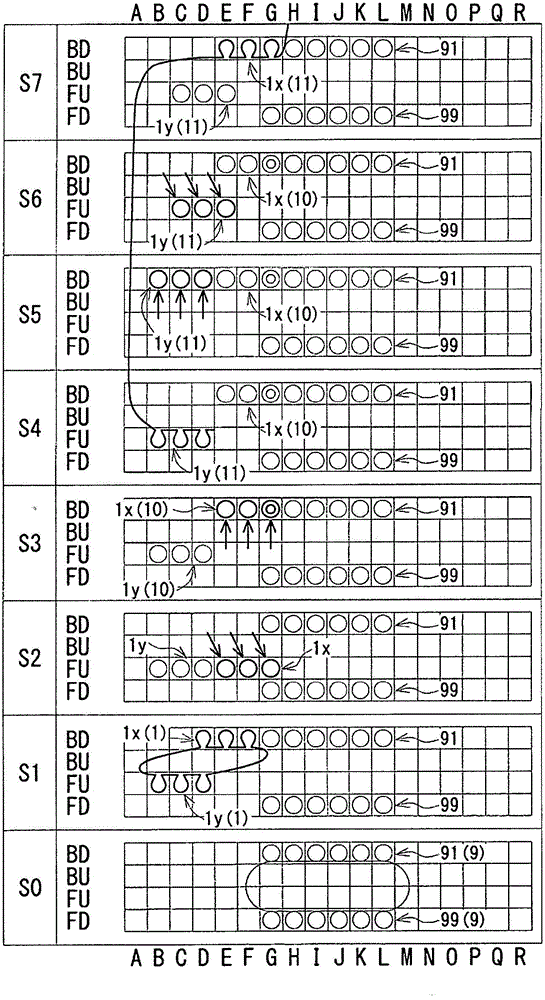

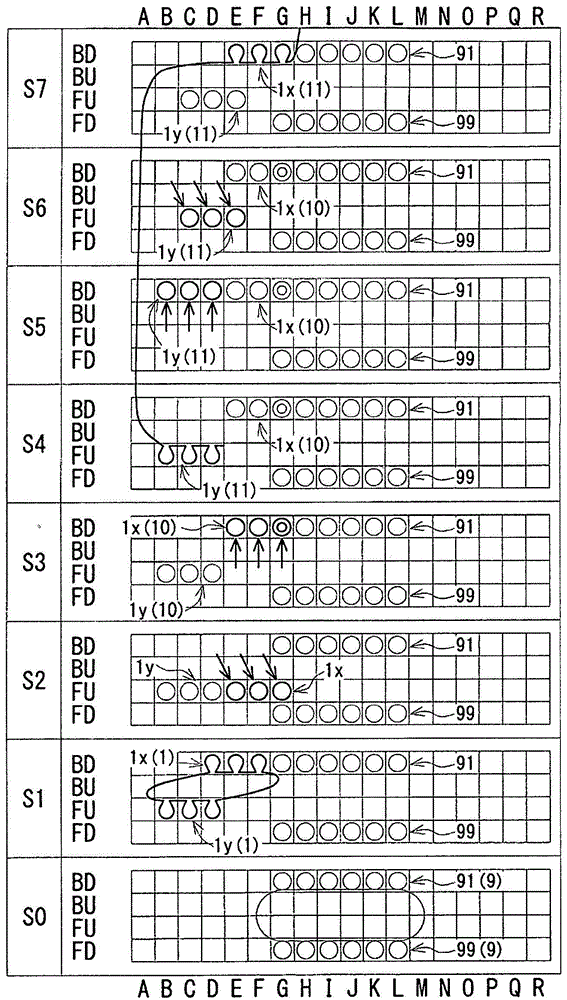

Method for knitting knitted fabric

There is provided a method for knitting a knitted fabric capable of knitting a bind-off processing portion having an appropriate stretchability and having a sufficient strength. Performing a tubular knitting at least once to knit a tubular stitch row (1) comprising front stitches, and overlapping some stitches of the tubular stitch row (1) with stitches of the base portion (9) are repeated. In the repetition, a new tubular stitch row (11) is knitted continuing in a wale direction of an existing tubular stitch row (10) to join the existing tubular stitch row (10) to the base portion (9). When knitting the tubular stitch row (1), in the tubular stitch row (1), a center position in a knitting width direction of a stitch row (1y) knitted with a needle bed (FU) on a side opposite to a side where a base section (91) is held is shifted toward a direction opposite to a direction of moving the tubular stitch row (1) to overlap with the base section (91), with respect to a center position in a knitting width direction of a stitch row (1x) knitted with a needle bed (BD) on the side where the base section (91) is held.

Owner:SHIMA SEIKI MFG LTD

Piezoelectric vibrating reed, piezoelectric vibrator, oscillator, electronic device, radio-controlled clock, and method for manufacturing piezoelectric vibrating reed

ActiveCN101964636AReduce the possibility of disconnectionSmooth movementPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksPiezoelectric actuatorsElectron

Providing a piezoelectric vibrating reed which has low disconnection possibility and ensures reliability for stable operation without requiring strict exposure position accuracy. A piezoelectric vibrating reed 1 including: a piezoelectric plate which includes vibrating arms 3 and 4, a base portion 5 to which base ends of vibrating arms are integrally fixed, and groove portions 6 which are formed on principal surfaces of vibrating arms; and excitation electrodes 10 and 11 to which vibrating arms are vibrate, wherein the excitation electrodes each include: a principal electrode portion 20, a side electrode portion 21 and a connection electrode portion 22, wherein the principal electrode portions are formed such that a horizontal width W1 on the base end sides of the vibrating arms is smaller than a horizontal width W2 in other portions so that a vacant area S is secured on a portion of the principal surface of each of the vibrating arms in the vicinity of a fork portion 15, and wherein the connection electrode portion is formed to have a large width on the principal surface of each of the vibrating arms so as to come close to an opening end side of each of the groove portions by occupying the vacant area.

Owner:SII CRYSTAL TECH

Display panel and display device

InactiveCN109830486ARelieve pressureReduce deformationSolid-state devicesSemiconductor devicesDisplay deviceWire breakage

The embodiment of the invention provides a display panel and a display device, and relates to the technical field of the display devices to solve the problem that the existing display panel is prone to wire breakage when bound to an IC. The display panel includes a substrate, a plurality of strip-shaped support structures disposed in the non-display area of the substrate, and a plurality of wiresdisposed on the support structures. The extension direction of the wires intersects with the extension direction of the support structures. The support structures are configured to make the wires disposed thereon have an uneven shape in the extension direction of the wires. The invention is used for the IC binding of the display panel.

