Electronic component and circuit module

An electronic component and electrode technology, which is applied in the direction of assembling printed circuits, printed circuit components, and circuits with electrical components, can solve the problems of large application of the winding 531a, and achieve the effect of reducing the possibility of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

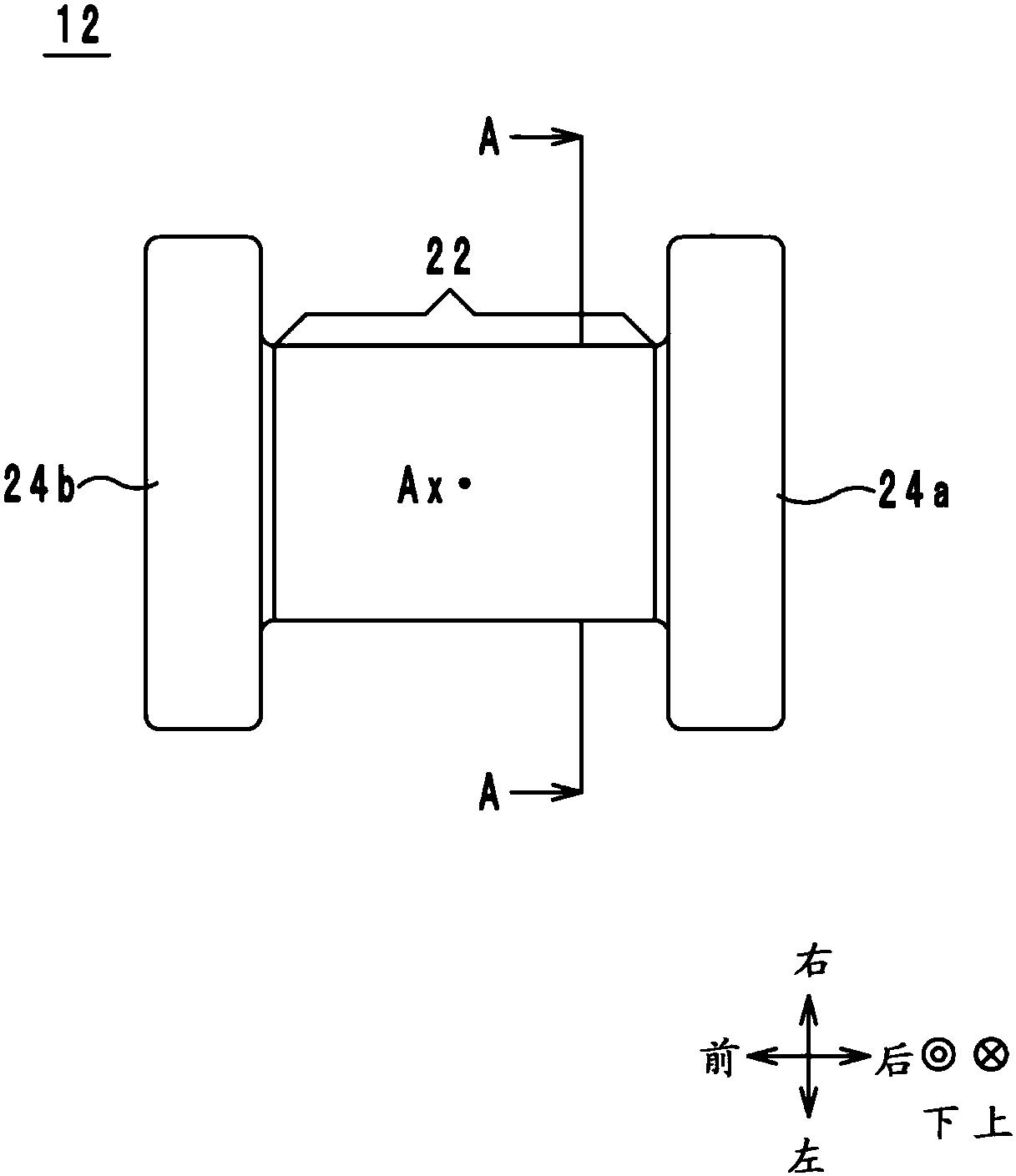

[0050] Hereinafter, an electronic component and a circuit module according to an embodiment will be described with reference to the drawings. figure 1 It is an external perspective view of the electronic component 10 . figure 2 It is a figure which looked at the iron core 12 of the electronic component 10 from the lower side. image 3 It is a figure which looked at the iron core 12 of the electronic component 10 from the upper side. Figure 4 yes figure 2 The cross-sectional structure diagram on A-A. exist Figure 4In the figure, the interval I1 from the winding core 22 to the external electrode 14a is illustrated, and the other windings 16a are omitted.

[0051] Hereinafter, the direction in which the winding core portion 22 of the core 12 of the electronic component 10 extends is defined as the front-rear direction (an example of the first direction, the rear side being an example of one side, and the front side being an example of the other side). In addition, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com