Enameled wire surface lubricating oil smearing device and technology

A technology of enameled wire and lubricating oil, which is applied in the manufacture of electrical components, cables/conductors, and the manufacture of extensible conductors/cables, etc. It can solve problems such as clogging die holes and disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

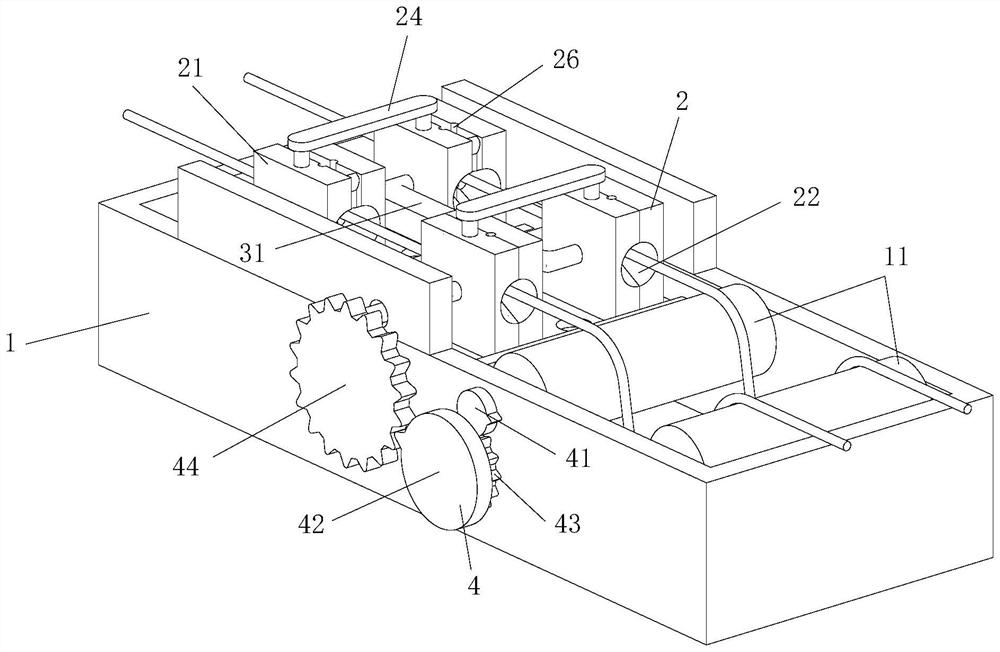

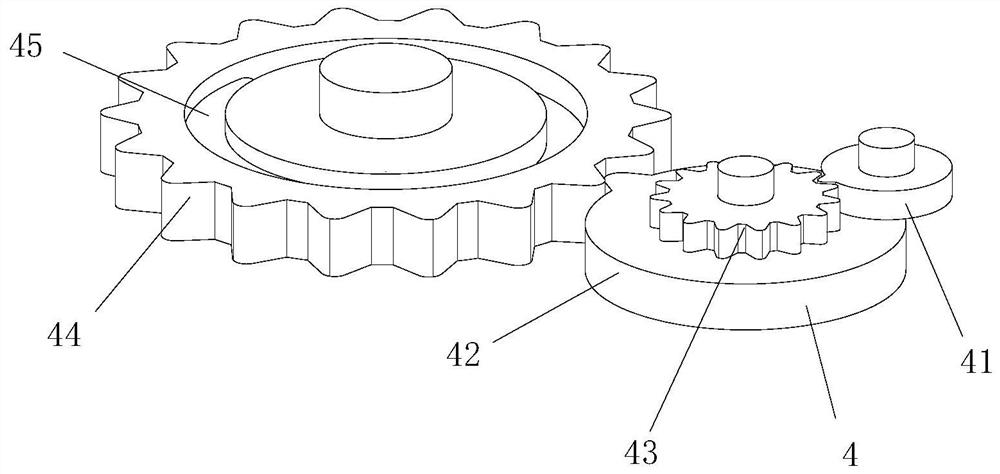

[0055] As an embodiment of the present invention, such as figure 1 , figure 2 , image 3 As shown, the intermittent mechanism 4 includes:

[0056] The first half gear 41, the first half gear 41 is fixedly installed on the rotating shaft of the tension roller 11, and the first half gear 41 is located outside the oil tank 1;

[0057] The second half gear 42, the second half gear 42 is rotatably mounted on the outer wall of the oil tank 1, the second half gear 42 is fixedly mounted on the side of the second half gear 42 close to the outer wall of the oil tank 1 with a full gear one 43, the full gear one 43 The teeth on the gear mesh with the teeth on the half gear 41;

[0058] The second full gear 44, the second full gear 44 is rotatably mounted on the outer wall of the oil tank 1, the teeth on the second full gear 44 mesh with the teeth on the second half gear 42, the full gear A stepped ring groove 45 is formed on the side of the second 44 close to the outer wall of the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com