Owner:MIANYANG BOE OPTOELECTRONICS TECH CO LTD +1

Textile thread positioning structure for producing and processing textiles

InactiveCN112249814ARelieve pressureReduce reaction forceFilament handlingMechanical engineeringIndustrial engineering

The invention relates to the technical field of production and processing of textiles and discloses a textile thread positioning structure for producing and processing textiles. The textile thread positioning structure comprises a base, wherein a shell is fixedly mounted on the right side of the top end of the base; a tension spring is fixedly mounted at the top of the inner wall of the shell; anda thread guide plate is fixedly mounted at the bottom end of the tension spring. According to the textile thread positioning structure for producing and processing textiles, when a textile machine accelerates suddenly in the working process, the pressure generated by a thread to a limiting block is increased suddenly, the limiting block transmits the pressure to a circle center of a second rotating column at the moment; a first moving block and a second moving block start to draw close inwards under the action of the pressure; the air of the first moving block is compressed and enters an airbag through a ventilation head; a second telescopic rod contracts, and the spring contracts, so that the pressure of the thread is greatly reduced, the counter-acting force applied to the thread is reduced, the possibility of thread breakage is reduced, and the effect that the thread is not easily broken is achieved.

Owner:新昌县奔力机械有限公司

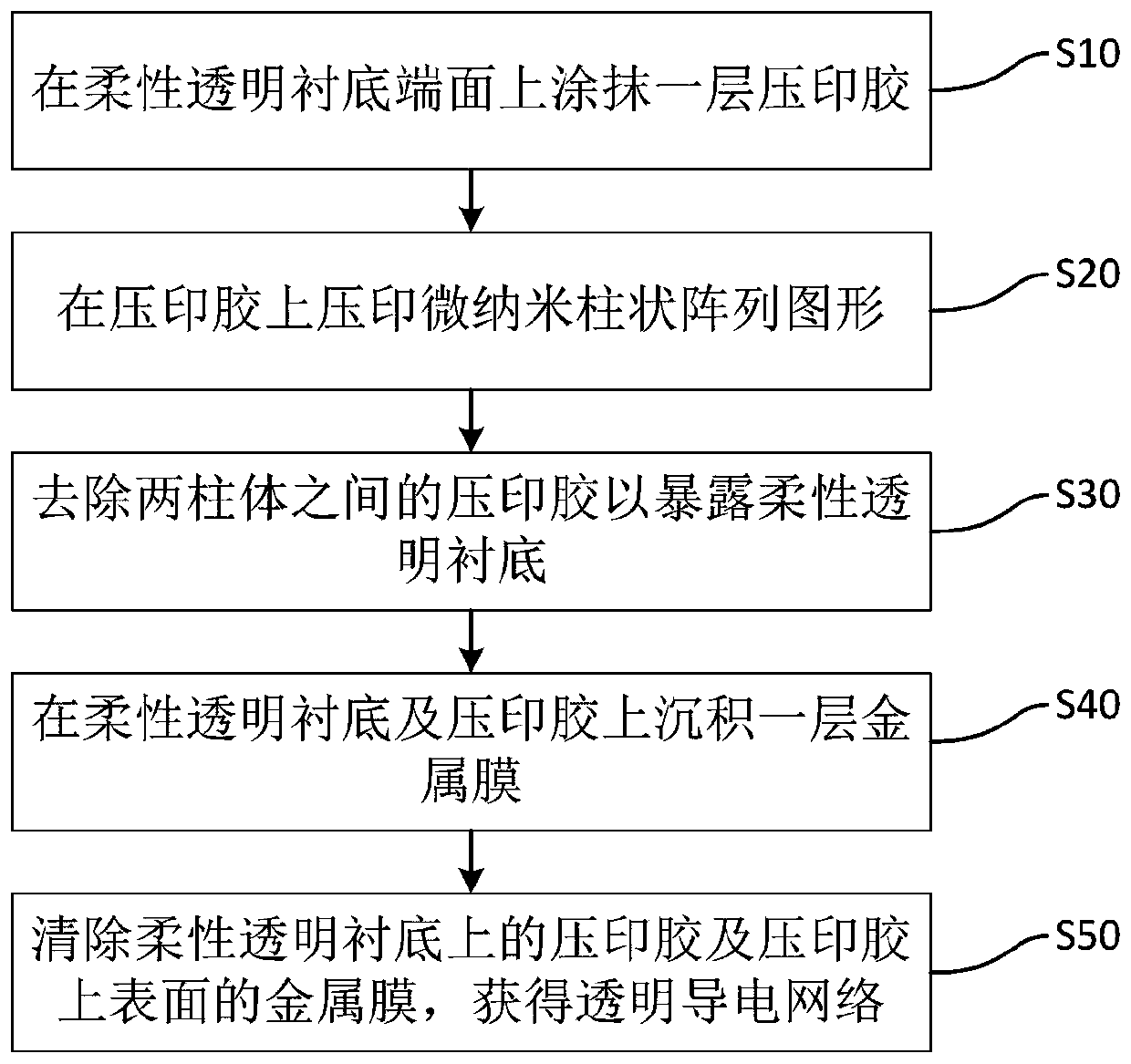

Preparation method of flexible transparent conductive film

InactiveCN110265178AReduce the possibility of disconnectionFlat surfaceConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersConductive pasteMicro nano

The invention relates to the technical field of conductive materials, and specifically relates to a preparation method of a flexible transparent conductive film. The preparation method includes the steps of applying a layer of imprinting glue to the end face of a flexible transparent substrate; imprinting a micro-nano cylindrical array pattern on the imprinting glue; removing the imprinting glue between two cylinders to expose the flexible transparent substrate; depositing a metal film on the flexible transparent substrate and the imprinting glue; removing the imprinting glue on the flexible transparent substrate and the metal film on the imprinting glue to obtain a transparent conductive network. According to the invention, the flexible transparent conductive film is prepared by means of combining nano imprinting and film coating, the problem of wire breakage existing in the conductive film prepared according to the traditional nano-imprinting assisted method of filling nano-imprinting grooves by scrape coating metal conductive paste is overcome, the conductivity of the flexible transparent conductive film is improved, and the prepared flexible transparent conductive film is better in stability and high in finished product rate.

