Bidirectional wire arranging device of multi-wire cutting machine and control method of bidirectional wire arranging device

A technology of multi-wire cutting machine and wire arranging device, which is applied in the mechanical field, can solve the problems of inflexible wire tracking, easy stacking of wires, and large shaking, so as to improve cutting efficiency and cutting quality, and reduce the possibility of wire breakage performance, the effect of solving the problem of overlapping lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

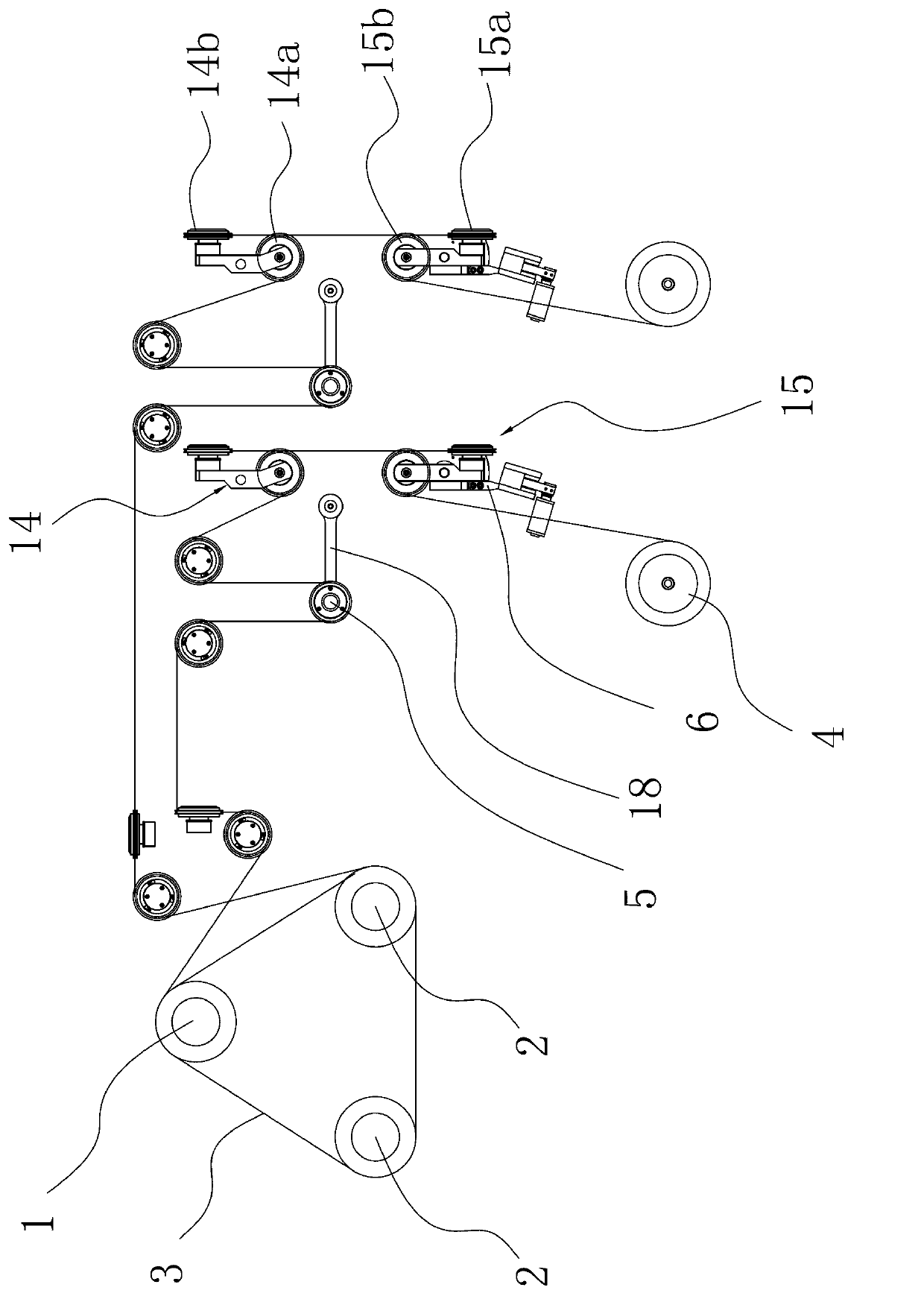

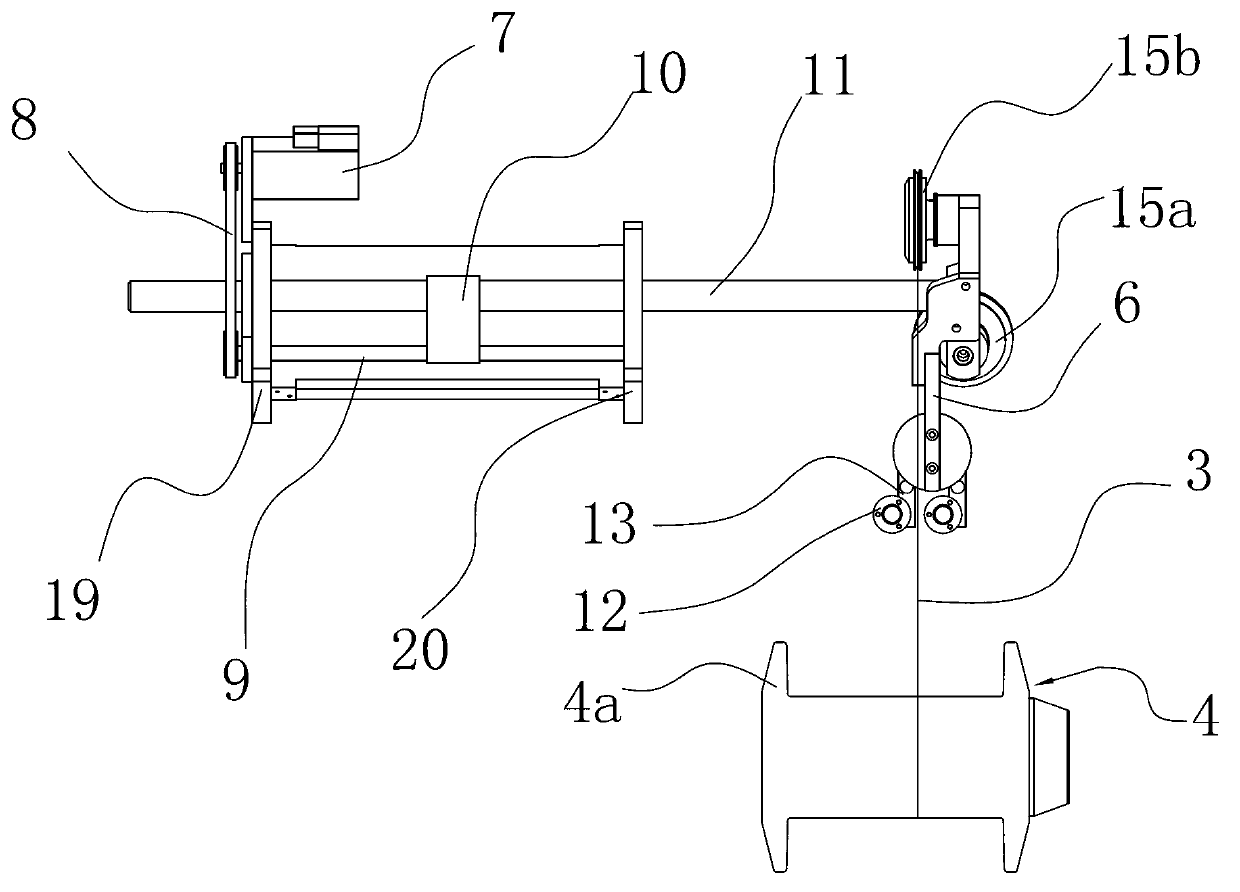

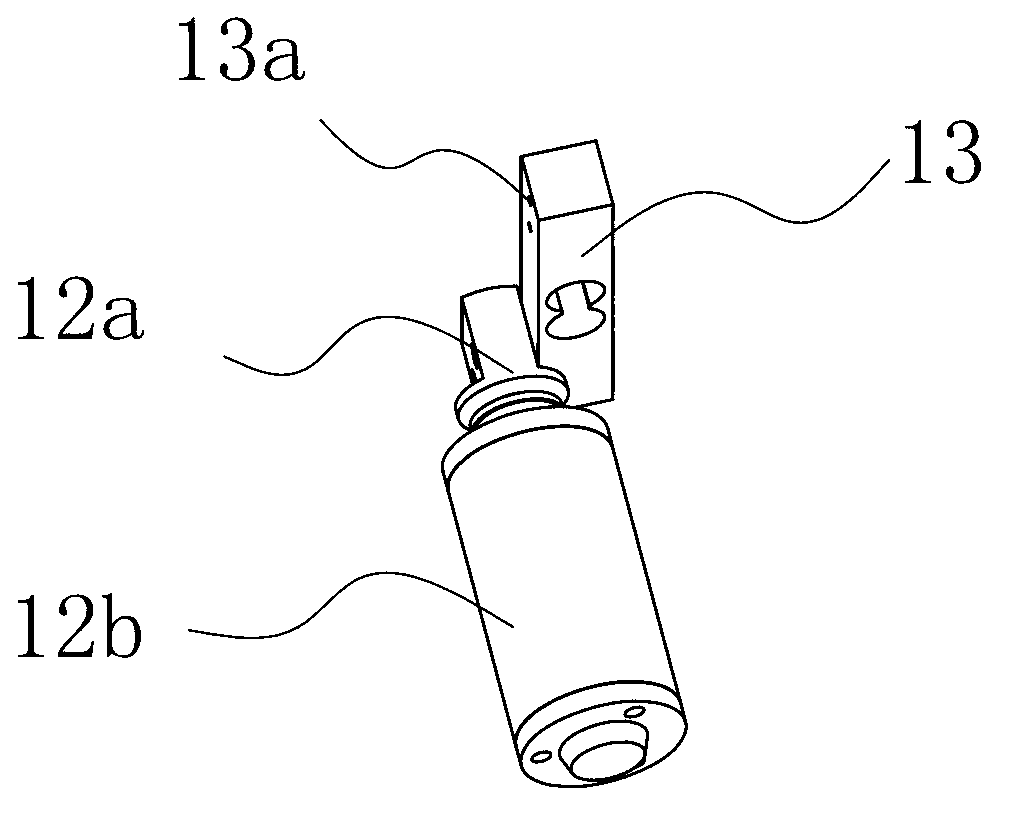

[0027] refer to figure 1 , this embodiment is a two-way wire arrangement device for a multi-wire cutting machine, the multi-wire cutting machine also includes a driving roller 1, two cutting rollers 2, a cutting line 3, and two wires respectively connected to both ends of the cutting line 3 Take-up and pay-off spool 4, two tension control pulleys 5, and two sets of two-way cable arrangement devices respectively arranged between take-up and take-off barrel 4 and tension control pulley 5, each set of two-way cable arrangement includes and is arranged on the take-up and take-off The installation bracket 6 above the wire drum 4, the drive mechanism that can drive the installation bracket 6 to reciprocate along the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com