Surface pressure distribution sensor

A surface pressure, sensor technology, applied in the direction of converting sensor output, instrument, measuring force, etc., can solve the problems of easy wiring durability, low wiring reliability, etc., to achieve high durability, low possibility of disconnection, The effect of strong bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the present invention will be described with reference to the drawings, but the present invention is not limited to the embodiments described below. In addition, in the following drawings, regarding the display scale of each component, it is described that the display scale is changed for each component for the convenience of illustration.

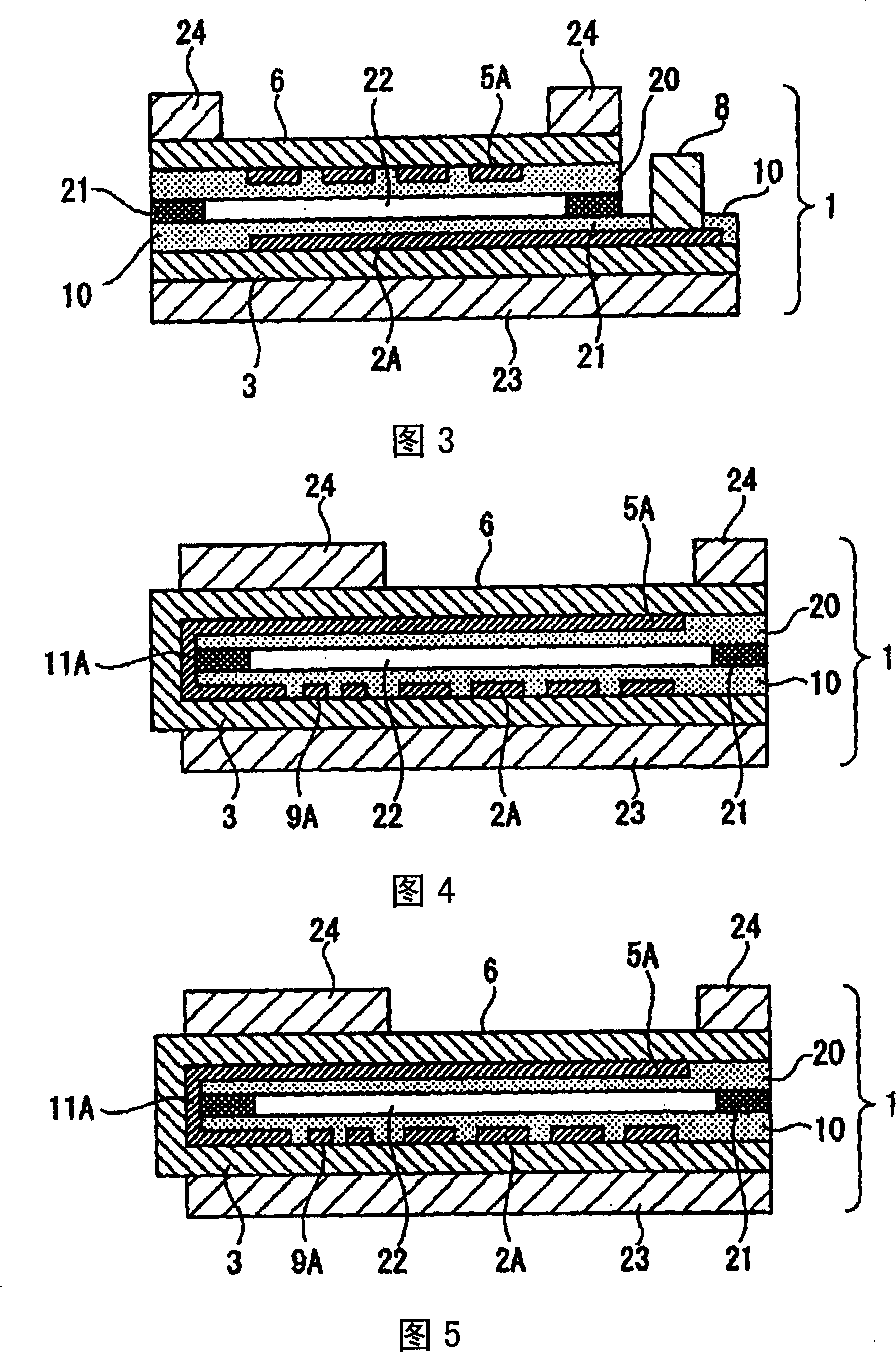

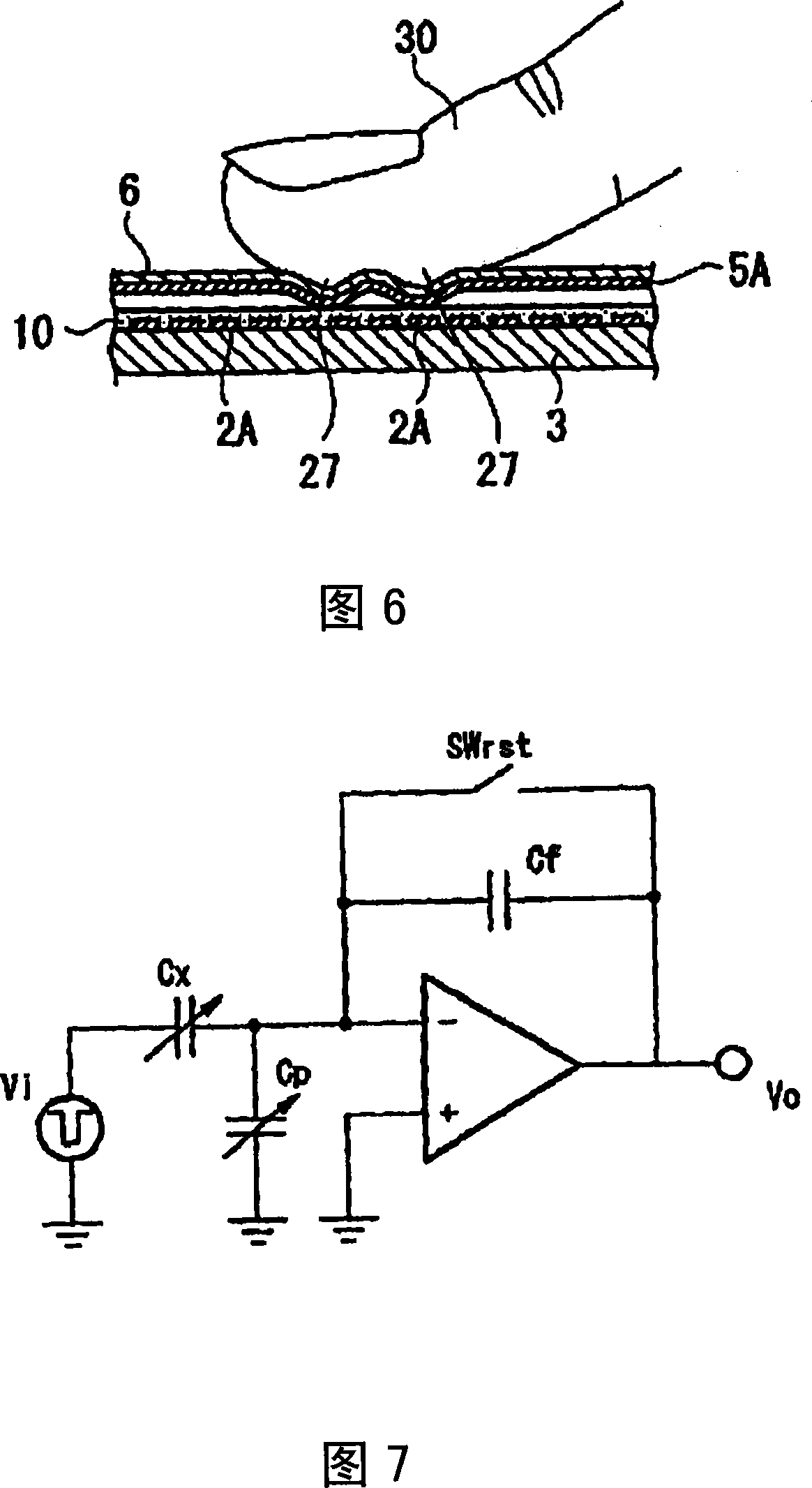

[0035] FIG. 1 is an explanatory diagram showing an equivalent circuit of the surface pressure distribution sensor of this embodiment, FIG. 2 is a developed view of the specific structure of the surface pressure distribution sensor shown in FIG. 1 before assembly, and FIG. Figure 4 is a cross-sectional view of the surface pressure distribution sensor shown in Figure 3 along the line A-A', and Figure 5 is a cross-sectional view of the surface pressure distribution sensor shown in Figure 3 along the A cross-sectional view along the line BB'.

[0036] In the surface pressure distribution sensor 1 of this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com