Owner:SHENZHEN TECH UNIV

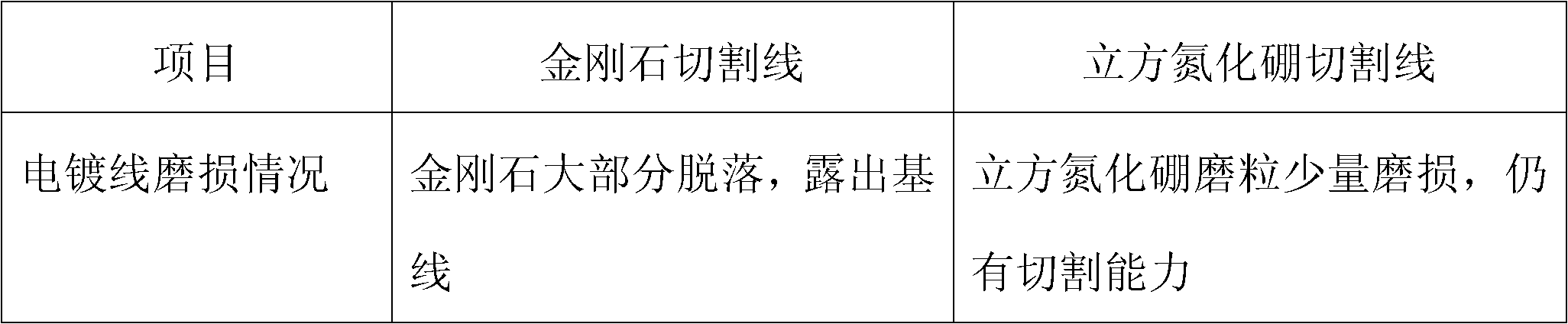

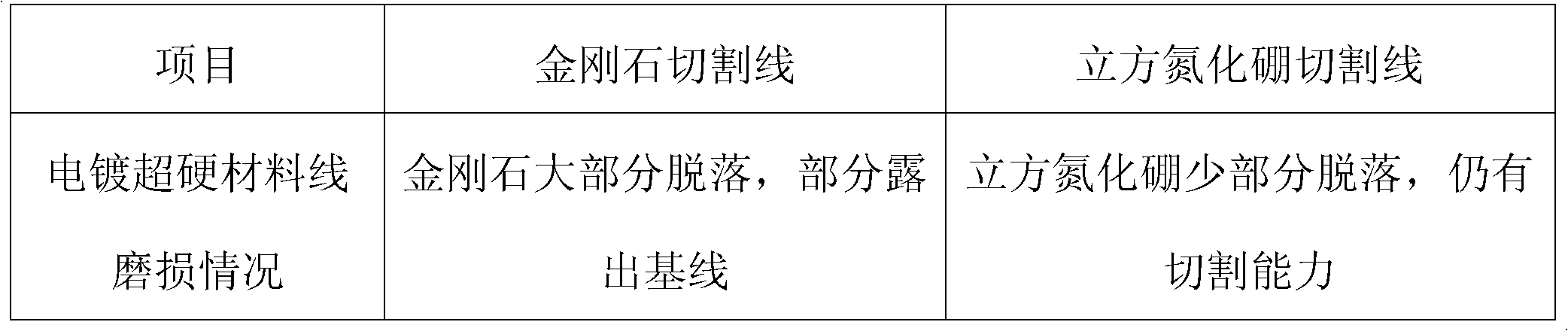

Cubic boron nitride cutting line

The invention discloses a cubic boron nitride cutting line. Cubic boron nitride is compositely and electrically deposited on the surface of a metal blank wire; the grain diameter of the cubic boron nitride is 10-75Mu m; and the diameter of the metal blank wire is 0.1-1.5mm. The preparation method of the cubic boron nitride cutting line is as follows: the metal blank wire is deoiled and derusted; and the cubic boron nitride and metal nickel are compositely and electrically deposited, and then are cleaned and dried. The cubic boron nitride cutting line has excellent high temperature oxidation resistance and a low friction coefficient, long service life, a low cost, smooth cutting and processing surfaces, high smoothness, and low surface material crystal structure damage. The cutting capacity of the cubic boron nitride cutting line is almost same with that of an electrodeposition diamond wire. The cubic boron nitride cutting line is suitable for extracting and cutting large-size silicon ingots at high speed, and cutting high-quality silicon wafers.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

Production method of double-interface smart card and double-interface smart card

ActiveCN105488558AReduce the possibility of disconnectionImprove pass rate and efficiencyRecord carriers used with machinesJoint surfaceEngineering

The invention discloses a production method of a double-interface smart card and a double-interface smart card. The production method of the double-interface smart card comprises: providing an antenna layer and an antenna, embedding the antenna on a joint surface of the antenna layer, and embedding an antenna head and an antenna tail of the antenna in a preset area of the antenna layer; providing a first protective layer, and embedding an isolation block on a binding face of the first protective layer; after laminating the binding face of the first protective layer to the joint surface of the antenna layer, combining the first protective layer with the antenna layer by a laminating technology, wherein the isolation block covers the preset area, and a melting point of the isolation block is higher than a heating temperature of the laminating technology; separating the preset area from other areas of the antenna layer; lifting the preset area, and separating the antenna head and the antenna tail of the antenna from the preset area; and providing a chip, and fixing the chip, the antenna head and the antenna tail on the antenna layer after electrically connecting the chip with the antenna head and the antenna tail. According to the technical scheme of the invention, efficiency of manufacturing the double-interface smart card and a qualified rate of the double-interface smart card can be improved.

Owner:SHENZHEN YUANMINGJIE TECH

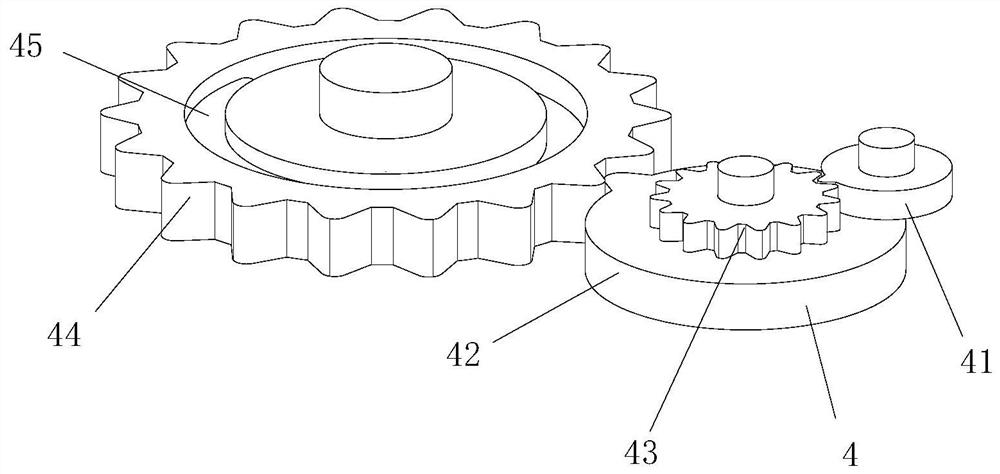

Enameled wire surface lubricating oil smearing device and technology

PendingCN114843043AReduce the possibility of disconnectionReduced force unevennessReduction of cables/conductors sizeManufacturing extensible conductors/cablesEngineeringMaterials science

