Method for knitting knitted fabric

A technology of knitted fabrics and flat knitting machines, which is applied in weft knitting, knitting, textiles and papermaking, etc. It can solve the problems of not being able to fully ensure the strength of the needle-handled part, and achieve the effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0027] In Embodiment 1, such as figure 1 As shown in (A), a sweater (knitted fabric) 100 having a tubular neck portion (base portion 9 ) is knitted. The end portion of the wale direction of the base portion 9 is as figure 1 As shown in (B), the acupuncture treatment is performed by the acupuncture treatment part 6 woven into a bag shape. The orientation of the stitches constituting the acupuncture treatment part 6 (see the rightward hollow arrow) is perpendicular to the orientation of the stitches constituting the base part 9 (see the upward hollow arrow). Below, according to figure 2 , 3 , explain the knitting sequence of this volt-acupuncture processing part 6.

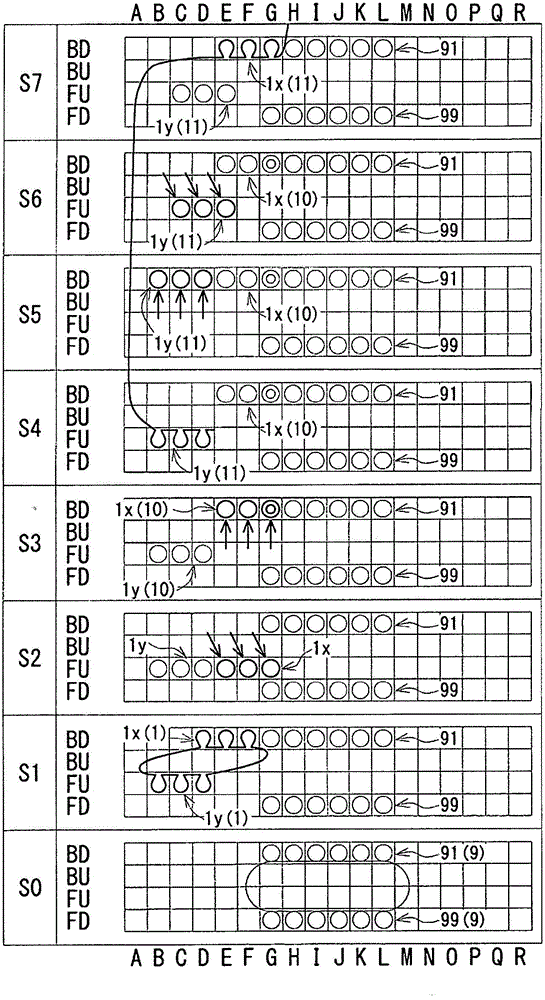

[0028] figure 2 , 3 It is a diagram of the knitting process of the acupuncture treatment part 6 . The "letter + number" in the left column in the figure indicates the number of the knitting process, the right column indicates the knitting state in the needle bed, and the operation actually performed in each...

Embodiment approach 2

[0046] In Embodiment 2, the example which performs the crouching process to the neck part of the cardigan (knitted fabric) which has an open part in a front body part is demonstrated.

[0047] In the case of a pair of bodice, the stitching process is started from the end of the opening on the right front body (left front body), and after the stitching process of the right front body is completed, the stitching process of the back body is performed. Then, after the pressing of the back body is completed, the pressing of the left front body (right front body) is performed. The acupuncture treatment of the right front body, the left front body and the back body only needs to be consistent with the figure 2 Just do the same. In addition, the transfer from the volt needling treatment of the right front body to the volt needling treatment of the back body and the transfer from the volt needling treatment of the back body to the volt needling treatment of the front body only need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com