The invention belongs to the technical field of varnished wire production and processing, and particularly relates to a varnished wire surface lubricating oil smearing device and technology. The varnished wire surface lubricating oil smearing device comprises an oil tank, and fixed clamping plates distributed in a matrix mode are fixedly installed in the oil tank; a transverse rod is fixedly installed in the oil tank, lever supports which are evenly distributed are hinged to the outer surface of the transverse rod, and movable clamping plates corresponding to the fixed clamping plates are hinged to the two ends of each lever support. Die holes are formed in the corresponding surfaces of the movable clamping plate and the fixed clamping plate; elastic telescopic rods are fixedly mounted at four corners of the corresponding surfaces of the movable clamping plate and the fixed clamping plate; the tops of the movable clamping plates distributed in the vertical direction are connected through a connecting frame. A fixed rod is fixedly mounted at the right end of the lever bracket close to the outer wall of the oil tank; an intermittent mechanism is rotationally mounted on the outer wall of the oil tank; the structure is simple, and the possibility that an oil film formed in a deformation area in the wire drawing process is too thick due to the fact that the grease content of wire drawing oil is too high, a die hole is blocked, and then wires are broken can be reduced.

Owner:张海勤

Semiconductor device, semiconductor package, interposer, semiconductor device manufacturing method and interposer manufacturing method

ActiveUS20120299193A1Possibility of disconnectionReduce the possibility of disconnectionSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor chipSemiconductor package

A semiconductor device includes an interposer having a base member including a first surface and a second surface opposite to the first surface, a first interconnect formed on the first surface of the base member, a first insulating film formed on the first surface of the base member, a first external terminal and a second external terminal neighboring the first external terminal formed on the second surface of the base member, a second interconnect formed on the second surface of the base member and passing between the first external terminal and the second external terminal, and a second insulating film formed on the second surface of the base member, a semiconductor chip mounted on the first insulating film, a sealing resin formed on the first insulating film and sealing the semiconductor chip. The second insulating film has an opening so that the second interconnect is exposed in an area.

Owner:RENESAS ELECTRONICS CORP

A kind of touch sensor and its manufacturing method, touch display panel

ActiveCN106803513BReduce manufacturing difficultyImprove processing stabilitySolid-state devicesPrint image acquisitionWell controlFilling-in

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

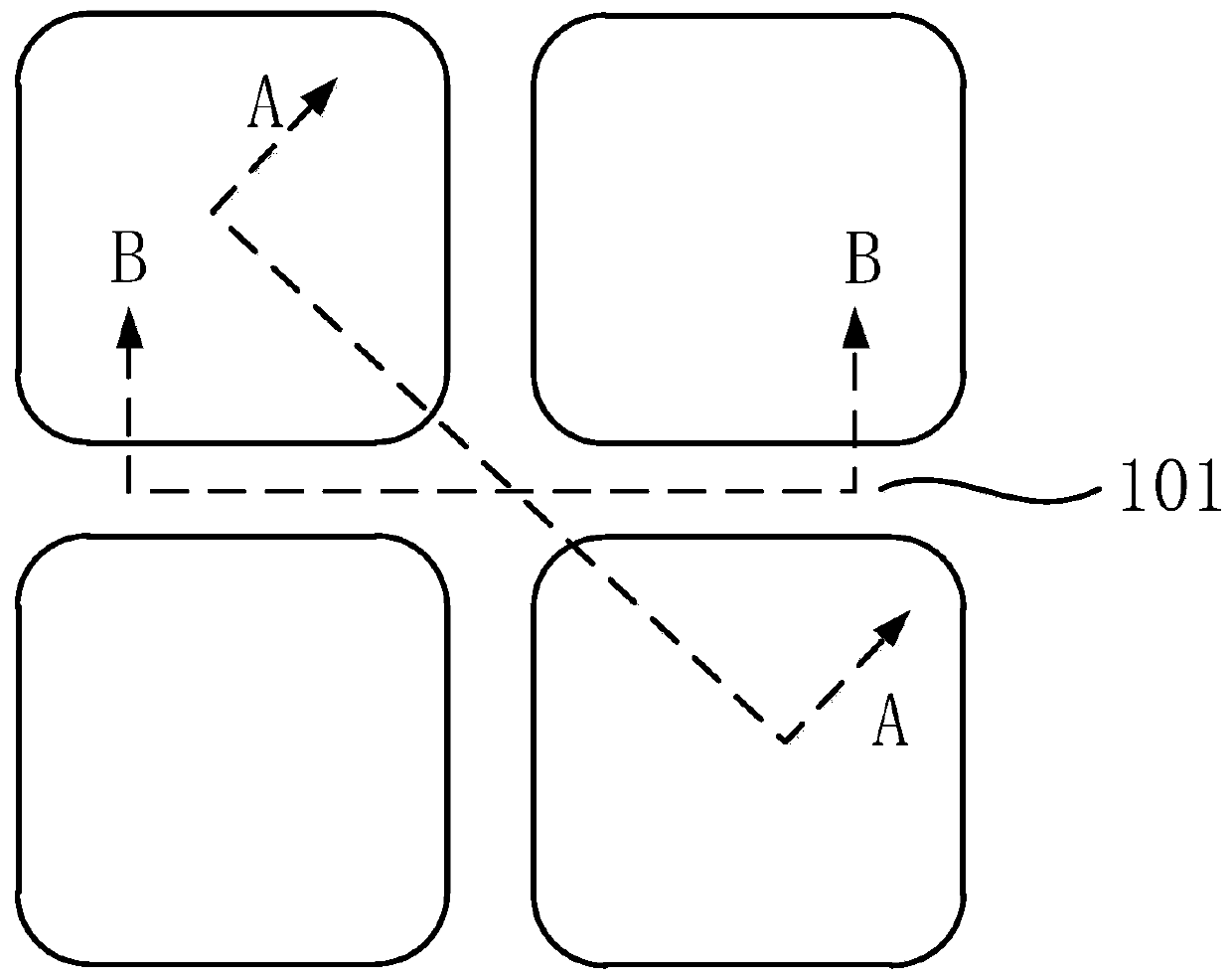

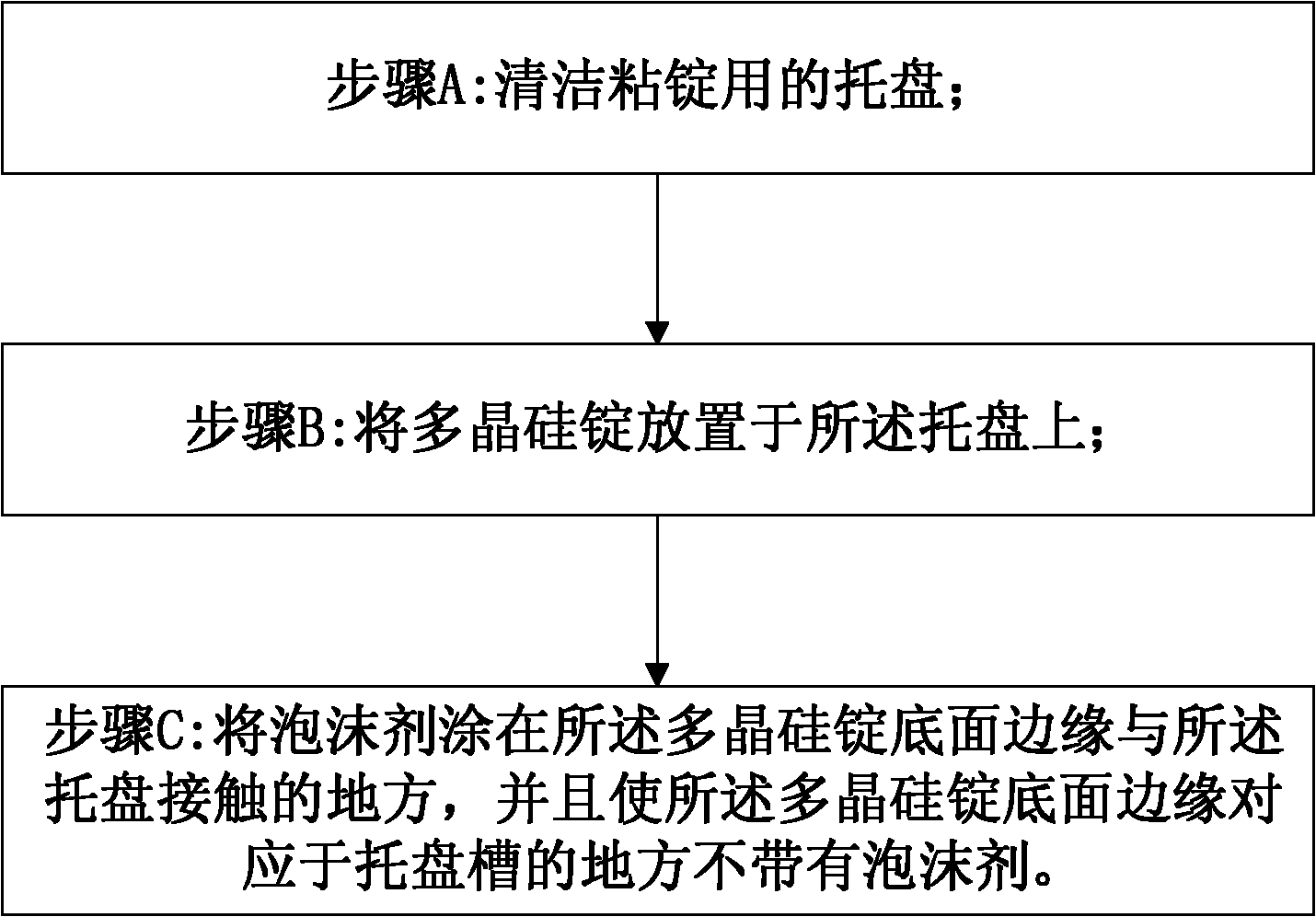

Method for bonding polysilicon ingot and tray

ActiveCN102225599BReduce dosageAvoid it happening againWorking accessoriesFine working devicesFoaming agentIngot

Owner:YANGZHOU RONGDE NEW ENERGY TECH

How to weave the fabric

There is provided a method for knitting a knitted fabric capable of knitting a bind-off processing portion having an appropriate stretchability and having a sufficient strength. Performing a tubular knitting at least once to knit a tubular stitch row (1) comprising front stitches, and overlapping some stitches of the tubular stitch row (1) with stitches of the base portion (9) are repeated. In the repetition, a new tubular stitch row (11) is knitted continuing in a wale direction of an existing tubular stitch row (10) to join the existing tubular stitch row (10) to the base portion (9). When knitting the tubular stitch row (1), in the tubular stitch row (1), a center position in a knitting width direction of a stitch row (1y) knitted with a needle bed (FU) on a side opposite to a side where a base section (91) is held is shifted toward a direction opposite to a direction of moving the tubular stitch row (1) to overlap with the base section (91), with respect to a center position in a knitting width direction of a stitch row (1x) knitted with a needle bed (BD) on the side where the base section (91) is held.

Owner:SHIMA SEIKI MFG LTD

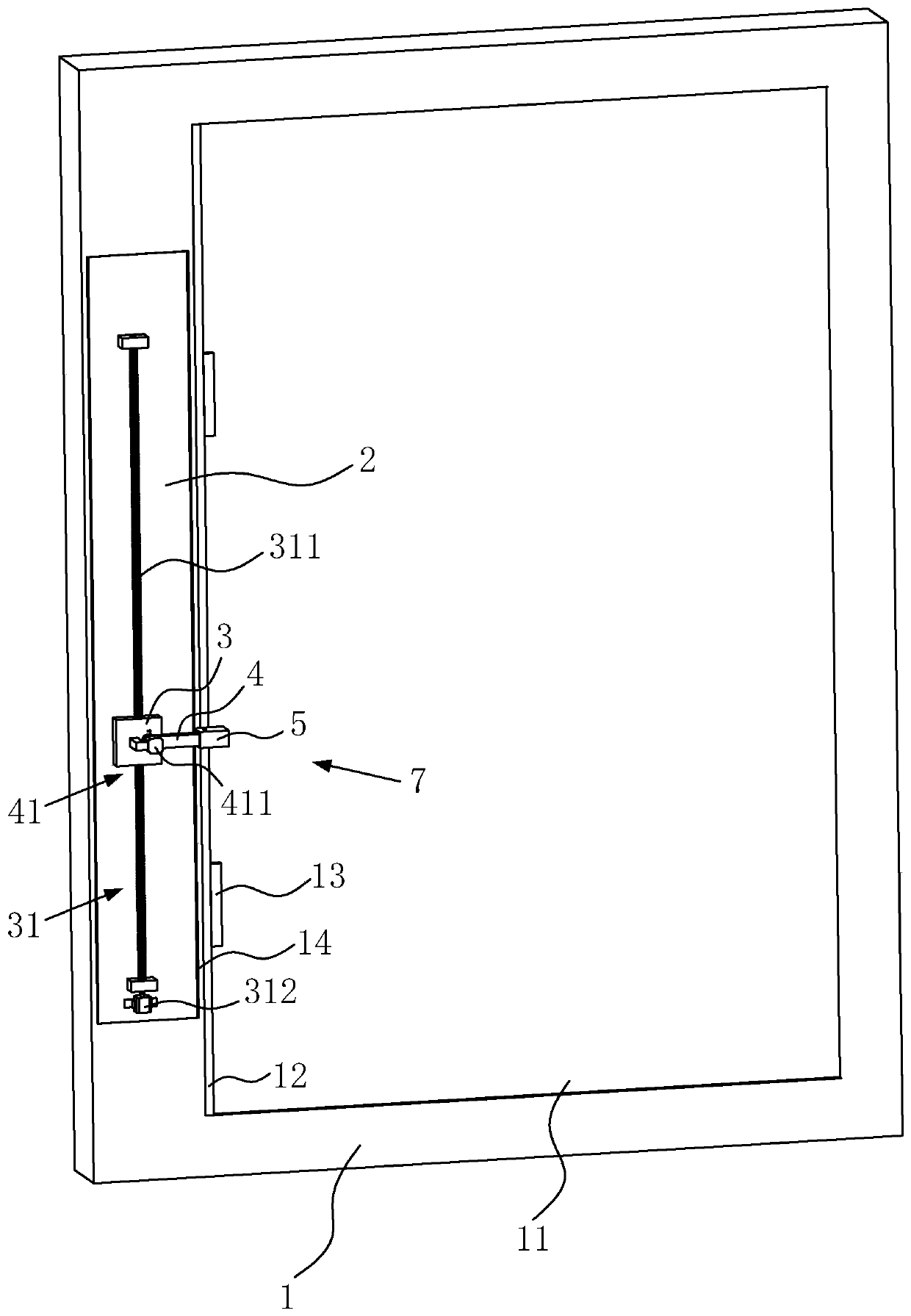

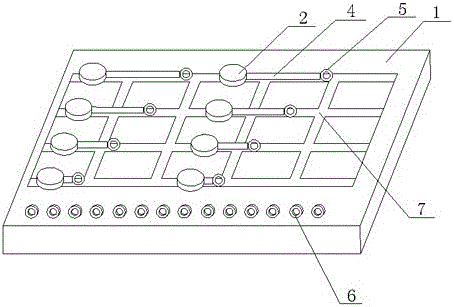

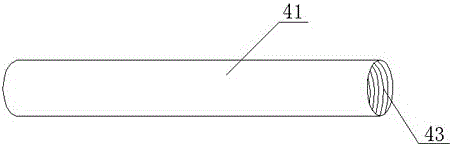

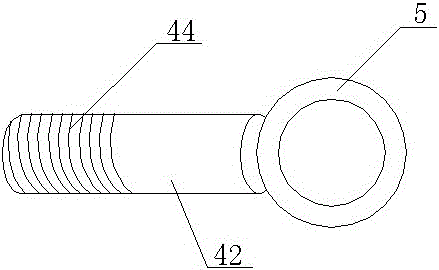

Energy-efficient built-in blinds

ActiveCN110593740BReduce the possibility of disconnectionImprove aestheticsDoor/window protective devicesWindow cleanersStructural engineeringControl theory

The invention relates to an energy-saving built-in louver, and relates to the technical field of louvers. The energy-saving built-in louver comprises a window frame, inner glass and a controller, wherein the controller is arranged at the junction of the window frame and the outer side surface of the inner glass in a manner of sliding in the vertical direction, a movable seat is connected to the window frame and aside the controller in a manner of sliding in the vertical direction, and a height adjustment device used for controlling the movable seat to vertically slide is arranged in the windowframe; a cleaning seat is rotationally connected to the movable seat, a rotary surface of the cleaning seat is parallel to the outer side surface of the inner glass, and a movable device used for controlling the cleaning seat to rotate is arranged on the movable seat; and a cleaning sponge block is connected to one end part away from the rotary shaft of the cleaning seat, of the cleaning seat, ina manner of sliding in an axis direction which is parallel to the rotary shaft of the cleaning seat, and a cleaning device used for driving the cleaning sponge block to slide to be abutted against the inner glass is arranged on the cleaning seat. The energy-saving built-in louver has the effect of conveniently cleaning the movable area of the controller on the inner glass.

Owner:苏州市东升铝合金制品有限公司

Quilting line setting-out system capable of realizing stable setting-out

InactiveCN105839307AThe output path is simpleClear output pathThread-break detectorsRound tableOutput device

The invention discloses a quilting line setting-out system capable of realizing stable setting-out. The quilting line setting-out system comprises a placement table body, and a plurality of bearing supports for mounting a thread reelline barrel and leading-out rings for leading out a stitching threadquilting line, which are arranged on the placement table body, wherein each bearing support comprises a round table, a supporting rod and a guide ring, the supporting rod is fixed on a side face of the round table at a horizontal state and the guide ring is fixed at one end, far away from the round table, of the supporting rod; the quilting line setting-out systemeach bearing support further comprises a stitching threadquilting line output device; the stitching threadquilting line output device comprises a rotary table, an inserting rod and the thread reelline barrel, and a tightening mechanism for fixing and locking the thread reelline barrel is arranged at the top of the inserting rod. With the adoption of the structure, the stitching threadquilting line can be prevented from crossing, and a line breaking condition of the stitching threadsuture line can be clearly judged; meanwhile, the line barrelthread reel and a line thread outlet can reasonably correspond to each other, so that the space utilization rate of a stitching threadquilting line output part is higher and the size of a quilting line machine tool is reduced to a certain extent; furthermore, the output reliability of the stitching threadquilting line can be guaranteed, and the quilting line machine tool can work stably and normally.

Owner:CHENGDU LINSHI SHAGUA TECH CO LTD

Display panel and display device

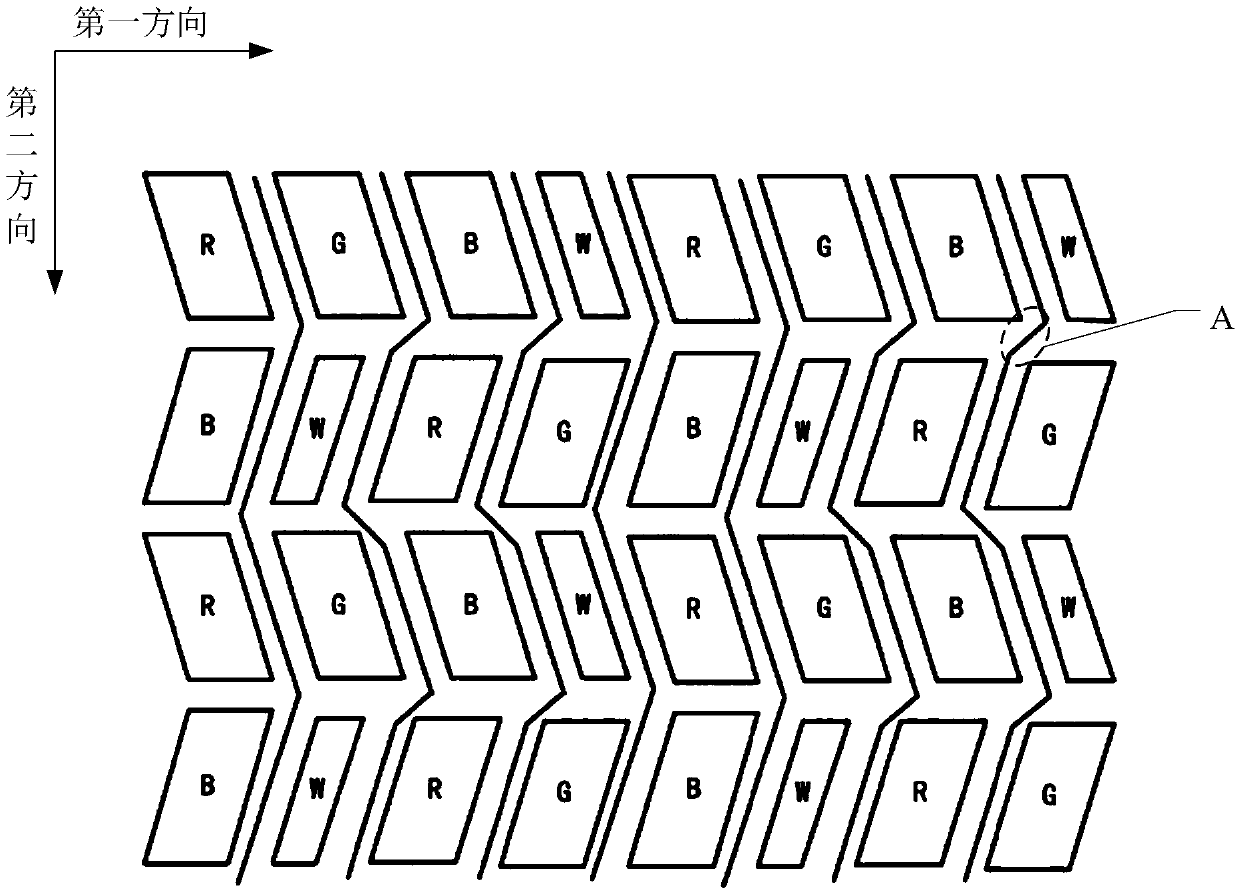

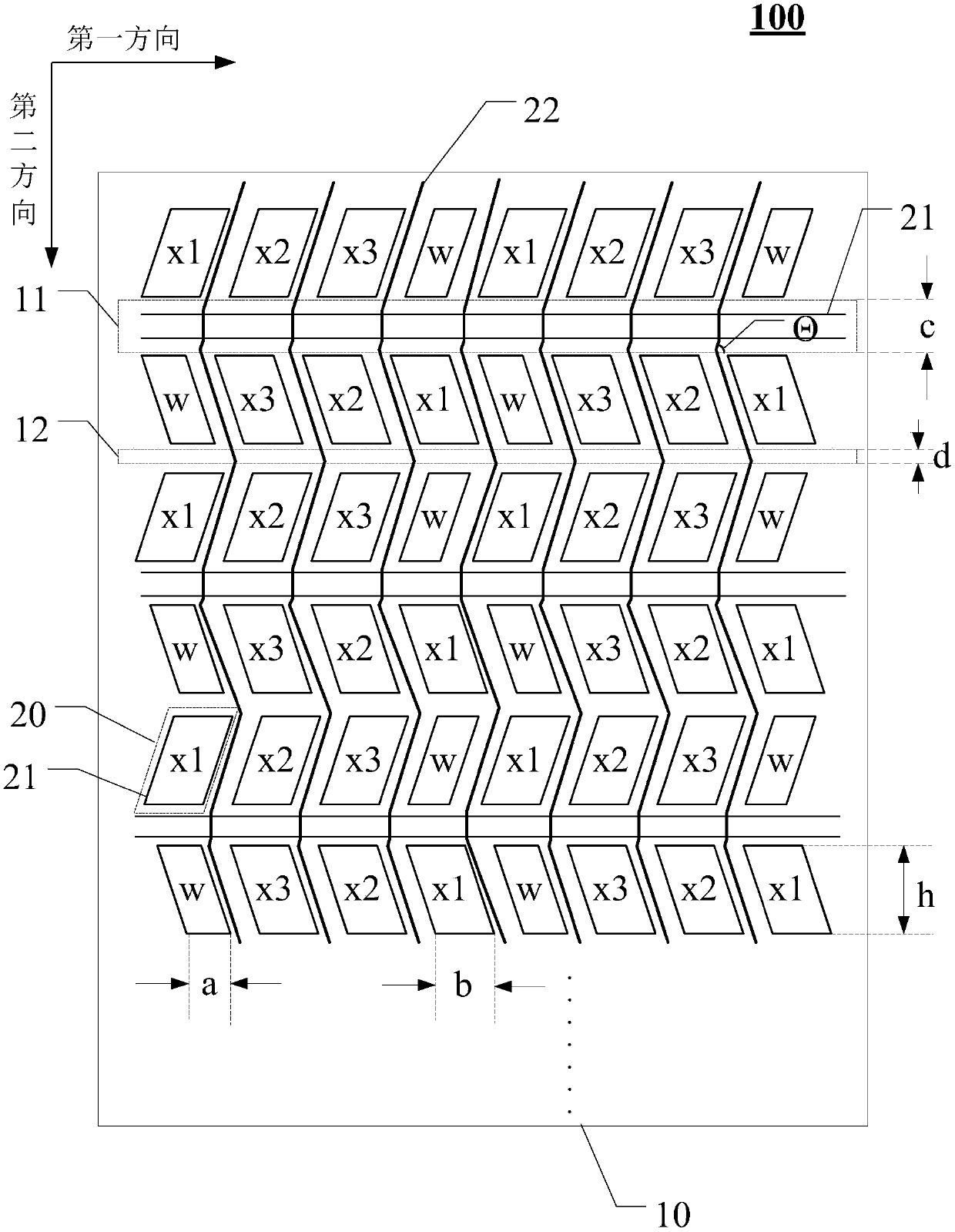

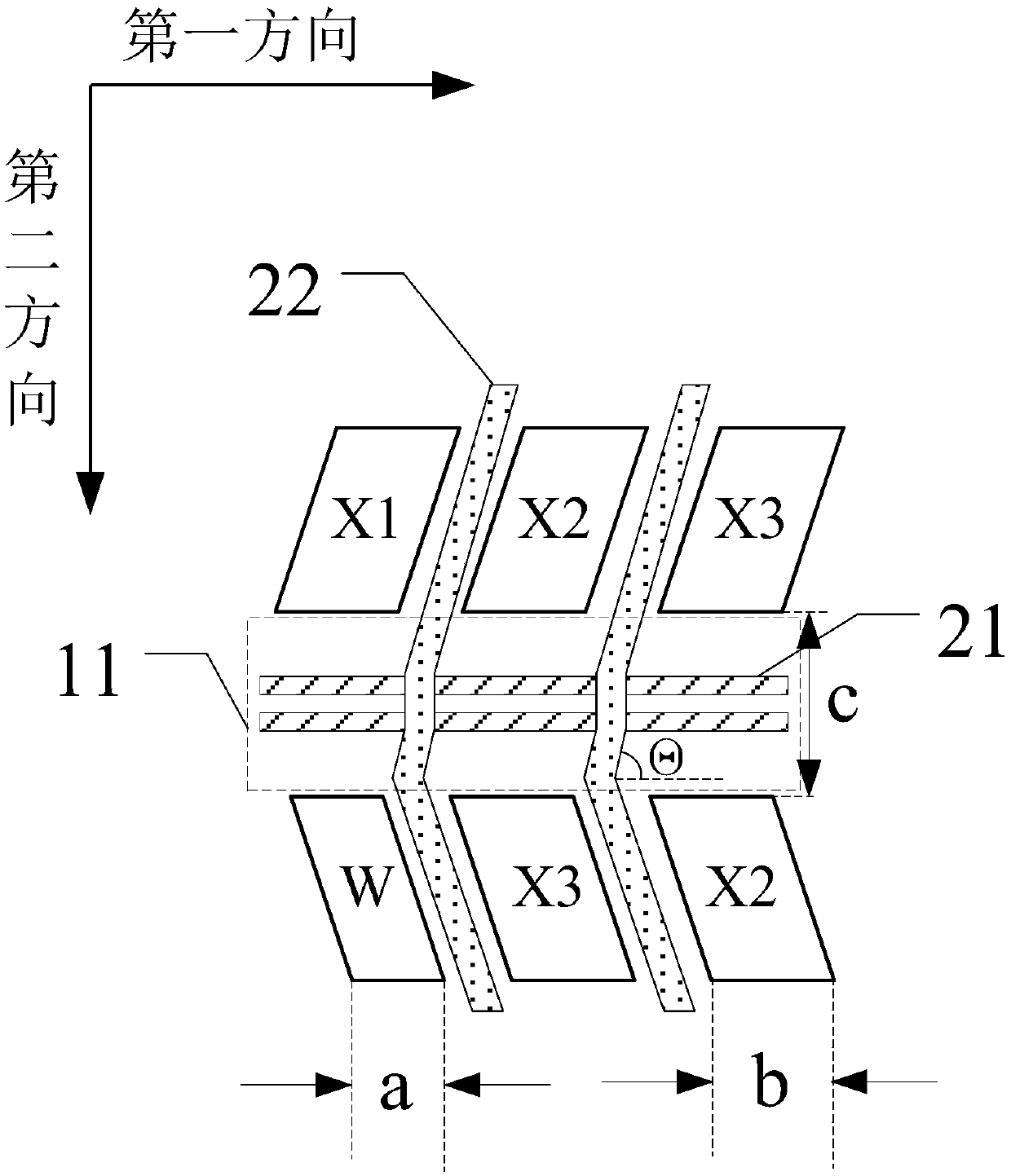

ActiveCN109637370AReduce bendingReduce the possibility of disconnectionIdentification meansAcute angleData lines

The invention discloses a display panel and a display device, the display panel comprises a scanning line extending in a first direction and a data line extending in a second direction; sub-pixel units, wherein each sub-pixel unit comprises a sub-pixel opening, the sub-pixel opening comprises a white sub-pixel opening, a first sub-pixel opening, a second sub-pixel opening and a third sub-pixel opening; in the first direction, the widths of the first sub-pixel opening, second sub-pixel opening and third sub-pixel opening are equal, and the width a of the white sub-pixel opening is smaller thanthe width b of the first sub-pixel opening; in the second direction, at least part of adjacent two rows of sub-pixel openings are provided with a first interval with a width of c, at least part of adjacent two rows of sub-pixel openings are provided with a second interval, two scanning lines are arranged in the first interval, and no scanning lines are arranged in the second interval; in the firstinterval, the angles between the data line and the scanning lines include an acute angle theta, wherein theta>=arctanc / (b / a). Thereby reducing the risk of disconnection of the data line is facilitated.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

A kind of touch sensor and its manufacturing method, touch display panel

ActiveCN106708319BReduce manufacturing difficultyImprove processing stabilitySolid-state devicesInput/output processes for data processingEngineeringSolution state

The present invention provides a touch sensor, a manufacturing method thereof, and a touch display panel, comprising: a base material, the base material includes a plurality of grooves, the plurality of grooves are strip-shaped, and the grooves intersect to form a grid; the first The wettability adjustment layer, the first wettability adjustment layer is arranged on the inner wall surface of the groove; the touch electrode, the touch electrode fills the groove, the first wettability adjustment layer is located between the groove and the touch electrode; the touch electrode In the solution state, the wetting angle with the first wettability adjustment layer is α, and the wetting angle between the touch electrode and the substrate in the solution state is β, wherein α and β are not equal; the formation of the touch electrode in the present invention can realize Better control reduces the difficulty of making the touch electrodes, enhances the process stability of the touch electrodes, and makes the touch electrodes evenly spread in the groove, greatly reducing the possibility of disconnection of the touch electrodes, thus improving the touch The touch reliability of the control electrode.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Electronic components and circuit modules

ActiveCN107622862BReduce the possibility of disconnectionPrinted circuit assemblingThin/thick film capacitorLine widthComputer module

The present invention provides an electronic component and a circuit module capable of reducing the possibility of wire breakage in winding. The electronic component according to the present invention includes an iron core, a first winding, and an external electrode, and the flange portion of the iron core includes a protrusion having a first surface facing upward and positioned above the winding core portion of the iron core The main body of the edge portion, the first electrode forming portion and the second electrode forming portion protruding toward the upper side of the first surface, and the external electrodes are provided on the second surface of the first electrode forming portion and are connected to the first winding to form There is a groove portion space surrounded by the first electrode forming portion, the second electrode forming portion, and the first surface, and a predetermined section on the first winding wire from the time it leaves the core portion to the time when it reaches the external electrode is viewed from the front side. The upper right side extends and does not have a portion that overlaps the groove portion space over the entire line width of the first winding.

Owner:MURATA MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com